Contents

2 / 10 EN-US · 30.30.01.02781 · 00 · 06/21

Contents

1 Important Information ...................................................................................................................................3

1.1 Note on Using this Document ............................................................................................................ 3

1.2 The technical documentation is part of the product ........................................................................ 3

1.3 Type Plate ............................................................................................................................................ 3

1.4 Warnings in This Document................................................................................................................ 3

1.5 Symbol.................................................................................................................................................. 4

2 Fundamental Safety Instructions...................................................................................................................4

2.1 Intended Use........................................................................................................................................ 4

2.2 Non-Intended Use ............................................................................................................................... 4

2.3 Personnel Qualifications ..................................................................................................................... 4

2.4 Modifications to the Product.............................................................................................................. 4

3 Product description.........................................................................................................................................5

3.1 Product Design .................................................................................................................................... 5

3.2 Description of Functions ..................................................................................................................... 5

3.2.1 Function of the Sensors............................................................................................................... 5

3.2.2 Circuit Diagram for Sensor System .............................................................................................6

3.2.3 Configuration of “Test Position” Sensor....................................................................................7

3.2.4 Configuration of “Storage Position” Sensor .............................................................................7

3.2.5 Functional Safety ......................................................................................................................... 7

4 Technical Data .................................................................................................................................................7

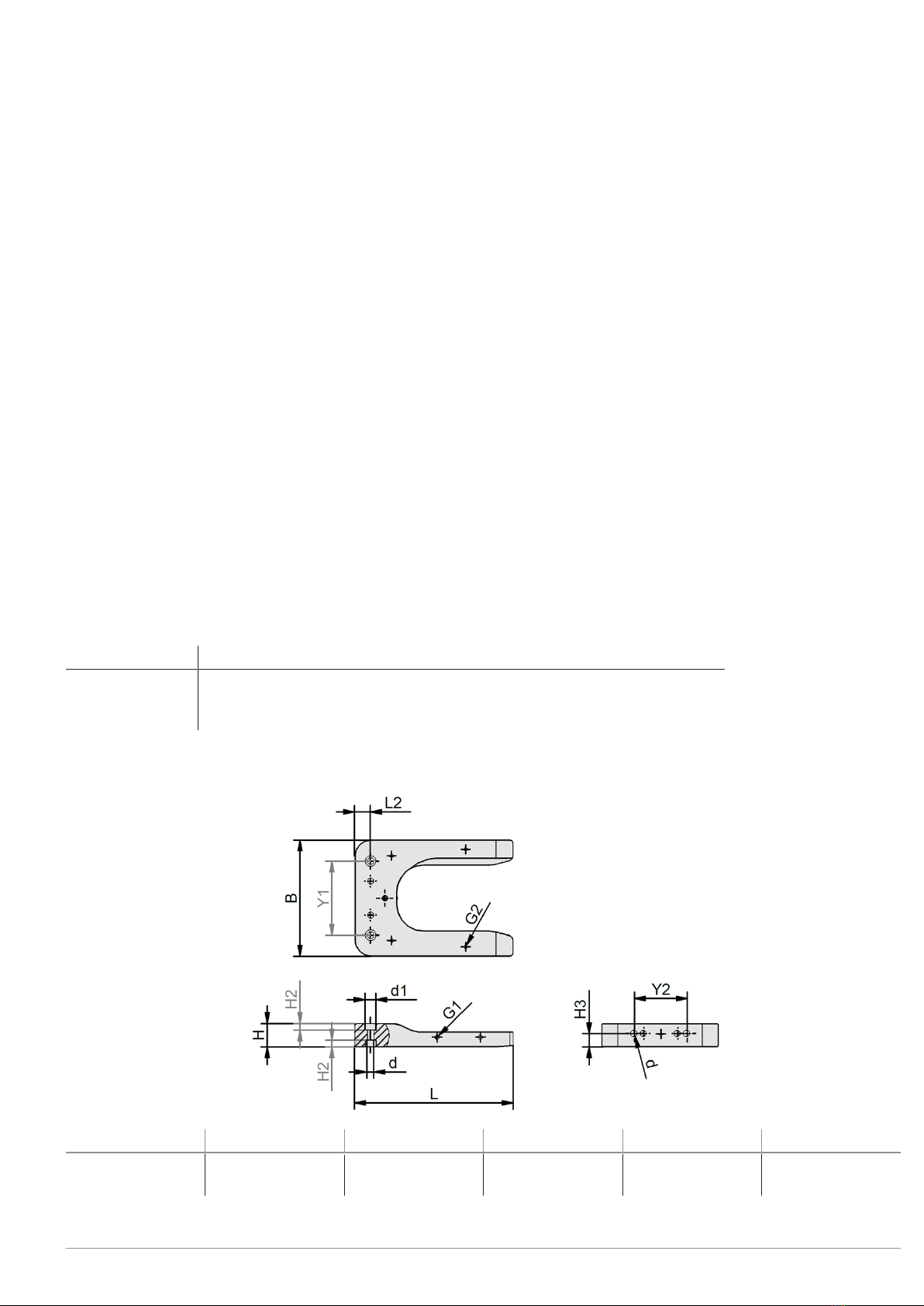

5 Dimensions ......................................................................................................................................................7

6 Checking the Delivery.....................................................................................................................................8

7 Installation.......................................................................................................................................................8

7.1 General Mounting Information.......................................................................................................... 8

7.2 Mounting ............................................................................................................................................. 8

7.3 Initial Setup (Loose Member with Storage Station)........................................................................ 10

8 Maintenance and Cleaning ..........................................................................................................................10

8.1 Maintenance...................................................................................................................................... 10

8.2 Cleaning ............................................................................................................................................. 10

9 Taking the Product Out of Operation and Disposal...................................................................................10

10 Accessories ....................................................................................................................................................10