Scodix Ultra Press Operating manual

i of 22

Scodix Ultra Press Preventive

Maintenance Guide

for Operators

ii of 22

Important Notice

Copyright © 2017.Scodix Ltd. All rights reserved.

All product names are trademarks of Scodix Ltd. Other names are the property of the respective owners. No part of this

publication may be reproduced, transmitted, transcribed, stored in a retrieval system or translated into any language or

computer language, in any form or by any means, electronic, mechanical or otherwise without prior written permission of Scodix

Ltd.

Disclaimer of Warranty

Scodix Ltd. has made every effort to ensure the accuracy and relevancy of the material in this document. It is expected that all

sections of this document will be read thoroughly and that all information and procedures should be fully understood. However,

Scodix Ltd. assumes no responsibility for any errors that may have been included in this document, and reserves the right to

make changes to the document without notice.

Scodix Ltd. makes no warranty of any kind in regard to this document including, but not limited to, the implied warranties of

merchantability and fitness for a particular purpose.

Scodix Ltd. disclaims any responsibility for incidental or consequential damages in connection with the furnishing, performance

or use of this document.

Parts of this document may be based on hardware or software developed by third-party vendors. Scodix Ltd. disclaims any

responsibility for the accuracy of this document with respect to such hardware and software, and assumes no responsibility for

incidental or consequential damages arising due to discrepancies between this document and such hardware or software.

When the system is operated properly, as specified by Scodix in this and other publications, there is no danger to operators or to

equipment. High-voltage power supplies and UV sources are behind protective covers, which should not be removed. Warning

labels are attached to each protective cover.

Environmental Policy

Service personnel are advised that when changing any part of the Scodix Ultra Press, care should

be taken to dispose of those parts in the correct manner and, where applicable, they should be

recycled.

When the lifecycle of parts, such as filters is complete, the product should be disposed of

according to the laws and regulations of the local authority.

For more details about these recommended procedures, refer to your local / regional Scodix

representative.

Scodix is committed to continuously seek and implement the best possible manufacturing

procedures and servicing routines.

Part Number: DBK-0005-02

Edition: July 2017

Revision: 02

Chapter 1 - Overview iii of 22

Contents

Chapter 1 - Overview...............................................................................................................1

Important Safety Information ..................................................................................................................................1

Tools, Jigs, and Accessories ......................................................................................................................................1

Chapter 2 –Summary Time Table ............................................................................................2

Chapter 3 –Operator Maintenance Procedure Details .............................................................4

Checking the Air Pressure Settings...........................................................................................................................4

Before You Begin ...............................................................................................................................................4

Engine Pneumatic Panel ....................................................................................................................................4

Foil System ECU .................................................................................................................................................4

Cleaning the Foil Infeed/Outfeed Conveyor Sensor Reflectors ................................................................................5

Cleaning the Press Print Tables ................................................................................................................................7

Checking the Foil Rewind and Unwind Shaft Tension ..............................................................................................8

General Dusting........................................................................................................................................................9

Cleaning the Print Table Vacuum Holes ...................................................................................................................9

Cleaning the UV LED Bridge....................................................................................................................................10

Cleaning the Suction Cups of the Loader and the Print Head Cleaning Unit ..........................................................11

Cleaning Foil Station Rollers and Heater Cover ......................................................................................................14

Checking the Polymer Expiration Date ...................................................................................................................15

Checking Tracking and Condition of Conveyor Belts ..............................................................................................15

Cleaning the OPA Bridge Encoders and Camera Encoders .....................................................................................16

Cleaning the UV Acrylic Filter .................................................................................................................................18

Cleaning Print Head's Fan Filter..............................................................................................................................18

Replacing Loader Suction Cups...............................................................................................................................20

Appendix A - Service and Support..........................................................................................22

Appendix B - Document History .............................................................................................22

Chapter 1 - Overview 1 of 22

Chapter 1 - Overview

It is important to maintain the Scodix Ultra Press to ensure best performance and print quality. This guide

describes the preventive maintenance procedures for the Scodix Ultra Press.

NOTE:

Only Scodix approved, trained, and qualified personnel should perform procedures on the Press.

Important Safety Information

Notes:

The press requires electrical isolation and lockout during service and maintenance procedures.

Make sure that an isolator box and key are mounted on the wall near the press. This key should be

conveniently positioned for the press operator.

Extreme caution must be exercised when inspecting and handling polymer. Protective goggles and

protective gloves must be worn at all times. You must read Scodix Bulletin 19: Materials Safety,

Handling, and Storage before performing maintenance tasks.

The neutral line of the press is permanently connected to the power supply. It is not turned on or off.

Ensure that no unauthorized person is on or near the machine.

Extreme caution must be exercised when inspecting and handling UV equipment. Protective gloves

must be worn at all times.

Tools, Jigs, and Accessories

TLS-0015-01 Hand grease gun (part of the ULTRA Accessories Kit (KIT-0100-01)

Gloves

Protective goggles

Isopropyl Alcohol (IPA)

Plastic scraper (see page 7)

HGL-0004-01 Clean room wipes

2.5 mm Allen key

Note:

You may need to order PVU-0008-01 (vacuum nipple).

2 of 22 Chapter 2 –Summary Time Table

Chapter 2 –Summary Time Table

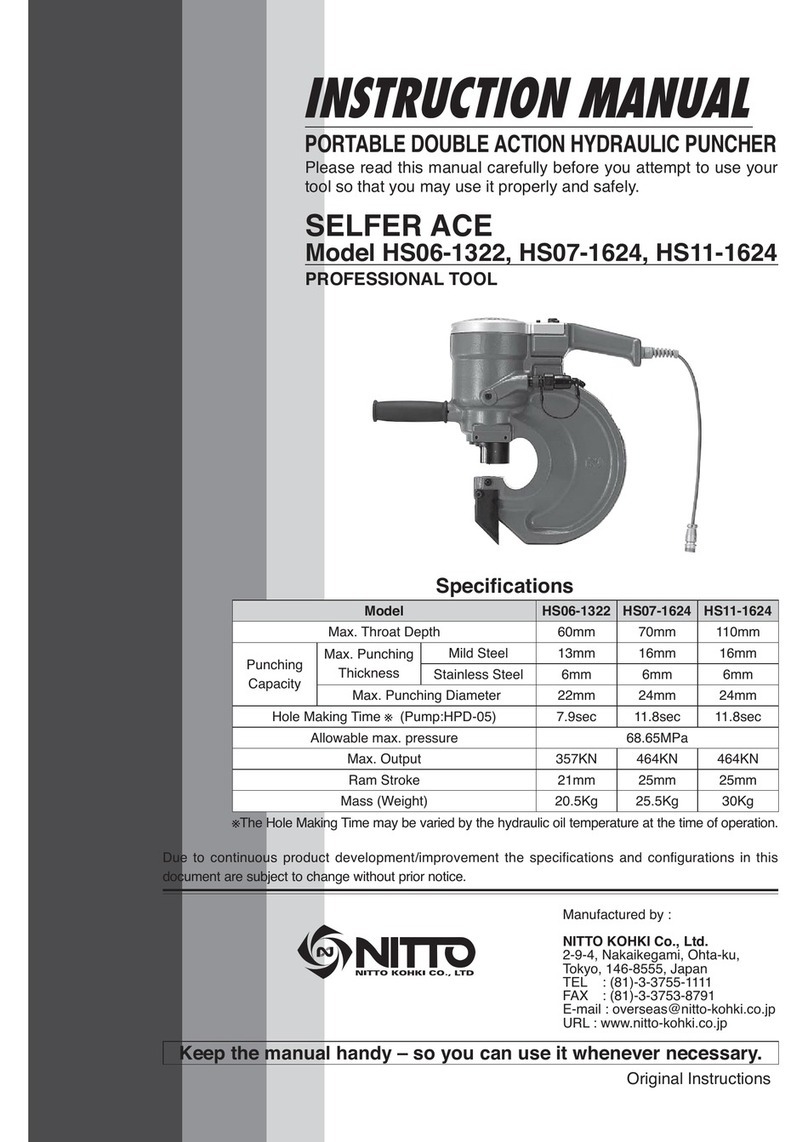

Maintenance Procedures

P/N /

Consumable

Every

Day

Every

Week

Every

Month

Every

3

Months

Usage-

based

Est. Time

1.

Checking air pressure settings

Details on page 4

10 min

2.

Foil: Cleaning infeed/outfeed conveyor

sensor reflectors

Details on page 5

Dry, lint-free

cloth

10 min

3.

Press: Cleaning Press print tables

Details on page 7

IPA

10 min

4.

Foil: Checking rewind and unwind shafts

Check for correct expanding operation

(tension). Details on page 8

10 min

5.

General dusting

Details on page 9

Clean, soft

cloth

10 min

6.

Press: Cleaning Press print table vacuum

holes

Details on page 9

2.5 mm Allen

key, clean

room wipes

5 min

7.

Press: Cleaning UV LED Bridge

Details on page 9

Dry paper

towels, IPA

10 min

8.

Press: Cleaning loader suction cups

Details on page 11

Ethanol or IPA

10 min

9.

Press: Cleaning print head cleaning unit

suction cups

Details on page 11

Ethanol or IPA

10 min

10.

Foil: Cleaning foil rollers and heater covers

Details on page 14

5 min

11.

Polymer: Check the expiration dates of all

polymers

Details on page 15

5 min

12.

Checking tracking and condition of

conveyor belts

Details on page 15

Dried clean-

room wipe

5 min

13.

Press: Cleaning OPA bridge encoders and

camera encoders

Details on page 16

Lint-free cloth

5 min

14.

Press: Cleaning UV acrylic filter

(Use a strong vacuum cleaner to remove the

dirt.) Details on page 18

Vacuum

cleaner

5 min

15.

Press: Cleaning print heads' fan filter

Details on page 18

Air pressure

10 min

Chapter 2 –Summary Time Table 3 of 22

Maintenance Procedures

P/N /

Consumable

Every

Day

Every

Week

Every

Month

Every

3

Months

Usage-

based

Est. Time

16.

Press: Replacing loader suction cups

Details on page 20.

Replace according to the criteria described.

PVU-0008-01

Yearly,

unless

needed

sooner

10 min

4 of 22 Chapter 3 –Operator Maintenance Procedure Details

Chapter 3 –Operator Maintenance Procedure

Details

Checking the Air Pressure Settings

Every day, check the air pressure settings:

Before You Begin

Press the E-stop button.

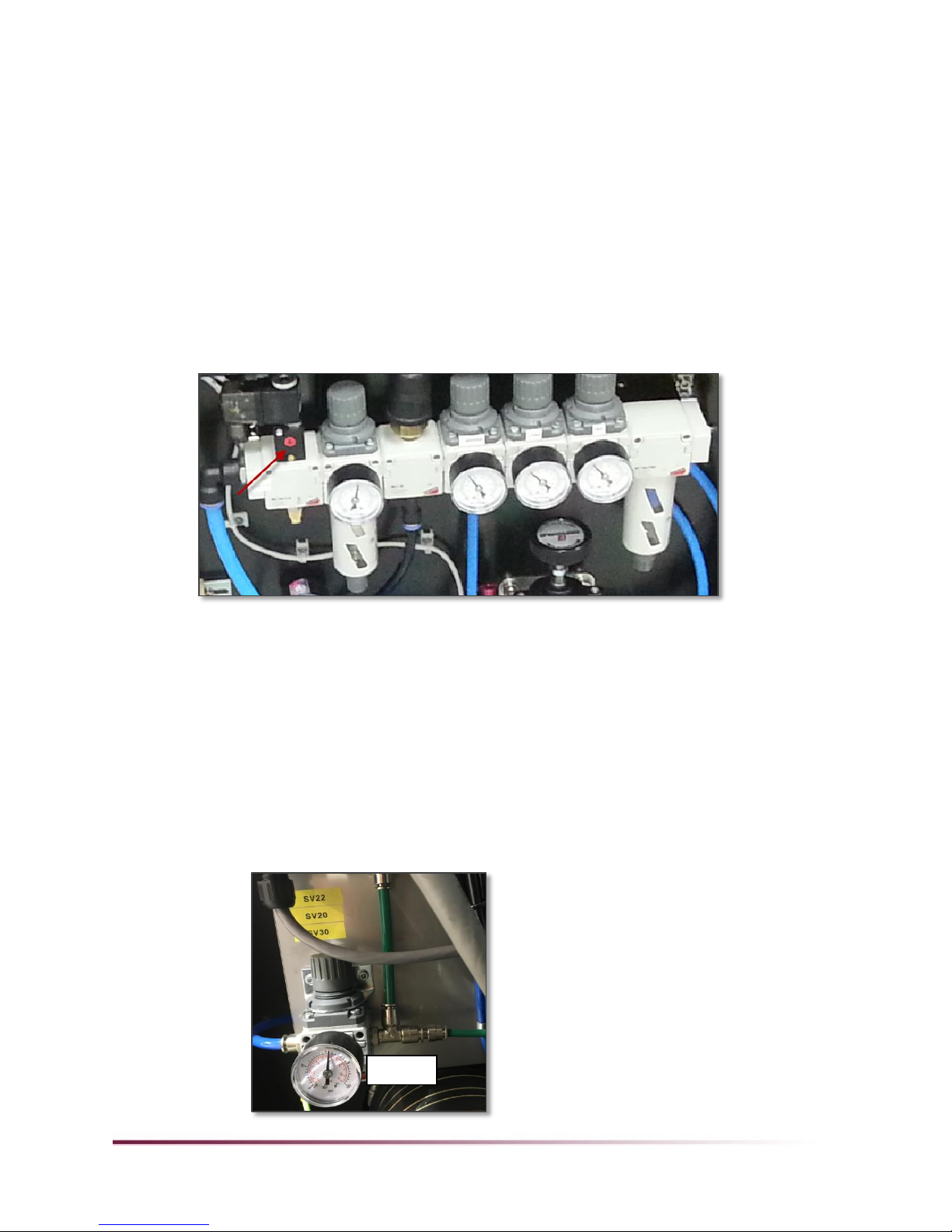

Engine Pneumatic Panel

Verify the following settings:

Main pressure: 6 Bars, ±1

Loader Bridge: 5 Bars

Loader Vacuum Zone: 5 Bars

Loader Tail: 5 Bars

Foil System ECU

1. On the non-operator side of the Foil System on the ECU, using a hex key, open the 4 screws.

2. Verify the following settings:

Main air pressure regulator: 6 bars.

6 bars

Chapter 3 –Operator Maintenance Procedure Details 5 of 22

REG31—Outfeed air jet: 2–4 bars

REG12—Infeed twitch bar (unwind): 1.2–2 bars

REG13—Outfeed twitch bar (rewind): 1.8 bars

Cleaning the Foil Infeed/Outfeed Conveyor Sensor

Reflectors

Every day, clean the Foil infeed/outfeed conveyor sensor reflectors with a clean, dry cloth, as

described following.

REG31

2–4 bars

REG12

1.2–2 bars

REG13

1.8 bars

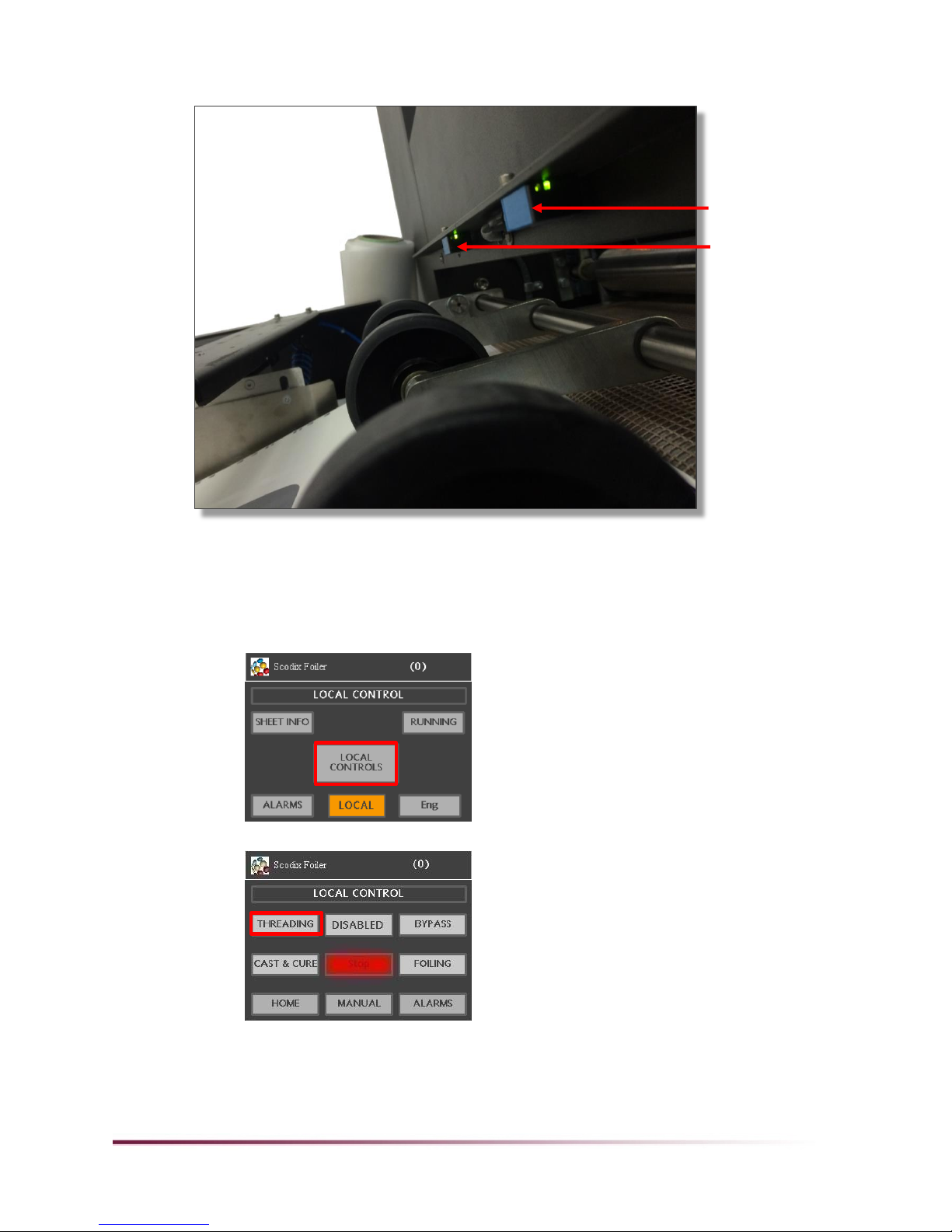

Infeed conveyor

sensor reflectors

Infeed conveyor

sensor reflectors

6 of 22 Chapter 3 –Operator Maintenance Procedure Details

1. Using a dry, lint-free cloth, wipe the infeed/outfeed conveyor sensors in one direction.

2. Using a clean section of the cloth, repeat step 1.

3. To enable access to the infeed reflectors, move the stitch area of the infeed conveyor directly

under the sensors:

a. In the HMI main menu, go to LOCAL > LOCAL CONTROLS.

b. Press THREADING.

Outfeed conveyor

sensor reflectors

Chapter 3 –Operator Maintenance Procedure Details 7 of 22

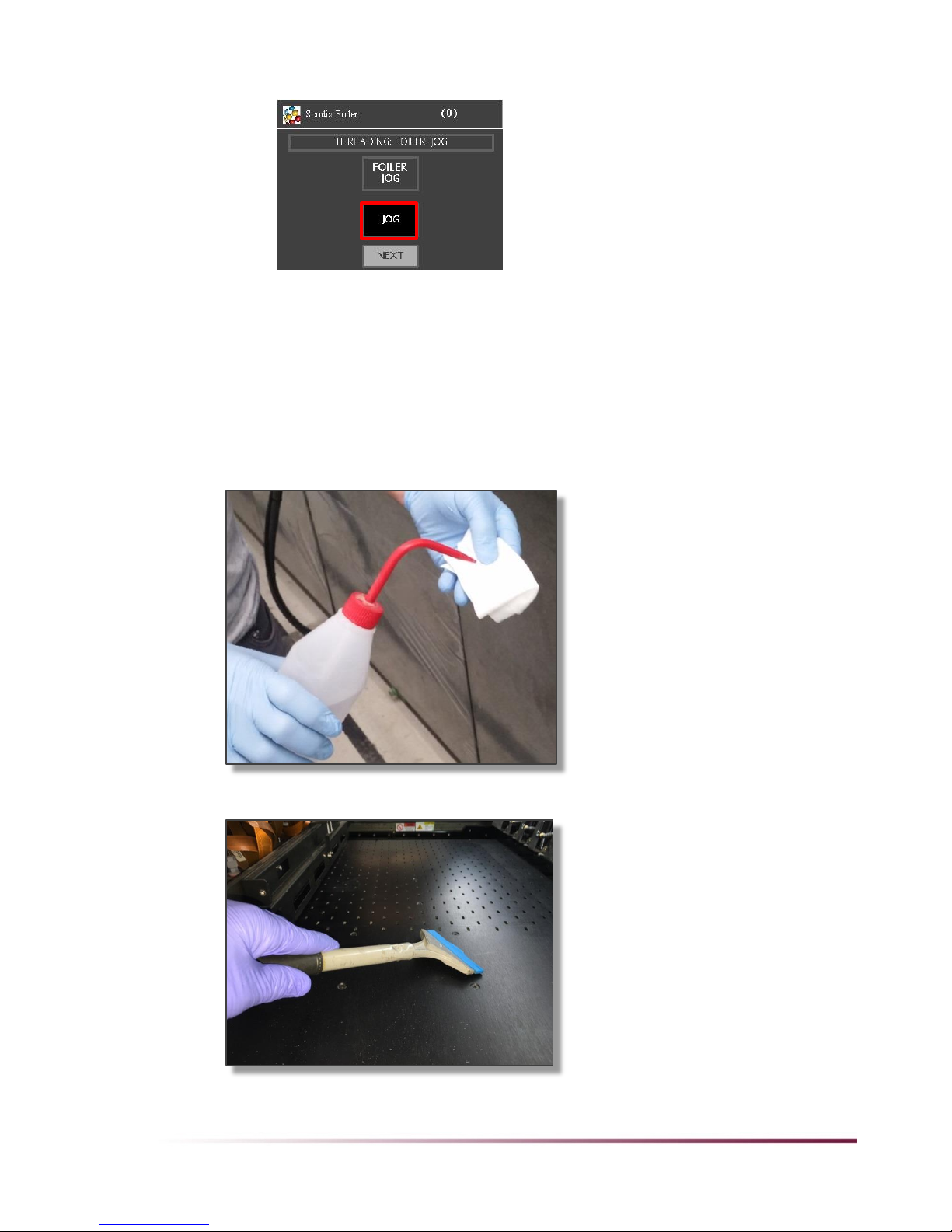

c. Press NEXT twice (or until JOG appears).

d. Press JOG until the stitch is directly under the sensors.

4. Using a dry, lint-free cloth, wipe the infeed reflectors in one direction.

5. Using a clean section of the cloth, repeat step 4.

6. Repeat steps 3–5 for the outfeed reflectors.

Cleaning the Press Print Tables

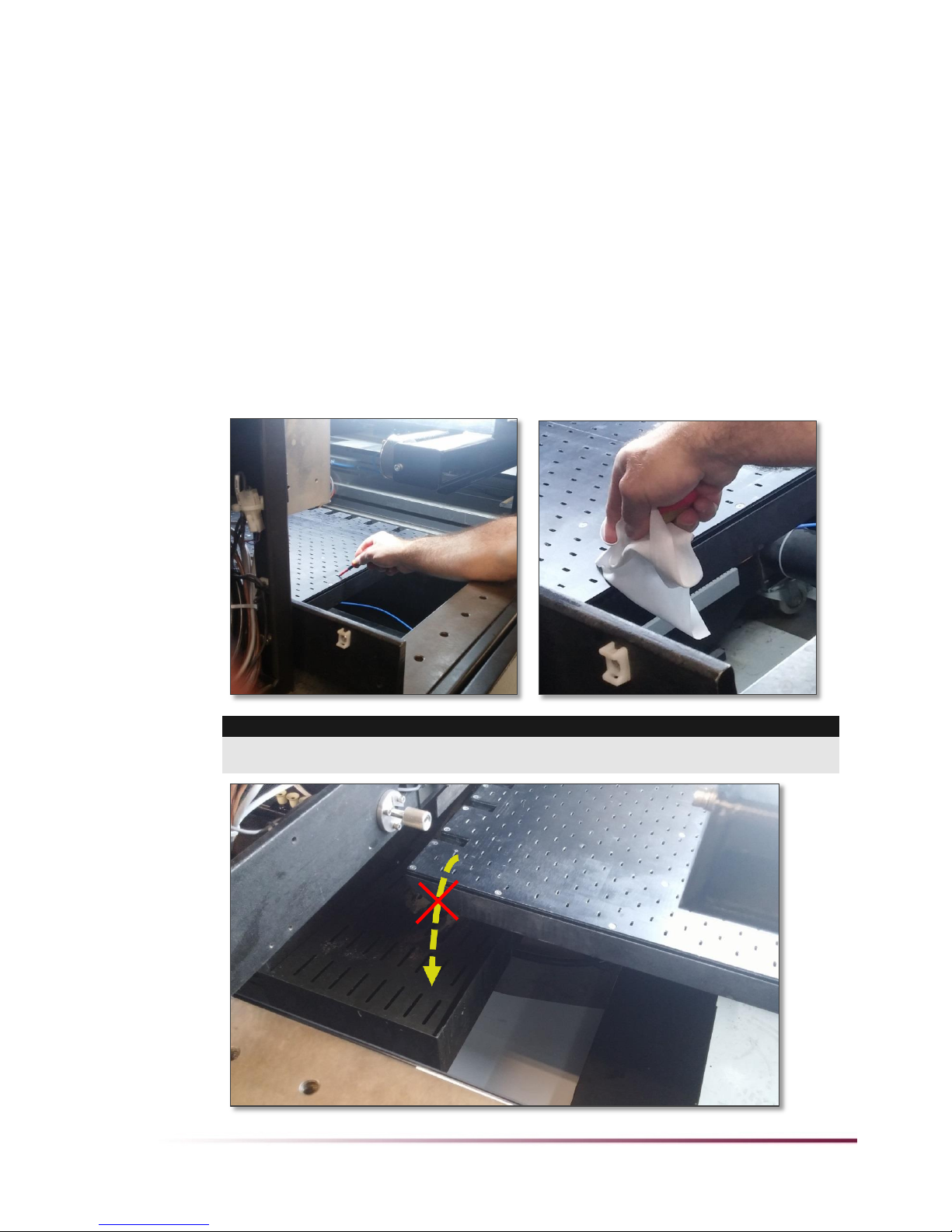

Every day, wearing gloves, fold and wet a lint-free wipe with isopropyl alcohol (IPA) and clean the

polymer from the printing tables.

To remove cured polymer, use a plastic scraper.

8 of 22 Chapter 3 –Operator Maintenance Procedure Details

Checking the Foil Rewind and Unwind Shaft Tension

Once a week, check the Foil rewind and unwind shafts for the correct expanding operation (tension),

as follows:

1. Open the Foil System's cover.

2. On the operator station, in REMOTE CONTROL mode, press TENSION.

3. Record the current tension values to use as a reference. You may need to obtain these values

again after the test.

4. Test the tension:

Set the tension to 0. Verify that you can easily rotate the differential shaft ring.

Set the tension to 100. Verify that you cannot manually rotate the differential shaft ring.

If the differential shaft ring did not react as specified in step 4, call your service representative.

Chapter 3 –Operator Maintenance Procedure Details 9 of 22

General Dusting

Once a week, wipe the dust from the press.

1. Verify that the machine is turned off.

2. Open the covers of each unit - the Feeder, Engine, UV Conveyor, Stacker, and Foil System if

relevant, and remove any dust and dirt from machine surfaces with a clean, lint-free cloth, or with

air pressure.

3. Clean internal paper-path components.

Cleaning the Print Table Vacuum Holes

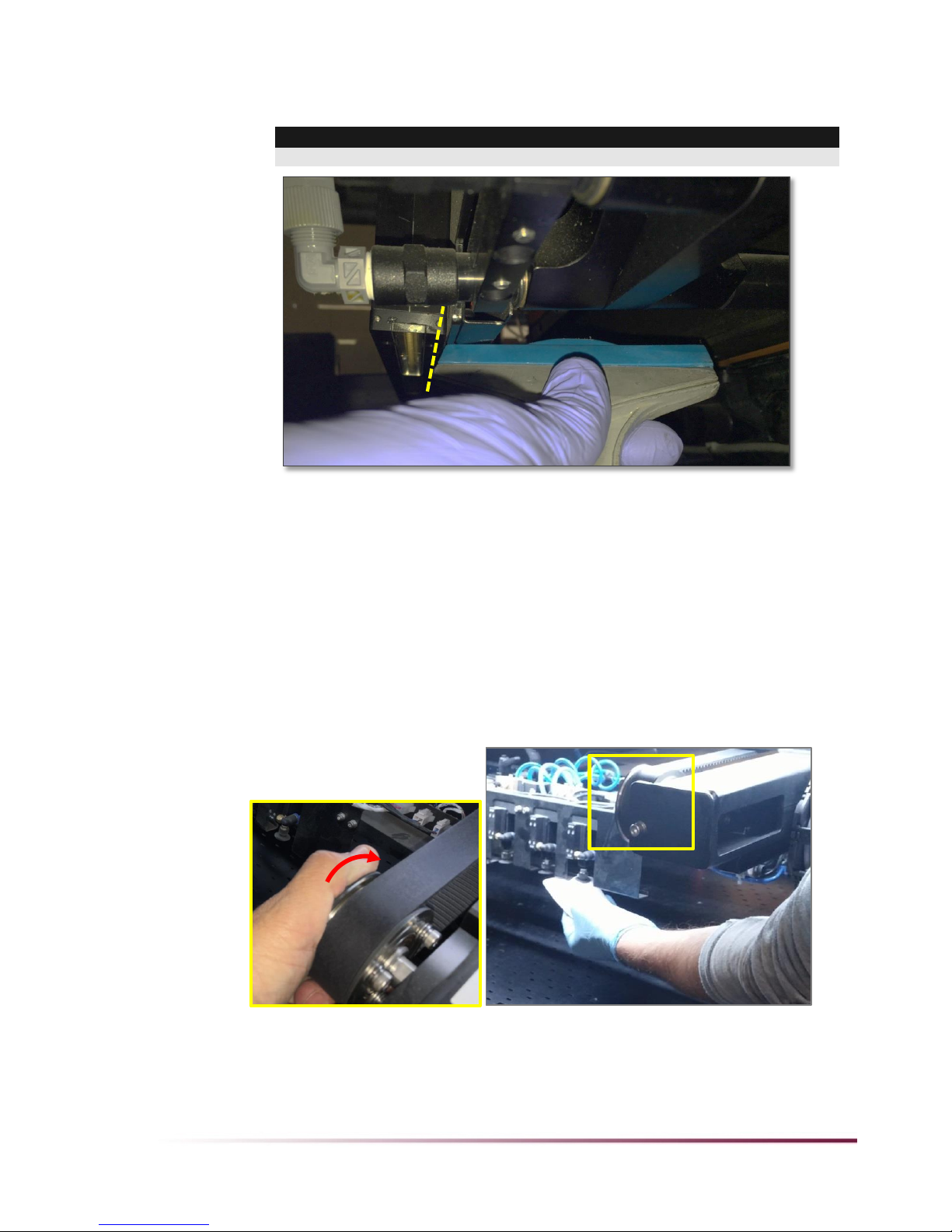

Once a week, clean the print table vacuum holes.

1. Press an emergency button.

2. Move the table towards the feeder side to clear the area under the UV LED module.

3. Clean the print table vacuum holes with a 2.5 mm Allen key and clean room wipes.

CAUTION!

Do not allow dirt particles to fall into the waste bath! Particles in the waste bath can block the polymer

passageways. Wipe dirt away from the waste bath.

10 of 22 Chapter 3 –Operator Maintenance Procedure Details

Cleaning the UV LED Bridge

Once a week, using a lint-free cloth dampened with isopropyl alcohol (IPA), clean the light source

emitting windows of the UV LED.

1. Turn off CB #23 to disconnect DC power from the UV LED.

1. Press an emergency button.

2. Move the table towards the feeder side to clear the area under the UV LED module.

3. Visually inspect the bridge by using a phone to photograph in the position shown following.

Important:

The phone must not touch the LED.

4. If necessary, clean the bridge (make sure to wear gloves) as follows:

Uncured polymer: Wipe the bridge with a lint-free cloth dampened with IPA.

Dirt

Chapter 3 –Operator Maintenance Procedure Details 11 of 22

Cured polymer: If there is cured polymer on the bridge, remove it very carefully using a

plastic scraper.

Important!

Do not scrape the glass! Scrape only on the bridge, as shown.

5. If the glass is also dirty, wipe with a lint-free cloth and IPA.

Cleaning the Suction Cups of the Loader and the Print

Head Cleaning Unit

Once a week, using ethanol or IPA, clean the Suction Cups of the Loader System and the Print Head

Cleaning Unit.

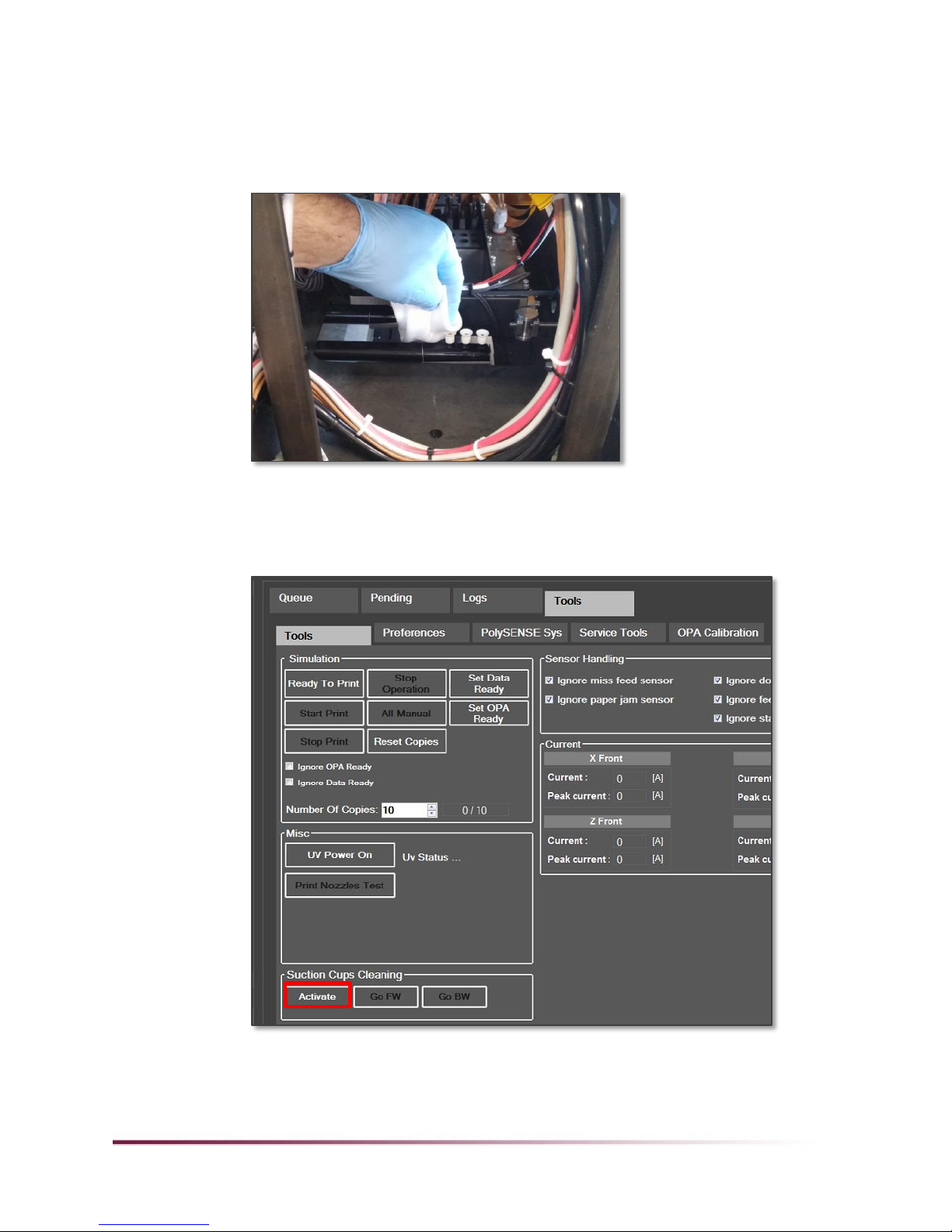

Loader:

1. Open the operator-side door.

2. To access the Suction Cups, rotate the pulley clockwise, as shown.

3. Using ethanol or IPA and lint-free wipes, wipe the entire surface of the Suction Cups.

12 of 22 Chapter 3 –Operator Maintenance Procedure Details

Cleaning Unit:

1. Clean the 3 external Suction Cups:

a. Open the operator-side door.

b. Using ethanol or IPA and lint-free wipes, wipe the entire surface of the 3 Suction Cups that are

closest to you.

c. Close the operator-side door.

2. Clean the 3 internal Suction Cups:

a. Lower the table: In the Scodix software, in Ready mode, go to Tools > Tools > Suction Cups

Cleaning and click Activate.

Chapter 3 –Operator Maintenance Procedure Details 13 of 22

b. With Activate enabled (button changes to Deactivate), press and hold the Go FW button so

that the Suction Cups descend as far as possible, and when they start moving away, release

the button.

c. Open the operator-side door.

d. Using ethanol or IPA and lint-free wipes, wipe the entire surface of the 3 Suction Cups that are

farther from you.

e. Close the operator-side door.

f. Press Deactivate.

14 of 22 Chapter 3 –Operator Maintenance Procedure Details

Cleaning Foil Station Rollers and Heater Cover

Once a month, clean the Foil Station rollers:

1. Remove the foil rolls from the rewind and unwind differential shafts.

2. Using a dried clean-room wipe (or if necessary, using IPA), wipe clean the metal twitch rollers

(1,2), the pull roller (5), the idler roller (3), the rewind and unwind shafts (6, 7) and the heater

cover (4).

1

1

2

4

1

3

1

5

1

6

7

Chapter 3 –Operator Maintenance Procedure Details 15 of 22

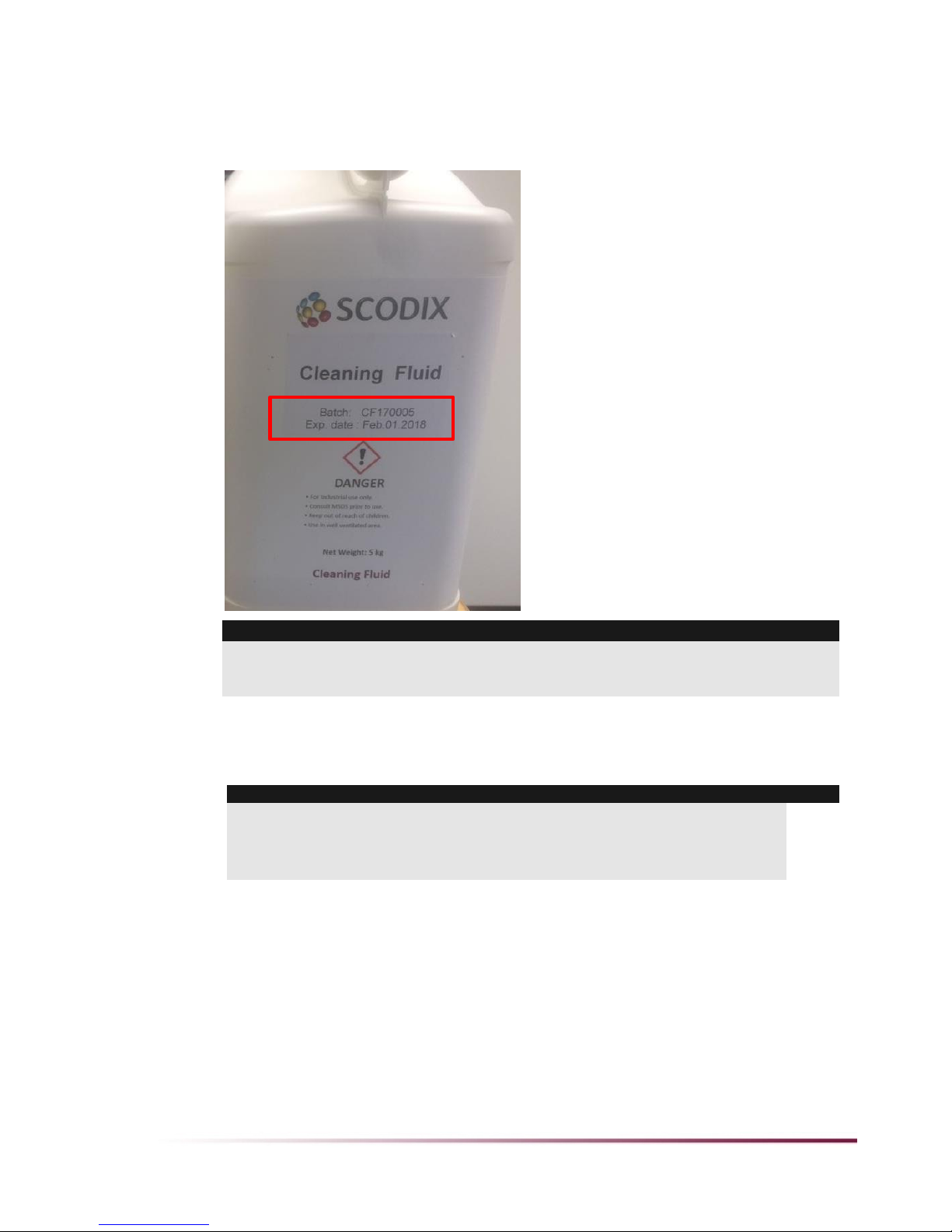

Checking the Polymer Expiration Date

Once a month, check the expiration date on all polymers and cleaning (or flushing) fluids in use and in

stock, and verify that none have expired.

CAUTION:

Do not use expired polymer. Using expired polymers and cleaning (or flushing) fluids can lead to

blocked print heads and material build-up inside the polymer system that standard cleaning and

flushing cannot repair.

Checking Tracking and Condition of Conveyor Belts

Once a month, check the condition of the Engine unit and Foil System UV conveyor belts.

Notes:

In the Foil System, to avoid wasting foil, first remove the roll of foil from the rewind shaft.

Then, using the HMI JOG procedure, move the belt, as described in step 3 on page 6.

In the Engine unit, if the stitch section of the belt is not visible, run print jobs one at a time

until the stitch area is visible.

16 of 22 Chapter 3 –Operator Maintenance Procedure Details

Verify the following:

The belts show no wear and tear.

The belts are centered and stable.

The Engine belt stitch area is smooth.

The Engine belt covers the external line of vacuum holes (see following illustration) on each side.

The Foil Station infeed sensors' red lights are centered in the conveyor belt cut-outs.

If the conveyor belts' condition is not as required, call your service representative.

Cleaning the OPA Bridge Encoders and Camera

Encoders

Once every three months, using a lint-free cloth, clean the OPA bridge encoders, camera encoders, and

camera lenses.

Important:

To prevent damaging the cameras during cleaning, perform this procedure first thing in the morning

after startup, when the cameras' position does not interfere with accessing the center of the machine.

Example of bad

position:

Vacuum holes

are not covered

Table of contents

Popular Power Tools manuals by other brands

Draper

Draper D20 user manual

aquatechnik

aquatechnik BST 32 PLUS Instructions for use

Big Daishowa

Big Daishowa BBT40-AG90-CA4SGM-226 Operation manual

Dynabrade

Dynabrade Dynangle II 14300 Important operating, maintenance and safety instructions

EINHELL

EINHELL TC-JS 18/2700 Li Original operating instructions

Baileigh

Baileigh SS-2822 Operator's manual