7

(Optional) Leakage Test with Nitrogen

4.5

•If the pressure has fallen, apply soapy water on the pipes, especially pipe joints, to check for

leakages. Rectify the leakages if any.

•If the pressure is stable, wrap all pipes and connectors with thermal insulation foam.

•Install a reducing valve on the outlet of the nitrogen cylinder. Its outlet pressure must not

exceed 0.8 MPa.

•In addition to the leakage test with nitrogen, there is the leakage test with water. You can

choose one test based on site requirements.

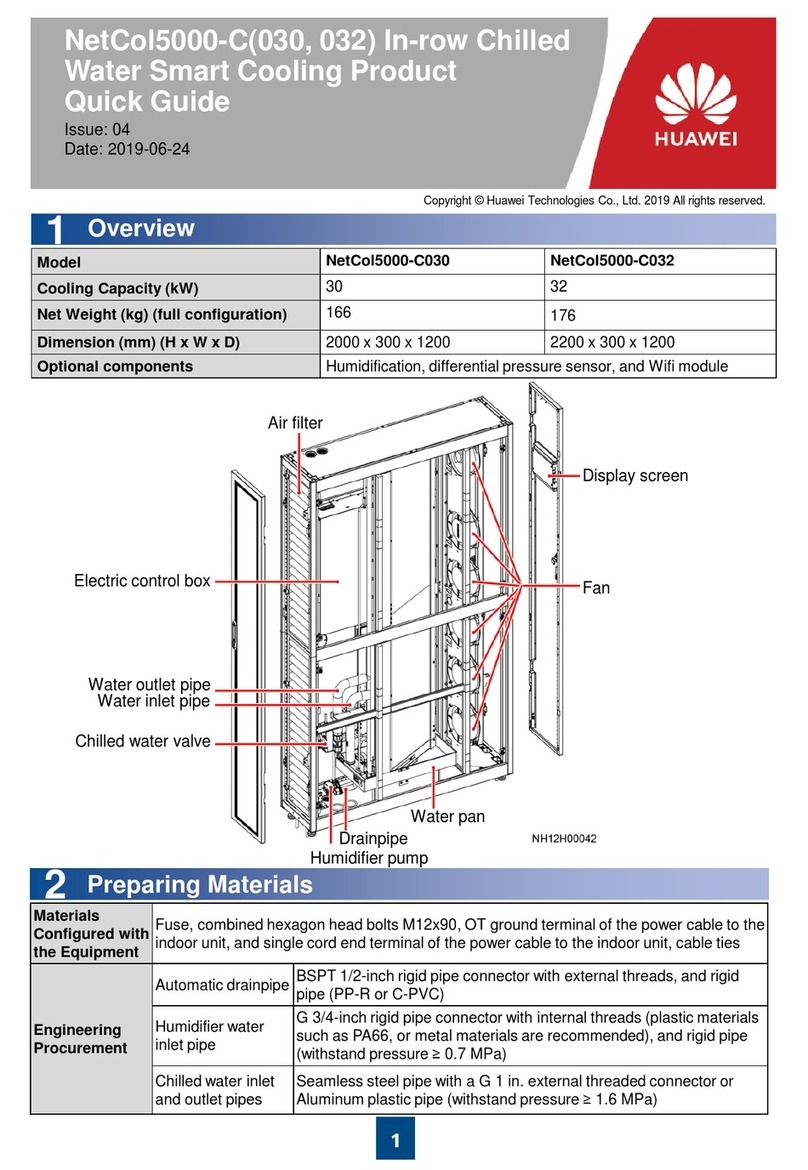

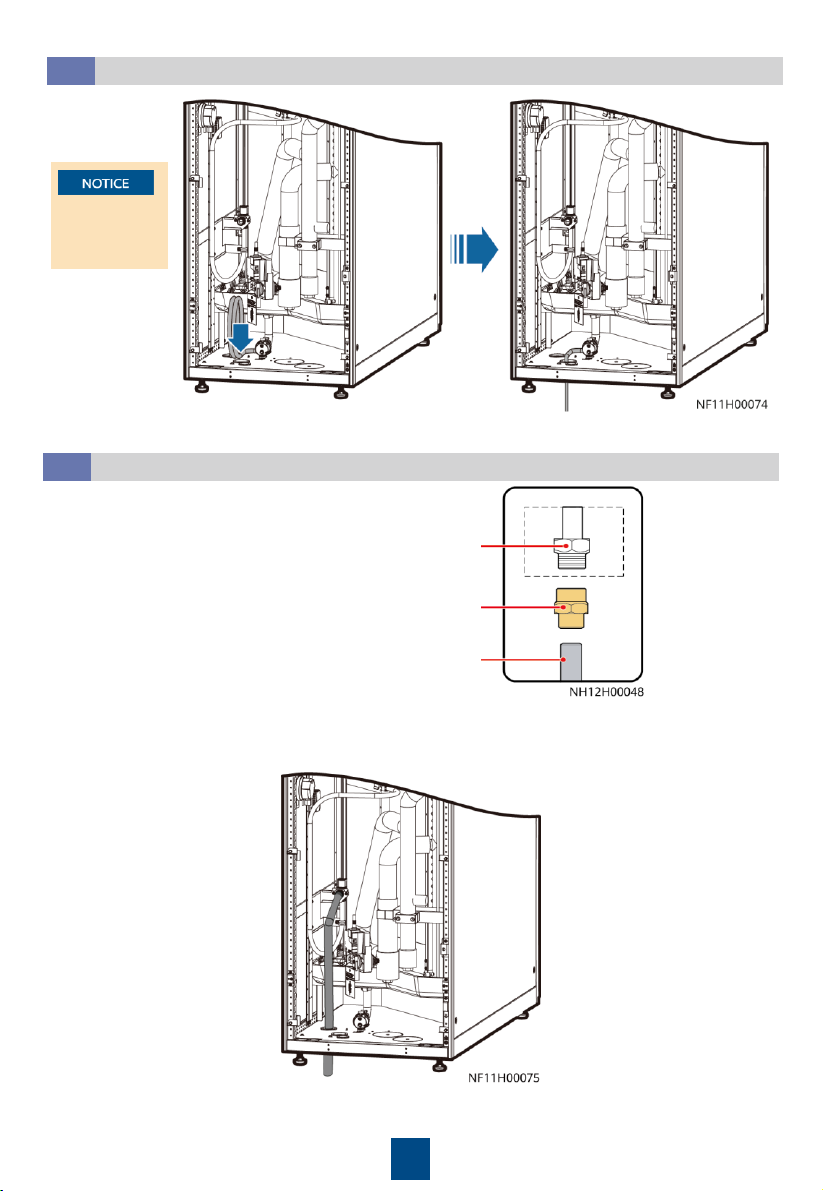

1. Rotate the chilled water valve to the

maximum (100%).

2. Check that the needle and exhaust valves

on the pipeline are closed.

3. Connect a reducing valve and a nitrogen

cylinder at the needle valve position

shown in the figure, charge 0.8 MPa of

nitrogen (when the pressure is stable),

and leave them for 24 hours.

4. Check for pressure change after 24 hours.

Injecting Water to Expel Nitrogen

4.7

Clean the main pipe beforehand to avoid blockage of the

heat exchanger due to foreign construction matter. Close

the isolation valve on the water inlet and outlet pipes

before the cleaning.

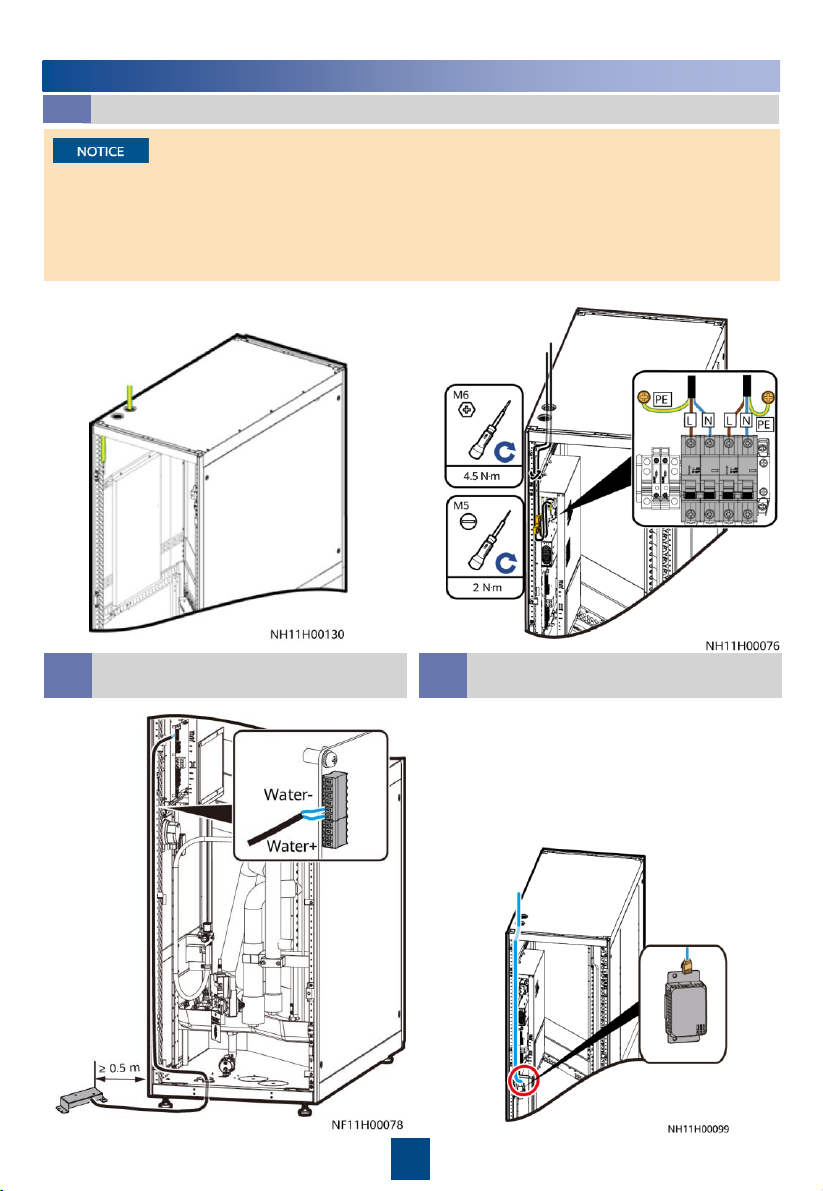

1. Open the general water supply valve.

2. Press the button on the side of the actuator and

manually rotate the valve handle to the maximum in

the specified direction. Check that the chilled water

valve is in the open state (100%).

3. Slowly open the exhaust valve to let out gas.

4. Adjust the gas releasing speed until no gas flows out

of the valve. Then close the exhaust valve.

5. Manually close the chilled water valve.

(Optional) Leakage Test with Water

4.6

Manually open the chilled water valve. Inject water to 0.8 MPa,

and preserve the pressure for 24 hours. Then connect a pressure

gauge to a needle valve on the pipeline to measure the

pressure. If the reading remains unchanged, the pipe is not

leaking. You can perform the following operations.

If the leakage test has been

done with nitrogen, skip the

test with water.