Schauer MV1240 Setup guide

Instruction 1905072740 Rev A - 1 -

Schauer

Japlar Group, Inc

Charging Systems Manufacturer Since 1949

4500 Alpine Avenue

Cincinnati, Ohio 45242

1-800-899-8658

Multi-Volt Charging System, 6.5-19 VDC, 40 ADC

Installation, Operation and Service Manual

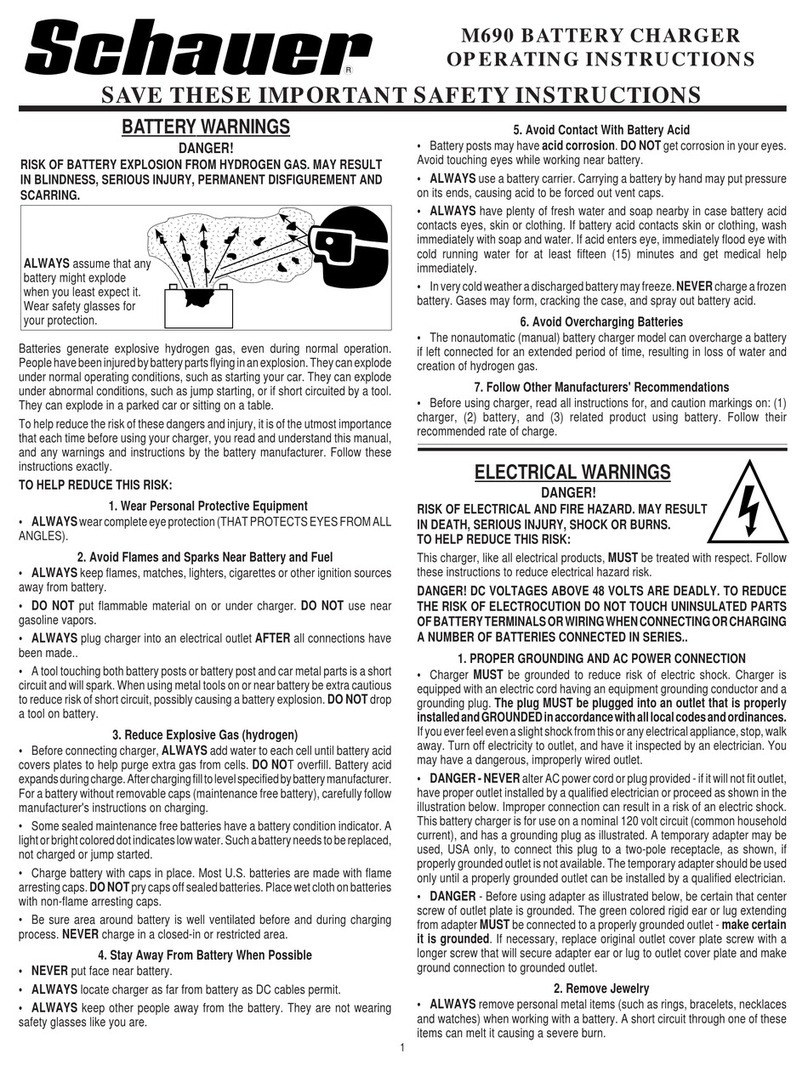

IMPORTANT: IT IS NECESSARY TO READ AND UNDERSTAND THIS ENTIRE MANUAL PRIOR TO

INSTALLATION, OPERATION OR SERVICING OF THE BATTERY CHARGER. FAILURE TO DO SO MAY

RESULT IN DAMAGE TO THE CHARGER, ASSOCIATED EQUIPMENT AND/OR PERSONAL INJURY.

ONLY TRAINED QUALIFIED PERSONNEL SHOULD SET-UP OR USE THIS EQUIPMENT.

THROUGHOUT THIS MANUAL YOU WILL NOTICE SYMBOLS INSERTED TO CAUTION OR WARN OF

POTENTIAL HAZARDS AND VITAL INFORMATION. PLEASE PAY CLOSE ATTENTION TO THESE SYMBOLS

TO MINIMIZE DAMAGE OR INJURY RISKS DURING SET-UP, OPERATION AND SERVICING.

THIS SYMBOL INDICATES A POTENTIAL RISK OF PROCEEDING WITHOUT CAUTION.

THIS SYMBOL INDICATES IMMEDIATE ATTENTION IS REQUIRED BEFORE CONTINUING.

SAFETY INSTRUCTIONS

Read this manual and be familiar with the charger front

panel controls before attempting setup. Be familiar with

the batteries and any associated equipment being

connected to the charger.

Use caution when working around batteries as they

produce hydrogen gas when operating. Never smoke,

use open flames or cause a spark near the area.

Read and understand the battery manufacturers

instructions for safety and proper application.

Be sure that all AC and DC power is disconnected from

this equipment prior to servicing. This battery charger

is not equipped with an AC power switch. Japlar does

NOT recommend disconnecting AC power by removing

the input fuses on the charger. AC power should be

turned off at the point of supply from the power source.

This battery charger is designed for indoor use only and

should not be exposed to rain, snow or liquids. Damage

due to water contamination is not covered under warranty.

DO NOT disassemble the charger whether energized or

de-energized. Improper re-assembly of the charger may

result in damage to the battery charger or batteries.

DO NOT make any adjustments to the control circuit board

that are not referenced in this instruction as an optional

adjustment for set-up or operation. Doing so may result

in equipment damage.

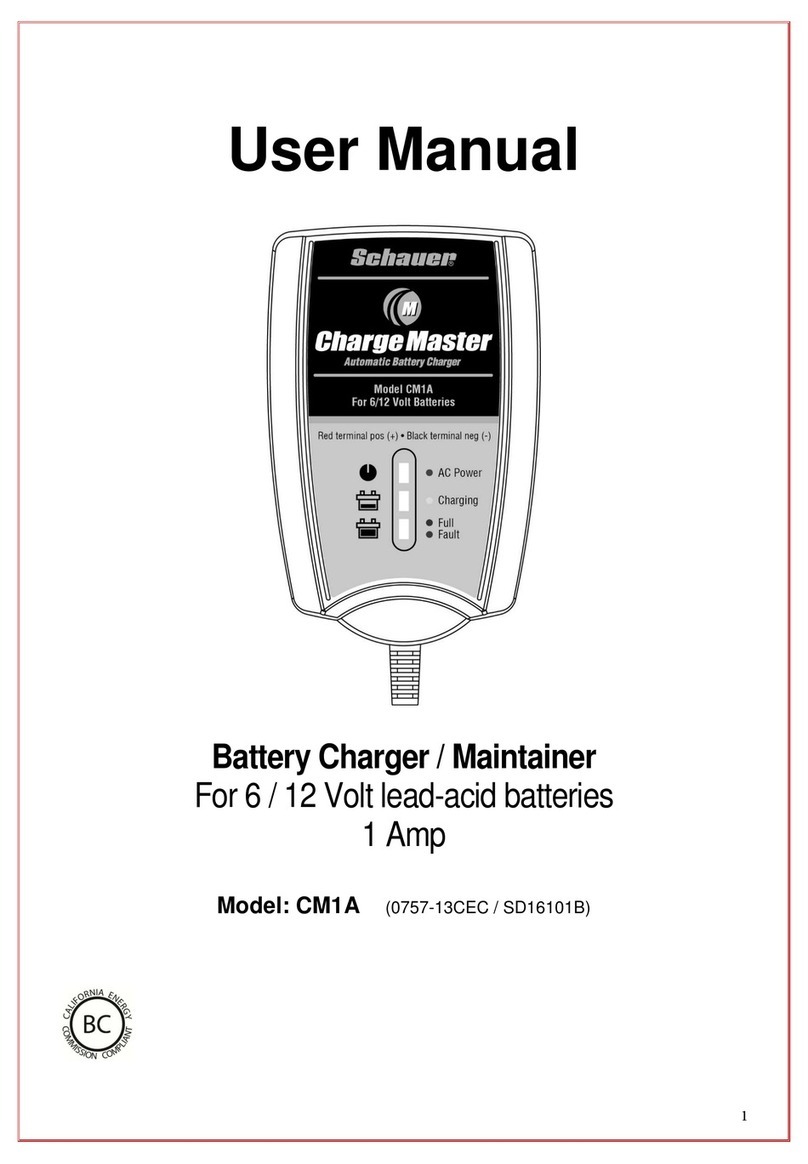

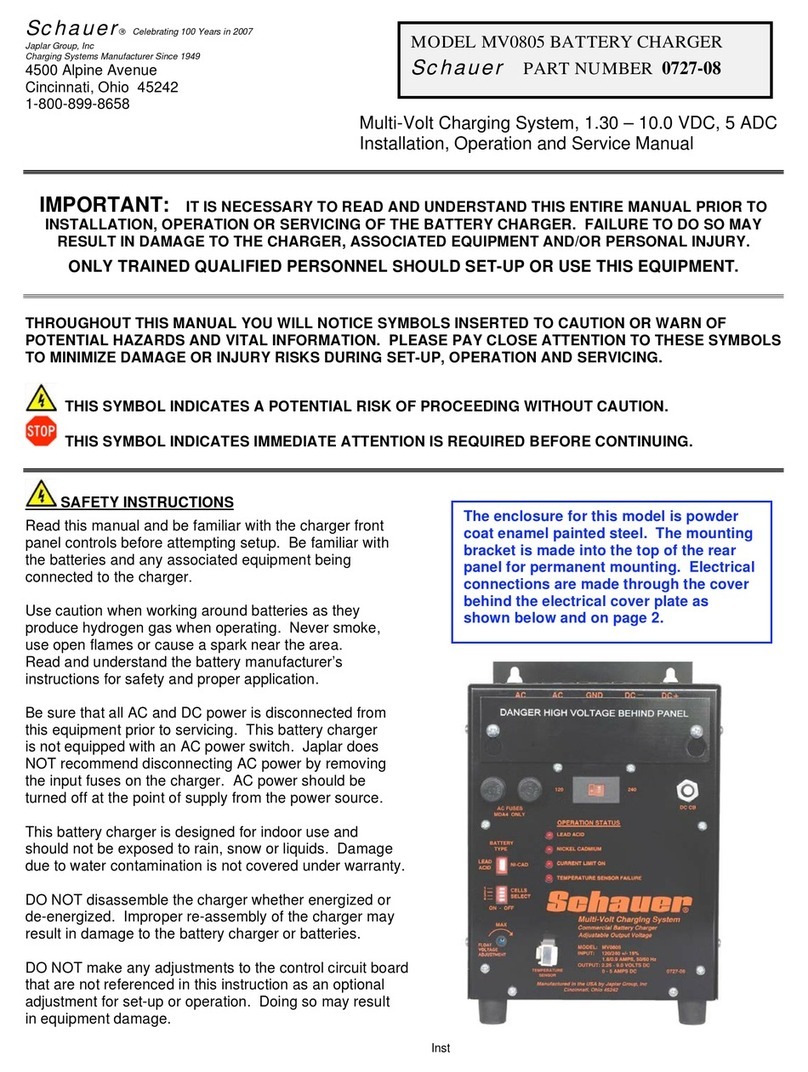

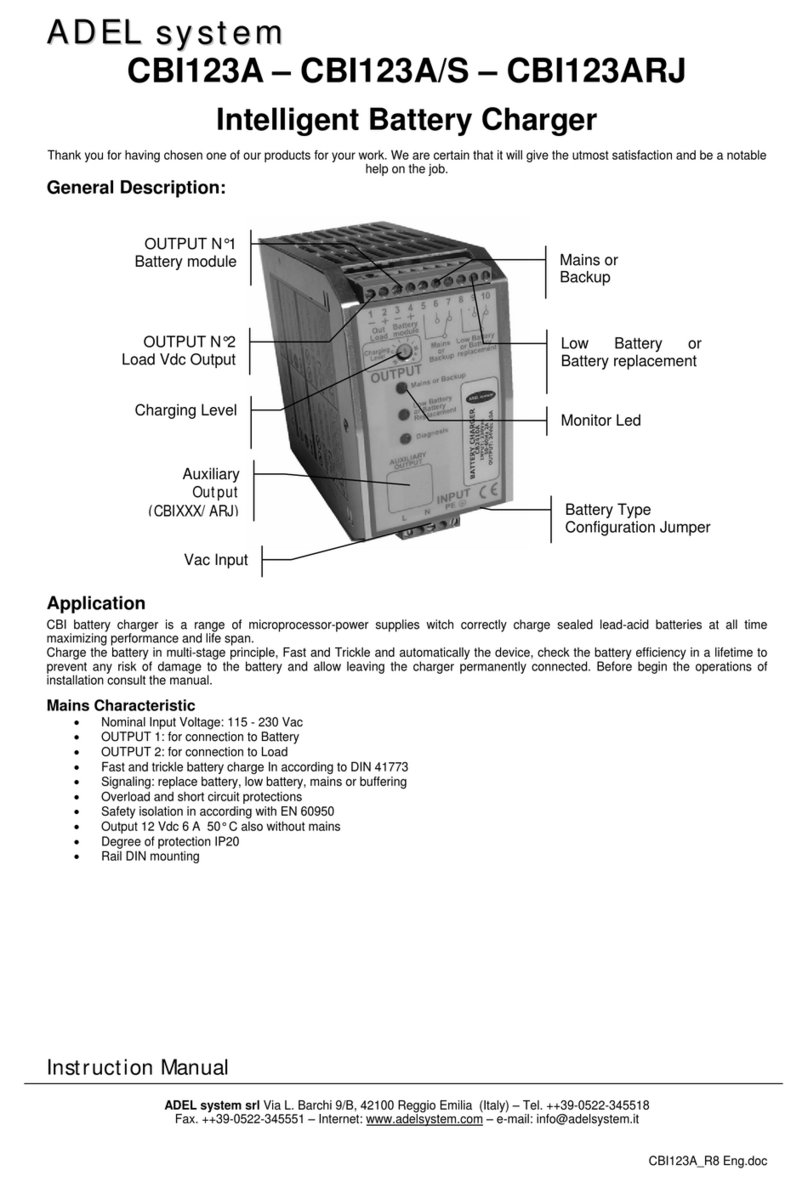

MODEL MV1240 BATTERY CHARGER

Schauer

PART NUMBER 0727-40

The enclosure for this model is zinc-

plated steel. Mounting brackets are

attached to the rear sides of the charger

for permanent mounting. The brackets

may be moved to the base for alternate

mounting preferences. Electrical

connections are made directly to the front

of the charger as shown. Meters are for

output volts and amps.

Instruction 1905072740 Rev A - 2 -

CHARGER THEORY OF OPERATION

The battery charger is powered by 120 or 240 volts AC jumper selectable on the connection terminal board. It is

designed to operate from 50 to 100 Hertz. The input circuit is protected with two 15 amp MDA type fuses. Surge

suppression is provided across the input terminals. The AC input provides voltage to a 1 KVA power transformer

primary winding. An auxiliary winding on the primary provides an electrically isolated input to the control board for

electronic control operation. The transformer secondary provides an output voltage suitable for charging the

batteries and is also electrically isolated from both the primary and auxiliary voltage windings. The control board

operates two high current SCR modules providing the AC to DC rectification. The transformer output is filtered

through a DC capacitor bank to provide a maximum of 1.0 volts AC peak-to-peak ripple at full rated output current.

The filter capacitor bank includes a DC shunt that provides current sensing to the control board for factory preset

current limiting of the charger output. Although not recommended this output current limit is customer adjustable.

Use only the “OUTPUT CURRENT ADJUST” pot for customer adjustments. A Current Limit LED is located on the

front panel to indicate a current limiting condition.

In series with the capacitor bank is a DC ammeter that provides front panel indication of the charging current.

There is also a DC output voltmeter. The charger output is interrupted by a manual reset circuit breaker providing

over-current protection. The batteries and wiring should be checked before resetting the circuit breaker if it trips.

Surge suppression is provided on the output terminals of the charger.

The battery charger is designed to operate as a constant current and constant voltage charger. When the

batteries are in a discharged state the control powers the SCRs to conduct in a constant current mode. As the

batteries become charged the output current decreases. Once the battery voltage has reached the float voltage

setting the charger then performs as a constant voltage charger maintaining a float voltage that is customer

adjustable within a limited range.

The control circuitry is designed to compensate charging voltage based on battery temperature changes with the

use of a temperature sensor plug (supplied) or an optional remote temperature sensor cable (12 or 25 ft.) attached

to the batteries for monitoring. This feature protects ONLY lead-acid batteries from over or under charging due to

temperature changes. An LED is located on the front panel to indicate improper operation of the temperature

compensation device. If no sensing device is connected or if the device is defective the TEMPERATURE SENSOR

FAILURE LED turns on. High and low voltage limits are designed into this circuit for extreme temperature

conditions. These functions do not operate when selecting Nickel-Cadmium type batteries.

Other set-up and operation controls (shown below) are selecting battery type, lead-acid or nickel-cadmium,

number of cells, float voltage adjustment and an LED for indication when the charger is operating in a Current

Limiting condition.

Instruction 1905072740 Rev A - 3 -

Unpacking Battery Charger

Packed with each charger is a temperature sensor plug, two jumper wires and two MOV assemblies. The

charger is secured to a shipping board along with a styrofoam pad. The screws and packaging should be retained

for return shipment should it be necessary. Inspect the charger for any damage during transit and report it

immediately to the carrier.

DO NOT INSTALL THE CHARGER IF THERE IS EVIDENCE OF ANY SHIPMENT DAMAGE.

Battery Charger Installation

Location of the charger installation requires air flow for convection cooling of the equipment. There should be a

minimum space of 3” on the sides and 4” above the top of the charger for free air flow. Mounting keyhole brackets

are provided at the sides of the charger rear panel. Proper gage wiring must be used to avoid voltage drops across

the DC wiring to the batteries.

DO NOT PLACE ANYTHING ON TOP OF THE CHARGER WHEN OPERATING. DAMAGE TO THE

CHARGER OR BATTERIES MAY OCCUR.

The two MOV assemblies and jumper wires are installed at the time of AC input power line connection.

Connections are made to the terminal board mounted at the bottom of the front panel (see page 1 photo). The 320

volt MOV (longer lead wires) is attached to terminals 1 & 4 of the input terminals. The 150 volt MOV (shorter lead

wires) is attached to terminals 2 & 3. For 120 volts supply line, install jumper 16 across terminals 1 & 2 and jumper

17 across terminals 3 & 4. For 240 volts supply line install the jumper wire across terminals 2 & 3 only. In either

configuration the MOV installation remains the same and the AC supply line is connected to terminals 1 & 4 with a

ground wire to the terminal marked GND. The DC output portion of the charger should not be connected to

batteries until all control switches and adjustments have been made on the front panel. IF THE BATTERIES ARE

CONNECTED AT THIS TIME A SPARK WILL OCCUR DUE TO CHARGING OF THE FILTER CAPACITOR BANK

INSIDE THE CHARGER.

MAKE SURE ALL JUMPER, MOV AND INPUT POWER LINES ARE CONNECTED PROPERLY BEFORE

THE CHARGER IS ENERGIZED. CHARGER MUST BE SOLIDLY GROUNDED!

Battery Charger Control Set-up

1. Select the battery type Lead-Acid or Nickel-Cadmium.

2. Select the number of cells, Lead-Acid 5-8 cells or Ni-Cad 5-12 cells (ON to the left, OFF to the right).

The control board is designed so cells 9 through 12 will not operate in the Lead-Acid switch position.

3. Do not connect the temperature sensor plug or cable at this time.

4. Connect a digital DC Voltmeter to the charger DC output terminals.

5. Turn ON the AC main power supply to the charger.

6. After allowing the charger output voltage to stabilize, set the FLOAT VOLTAGE ADJUST potentiometer to the

desired float voltage. Recommended voltages at 77°F (25°C) are as follows;

Lead Acid Flooded = 2.20 volts/cell

Lead Acid Sealed = 2.25 volts/cell

Nickel Cadmium = 1.47 volts/cell all +/- .03 volts/cell

Always refer to the battery manufacturer’s recommendations for charging voltages.

7. Turn OFF the AC main power supply to the charger.

8. If desired, external wiring (22 GA minimum) may be connected from the battery terminals to the remote sense

terminal block. Simply remove the jumpers that are factory installed. This will monitor the voltage at the

batteries rather than the output terminals of the charger. Be sure the polarity is correct.

9. Connect the temperature sensor plug or cable to the front panel.

10. The batteries may now be connected to the DC output positive and negative terminals.

CAUTION: POLARITY OF THE DC CONNECTIONS MUST BE CORRECT.

11. The output current limit is preset at the factory. Although we do not recommend doing so, it is internally

adjustable. An additional adjustment pot is located on the setup controls indicated as OUTPUT CURRENT

ADJUST. It will adjust from full output current to approximately 50 - 60% of rated output current at the minimum

position. Selection should be made based on the application.

Instruction 1905072740 Rev A - 4 -

Battery Charger Maintenance

The charger should be kept clean, dry and the electrical connections checked periodically for proper torque (30

inch/pounds). Surge suppressors (MOVs) should be inspected for damage to ensure continued protection. Verify

the meter and LEDs are functional. No other routine maintenance is required for this equipment.

Special Application

With the DC output being filtered through a capacitor bank, there are also applications when this charger can be

used as a DC power supply. Contact the factory for further information.

Troubleshooting and Servicing

If the battery charger seems to be operating improperly begin with the basic steps below.

Symptom Possible Cause

No charger LED operation on the front panel Check AC input power supply line and charger fuses

Check for proper wiring at the connection terminal board

Charger LEDs operate but low or no DC output Verify proper DC connections and torque

Check DC circuit breaker and push to reset if required*

Chargerincurrentlimit – check batteries and cables

TEMPERATURE SENSOR FAILURE LED is ON Temperature sensor not connected or is defective

The charger stays in current limit at all times. Due to the size of the batteries in some applications it is

possibleforthe unit to remain in current limit for extended

periods of time. It depends on battery discharge level. Be

certain the charger is sized properly for the batteries used.

If the problem is not solved using the steps above bench testing is recommended rather than field

troubleshooting. Contact the factory for additional technical service. Please have the model number, part number

and serial number from the front panel information available prior to contacting the factory.

* The charger has a 70 amp DC circuit breaker. If it trips, be sure to check all wiring and the batteries before

resetting the circuit breaker.

Battery Charger Specifications

AC Input Voltage 120/240 VAC +/- 15%, 50 to 100 Hertz

AC Input Current 14/7 AAC +/- 5% @ 40 ADC Full Load (slightly higher in current limit)

AC Input Regulation Range +/- 15% (102-138 @ 120 input, 204-276 @ 240 input)

AC Input Fuses 15 Amp MDA type only

Efficiency Rating 75 % @ 13.5 VDC, 40 ADC

80% @ 17.6 VDC, 40 ADC

DC Output Voltage Range 6.5 - 19 VDC filtered output

DC Output Float Adjust Range Lead-Acid –2.5% / +4.5%, NiCad –13% / +10% of nominal setting

L/A Temperature Compensation Offset is 3mV per °F per cell when the sensor plug or cable is used

DC Output Current Limit 41.5 ADC +/- 3%

DC Output AC Ripple Less than 1.0 VAC @ 40 ADC at the DC output terminals

Physical Dimensions 13” Width x 12” Depth x 14” Height

Charger Weight 52 pounds

Instruction 1905072740 Rev A - 5 -

Replacement Parts List

Japlar Part Number Qty Req'd Description

504927 1 Power Transformer Assembly

3597V12-02 1 Electronic Control Board

0625000006 5 Control Board Mounting Stand-offs

651578 2 Front Panel Fuseholder

651328 2 AC Input Fuses 15 amp MDA type only

653037 1 DC Circuit Breaker 70 amp

3316010320 1 320 Volt AC MOV Assembly (longer lead wires) MOV1

3316010150 1 150 Volt AC MOV Assembly (shorter lead wires) MOV2

2076 1 DC Output MOV Assembly

649070

1531

1

1

Ammeter 0-30 ADC

Voltmeter 0-20 VDC

3566-0 1 Temperature Sensor Plug

3308000435 1 Heatsink Assembly (including SCRs and wires 13, 14 & 18)

3589 4 10 Amp 50 mV Current Shunt (requires a stack of 4 pieces)

644130 2 80 Amp 400 Volt SCR

600422 4 Output Filter Capacitor Bank (replace in sets of 4 only)

619398-1 1 R1 Bleeder Resistor Assembly (installed on voltmeter)

1464 1 Cover, Aluminum

191061-1

191061-2

5

5

AC Connector Insulator Shield

AC Connector Insulator Cap

3566-25 Optional 25 Feet Temperature Sensor Cable

3566-12 Optional 12 Feet Temperature Sensor Cable

Use only original equipment replacement parts in this battery charger as substitutions may have an adverse effect

on proper operation and reliability. Contact the

Japlar Group

sales department for parts orders.

For additional technical information contact the engineering department at 513-791-3030 extension 144.

Instruction 1905072740 Rev A - 6 -

Schematic for Reference

This manual suits for next models

1

Table of contents

Other Schauer Batteries Charger manuals

Popular Batteries Charger manuals by other brands

Schumacher

Schumacher SC1340 owner's manual

VOLTCRAFT

VOLTCRAFT V-CHARGE 600 DUO operating instructions

Power One

Power One 675charger operating instructions

Milwaukee

Milwaukee M28 48-59-2819 Operator's manual

Dolphin

Dolphin All In One Series Operating user manual

Battery Controller

Battery Controller BC SMART 400 quick start guide