2

Thank you for choosing a Softline Non Electric Water Softener.

It is important that you take the time to read this installation guide. It will tell you in a simple

format how to install your Water Softener and how to start enjoying the benefits of

softened water.

This instruction manual applies to the SL150, SL150 Mini & SL450 models only.

1. Introduction.

The SL Non-Electric range of Water Softeners from Scalemaster present a new approach to

the world of water softeners. Based on proven technology, Because these softeners are

non-electric there are no issues relating to electrical installation compliance. These units

are still fully automatic. The units operate purely through the hydraulic pressure of the

incoming water whether that be from the mains or from a well. Scalemaster non-electric

water softeners have no motors and no wires, they just do not need them! The moving

parts are operated by dynamic water pressure above 1 bar (dynamic).

Scalemaster SL Water Softeners are one of the most efficient water softeners on the

market. For example, through it’s advanced technology, the SL150 version typically uses

only 330 grams of salt and 18 litres of water for every regeneration making it one of the

most environmentally friendly water softeners on the market today. Water usage is less

than 4% per regeneration which meets the minimum performance requirements of the

Code for Sustainable Homes published by the Buildings Research Establishment.

2. Features & Benefits.

• NON-ELECTRIC: The 150 & 450 range work entirely without electricity.

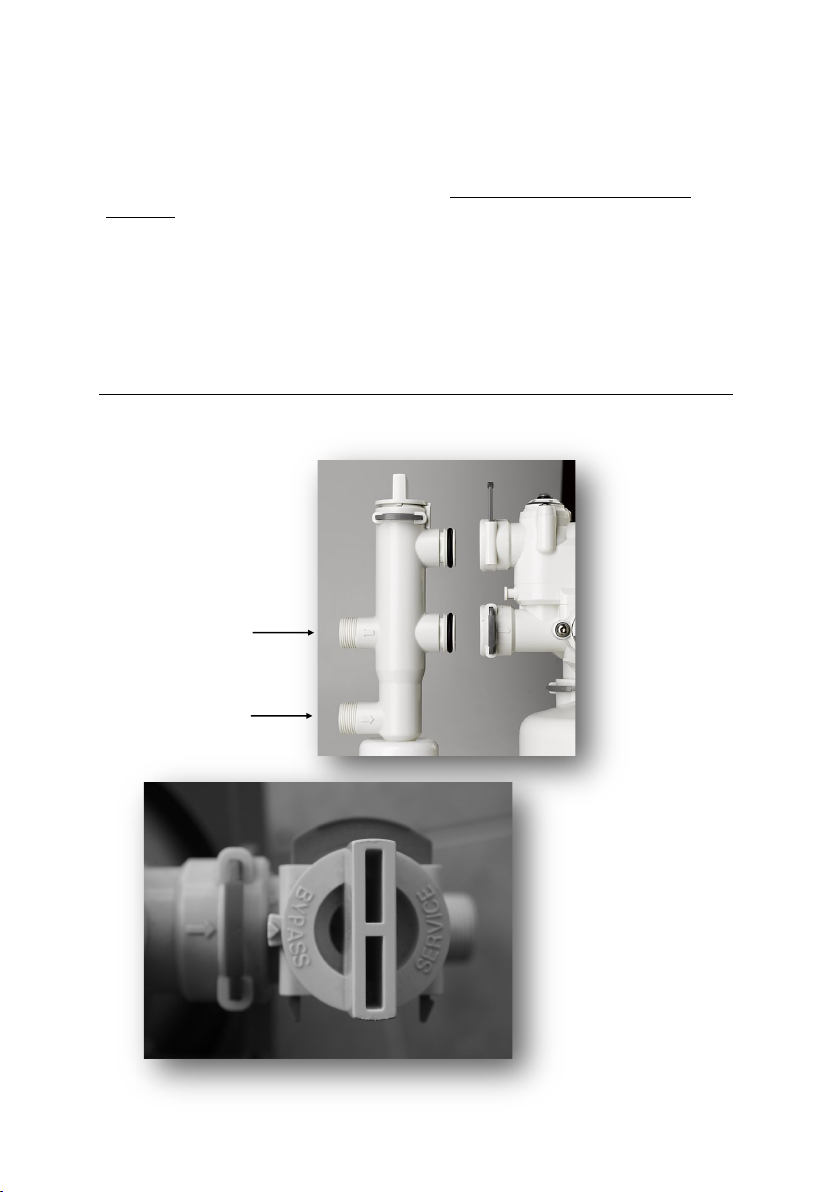

• EASE OF INSTALLATION: Far simpler than standard water softeners to install due to the

simple and unique ‘clip-connect’ design and integrated bypass manifold.

• COMPACT DESIGN: The SL150 is designed to fit into a standard kitchen cabinet and

other areas where space is at a premium.

• MINIMAL PROGRAMMING: Just set the water hardness for your area.

• ENVIRONMENTALLY FRIENDLY: Designed to use minimal salt & water during regenera-

tion.

• HIGH TEST STANDARDS: The units are all ‘wet tested’ before leaving the factory.

• HIGH FLOW RATES: Nominal flow rate (1 bar loss of pressure) 25 litres per minute (1500

litres per hour).

DID YOU KNOW?

The salt used in a water softener is not used to soften the water, it’s used

as part of the cleaning process (regeneration) that the softener will go

through periodically.