Maintenance, Cleaning and Sanitizing Instructions

To ensure your Scotsman ice machine operates effectively, efficiently and in peak

performance, the ice machine requires regular maintenance, cleaning, and sanitizing.

As per Health and Safety requirements in Australia, it is the owner’s responsibility

to ensure the ice machine is installed, maintained, and regularly cleaned as per the

manufacture’s specifications. Ice is classed as a food product so the machine must

be regularly inspected and maintained to ensure the ice is clean, safe, and fit for

human consumption.

Cleaning Schedules

All Scotsman ice machines require a general clean and sanitize procedure every two

weeks to a month (depending on the location of the machine)

All Scotsman ice machines require a major strip down, a deep clean and sanitizing

twice a year by a qualified technician (depending on the location of the machine it

may require more frequent cleaning)

General Weekly or Monthly Clean

Shut down the machine, remove the air filter element and inspect and clean with a

soft bristle brush or wash air filter with warm soapy water and dry, replace the air

filter. Remove all the ice from the storage bin, depress and remove the steel wire clip

and rubber cup from the base of the water trough and clean. (Regularly clean the ice

bin level sensors on the EC–177 models as below)

Clean the inside of the ice bin thoroughly with a cleaner and then rinse off. Sanitize

the ice bin using Moffat ice machine sanitizer and then rinse off with water.

Pour 1 liter of warm water and Moffat ice machine sanitizer down the ice bin drain

to keep drain and drain hoses clean and free of bacteria. (Mixture 10 parts water

and 1 part Moffat ice machine sanitizer) Wipe down and clean the outside of the ice

machine cabinet and clean the ice bin door using disposable sanitizing wipes. Check

the machine has the required 150mm side and 100mm rear clearance for maximum

air ventilation. Check the water filter is not blocked and that the general area around

the machine is clean and tidy. Turn the ice machine back on and discard the first 2 x

batches of ice. Inspect the quality of the ice after two drops.

Six Month Major Strip Down and Deep Clean

A major strip down deep clean should only be performed by a qualified technician.

At the end of the harvest cycle shut down the ice machine. Remove ALL the ice from

the ice storage bin. Remove the air filter element, remove the top panel and the front

panel of the machine. Inspect and clean the air filter element with a soft bristle brush

or wash with warm soapy water and rinse if required and allow to dry. Inspect the

condenser area and clean with a soft brush. Use a soft bristle brush or a vacuum

cleaner with soft brush and gently clean the condenser.

Open the ice bin door, depress, and remove the steel wire clip and rubber cup from

the base of the water trough. Lift up and remove the water curtain finger rod from

the water trough. Lift up and remove the wire ice deflector (or lift and remove the

plastic ice deflector tray) Lift up and remove the water spray bar from the food zone.

Using a bucket mix up a solution of warm water and Moffat nickel safe cleaner, wash

all the components thoroughly and then sanitize. Rinse off all parts with water and

dry.

Reassemble the food zone components, the steel wire clip and rubber cup. Re-fit the

water spray bar, re-fit the wire ice deflector and the water curtain rod and fingers.

Mix 2 liters of water with 200mls of Moffat’s nickel safe ice machine cleaner, remove

the white evaporator plastic cover and slowly pour the cleaning solution over the top

of the evaporator. Using a soft bristle brush, gently clean the evaporator on both

sides (inside and outside) Do NOT use anything abrasive that may damage the nickel

plating.

WARNING

Only use Moffat’s Nickel Safe ice machine cleaner for all Scotsman ice machines.

Using a non-nickel safe cleaner will DAMAGE the nickel-plating on the evaporator.

Restart the ice machine and press the CLEAN button for more than 2 seconds but less

than 5 seconds. The machine will go into the clean mode, let the machine run for 20

minutes to clean the food zone and water system and then shut down the machine.

Depress and remove the steel wire clip and rubber cup from the base of the water

trough. Allow the cleaning solution to drain out the food zone.

Refit the steel wipe clip and plastic cup. Slowly pour 2 to 3 liters of fresh water over

the top of the evaporator and allow to rinse the evaporator into the food zone.

Restart the machine and allow the machine to run for 20 minutes to rinse off the

food zone. Repeat this last rinsing step two times to ensure the machine is clean and

free of the cleaning solution.

Repeat the cleaning process BUT this time use a mixture of warm water and sanitizer.

Press the CLEAN button for more than 2 seconds but less than 5 seconds, the

machine will go into a clean mode. Let the machine to run for 10 minutes to sanitize

the food zone and water system and then shut down the machine. Depress and

remove the steel wire clip and rubber cup from the base of the water trough. Allow

the cleaning solution to drain out the food zone. Rinse off the water through, food

zone and ice storage bin with fresh water and replace the rubber cup and steel wire

clip. Wipe down and clean the ice bin level sensors on the EC–177-207-226 models as

below.

Reassemble the ice machine and double check all parts are re-fitted correctly.

Moffat’s Sanitizer mixture –1 x liter of water to - 100 ml sanitizer ( 10 parts to 1 )

Wipe down the outside off the machine cabinet and storage bin using disposable

cleaning wipes. Pour the reminder of the sanitizer / water mixture down the drain to

keep the drain and drain hose clean and free of bacteria. Allow the machine to make

2 x batches of ice and inspect the ice cubes. Discard the first 2 drops of ice to ensure

the ice is clean and free of any cleaner or sanitizer.

Ice Machine Fault Finding Check List

For ice machine fault finding, first check the 12 Point Checklist in this manual, then

check below points before calling Moffat Service.

Slow production - check water tap is on full, check the water filter strainer is clean on

the inlet valve (remove hose to check) check water filter. Is there any equipment

generating heat next to the machine? (refrigerators, dishwashers, fryers, ovens)

Check there is cool air ventilation around the machine.

Deformed ice cubes –check water spray system is fitted correctly; check spray

nozzles are clean and not blocked. Has the machine had regular cleaning and

sanitizing? when last was the machine striped and cleaned professionally?

Water Leaks –Has the machine been sanitized regularly? A dirty blocked up machine

will cause water leaks, check water filter, water hoses and drain hoses for water

leaks. Check the drain hose is securely located in a vented drain or tundish.

Ice machine error codes are located inside the front door panel.

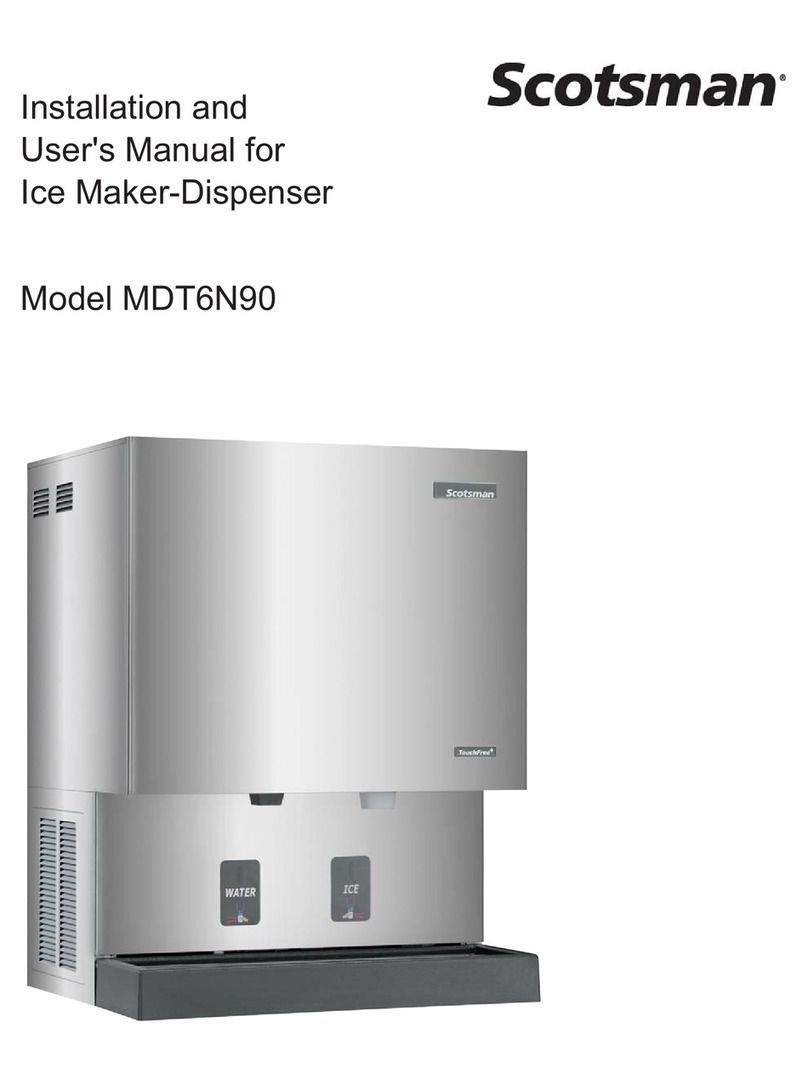

How an Ice Machine Works

An ice machine works by transferring heat from the water inside the ice machine, to

the condenser through the refrigeration system. The condenser fan exhausts this

heat out and away from the ice machine. The transfer of heat is so efficient that it

freezes the water into the evaporator mold making ice cubes.

NOTE: If the airflow is restricted or blocked on either the air inlet or air outlet vents

the heat transfer process will not take place. This means the ice machine will make

little or no ice. It requires good cool airflow through the machine to operate

effectively and efficiently.

Ensure there is NO heat generating equipment next to or close by the ice machine.

The hotter the work area and water temperature is going into the machine, the less

ice the machine will make.

Warranty Details, terms and conditions

Warranty issues are all subject to Moffat Pty Ltd.’s standard terms and

conditions. To view Moffat’s terms and conditions, please visit the Moffat

web site on www.moffat.com.au