Spreader

information

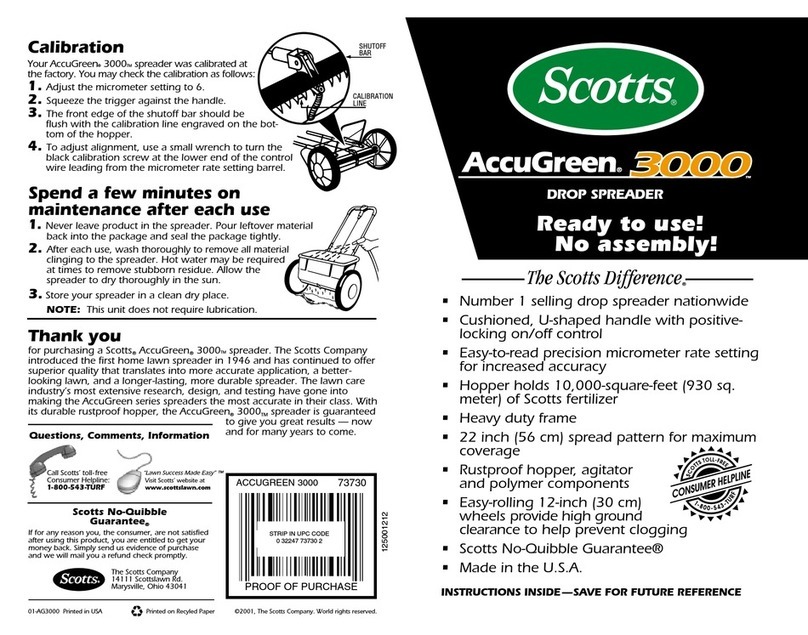

BENEFITS

1. Hopper capacity: 46 litres

2. Spreader width: 91 cm

3. Exact setting of fertilizer application rates

4. Can also be used for grass seed and sand

5. Easy to handle because of large wheels with broad pneumatic tyres

6. Stainless steel frame, hopper and fasteners provide outstanding durability and

corrosion resistance

7. Extended handle with grips for added comfort

8. Lift handles in the front and bank for easier loading and unloading

SS-2

Professional Drop Spreader

SPREADER SETTING GUIDELINES

Settings for SINGLE PASS application at full rate

Spreader setting at full label rates. Amount of product (g/m2) applied after one run:Product Name Effective

width (m) 5 10 15 20 25 30 35 40 45 50 55

Sierraform GT 0,91 3,25 3,75 4,25 4,75 5,25 5,75 6,25 6,50 6,75

Sportsmaster 0,91 3,75 4,25 4,75 5,25 6,00 6,25 6,75 7,00 7,25 7,75

Sportsmaster Organic 0,91 4,00 5,00 6,00 7,00 8,00 9,00 10,00 11,00 12,00

Greenmaster Organic 0,91 4,25 4,75 5,00 5,50 6,00 6,25 6,50 6,75 7,25

Greenmaster Pro-Lite 0,91 3,75 4,00 4,50 5,00 5,25 5,50 6,00 6,25 6,50

H2Pro granules 0,91 2,00 2,75 3,25

STEP 091 3,75 4,25 4,75

Coated products aren’t suitable for drop spreaders.

The spreader settings are guidelines only. The spreader should be calibrated

prior to application to ensure accuracy. The spreader settings are based on a

walking speed of 5 km/hour. Walking faster or slower than 5 km/hour

will alter the spread width and application rate. Exact rates are dependent

upon the spreader itself and the accuracy of the person operating it.

Scotts International B.V.,

Scotts Professional

P.O. Box 40, 4190 CA Geldermalsen,

The Netherlands

Tel.: +31 (0)418 655 700

Fax: +31 (0)418 655 795

E-mail: info@scottsprofessional.com

Internet: www.scottsprofessional.com