BATTERIES INSTALLATION

This charter describes the procedure to be followed to install the batteries in the BATTERY BOX.

WARNING: in order to guarantee your safety and your product, please follow the instructions given below very

carefully.

MAKE SURE THAT THE BATTERY BOX IS DISCONNECTED FROM

THE UPS BEFORE PERFORMING THE FOLLOWING SEQUENCE OF

OPERATIONS

The Manufacturer shall not be held responsible for any damage caused by incorrect connections or by operations that are

not described in this manual

The electrical specifications of the BATTERY BOX are shown on the data plate attached to the rear of the apparatus.

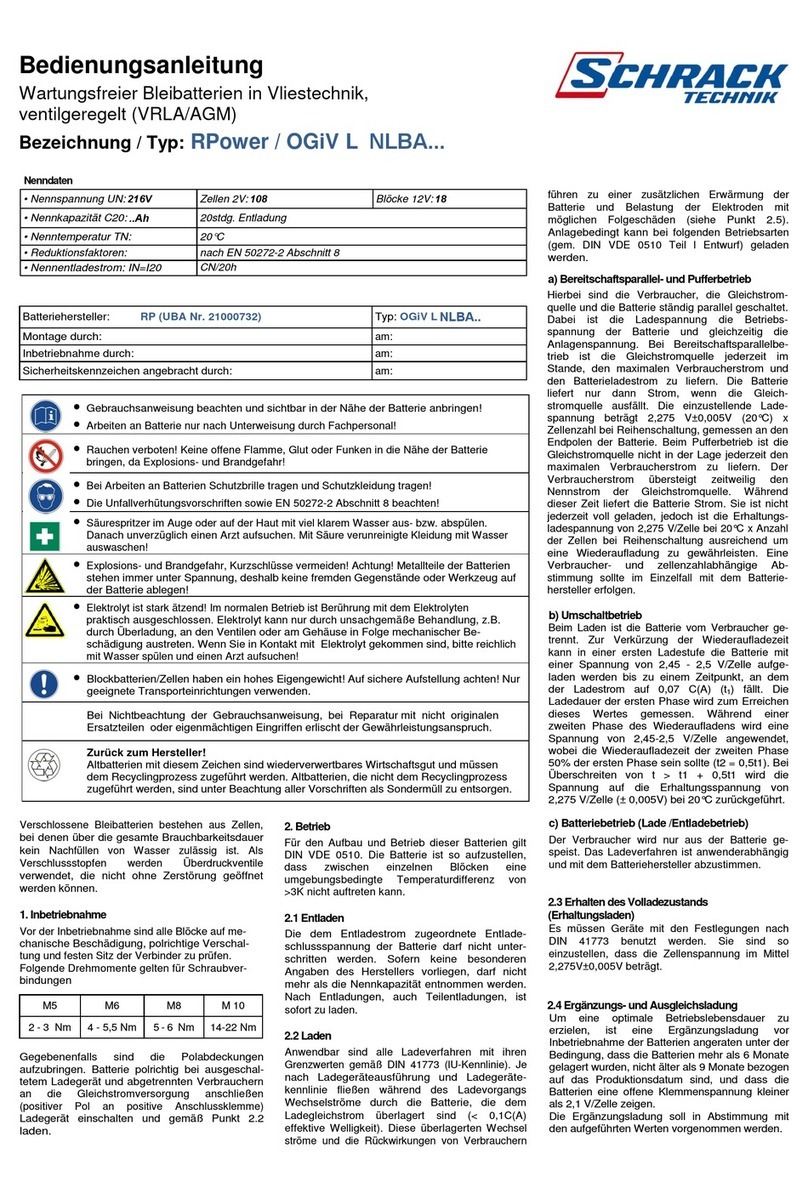

TYPE OF BATTERIES REQUIRED

The BATTERY BOX has been designed to operate with the following types of batteries:

Models USBB96…-

•A5D / 9Ah Version: n° 8 batteries 12Vdc 9Ah

•M1D / 14Ah Version: n° 8+8 batteries 12Vdc 7Ah (connected in parallel)

•M4D / 18Ah Version: n° 8+8 batteries 12Vdc 9Ah (connected in parallel)

Models USBB180…-

•A3D / 7Ah Version: n° 15 batteries 12Vdc 7Ah

Models USBB240…-

•A3D / 7Ah Version: n° 20 batteries 12Vdc 7Ah

•A5H / 9Ah Version: n° 20 batteries 12Vdc 9Ah (only if the Battery Box is coupled with UPS)*

*in this case the UPS and the Battery Box have the same S/N