Thank you for choosing a Scalemaster Water Soener

Please take the me to read this installaon guide. It will tell you in simple terms how to install

and commission your new Scalemaster Water Soener to begin enjoying the benets of

soened water.

Before You Start

Before starng installaon, inspect the Water Soener for shipping damage or shortages.

Make sure you have all the necessary tools on hand before starng the installaon.

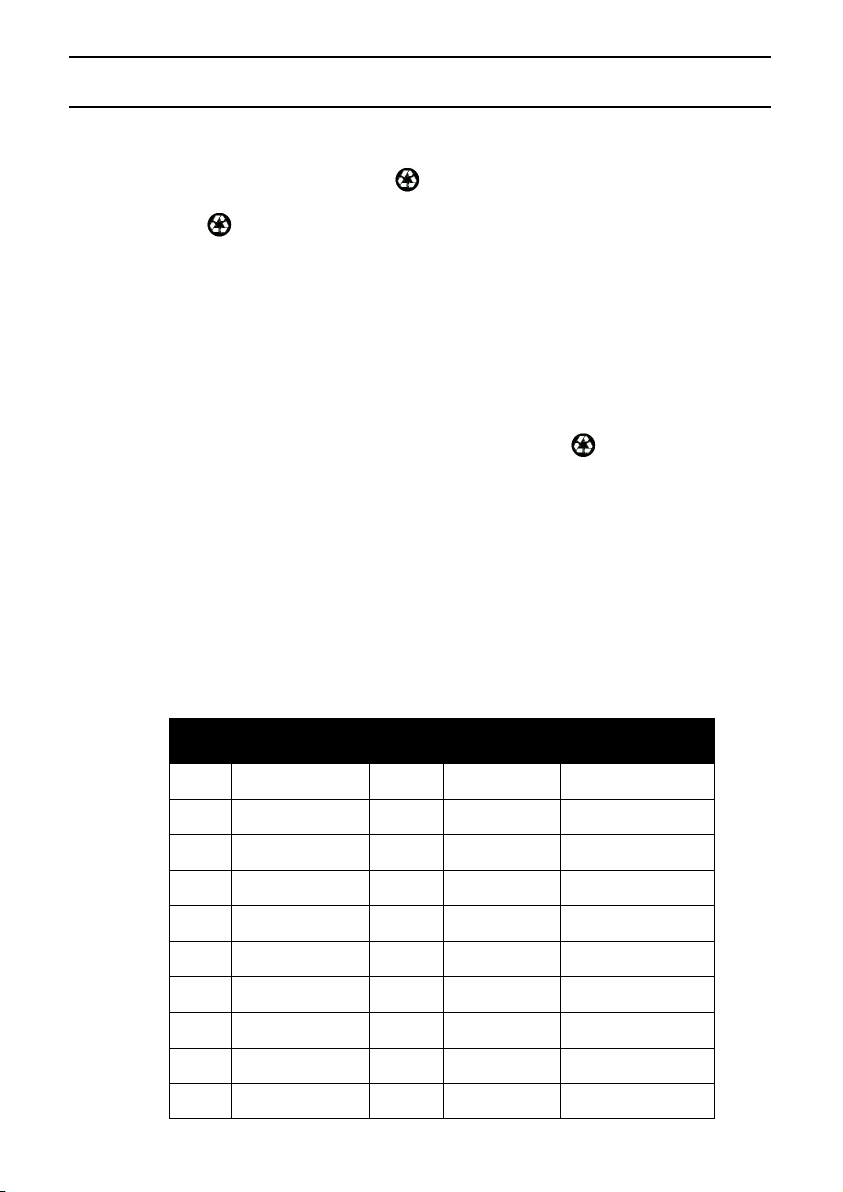

Follow all applicable Plumbing and Electrical regulaons when installing the Water Soener.

If in doubt, refer to the relevant WRAS Informaon and Guidance note at:

www.wras.co.uk/PDF_Files/ign9-07-01.pdf

This Water Soener is not intended for the treatment of water that is microbiologically

unsafe or of unknown quality without adequate disinfecon before or aer the Water

Soener and is to be used only for potable water.

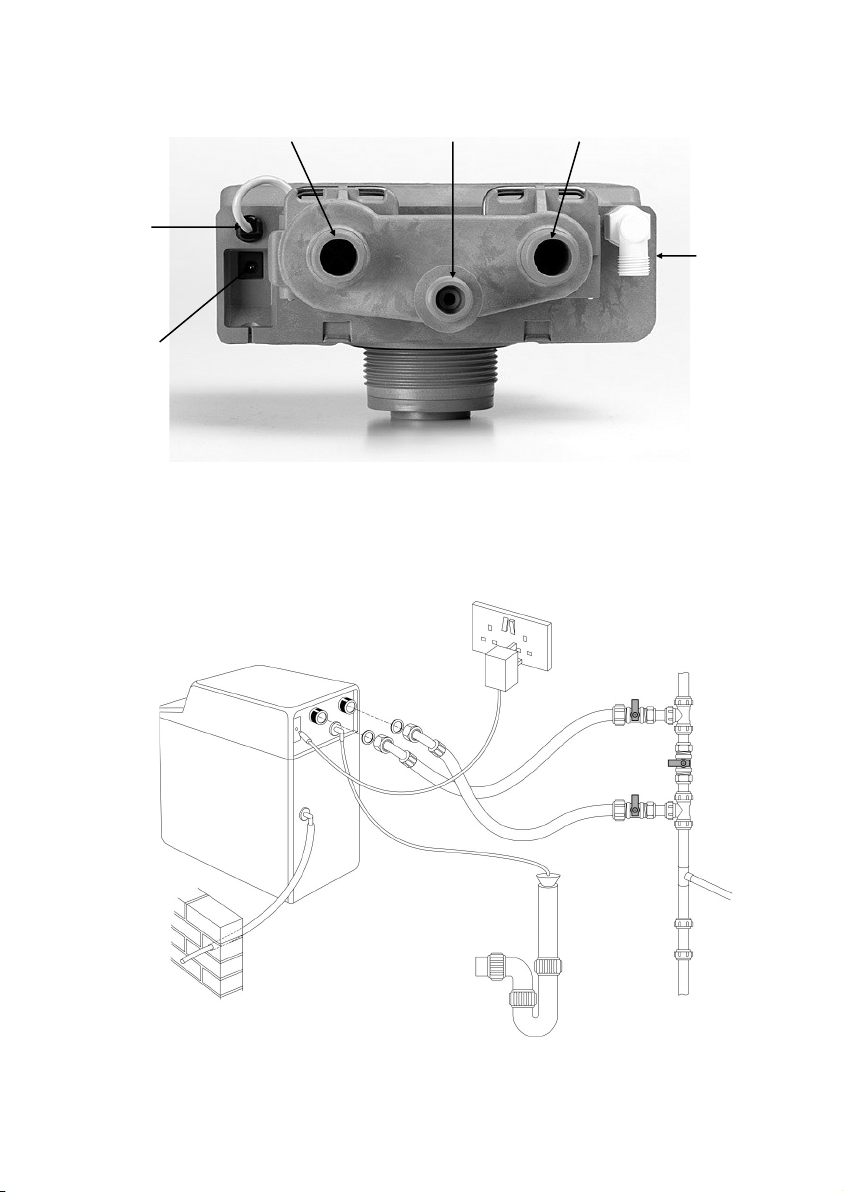

Use cauon when installing soldered metal piping near the Water Soener. Heat can

adversely aect the plasc control valve or bypass valve system. Be sure all soldered pipes

are fully cooled before aaching plasc plumbing ngs.

Take care not to strip the threads when ghtening plasc pipe ngs. PTFE tape may be

used on connecons that do not use an ‘O’ ring seal. Do not allow pipe joinng compound

or sealant to come into contact with any plasc parts.

There should be a minimum runo at least 3 meters of pipe between a soener and a water

heater to prevent the possibility of hot water entering the soener unit.

Use only the power transformer supplied with the Water Soener unit.

The mains power adapter supplied is double-insulated and does not require earthing. Earth

bonding should be applied across metal inlet and outlet pipework of the Water Soener to

maintain earth connuity.

Observe drain line requirements. The drain line must be a minimum of 12.5mm diameter.

The unit should be above, and not more than 6 metres from a drain.

Do not support the weight of the Water Soener on the control valve connecons or

plumbing.

Protect the soener, soener drain and all other components from the eects of frost.

Evidence of damage due to freezing will invalidate your Water Soener warranty.

Keep the media vessel in the upright posion. Do not turn upside down or drop. Turning the

vessel upside down or laying the vessel on it’s side can cause treatment media to enter the

valve.

If in doubt contact the Technical Helpline on 07990 064096

3