Navsight Solution – Hardware Manual NAVSIGHTHM 1 5

2 Solution overview

Navsight is a comprehensive inertial navigation solution,

specifically designed for the survey markets Leveraging

on existing SBGSystems inertial sensors, advanced

algorithms and high performance GNSS technology, it

also adds an incredibly easy to use setup

Navsight solution is composed of various components

that can be adjusted or configured according to your

specific application needs:

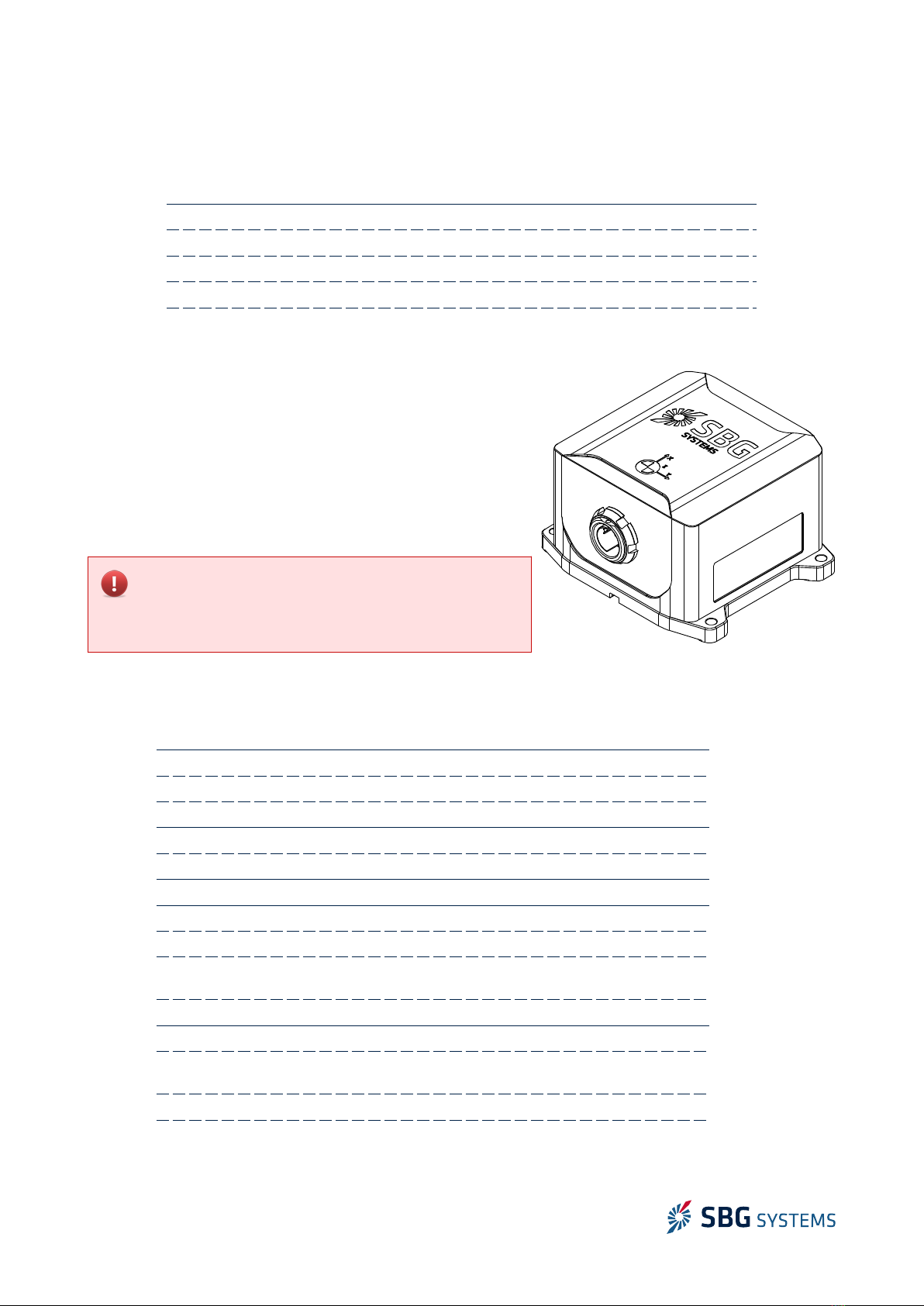

The IMU is the main sensing element and the most important performance driving factor In case of good

GNSS conditions and shallow water or entry level land/air survey, the Ekinox IMU can be selected In case of

more challenging conditions, such as dicult GNSS environments, or high altitude / high depth survey, the

Apogee grade is the sensor of choice to maintain the best accuracy In case of airborne survey with single

antenna setup, or more generally, for ultimate accuracy, the Horizon IMU should be selected All IMUs are

delivered in a rugged IP-68 package, and Ekinox / Apogee IMUs have optional salt water proof titanium

enclosures

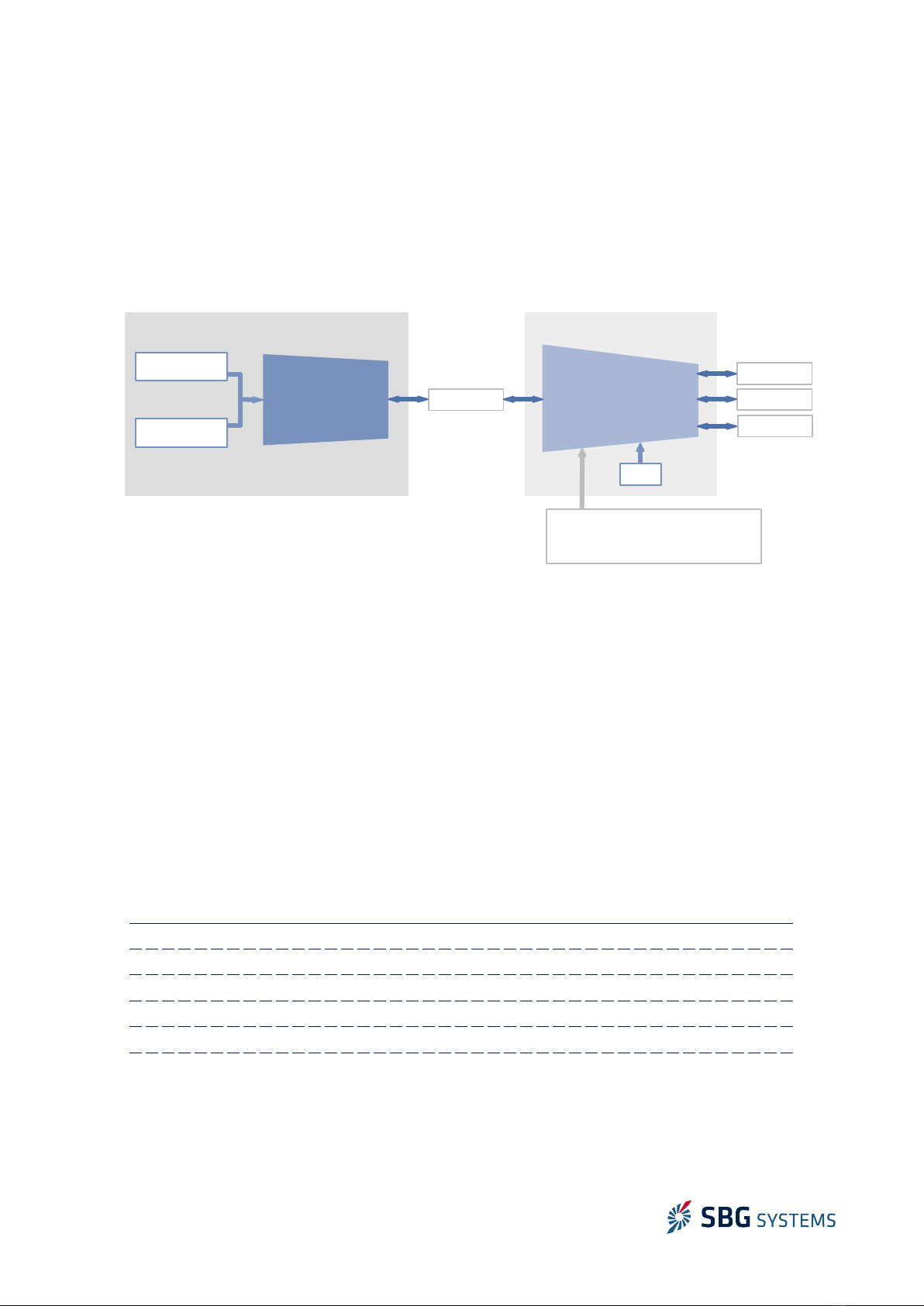

The other main component is the processing unit Available in a rugged IP-67 form factor or easy to

integrate rack enclosure, it embeds all the navigation algorithms processing, a dual antenna, triple

frequency GNSS receiver (optional), capable of PPP and centimetre precision using RTK, and all inputs and

outputs interfaces In addition to the standard Inertial Navigation System outputs (precise position, velocity

and attitude), the marine variant of Navsight Processing unit also delivers precise heave and delayed heave

For some cost sensitive applications, it is also possible to select a simple MRU setup, with only roll, pitch,

yaw and heave outputs

For easier installation, the Navsight processing unit and IMU can be installed at dierent locations: IMU

close to the location we want to track (eg multibeam sonar), and processing unit, close to user

SBGSystems tested successfully installations with more than 50m distance between processing unit and

IMU

The Navsight processing unit can be connected to a wide range of aiding sensors such as GNSS, DVL,

Odometer

To achieve the best performance in every project, specific error models have been implemented to meet

applications requirements and to adapt the solution to your vehicle Sensor configuration is made easy

through the modern embedded web interface

Finally, the 8 GB embedded data-logger enables seamless post processing work-flow with Qinertia

software This makes Navsight solution suitable for the most demanding applications

Navsight solution is fully compatible with integrated Ekinox and Apogee series in terms of protocols,

firmware and features

8/73