THE PRESENT MANUAL BELONGS TO - Schenker Italia -ALL RIGHTS RESERVED

INDEX

1. LAYOUT OF MANUAL........................................................................................................................................4

1.1 STRUCTURE OF THE MANUAL ............................................................................................................................4

1.2DESCRIPTION OF THE PICTOGRAMS.................................................................................................................4

2. GENERAL WARNINGS AND INFORMATION TO THE RECIPIENT .....................................................5

2.1 IMPORTANT INFORMATION ................................................................................................................................5

2.2 SAFETY WARNINGS ............................................................................................................................................5

2.3WARRANTY..........................................................................................................................................................6

2.4IDENTIFICATION OF THE UNIT ..........................................................................................................................7

2.5LEGISLATIVE REFERENCE ..................................................................................................................................7

2.5.1 DIRECTIVES AND STANDARDS CONCERNING MACHINE SAFETY .................................................................7

2.5.2 RESPECT FOR THE ENVIRONMENT –REQUIREMENTS FOR REMOVAL AND DISPOSAL...............................7

3. PRODUCT PRESENTATION ............................................................................................................................9

3.1 TRANSPORT AND MATERIAL HANDLING ...........................................................................................................9

3.2 STOCK ...............................................................................................................................................................10

3.3 PACKAGING.......................................................................................................................................................10

3.3.1 PACKAGING CONTENTS.................................................................................................................................10

3.4 ATTACHED DOCUMENTS ..................................................................................................................................11

3.5 TECHNICAL DATA .............................................................................................................................................11

3.6 FEATURES OF THE PRODUCT ...........................................................................................................................12

3.7 ADVANTAGES OF THE ENERGY RECOVERY SYSTEM ......................................................................................13

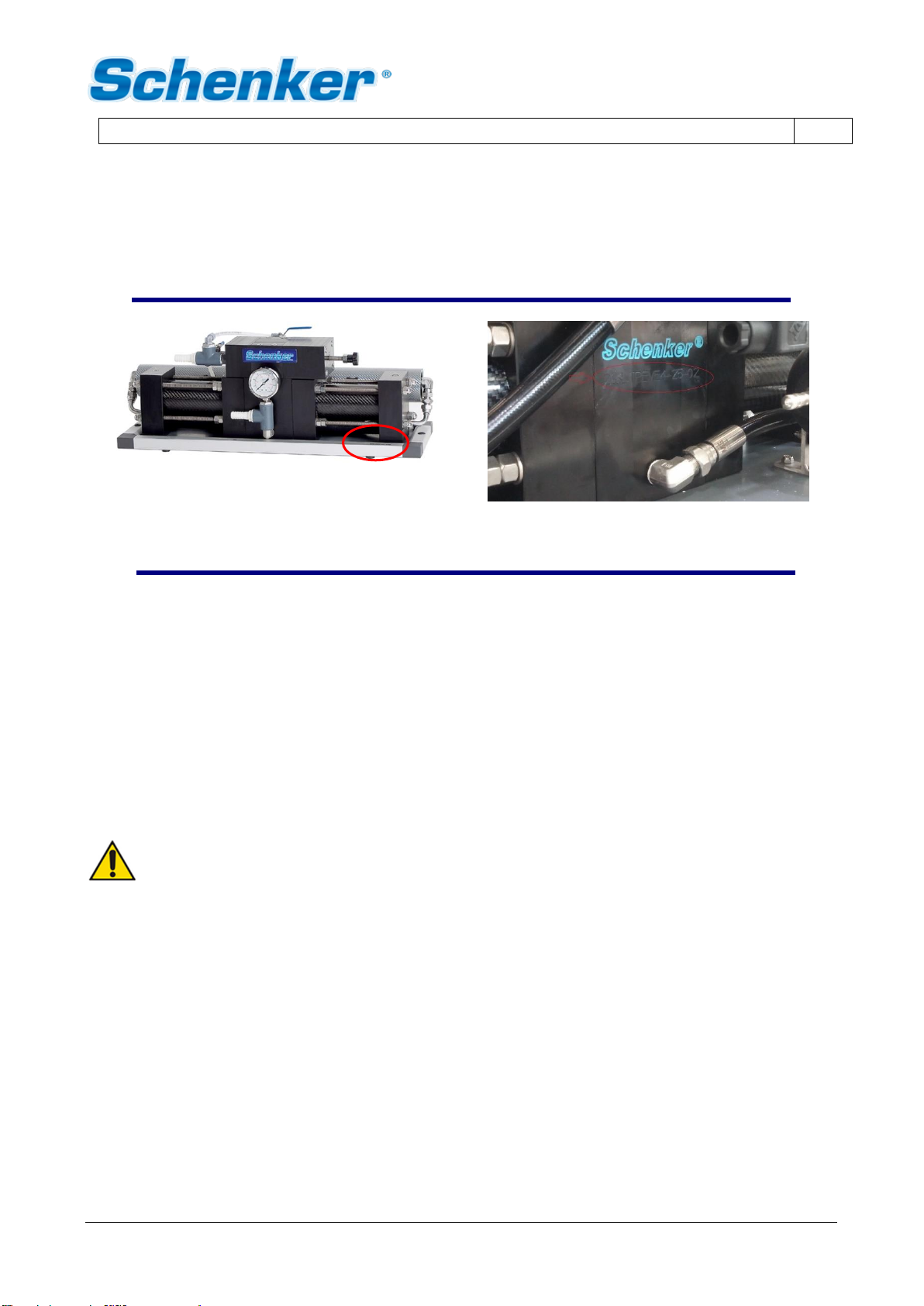

3.8 COMPOSITION OF THE MACHINE ....................................................................................................................14

3.8.1 PUMP GROUP ..................................................................................................................................................14

3.8.2 WATERMAKER GROUP....................................................................................................................................15

3.8.3 ACCESSORIES ................................................................................................................................................17

4. MOUNTING AND INSTALLATION...............................................................................................................18

4.1 GENERAL CRITERIA ..........................................................................................................................................18

4.2 COMPONENTS MOUNTINGS .............................................................................................................................19

4.2.1 PUMP GROUP..................................................................................................................................................19

4.2.2 WATERMAKER GROUP ...................................................................................................................................19

4.2.3 ACCESSORIES................................................................................................................................................19

4.3 INSTALLATION ..................................................................................................................................................19

4.3.1 WATER INTAKES AND DISCHARGES ............................................................................................................19

4.3.2 SEAWATER INTAKE........................................................................................................................................20

4.3.3 FRESH WATER INTAKE FOR WASHING.........................................................................................................21

4.3.4 BRINE DISCHARGE ........................................................................................................................................21

4.4 HYDRAULIC CONNECTIONS .............................................................................................................................22

4.5 ELECTRIC CONNECTIONS.................................................................................................................................25

4.5.1 REMOTE CONTROL PANEL MOUNTING .........................................................................................................25

4.5.2 ELECTRIC CONNECTIONS:WIRES (ZEN 30 12/24V DC) .....................................................................26

5. FUNCTIONING AND USE..............................................................................................................................28

5.1 COMMAND DESCRIPTION.................................................................................................................................28

5.2 FIRST START UP PROCEDURE ..........................................................................................................................28

5.2.1 PRELIMINARY CHECKS BEFORE PROCEEDING WITH THE STARTUP PROCEDURE .....................................28

5.2.2 START UP .......................................................................................................................................................29

5.3 NORMAL OPERATING PROCEDURE ..................................................................................................................31

5.3.1 NORMAL OPERATING PROCEDURE WITHOUT FINAL FLUSHING .................................................................31