automatic cable rewinder FT 038 e-mobility with integrated charging electronic

installation and operating instruction

installation and operation instruction FT 038 e-mobility miL - A4 - version B Seite 9 11.03.2021

Schill GmbH & Co. KG; Bruckstraße 44; 70734 Fellbach www.schill.de

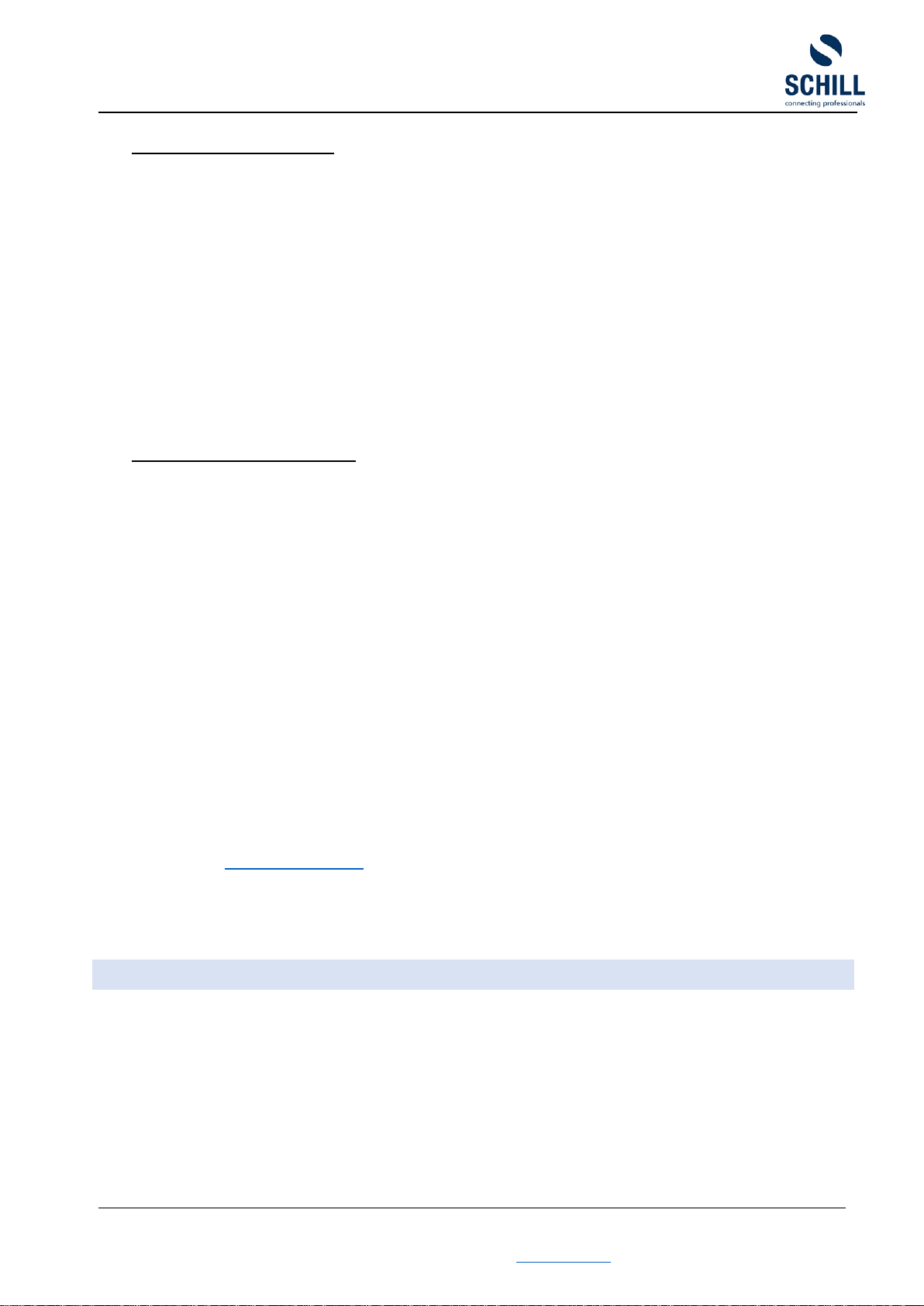

•Input / power connection

➢Connecting cable (standard 2m / optional >2m)

▪H07RN-F 3G2,5 (3,7kW) / H07RN-F 3G6 (7,4kW)

▪H07RN-F 5G2,5 (11kW) / H07RN-F 5G6 (22kW)

➢Nominal Voltage 230V / 400V AC

➢Rated Current: 16A / 32A

➢Nominal frequency: 50Hz

➢16A / 32A back-up fuse (optional or required by customer) recommended C-

characteristic

➢RCCB type A, 30mA (optional or required on site)

➢DC residual current detection electronic, IΔn DC ≥ 6mA (optional or required on

site)

➢as an alternative to DC residual current detection and RCCB type A. RCCB RCCB,

type B (optional or required on site)

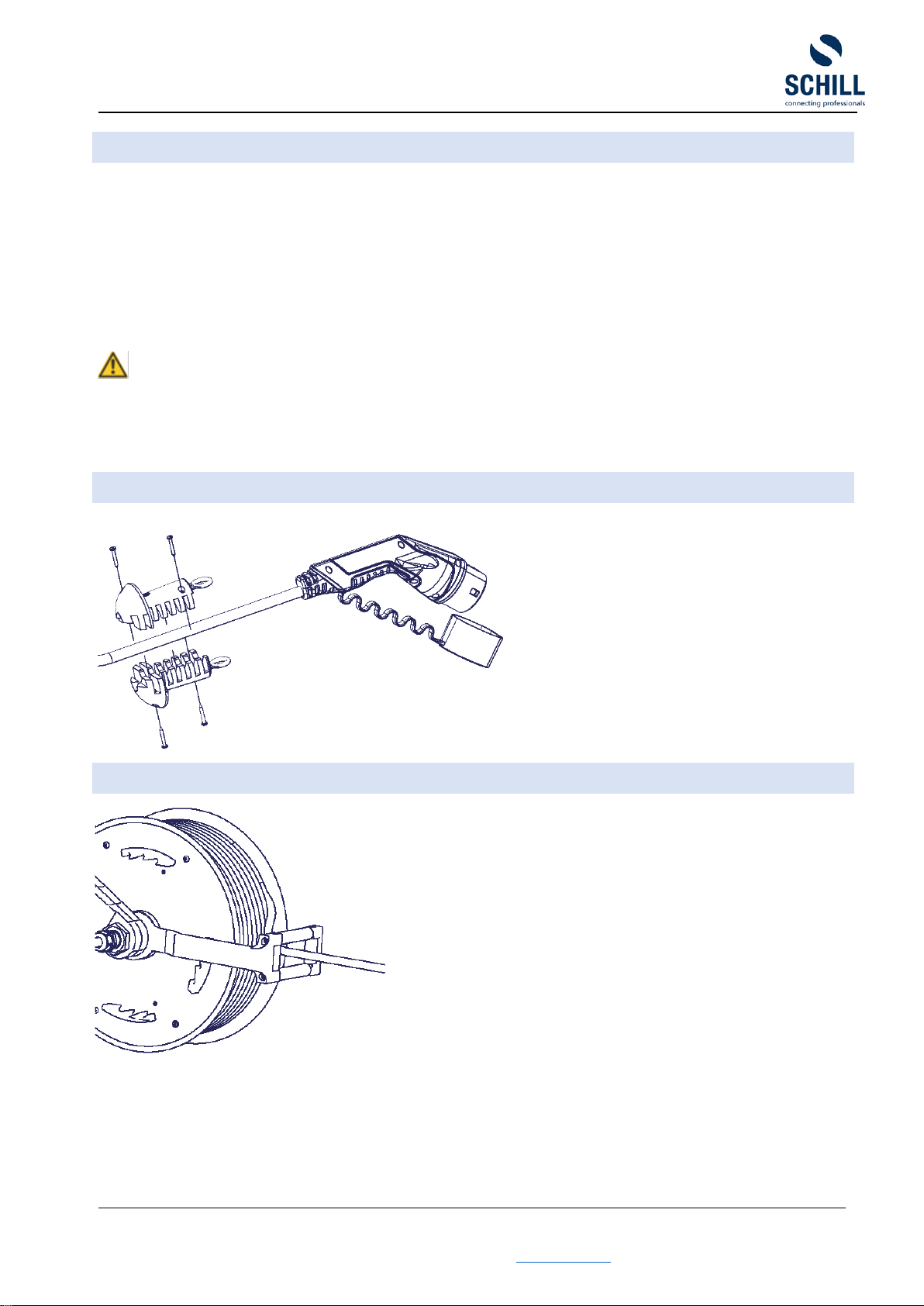

•Output / vehicle connection

➢Max. 10m extension cable with connector Typ 2 (optional Typ 1)

▪5G2,5 + 1x0,5 (11kW) 3G2,5 + 1x0,5 (3,6kW)

▪5G6 + 1x0,5 (22kW) 3G6 + 1x0,5 (7,2kW)

Standards for the charging cable: IEC 60332-1; IEC 60228; DIN EN 50620; DIN

EN 50363-10-2; DIN EN 50267-2-1; DIN EN 50363-10-2; ISO 4982-2

➢Cable stopper with segmented gentle clamp 6 –16 mm

➢Output Voltage: 230V / 400V AC

➢Maximum charging current [A]: 16 / 32

➢Maximum charging power [kW]: 3,6 / 7,4 (1ph) - 11 / 22 (3ph)

➢Communication EV according to IEC 61851-1, mode 3

The stated operating temperatures relate only to the standard cable reel as described

above and do not apply to e.g. plug-in device. They are only as an exception part of the

delivery. Specification for plug-in devices can be found within the relevant standard DIN

EN 60309 or respectively DIN VDE 0620. For other operating temperatures please

contact us.

Additional information with respect to cable types, spring tensions, power loads and

weights can be found on the product rating plate, in our current product catalogue and also

on our website www.schill.de/en

The dimensions, weights, lengths, coloures and traction are subject to modifications. We

cannot rule out discrepancies and we reserve the right to make technical changes to the

product without giving advance notice.

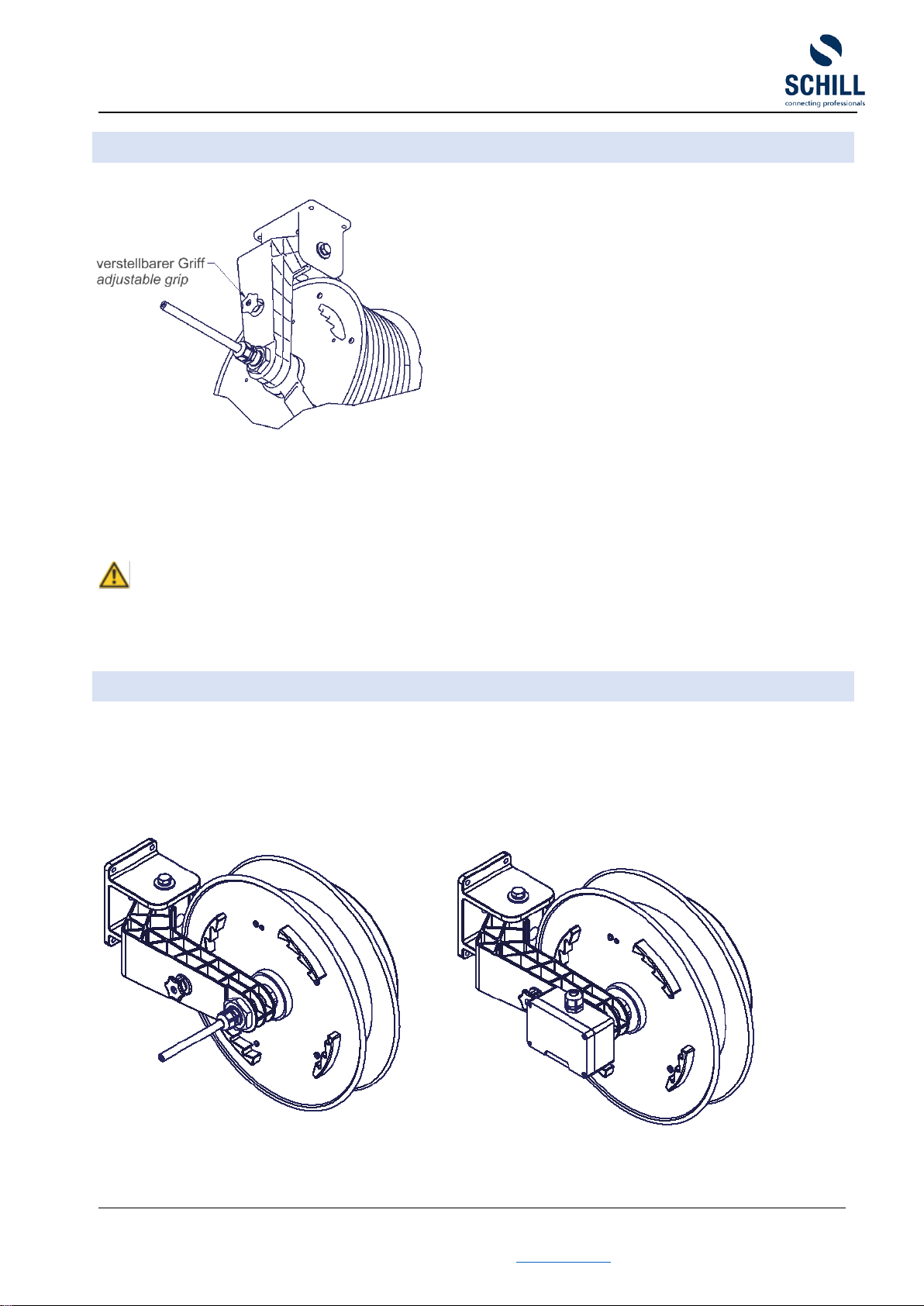

INSTALLATION HEIGHT

The installation height of the cable rewinder is not limited. The maximum extension length

is the specified cable length. The standard cables are designed to withstand the weight of

the extended cable included cable stopper. Additional tensile forces (cause by additional

weights for example) are not permitted.

When the cable is pull-out horizontally due to the weight of cable a slack occurs. This is

about 10% of the cable pull-out length.