SECTION I

GENERAL INFORMATION

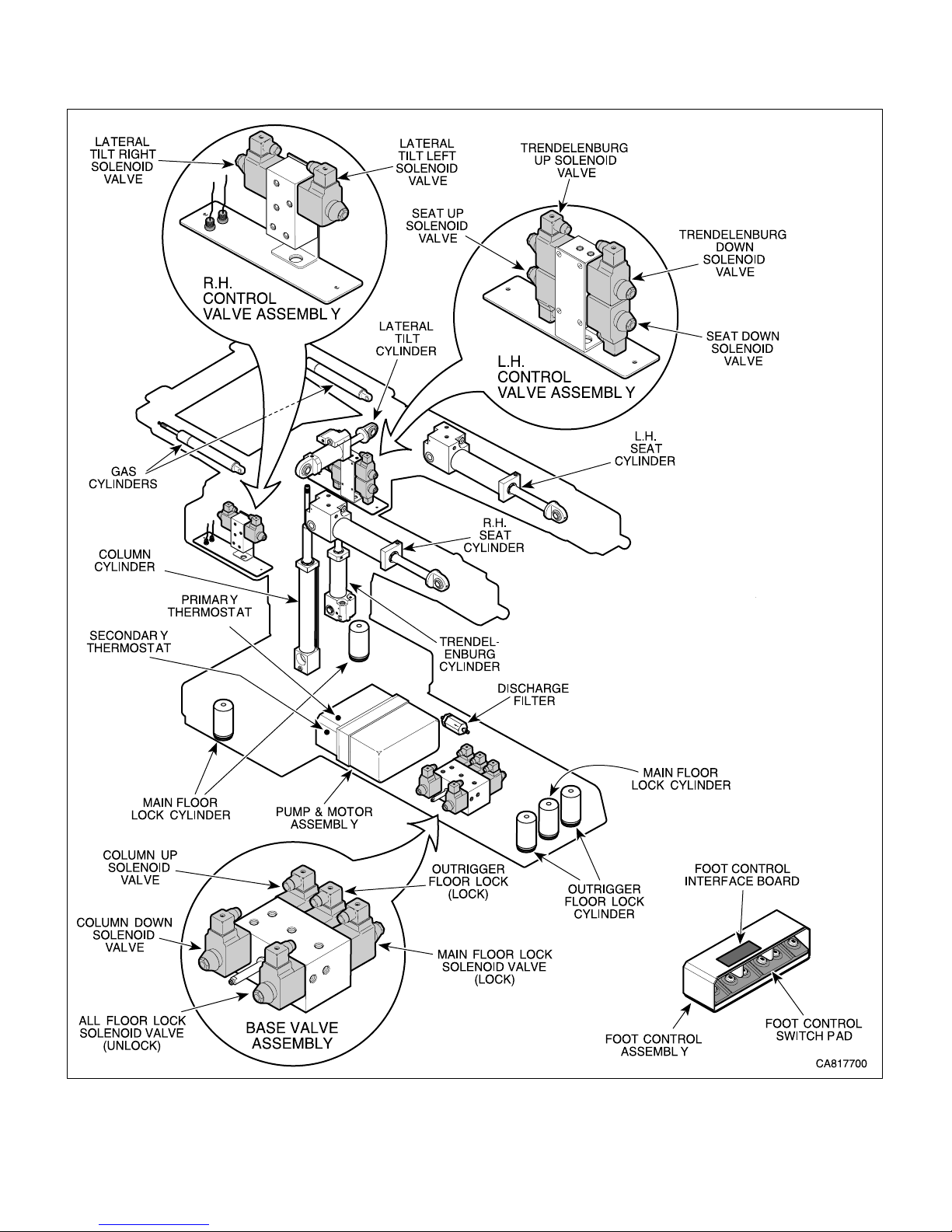

B. Theory of Operation. See Figures 5-1, Sheets 1

and 2, and Figure 5-2 for electrical schematic /

wiring diagram. See Figure 5-3 for hydraulic

schematic.

Electrical Theory Of Operation

When power cord is plugged into power cord recep-

tacle, line voltage (approximately 115 VAC) is supplied

to table. Line voltage is applied across an RFI filter.

RFI filter reduces line conducted RFI / EMI that is

present on incoming power line. Across RFI filter

output is a line power pilot lamp which illuminates to

indicate power is present at output of RFI filter.

Transformer primary lines are also connected across

RFI filter output. Transformer steps line voltage down

to 32.5 VAC ± 2 VAC. The 32.5 VAC from output of

transformer is applied to charging / power driver board.

Charging / power driver board uses a DC rectifying

circuit to convert 32.5 VAC to approximately 27.8 VDC.

Charging / power driver board regulates charging rate

of four batteries by regulating rate at which 27.8 VDC is

applied to batteries. Charging / power driver board also

supplies 27.5 VDC to main controller board to power it.

Transformer has thermal fuses connected in each

primary winding and they are embedded between the

primary and secondary windings. If transformer over-

heats, normally closed (N.C.) thermal fuses open,

disconnecting power to transformer.

Transformer is primarily used to supply power to

charging / power driver board, so board can charge

batteries and supply power to rest of table.

Charging / power driver board regulates charge rate

of batteries when batteries are being charged. This

means that a full load is not continuously being placed

on transformer, which is important because transformer

is not sized to draw a full current load continuously. If

batteries are low and a function is selected, power to

drive motor pump(s) is drawn from batteries first and

then from transformer as necessary. If batteries are too

low or a function is selected for too long, continuous

current draw thru transformer will overheat transformer

very quickly, causing thermal fuses to blow.

CAUTION

It is important that a table with a low bat-

tery charge be operated only in case of

emergency and for a very short time period (less

than a minute).

Logic Theory Of Operation

When ENABLE button is pressed, a 5 VDC signal is

sent to main controller board, activating it. Main

controller board performs a self diagnostic check on

itself. If self diagnostic check fails, error code E11

(Internal RAM / Register Failure) is displayed on hand

control.

Main controller board and charging / power driver board

uses status circuits to check functionality of following

electrical components: motors, charging / power driver

board, valve spool solenoids, main controller board,

position sensors, foot control switch pad, and hand

control button board.

A status circuit, on charging / power driver board,

monitors amount of current draw thru motor pump

windings, when a function has been selected. If current

draw exceeds a predetermined value, main controller

board stops all functions and displays error code E02

(Overcurrent - Motor Pump #1) or E03 (Overcurrent -

Motor Pump #2), which indicates a failure of a motor

pump.

If current draw falls below a predetermined value, main

controller board stops all functions and displays error

code E04, which indicates failure of charging / power

driver board.

A status circuit, on main controller board, monitors

enable circuitry for each valve spool solenoid and

detects if a valve spool solenoid or enable circuitry of

main controller board is functioning correctly. If not,

main controller board stops all functions and displays

error code E05 (Valve Drive Failure), which indicates

failure of either a valve spool solenoid or main controller

board.

Another status circuit, on main controller board, moni-

tors voltage input from position sensors. If voltage

value exceeds or falls below a predetermined range,

main controller board stops all functions and displays

appropriate error code: E07 (Trendelenburg Position

Sensor Failure), E08 (Tilt Position Sensor Failure), E09

(Seat Position Sensor Failure). An error code indicates

failure of either a position sensor, main controller board,

or wiring.

Main controller board also monitors main floor lock

status switch, outrigger floor lock status switch, motor

pump #1 primary thermostat, and motor pump # 2

primary thermostat. When hand control is ENABLED,

main controller board checks if normally open (N.C.)

main floor lock status switch and outrigger floor lock

status switch is untripped. If main controller does not

detect that

both

status switches are untripped, it

energizes main floor lock valve spool and motor pump,

causing main floor locks to extend. After eight seconds,

main controller de-energizes main floor lock valve spool

Page 1-4Printed in U.S.A.©SchaererMayfieldUSA,Inc.2004