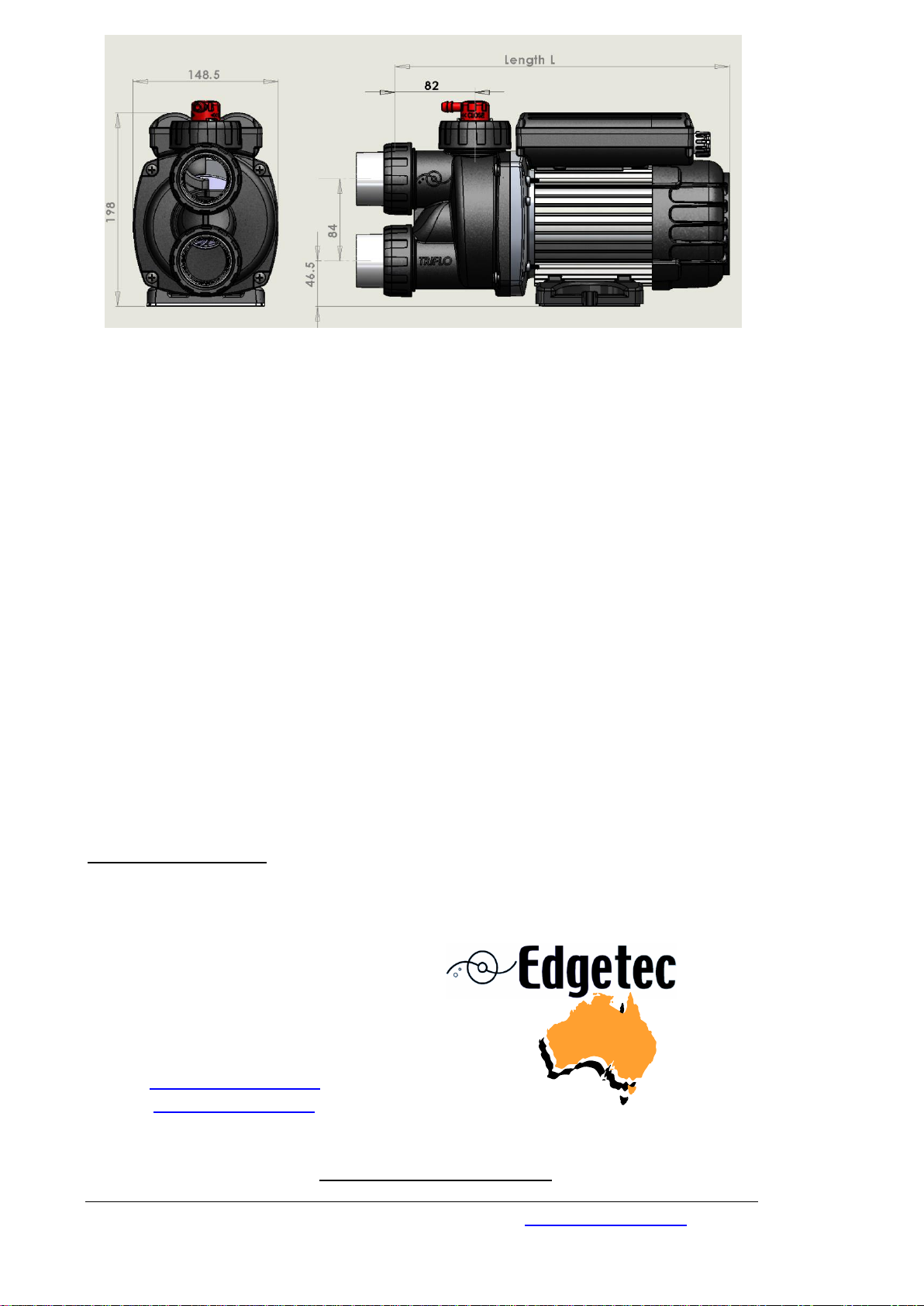

EDGETEC SYSTEMS PTY LTD Part # 9-2100 SEP2015 www.edgetec.net

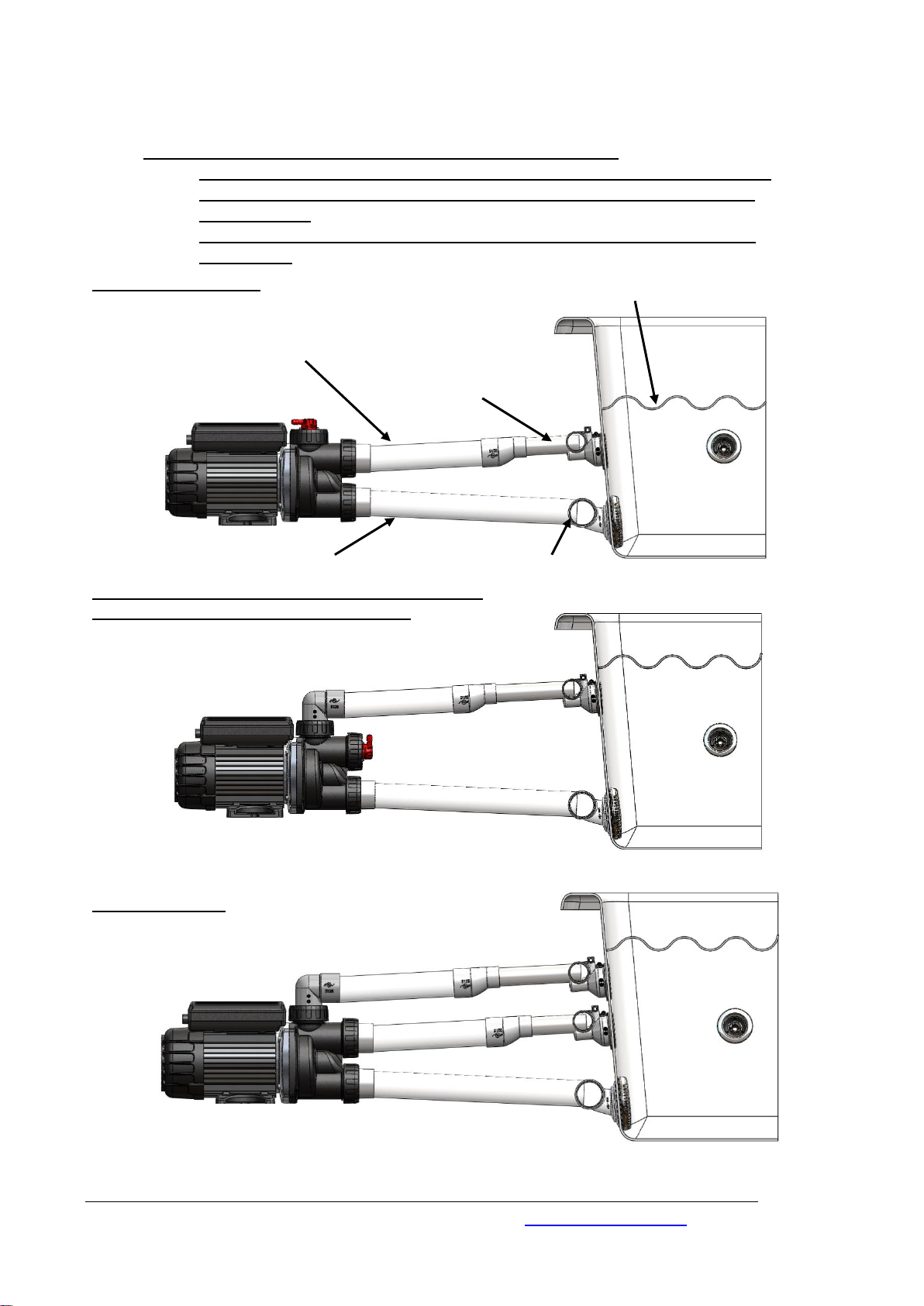

Installation Instructions (refer diagram 1)

1. To ensure optimum performance of your spa bath the TriFlo pump should be

located as close as possible to your spa bath (maximum 3 Metres). To ensure

high efficiency of your TriFlo pump, use the minimum amount of pipe fittings

during your pump to spa bath installation. Correct installation allows water to

drain from pipe work to pump and from pump to the self-drain suction fitting

in the bath.

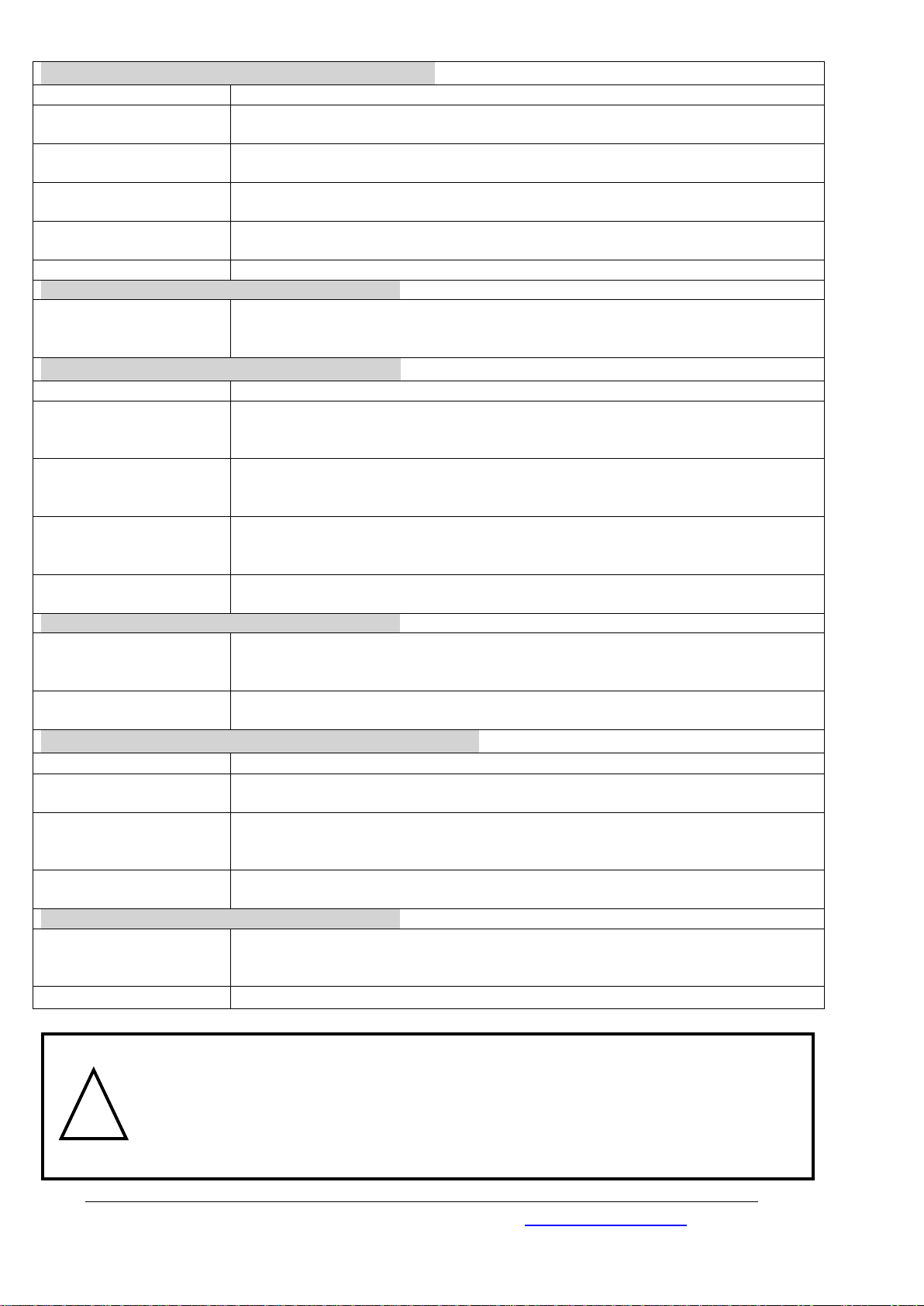

2. The pump can be located internally or externally. If you are fitting the pump

externally, fit the Pro-Tec pump cover as shown on page 7 (not supplied).

3. Internal installation must have adequate ventilation (minimum area 50cm²)

for the pump motor. Inadequate ventilation may cause the motor to cut out

on thermal over load. If this occurs the thermal will reset when the motor

cools down.

4. Asuitable drain tray on internal installations should be installed to avoid

water damage to property should any leaks occur from pipe work,

connections or normal wear.

5. Install the TriFlo pump as per diagram 1 (using the least amount of elbows, if

required). It is most important that the suction line be installed with a

minimum of 1:36 gradient (1.5°) (refer Diagram 1) as this allows the water to

drain from the pump and pipe work when the bath is emptied.

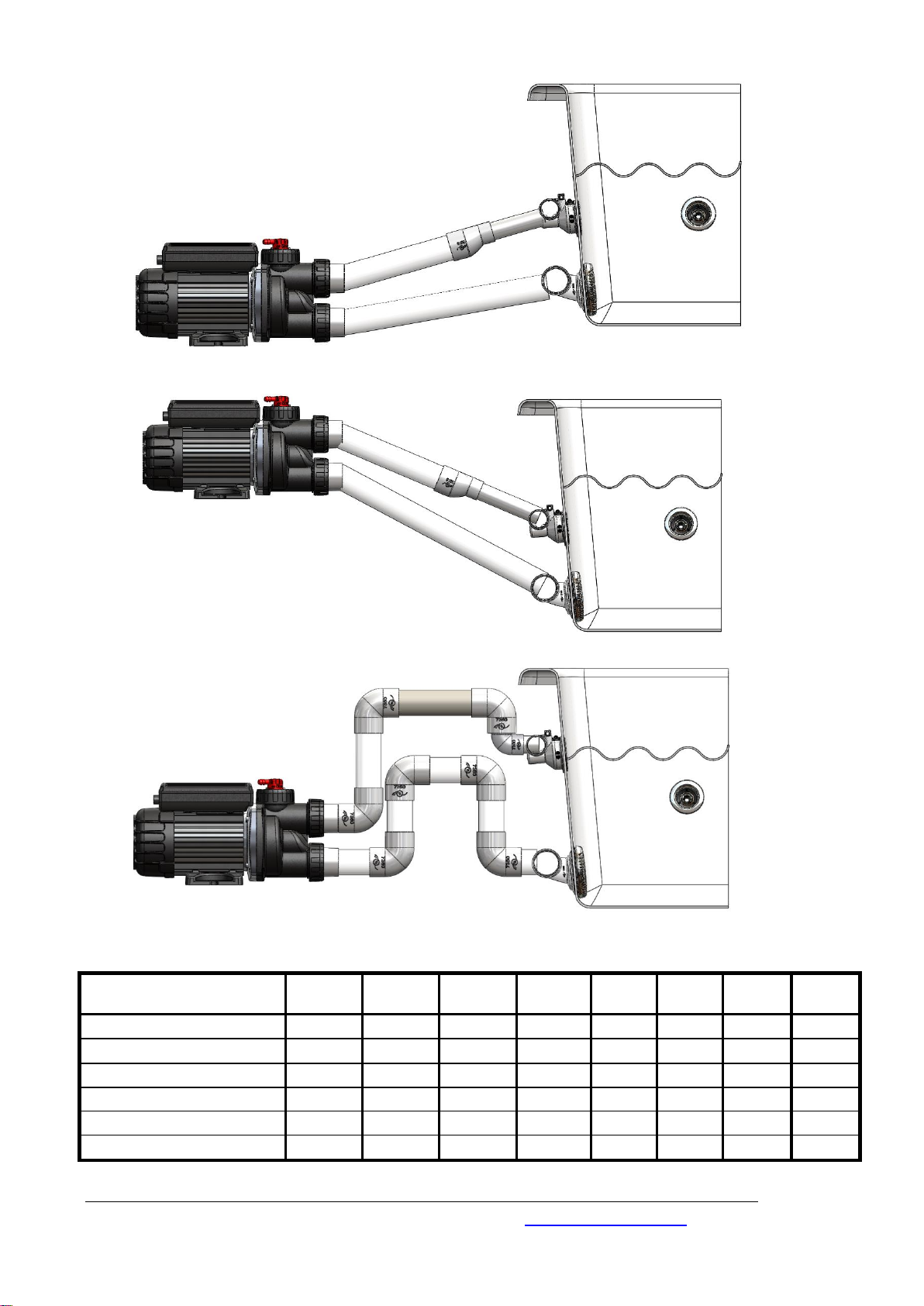

6. The pump should never be installed as shown in diagram 2.

The pump return line should be installed below the water level of the bath, if

the return line is above the water level the pump may air lock and may not

prime (pump starts but no jets are operating). Should this occur you may

have to activate the air bleed valve (Refer to Activating Air Bleed; diagram 5)

or your pump may be mounted too high check pump height.

7. The pump to be fixed to the frame or support through the pump mounting

points in the pump base with appropriate fasteners. Two anti-vibration

isolation washer buttons are provided with the pump for the fasteners.

8. Barrel unions only require to be hand tightened, over tightening may cause

damage to the unions and or o rings. Do not use stillsons or any other

mechanical leverage.

9. Before connecting the pump to the pipe work, ensure that all the pipe work is

clear of any debris as small particles can cause blockage to spa jets or the

pump impeller causing serious damage.

10. IMPORTANT REQUIREMENT FOR PUMP SERVICE:

Pump installation must provide reasonable access for pump removal.

To allow for pump removal a serviceman must be able to reach the

barrel unions.

For under the hob installation- an access panel must be provided on

every installation.

Electrical Connection

1. Spa bath pumps must be fitted in accord with AS3000 electrical wiring rules

2. AS3000 requires all 240 V pumps installed in Spa Bath to be supplied from a

circuit protected by a residual current device (RCD) with a maximum rated

residual current 30 mA.

3. The TriFlo spa bath pump is fitted with a standard lead and three pin plug for

240-220V 50Hz power supply.

4. The spa bath pump power connection must be accessible so that it can be

independently switched off in case of an emergency but must not be

accessible by the bath user.

5. If damage occurs to the power cord it must be replaced by Edgetec or an

authorised service agent or suitably qualified person.