9

ASSEMBLY

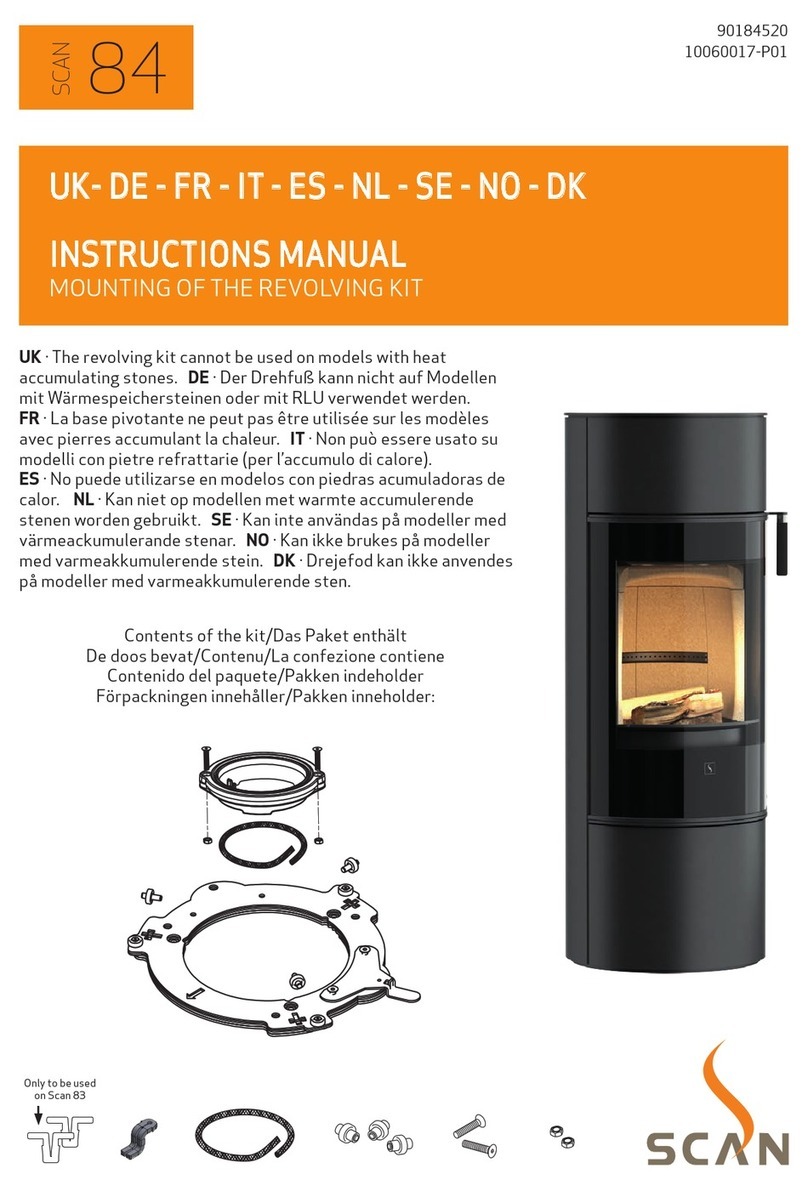

ADDITIONAL ACCESSORIES

¬ Fresh air box (see page 12) ¬ Connection pipe Ø 100 mm

¬ Heat-storage stones (see page 13) ¬ Heat shields/convection covers (see page 14)

¬ Frames (see page 18) ¬ Convection air grid (see page 21)

¬ Adjustable legs 100 mm and 190 mm ¬ Detachable handle

DISPOSAL OF PACKAGING

Your Scan built-in stove may come supplied with the following packaging:

Wood packaging The wood packaging can be reused and after final use can be incinerated as a CO2neutral

product or sent for recycling

Foam Send for recycling or waste disposal

Plastic bags Send for recycling or waste disposal

Stretch/plastic film Send for recycling or waste disposal

LOAD-BEARING FOUNDATION

All items in our product range come under the category of lightweight fireplaces and stoves and do not normally require any

reinforcement of the beam structure. They can be positioned on ordinary beams/floor.

You should of course make sure that the foundation on which the stove is positioned can indeed support the weight of the stove

and, where applicable, a steel chimney, if you have opted for this solution. In case of doubt about the carrying capacity of the

floor, please consult a building expert.

FLOOR PLATE

If you are placing the stove on a flammable floor, you must comply with the national and local regulations on the size of any

non-flammable subsurface required to cover the floor around the stove.

Your local Scan dealer can advise you on regulations concerning protection of flammable materials in the vicinity of your stove.

The floor plate’s function is to protect the floor and flammable material against any sparks that may occur.

EXISTING CHIMNEY AND PRE-FABRICATED ELEMENT CHIMNEY

If you intend to connect your stove to an existing chimney, it makes sense to contact an authorised Scan dealer, or a local chim-

ney sweep, for advice. These experts will also let you know if your chimney needs renovating.

¬ When connecting a pre-fabricated element chimney, follow the manufacturer’s connection instructions for the

relevant chimney type.

CONNECTION BETWEEN BUILT-IN STOVE AND STEEL CHIMNEY

Your Scan dealer, or local chimney sweep, can advise you on choosing a make and type of steel chimney. This ensures that the

chimney will match your wood-burning stove.