Table of contents

Table of contents

1 Introduction 5

1.1 Preface.................................................... 5

1.2 Product identification/Product information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3 Storage.................................................... 5

1.4 Definitionofterms.............................................. 6

1.5 Officesabroad................................................ 6

1.6 Symbolsusedinthismanual........................................ 7

1.6.1 Dangerwarninglevels....................................... 7

1.6.2 Dangersymbols .......................................... 8

1.6.3 Commandsymbols ........................................ 9

1.6.4 Generalsymbols.......................................... 10

1.7 Personalprotectiveequipment ....................................... 10

1.8 Definition of qualified/authorized personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.9 Obligationsoftheoperator ......................................... 11

1.10ObligationsofthePersonnel ........................................ 12

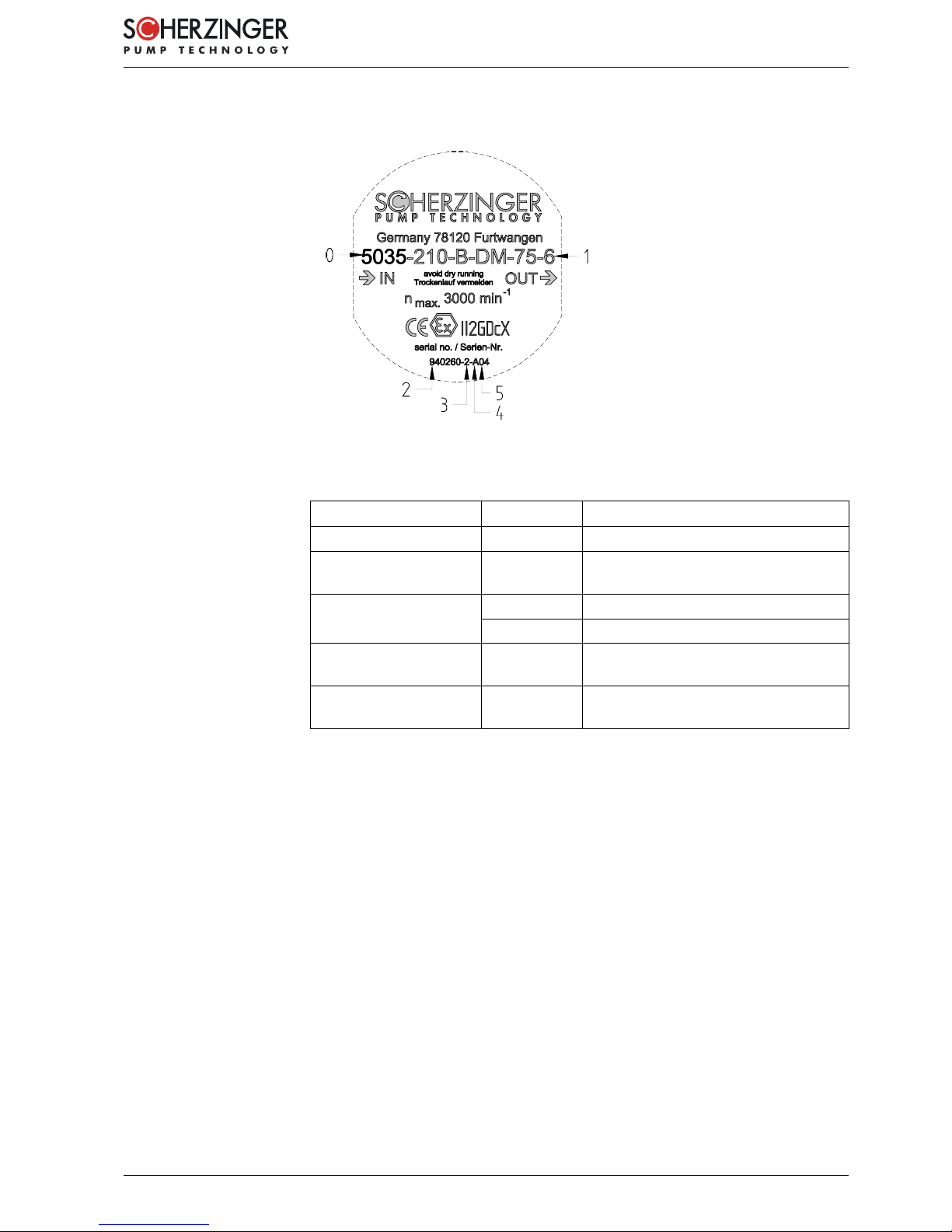

1.11 Identification based on the example of the pump type 5035-210-B-DM-75-6 . . . . . . . . . . . . . . 13

1.12Intendeduse/normaloperation....................................... 13

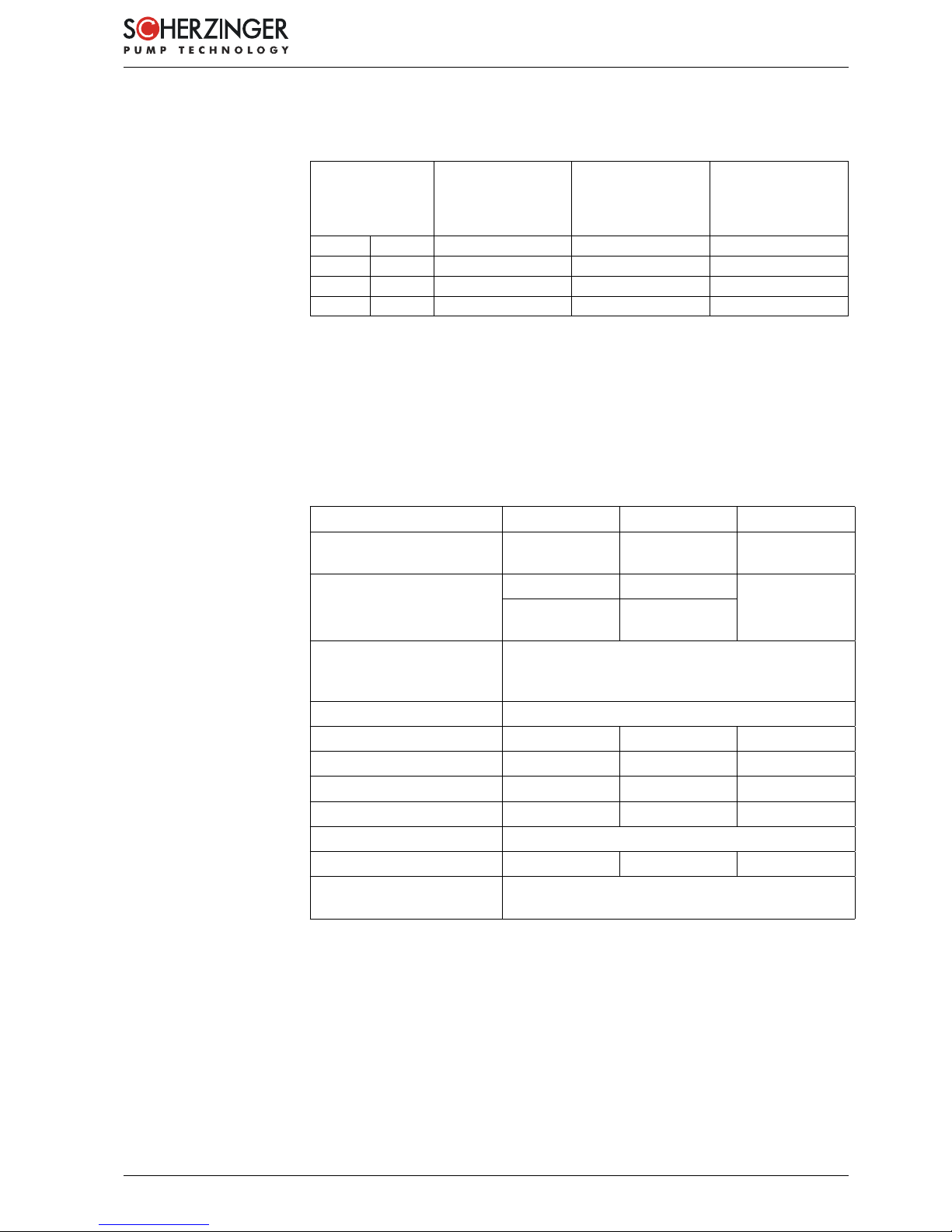

1.12.1 Limitvalues............................................. 14

1.12.2 Temperature classes and approved temperatures . . . . . . . . . . . . . . . . . . . . . . . 15

1.12.3 Overview of series/wetted parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

1.12.4 Paint ................................................ 16

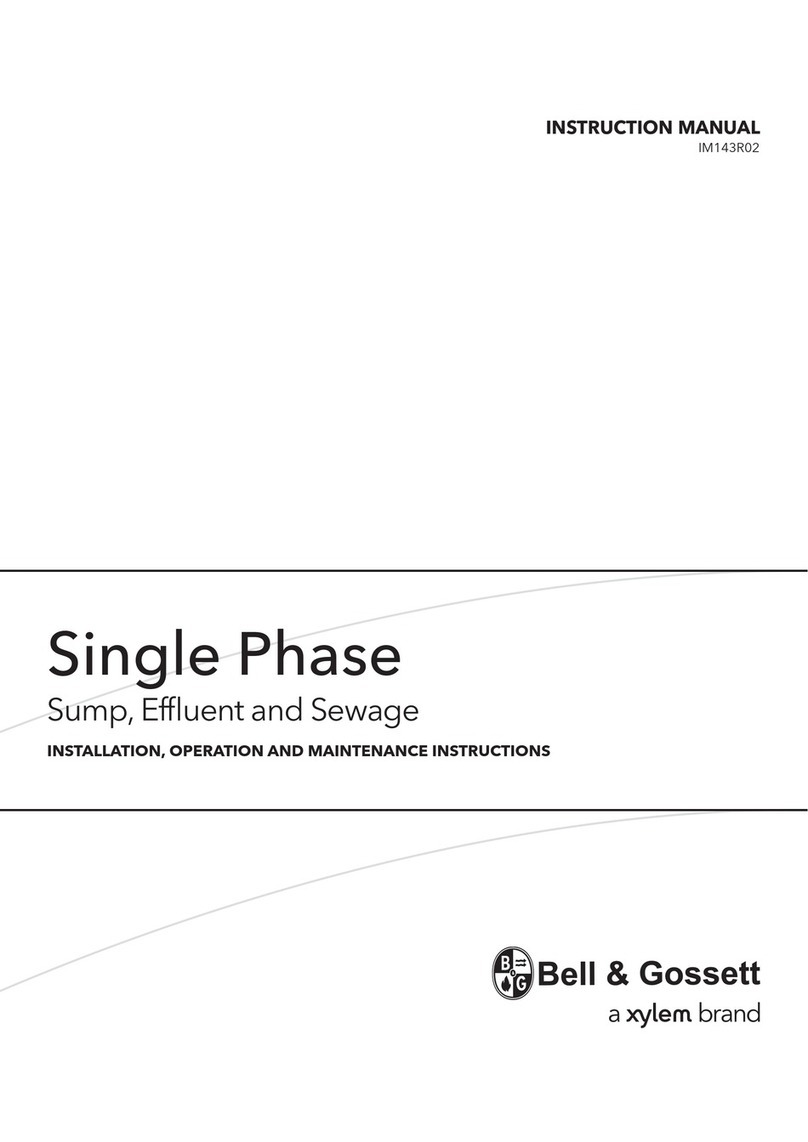

1.12.5 Maximumpossiblespeed..................................... 16

1.13Improperuse/fault.............................................. 17

1.13.1 Dangerfromdust ......................................... 17

1.13.2 Danger from dry running of the pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.13.3 Danger from overheating of the pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

1.13.4 Danger from overpressure in the pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

1.13.5 Danger from particles/foreign matter in the fluid . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.13.6 Danger from incorrect direction of rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

1.13.7 Danger from operation with too high of a speed . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.13.8 Danger from potential difference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.13.9 Danger from exceeding the maximum torque . . . . . . . . . . . . . . . . . . . . . . . . . . 21

1.13.10 Danger from mechanically produced sparks . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

1.14Complaints.................................................. 23

1.15Warrantyandliability ............................................ 24

1.16Declarationofconformity .......................................... 25

1.16.1 Declaration of conformity as per Directive 2014/34/EU . . . . . . . . . . . . . . . . . . . . . 25

1.16.2 Declaration of conformity as per Directive 2006/42/EC (Machinery Directive) . . . . . . . . 26

1.16.3 CE conformity notes relating to fitting a motor/drive . . . . . . . . . . . . . . . . . . . . . . . 27

1.17Certificateofnon-objection......................................... 28

2 Safety Instructions 29

2.1 Dangerfrommovingmachineparts .................................... 29

2.2 Dangerfromhotparts............................................ 30

2.3 Dangerfromelectricshock ......................................... 30

2.4 Dangerfrommagneticfields ........................................ 31

2.5 Dangerfromfluids.............................................. 32

3 Transport and interim storage 33

3.1 Shipping of the pump and protective measures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

3.2 Interimstorage................................................ 33

3.3 Conserving the machine for storage after operating/flushing the pump . . . . . . . . . . . . . . . . . 34

3.4 Returntothefactory............................................. 34

4 Mode of operation/Functional description 35

4.1 Pumpfunction ................................................ 35

OI Pump Edition 4.3 3