MAINTENANCE

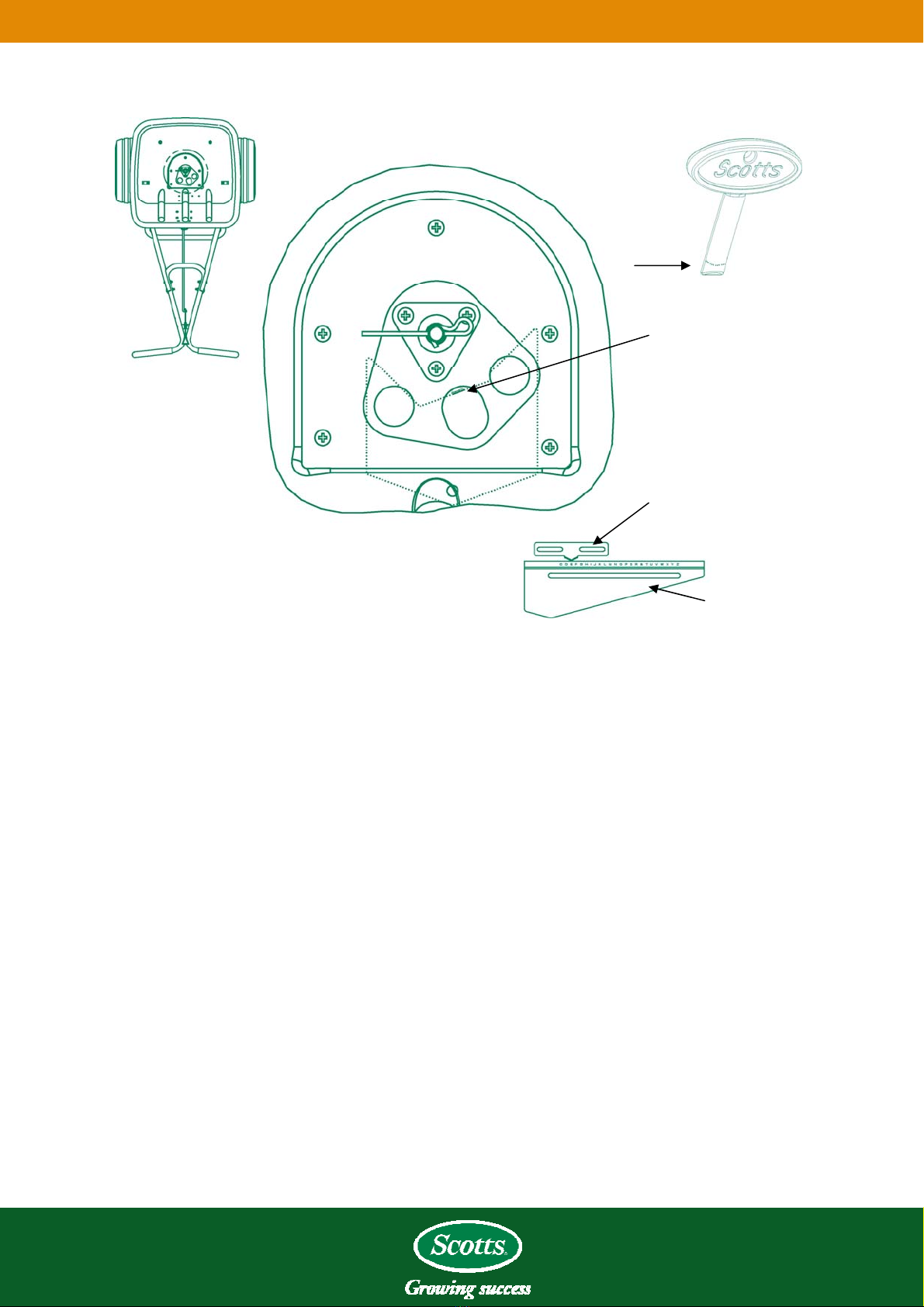

7. Using a grease gun, lubricate the grease fittings on

the axle bearing housings and gear carrier. Apply a

small amount of grease to the gear teeth. Install the two

gearbox cover halves and secure with the three retainer

clips. Insert the screen inside the hopper and secure it

with factory installed clips.

1. Empty the spreader after each use. Return the unused material

to its original container and seal to prevent moisture-caused

clumping.

2. Wash the spreader thoroughly and dry in sunny or heated area.

Wipe or blow off excess water to revent corrosion. Clean all

residue from rotor plate.

Grease Fittings 3. Periodically grease the axle bearing housings as indicated in

assembly step #7.

4. Periodically oil the pivot points on the main shutoff/rate

control linkage, as well as the spring inside the rate control

housing.

5. Periodically clean and inspect the gears by removing the

gearbox cover halves. Apply a small amount of grease to the gear

teeth for lubrication. Apply grease at the gear carrier fittings

indicated in assembly step #7. Be sure to reinstall gearbox cover

halves prior to use.

6. Maintain tire pressure at 20 psi maximum.

7. If the axle requires disassembly, be sure to reassemble it so the

drive wheel attaches on the right side. Incorrect spread patterns

will result if the rotor plate does not rotate in a counter-clockwise

direction.

Grease Fittings

7. A hopper cover is provided with your new spreader. Use it to

protect turf product inside the hopper from light rain or windy

conditions during transportation.

HOW TO USE

1. Check product bag for rate setting (letter), cone setting

(number), and swath width. The rate setting is achieved by

loosening the rate control knob and sliding the rate control plate

to the desired letter. The cone setting is used to control-spread

pattern and is adjusted by rotating the index tab on the orange

helical cone to the desired number.

Rate Control Plate

Helical Cone

2. Pull the main shutoff lever to the closed position before filling

the hopper.

3. Start rolling the spreader forward before opening the ports;

close ports before stopping.

4. Hold handle so that the hopper is level. Tipping the spreader

too far forward or backward will cause uneven spreading.

5. Use the swath width recommended on the bag for your

spreader model and push the spreader at 3 mph (a brisk walking

pace). Apply material only in the forward direction, not while

pulling.

Main Shut Off Lever

6. The settings given on the product label are recommended

starting points. Test rate and pattern on a small area before

treating a large area. Actual application rate can vary

depending on weather, spreader condition, and walking

speed.

Cone Setting

RECOMMENDED WALKING PATTERN

Optimum distribution at half rate

and double pass.