11. Stay alert. Watch what you are doing, use common sense. Do not operate any tool

when you are tired.

12. Check for damaged parts. Before using any tool, any part that appears damaged

should be carefully checked to determine that it will operate properly and perform its

intended function. Check for alignment and binding of moving parts; any broken parts

or mounting fixtures; and any other condition that may affect proper operation. Any

part that is damaged should be properly repaired or replaced by a qualified technician.

13. Replacement parts and accessories. When servicing, use only identical replacement

parts. Use of any other parts will void the warranty. Only use accessories intended for

use with this tool.

14. Do not operate tool if under the influence of alcohol or drugs. Read warning labels on

prescriptions to determine if your judgment or reflexes are impaired while taking drugs.

If there is any doubt, do not operate the tool.

15. For your safety, maintenance should be performed regularly by a qualified technician.

16. Never exceed 12,000kg limit of ram; ram may be damaged or fail.

WARNING: The warnings, cautions, and instructions discussed in this instruction manual

cannot cover all possible conditions and situations that may occur. It must be understood

by the operator that common sense and caution are factors which cannot be built into this

product, but must be supplied by the operator.

UNPACKING

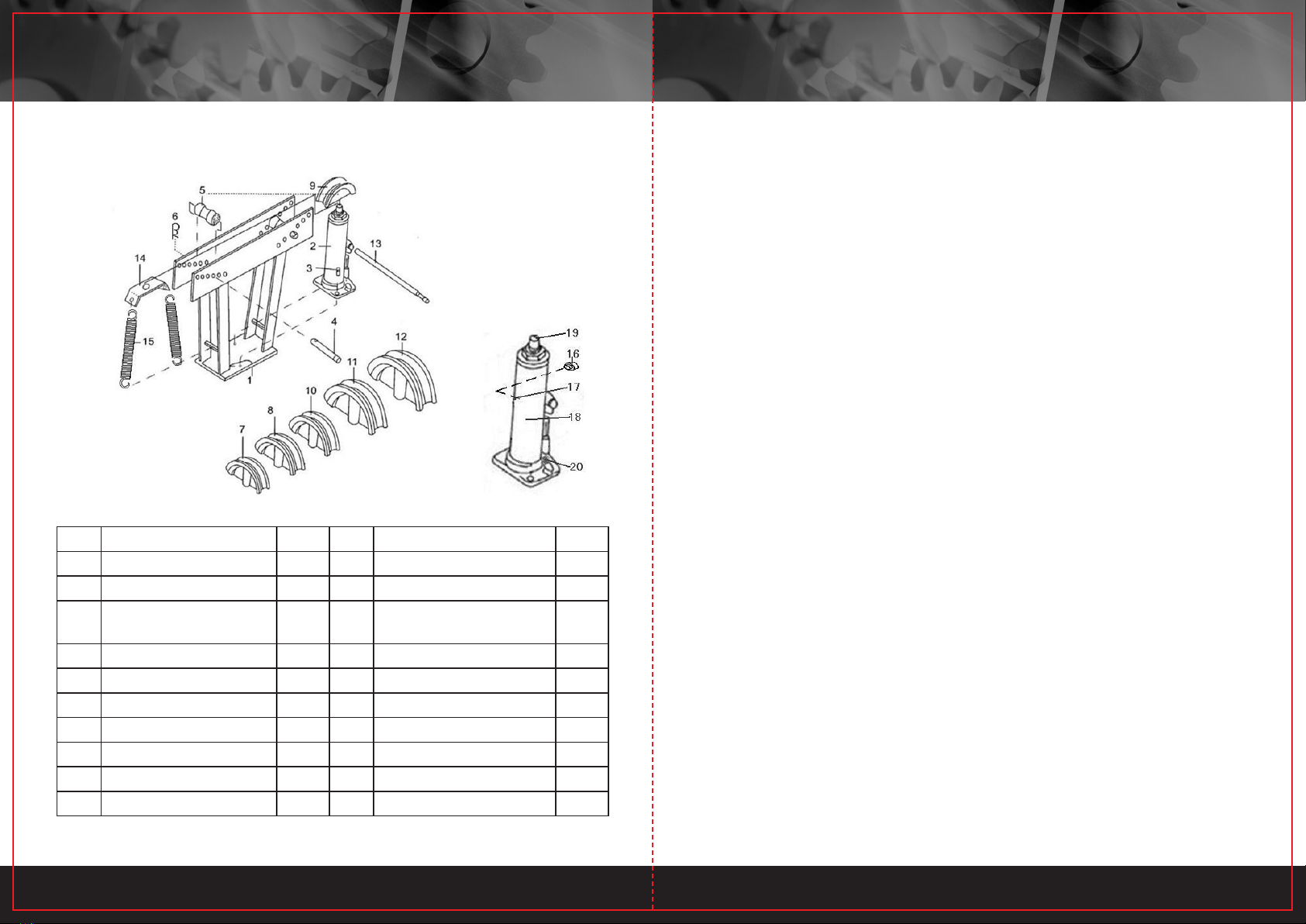

When unpacking, check to make sure all the parts listed are included. If any parts are

missing or broken, please return to your local store.

NOTE: Some parts are listed and shown for illustration purposes only and are not available

individually as replacement parts.

OPERATION

Note: The Pipe Bender is designed to bend water pipe and heavy gauge galvanized pipe

used in commercial applications. When bending conduit or thin walled pipe, you may

experience problems with kinks or creases. To help limit the problem, fill the pipe with

sand and cap both ends, before bending.

Set Up.

1. Place the Pipe Bender on a solid, flat, level surface. Pipe Bender must always be

clamped or bolted down to a workbench.

2. Select the Bending Die that matches the size of pipe you want to bend. Each Die is

stamped with the size.

3. Place the Bending Die onto the 12,000kg Ram.

3 4

4. Depending on the size of the pipe you wish to bend, the Rollers might need adjustment

so that the top of the pipe to be bent rests against the bottom of the rollers.

A. Remove both Hitch Pins. Set Aside.

B. Individually, remove a Roller Shaft and move the Rollers to the desired hole in the

Frame. Repeat on other side.

C. One at a time, fully slide the Roller Shaft through the holes in the Frame and the Rollers.

Repeat on other side.

D. Insert both of the Hitch Pins through the Roller Shafts.

5. Slide the pipe you want to bend, through the Pipe Bender on top of the Bending Die.

Make sure the top of the pipe rests against the bottom of the Rollers.

6. Using the slotted end of the Handle, tighten (clockwise) the Ram Relief Valve

7. Insert the Handle into the 12,000kg Ram. Crank it up and down to raise the Ram and

bend the pipe.

8. After bending pipe to desired angle, remove the Handle from the Ram and loosen the

Relief Valve (counterclockwise). The ram will lower. The pipe will release from the Pipe

Bender. Carefully remove the pipe.

HOW TO BLEED RAM/HOW TO FILL RAM WITH HYDRAULIC OIL

IMPORTANT! Before first use, check for proper hydraulic oil level in the Ram. Then

thoroughly test the Ram for proper operation prior to its actual use. If the Ram does not

work properly, bleed excess air from its hydraulic system as follows:

1. Open the Ram Relief Valve.

2. Remove the Oil Filler Plug and fill the Ram with hydraulic fluid to full level.

3. Apply pressure to the Saddle, and pump the Handle quickly several times.

4. Check the Oil Fill Hole and, if necessary, top off the Oil Fill Hole with hydraulic oil.

5. Replace the Oil Fill Plug and close the Ram Relief Valve.

6. Test the Ram several times for proper operation before putting into use. If, after

bleeding, the Ram still does not appear to be working properly, do not use the Ram until

it has been repaired by a qualified service technician.