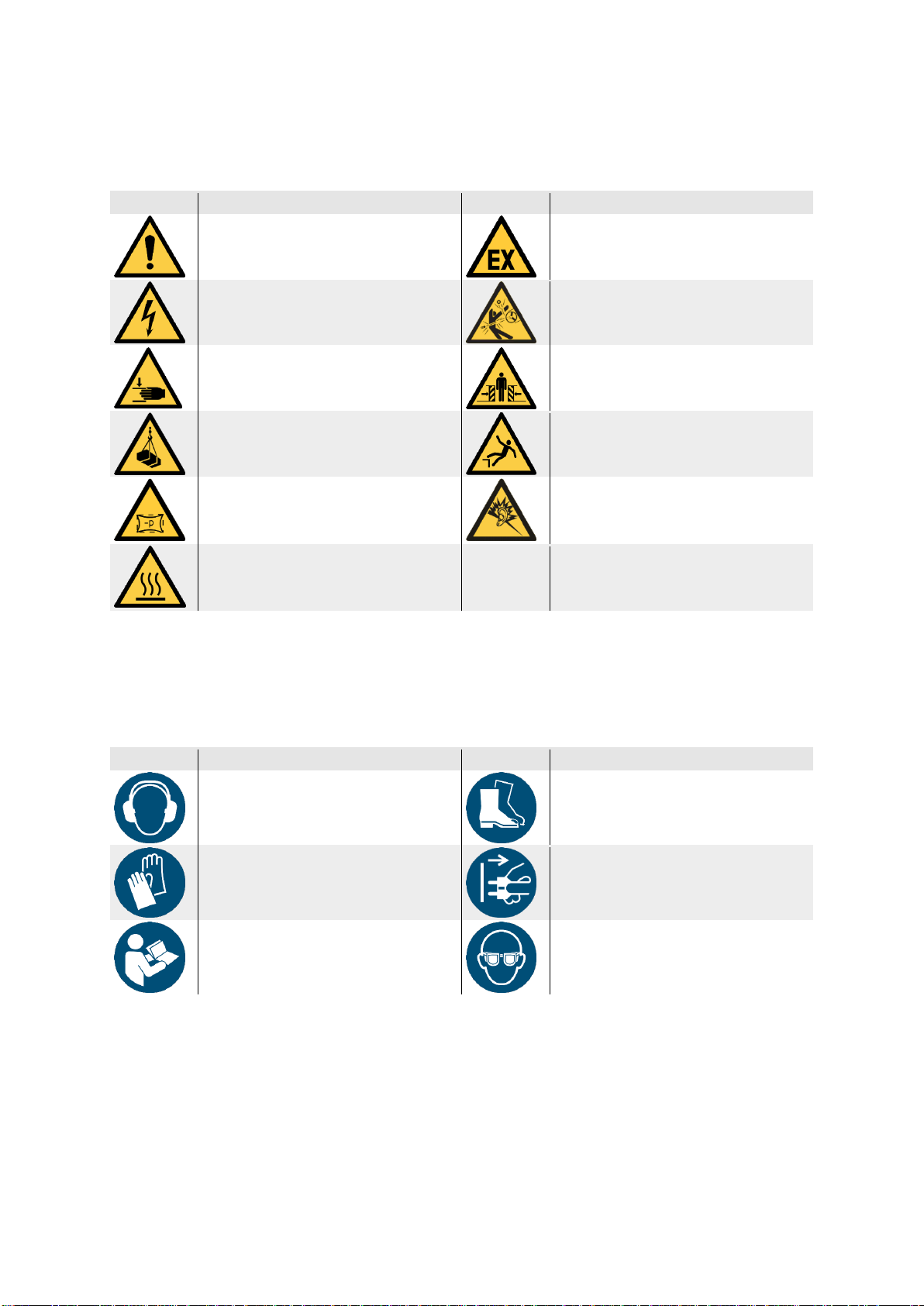

SAFETY INSTRUCTIONS

4 | EN www.schmalz.com 30.30.01.00226/03

4.1 Delivery............................................................................................................................28

Items included in delivery................................................................................................284.1.1 Check for completeness..................................................................................................284.1.2 Report damage................................................................................................................284.1.3

4.2 Packaging........................................................................................................................28

4.3 Transport.........................................................................................................................28

4.4 Removal of crane components........................................................................................29

5Installation.........................................................................................................30

5.1 Preparation of parts.........................................................................................................31

5.2 Tool list............................................................................................................................31

5.3 Electrical installation........................................................................................................32

Installation of electrical supply lines................................................................................325.3.1

5.4 Mechanical installation ....................................................................................................33

Positioning the crane column..........................................................................................335.4.1 Erecting the crane column with mobile base plate..........................................................365.4.2 Mounting the wall bracket................................................................................................365.4.3

5.5 Mounting the flat jib .........................................................................................................39

5.6 Pre-assembly of articulated-arm jib.................................................................................40

5.7 Pre-assembly of flat jib....................................................................................................40

5.8 Mounting the crane jib on the crane column or wall bracket...........................................41

Tool list............................................................................................................................415.8.1 Lower bearing mounting..................................................................................................41

5.8.2 Upper bearing mounting..................................................................................................455.8.3

5.9 Aligning the steel crane jib for column-mounted or wall-mounted jib crane....................46

5.10 Mounting the slewing angle limiter..................................................................................47

5.11 Mounting the crane buffer for crane rails ........................................................................48

5.12 Mounting the hoist...........................................................................................................48

5.13 Mounting the energy supply............................................................................................48

Vacuum power supply.....................................................................................................485.13.1

5.14 Establishing equipotential bonding..................................................................................49

Grounding points for vacuum tube lifter Jumbo Sprint EX blower ..................................505.14.1 Grounding points for vacuum tube lifter Jumbo Sprint EX ejector ..................................515.14.2 Connecting grounding wires............................................................................................525.14.3 Resistance measurement................................................................................................525.14.4

5.15 Preparing for operation....................................................................................................53

Other energy supply........................................................................................................535.15.1 Attaching the type plate...................................................................................................535.15.2

6Operation ..........................................................................................................54

6.1 General safety instructions regarding operation .............................................................54

6.2 Operation.........................................................................................................................55

6.3 Checks before starting work............................................................................................56

6.4 Erecting the crane column on a mobile base plate in another location...........................56

6.5 What to do in an emergency ...........................................................................................57

Production of an ignition source in a potentially explosive atmosphere..........................576.5.1 Falling load......................................................................................................................576.5.2

7Troubleshooting ................................................................................................58