page 4 of 6

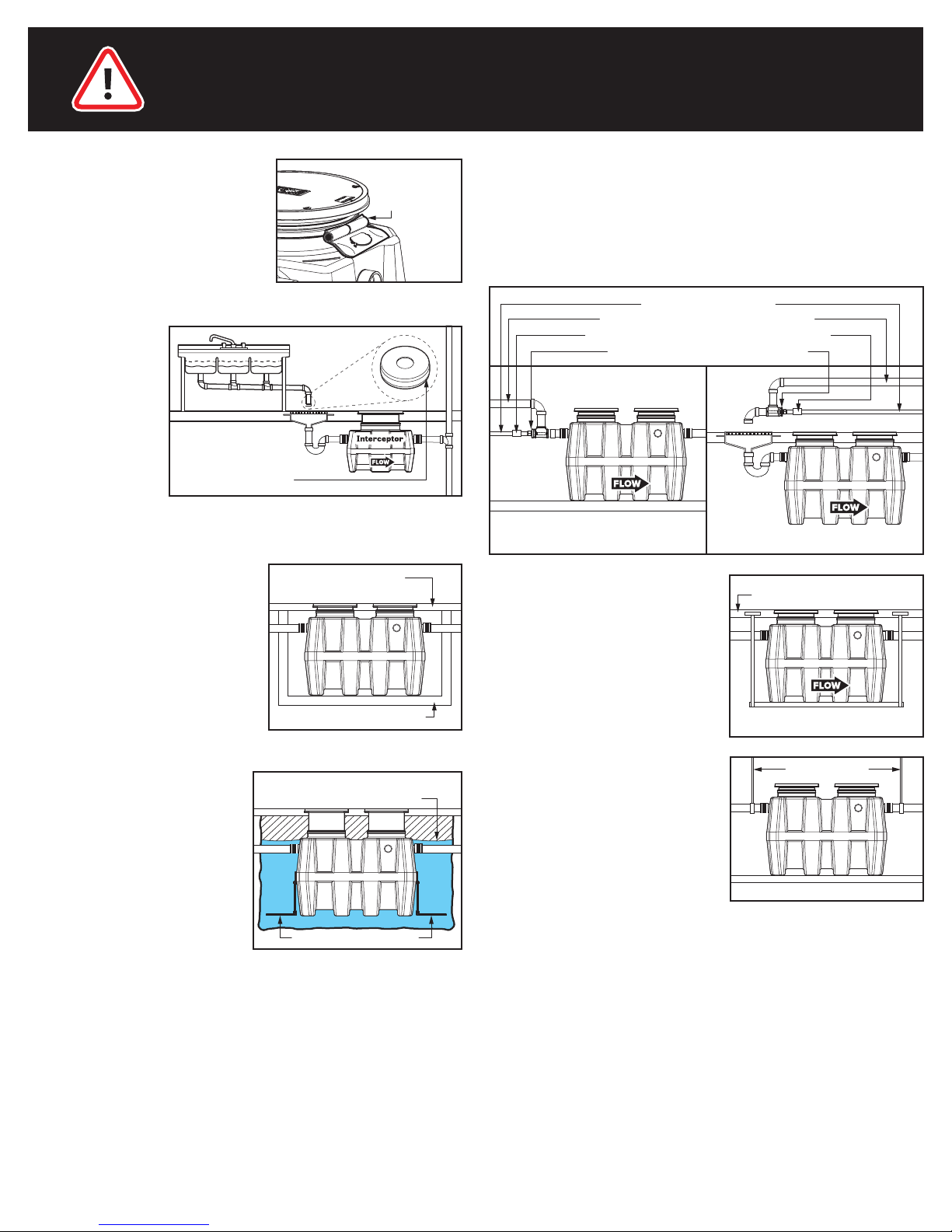

Table 1

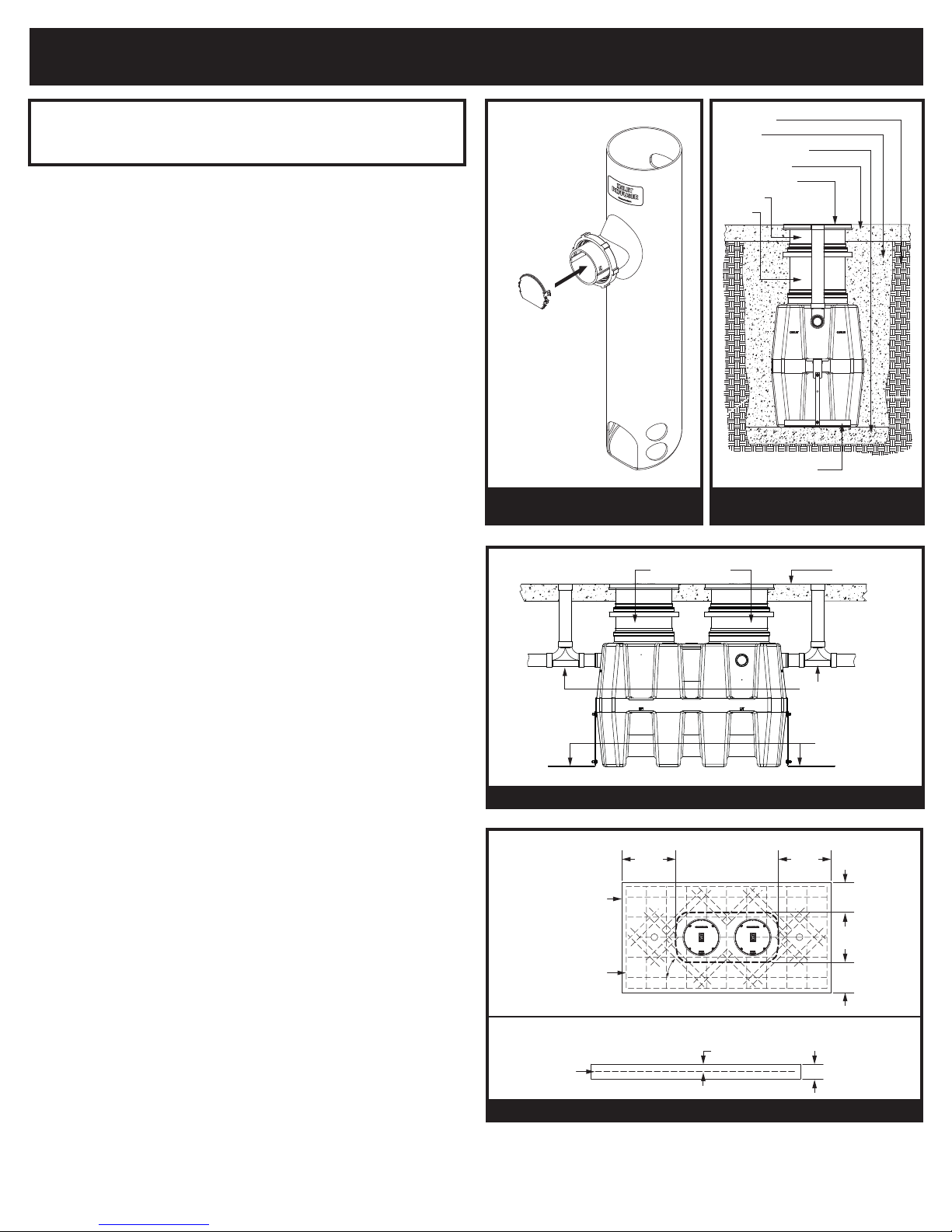

Riser Height Needed Risers Required

0 - 3-1/2" None (use adapter)

5" - 23" SR24 (x2)

>23" - 38" LR24 (x2)

>38" - 43" SR24 (x4)

>43" - 58" SR24 (x2) + LR24 (x2)

>58" - 72" LR24 (x4)

Riser

Height

Needed

Adapter

Riser

Cut Line

Alignment Mark

Figure 1 - Riser Measurements

6"

2"

4"

LR24

Long Riser

Adapter

SR24

Short Riser

Adapter (shown)

or Riser

Cover

Gasket

Upper Band Clamp

(

field adjustable)

Lower Band Clamp

(

factory set - do not

adjust or remove)

GB Unit (shown)

or Riser

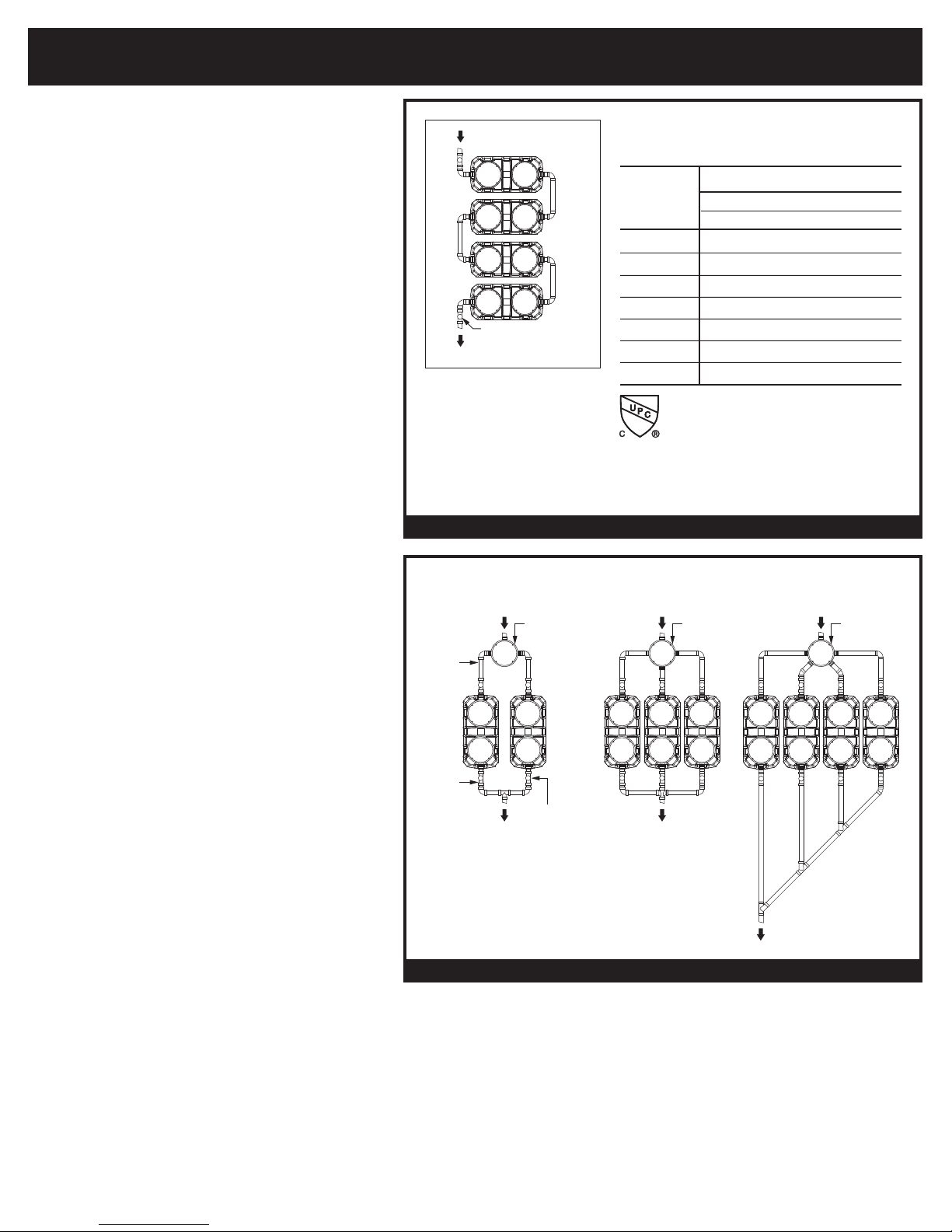

Anchor hook

Anchor strap

Anchor plate

Figure 2 - Insertion Depths

ANCHOR KIT INSTALLATION DETAIL

2-1/2" Minimum Insertion Depth

4" Maximum Insertion Depth

(into GB unit only)

FIELD CUT RISER (24 SERIES)

INSTALLATION GUIDELINES

Tools needed: 7/16" Nut driver tool/bit (included), marker (included), tape

measure and drill with 1/2" chuck. Jigsaw, circular saw or reciprocating

saw will be needed if risers need to be cut.

NOTE: To remove a component or adjust its position, the Upper Band

Clamp needs to be loosened or removed using nut driver bit. The

Lower Band Clamp is factory set and should not be removed. For

proper fastening ensure clamps are tightened to 5 - 8 ft lbs. of torque

(same as a rubber no-hub coupling) prior to installation.

Riser Assembly Instructions/Steps

1. Set unit so the pipe connections line up with job site piping and

measure riser height needed from top of cover to finished grade.

See Table 1 to select risers needed.

2. Remove covers from adapters. Remove adapters from main unit.

On a level surface, pre-assemble the risers and adapters,

adjusting the components upwards or downwards to achieve the

riser height needed. Make sure to maintain minimum and

maximum insertion depths as shown in Figure 2. If components

are too long, make a circular line around the sidewall with marker

and cut with a power saw. The lowest cut line on the riser assembly

will be 6" beyond the riser height needed to allow for ideal insertion

depth (See Figure 1). An alignment mark should be drawn 2"

beyond the riser height needed which will align with the top of the

base unit gasket. DO NOT cut the alignment mark. The Adapters

and risers should sit level with each other. Tighten upper clamps

to keep riser/adapter assembly from shifting. Make alignment

marks on the sidewalls at the top of all riser gaskets to aid final

assembly.

3. IMPORTANT: Before the next step, make sure both diffusers are

installed inside the main unit at the appropriate locations. Check if

there needs to be any flow control adjustment at the inlet diffuser

(see general installation instructions).

4. Take apart riser assembly and clean all sidewalls and insides of

gaskets to remove dust/debris. Install components into the main

units starting from the lowest riser and work your way up to finished

grade. Ensure that riser will not interfere with diffuser, allow min. 1"

clearance. Maintain minimum and maximum insertion depths for all

components (see Figure 2). Tighten Upper Clamps to specified

torque after correctly positioning components. Riser assembly may

need to be supported during backfill.

5. If tilting of the adapter is required to be flush with grade, do so

AFTER all clamps have been tightened with riser(s)/adapter in a

vertical and level position. Tilting is done using gasket flexibility.

Tilting before tightening clamps may ruin a perfect gasket seal.

Schier recommends tilting only the adapter versus the entire

riser assembly to make sure your riser height and proper tank

access is maintained.

6. If riser height conditions change after completing above steps,

there may be room for adjustment. As long as minimum and

maximum insertion depths are maintained (see Figure 2), the

adapters/risers can be adjusted/cut as many times as neces-

sary.When riser system installation is complete, see Leak/Seal

Testing procedure if required (pg 3 of 6).

ANCHOR KIT INSTALLATION

Stainless steel anchor kit is recommended for installation in high

water table conditions to prevent float out. Necessity to be deter-

mined by specifying engineer. Hold down force achieved by backfill

weight acting on Anchor Plate.

Slide Anchor Hook over tie down point on end wall and bolt to Anchor

Strap. Bolt Anchor Strap to Anchor Plate using provided stainless

steel hardware. If required, Anchor Plate may be bolted to concrete

slab using provided holes.

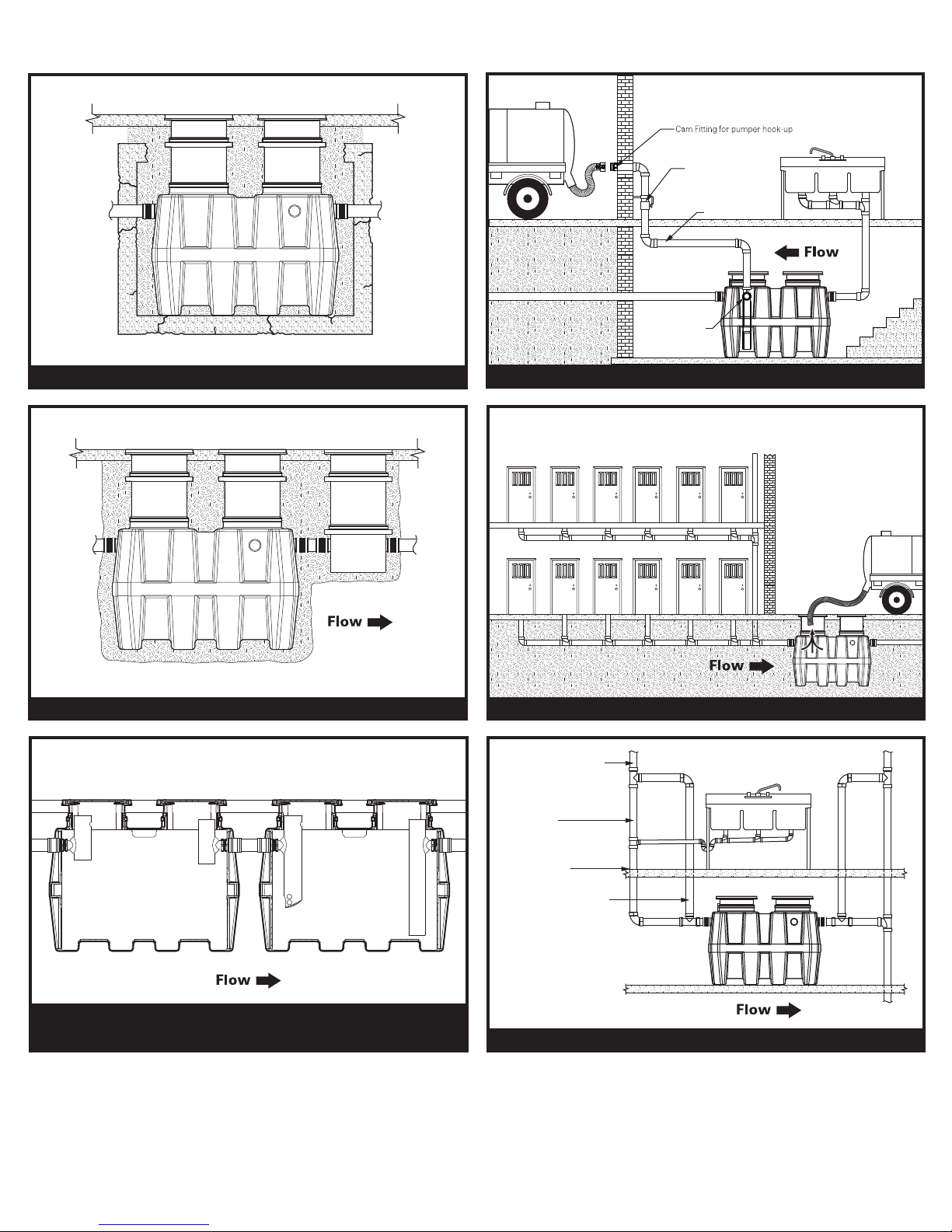

Field Cut Riser

Components

057-0780-05

INSTALLATION (2 of 3)