SCOV SV800 Series User manual

SV800 Series

Intelligent vector inverter

Users’Manual

Ver:1.0-01

Shenzhen SCOV Electric Technologies Co., Ltd.

SV800/SV800A User Manual Version:V1.0-01

Foreword

Thank you for purchasing and using SCOV SV800 series intelligent vector frequency inverter.

The SV800 series inverter is a kind of high-performance intelligent frequency inverter. We have

made great breakthrough in dynamic response, speed-stabilizing precision, torque precision,

intelligent start-up, weak magnetic control features and so on and made them reach international

top technology level. After combined with the application characteristics of some new industries,

the applicability and the industry design of the products are further strengthened, so it can better

meet the requirements of all kinds of transmission applications.

After careful study, SCOV found that if we want to achieve a breakthrough in the core

algorithm, we must systematically study the solution, especially perform algorithmically

accurate calculations for the nuances of the theoretical model of the motor and the actual motor

parameters, the nonlinear loss of the drive circuit and the loss of the connecting wire.

The practice has proved that the implementation of these methods has achieved a surprising

result and has reached even surpassed the level of international first-class brands on a number of

core indicators, which indicates that the era of truly cost-effective and high-performance

frequency inverter has arrived.

No professional parameter adjustment required, a high-performance drive can be realized only

after self-learning or auto-tuning , so we re-define SV800 series inverter as the intelligent vector

frequency inverter.

Born for intelligence, SCOV will work with you to move forward!

Content

1 Safety information and precautions ...................................................................................1

1.1 Safety precautions...................................................................................................1

1.1.1 Safety precautions before installation ..........................................................1

1.1.2 Safety precautions for transporting and installation.....................................1

1.1.3 Safety precautions for wiring.......................................................................2

1.1.4 Safety precautions for debugging and operation..........................................2

1.1.5 Safety precautions for maintenance and rejection........................................3

1.1.6 Other safety precautions...............................................................................3

2 Product Introduction..........................................................................................................5

2.1 Model and specifications ........................................................................................5

2.1.1 Nameplate explanation.................................................................................5

2.1.2 Designation Rules of SV800/SV800A models.............................................6

2.1.3 Components name of the frequency inverter................................................7

2.1.4 Product models and specifications...............................................................9

2.1.5 Heavy load application and de-rating use of frequency inverter................10

2.2 Description of control performance ......................................................................13

3 Mechanical Installation....................................................................................................19

3.1 Mechanical Installation.........................................................................................19

3.1.1 Installation Environment............................................................................19

3.2 Installation direction and space.............................................................................20

3.2.1 Installation space........................................................................................20

3.2.2 Installation direction ..................................................................................22

3.3 Installation Guidance............................................................................................23

3.3.1 Wall-mounted Installation..........................................................................23

3.4 Disassembly and installation of keyboard.............................................................24

3.4.1 Disassembly of the keyboard .....................................................................24

3.4.2 Installation of the keyboard........................................................................24

3.5 Disassembly and installation of SV800 cover.......................................................25

3.5.1 Disassembly and installation of SV800 cover (plastic housing) ................25

3.5.2 Disassembly and installation of SV800 cover (sheet metal housing).........26

3.6 SV800 appearance and installation dimensions....................................................27

3.7 Keyboard appearance and installation dimensions................................................31

4 Electrical wiring and precautions.....................................................................................33

4.1 Main circuit electrical wiring................................................................................33

4.1.1 Arrangement and definition of main circuit terminals................................33

4.1.2 Main circuit wiring precautions .................................................................36

4.1.3 Installation size and wire selection of power terminals..............................38

4.2 Description of control terminals ...........................................................................40

4.2.1 Function descriptions of the switching terminals connection.....................44

4.2.2 Wiring method of frequency inverter electric control circuit .....................46

4.2.3 Wiring description of control signal terminals...........................................47

4.3 EMC .....................................................................................................................49

4.3.1 Definitions of related terms........................................................................49

4.3.2 Introduction of EMC standards..................................................................50

4.3.4 Installation of EMC input filter on Power supply input .............................50

4.3.5 Installation of AC input reactor on power supply input .............................50

4.3.6 Installation of AC output reactor on frequency inverter output..................50

4.3.7 Installation of external DC reactor.............................................................51

4.3.8 Shielded cable............................................................................................51

5 Introduction of operation and running .............................................................................55

5.1 Confirmation before running ................................................................................55

5.1.1 Wiring check of the frequency inverter......................................................55

5.1.2 The setting and debugging check of the frequency inverter.......................57

5.2 Instructions of the keyboard using........................................................................59

5.2.1 Function and name of each part .................................................................59

5.2.2 Description of LED indicators ...................................................................60

5.2.3 Level structure of the keyboard display functions......................................62

5.2.4 Examples of the keyboard using ................................................................63

5.2.5 Operation of monitoring parameters ..........................................................66

5.2.6 Connection mode of external keyboard......................................................67

5.3 Induction motors parameters self-learning............................................................68

5.3.1 Induction motor parameters self-learning method and procedure..............68

5.3.2 Preparation before induction motor self-learning.......................................72

5.3.3 Instructions of induction motor DC self-learning mode.............................73

5.3.4 Instructions of induction motor Full-mode self-learning............................74

5.3.5 Instructions of the second induction motor self-learning...........................76

5.3.6 Status display and fault description of induction motor self-learning........79

5.4 Inverter model, carrier frequency and control mode settings................................81

5.4.1 The model setting and modification...........................................................81

5.4.2 Carrier frequency setting and modification................................................81

5.4.3 The control mode setting and modification................................................82

5.5 Speed control and regulator parameter debugging................................................82

5.5.1 Speed control indicator description............................................................82

5.5.2 Setting of motor rotation inertia.................................................................83

5.5.3 Speed control proportional coefficient and integral time constant setting..83

5.5.4 The setting of speed observer and torque observer ....................................84

5.6.5 The setting of speed variable structure control parameters ........................85

5.5.6 Switching of speed control proportional coefficient ..................................85

6 Function Parameters List .................................................................................................86

6.1 Reading method of function parameters list..........................................................86

6.1.1 Representation of icons in parameters list..................................................86

6.1.2 Keyboard LED display character and letter correspondence table.............86

6.2 The type of parameters..........................................................................................87

6.2.1 Parameters Type Correspondence Table.....................................................87

6.3 Function Parameters List ......................................................................................89

7 Detailed function description.........................................................................................135

7.1 System parameters A group ................................................................................135

7.1.1 Basic parameter A0 group........................................................................135

7.2 b:Induction motor parameters.............................................................................141

7.2.1 b0: Induction motor basic parameters ......................................................141

7.2.2 b1: The first induction motor parameters group.......................................143

7.2.3 b2:The second induction motor parameters group ...................................146

7.3 d: debugging and controlling parameters............................................................147

7.3.1 d0: speed control debugging parameters..................................................147

7.3.2 d1: Command input selection...................................................................148

7.3.3 d2: Operating module control parameters................................................154

7.3.4 d3:Torque control module parameters......................................................162

7.3.5 d4:V/F control mode parameters..............................................................162

7.4 E: Acc./Dec. curve setting parameters ................................................................165

7.4.1 E0:The upper and low limit speed/ frequency..........................................165

7.4.2 E1:Speed/ frequency instructions.............................................................165

7.4.3 E2: Acc./Dec. time selection ....................................................................165

7.4.4 E3: Jump Speed and UP/DOWN .............................................................168

7.5 F:Application function parameters group ...........................................................173

7.5.1 F0: PID control parameters......................................................................173

7.5.2 F1: Constant pressure water supply .........................................................178

7.5.3 F2:Paper towel equipment parameters .....................................................180

7.5.4 F3:Lift and hoist equipment parameters...................................................180

7.6 H:Terminals function parameters........................................................................181

7.6.1 H0: Multi-function input terminals ..........................................................181

7.6.2 H1: Multi-function output terminals........................................................188

7.6.3 H2: Multi-function Analog input AI.........................................................192

7.6.4 H3: Multi-function analog output AO......................................................194

7.6.5 H4: Multi-function pulse input and output...............................................195

7.7 L:Communication parameters.............................................................................197

7.7.1 L0:Basic communication parameters.......................................................197

7.8 P:Protection parameters ......................................................................................198

7.8.1 P0:Basic protection parameters................................................................198

8 Fault and maintenance...................................................................................................202

8.1 Faults and warning list........................................................................................202

8.2 Faults and solutions ............................................................................................204

8.3 Warning and solutions.........................................................................................213

8.4 Maintenance........................................................................................................216

8.4.1 Daily and periodic inspection...................................................................216

8.4.2 Wearing parts replacement.......................................................................216

8.4.3 Inverter storage ........................................................................................216

Appendix A: Braking........................................................................................................217

A.1 Selection of braking unit and braking resistor....................................................217

A.1.1 Selection of braking resistor resistance...................................................217

A.1.3 Wiring of braking unit and braking resistor.............................................218

Appendix B: Communication...........................................................................................220

B.1 Modbus communication.....................................................................................220

B.1.1 Support protocol......................................................................................220

B.1.2 Interface mode.........................................................................................220

B.1.3 Format of protocol...................................................................................220

B.1.4 Modbus Functions...................................................................................220

B.1.5 Register address of control parameters....................................................224

B.1.6 Examples of Modbus communication .....................................................225

B.1.7 CRC16 function.......................................................................................227

Appendix C: Control Block diagram ................................................................................228

C.1 Control Block diagram.......................................................................................228

Appendix D: A1 application selection and parameter mapping........................................230

D.1 Application of general speed regulation (A1-00 = 1).........................................230

D.2 Application of air supply/exhaust fan (A1-00=2)...............................................232

D.3 Application of constant pressure water supply...................................................234

SV800/SV800A User Manual 1 Safety information and precautions

1

1 Safety information and precautions

1.1 Safety precautions

Users should familiar with the manual and other related technical materials and be sure to

follow the safety precautions required in this chapter when installing, operating, and

maintaining the product. At the same time, you should also know about the mechanical

knowledge, safety information, precautions and so on.

In the manual, safety precautions are classified into <Danger> and <Warning> two categories:

DANGER: Failure to comply with the notice will result in fire, serious injury or even

death.

WARNING: Failure to comply with the notice will result in personal injury or devices and

property damage, even accidents.

Both marks which used in the manual indicate that there is an important content of safety.

Failure to comply with those notices may lead to death, serious injury, damage to the products

and related machines and systems. SCOV will assume no liability or responsibility for any

injury, damage or loss caused by improper operation.

1.1.1 Safety precautions before installation

DANGER

To avoid damage expanding and injury, please don't install the frequency inverter if you find water

seepage, component missing or damaged.

Do not install it if the packing list not conform to the product.

WARNING

Do not touch the components with your hands. Electrostatic may cause damages.

The withstand voltage test has been done before leaving the factory. The users do not need to perform

the test on the inverter again. It may cause damage to the inverter insulation and internal components.

Do not use the product when the rated value in the nameplate is inconsistent with the order

requirements.

1.1.2 Safety precautions for transporting and installation

DANGER

Install the equipment longitudinally on incombustible objects such as metal, and keep it away from

combustible materials. Otherwise it may result in a fire.

Install the equipment in the place that can bear the weight to avoid danger of injury due to falling.

Do not install the equipment in an environment containing explosive gas. It may has danger of

explosion.

1 Safety information and precautions SV800/SV800A User Manual

2

WARNING

Lift and handle the inverter gently when carrying, do not hold the front cover with one hand only. It

may hurt your feet or damage the inverter if it falls off.

Prevent conductive objects such as screws and metal shavings from falling into the inverter during

installation. It may cause the inverter to malfunction or be damaged.

Avoid places with harsh environments such as oil mist, dust suspension, vibration, etc. When

installing in a cabinet, please ensure that the ambient temperature in the cabinet is within the allowed

temperature range of the inverter. Otherwise it may cause the inverter to malfunction or be damaged.

1.1.3 Safety precautions for wiring

DANGER

Do not perform wiring work expect for electrical construction professionals. Otherwise it has risk of

electric shock and fire.

Before wiring the inverter terminals, you must cut off all power connected to the inverter. The waiting

time after the power is cut off is not shorter than the time marked on the inverter. Also ensure the DC

voltage between +1 ~- or + 2 ~- is less than 30V. What's more, the inverter must properly regulate

the ground wire. Otherwise it has a danger of electric shock.

Please connect the input power cable and the motor cable correctly. Never connect the input power to

the output terminals (U, V, W) of the inverter. Pay attention to the marks on the terminals and do not

connect the wrong wires. Otherwise it has risk of damage to the inverter.

Never connect the braking resistor directly between the DC bus positive terminal +1 or +2 and the

negative terminal -. Otherwise it has risk of fire and damage to the inverter.

The main circuit terminal wiring screws must be tightened well. For the wire diameter, please refer to

the recommendations in this manual. Otherwise it has risk of fire and damage to the inverter.

It is forbidden to connect AC220V voltage level signals to terminals except for the control terminals

TA, TB, TC and MA, MB, and MG. Otherwise is has risk of damage to the inverter.

WARNING

Ensure that the rated voltage of the inverter is consistent with the voltage of the AC power supply.

Otherwise it may cause damage to the inverter.

The encoder signal line should uses shielded wire, and the single end of the shield layer should

reliably grounded. Otherwise it may cause the inverter to malfunction.

1.1.4 Safety precautions for debugging and operation

DANGER

Ensure the front cover installed well before connect the input power supply. After power-on, do not

open the cover and operate it as there is a high voltage inside. Otherwise it has a danger of electric

shock.

Please ensure the safety and reliability around the motor and mechanical load during motor electric

parameters auto-tuning and the inverter operation. Otherwise it has risk of injury.

Non-professional technicians are prohibited from testing signals during power-on. Otherwise it has

risk of electric shock and damage to the inverter.

Forbidden to repair the motor and mechanical equipment during power-on. Otherwise it has risk of

electric shock and personal injury.

SV800/SV800A User Manual 1 Safety information and precautions

3

WARNING

Do not touch the fan, radiator or braking resistor directly. May cause mechanical injury and burns.

Do not use the input contactor on/off frequently to control the start and stop of the frequency inverter.

May cause damage to the inverter.

Check the allowable operating range of the motor and machine before operating as it is very easy for

the inverter to drive the motor from low speed to high speed. Otherwise it may cause equipment

damage.

1.1.5 Safety precautions for maintenance and rejection

DANGER

Product maintenance, inspection and component replacement must be performed by qualified

professional engineer. Otherwise it has danger of electric shock.

Forbidden to carry out maintenance or repair on the inverter still with power on. Even if the power is

cut off, the capacitor inside the inverter needs a certain discharge time and the waiting time is not

shorter than the time marked on the inverter. Please confirm that the DC voltage between + 1 ~- or + 2

~- is less than 30V. Otherwise it has danger of electric shock.

WARNING

All pluggable devices must be plugged in and removed when the power supply is off. Otherwise it

may cause damage to the inverter.

Do not touch the component body by hand when maintaining, inspecting or replacing parts. Otherwise

it may damage devices by electrostatic.

The inverter must be treated as industrial waste after it is discarded.

1.1.6 Other safety precautions

WARNING

Insulation inspection of motor

When the motor is used for the first time or after being left for a long time and periodically inspected,

the motor insulation inspection should be performed to prevent the inverter from alarming or

damaging due to the insulation failure of the motor winding. The motor wiring must be separated from

the inverter during the insulation check. 500V voltage megohmmeter is recommended and the

insulation resistance of the motor wiring should be larger than 5MΩ.

Low-frequency operation of motor

Non-frequency variable standard motors will have poor cooling effect at low speed and the

temperature of the motor will increase, so please reduce the load torque of the motor at low speed.

Thermal protection of motor

If the rated power of the inverter is greater than the rated power of the motor, please adjust the related

parameters of motor protection in the inverter or install a thermal relay on the front of the motor to

protect it.

Surge protection

This series of inverter is equipped with a surge suppressor inside which has a certain degree of

protection against induced lightning. However, for lightning-prone areas, users need to place an

1 Safety information and precautions SV800/SV800A User Manual

4

WARNING

external surge suppressor in front of the inverter power input.

The using of contactors

If a contactor is installed between the power supply and the inverter input terminal, do not frequently

use the input contactor on/off mode to control the start and stop of the inverter. Charging and

discharging frequently will affect the service life of its internal electrolytic capacitor.

If a contactor is installed between the inverter output and the motor, make sure that the inverter is in

the stop state before the contactor is turned on / off, otherwise the inverter may be damaged.

Output filter

The inverter output is a PWM high-frequency chopping voltage. Adding an output filter, output AC

reactor or a magnetic ring between the inverter and the motor can effectively reduce electromagnetic

noise.

Please do not install capacitors to improve the power factor on the output side of the inverter which

may cause over-current or even damage to the inverter.

Input power supply

This series of inverters are not suitable for exceeding the working voltage range specified in the

manual. If necessary, adjust to the specified voltage range through a step-up or step-down device.

All products of this series inverter support common DC bus input.

De-rating using

In areas with an altitude of more than 1000 meters, the thin air will cause the cooling effect of the

inverter to deteriorate, so it should be de-rated. It is recommended that the rated output current be

reduced by 1% for every 100m increase in altitude.

SV800/SV800A User Manual 2 Production Introduction

5

2 Product Introduction

2.1 Model and specifications

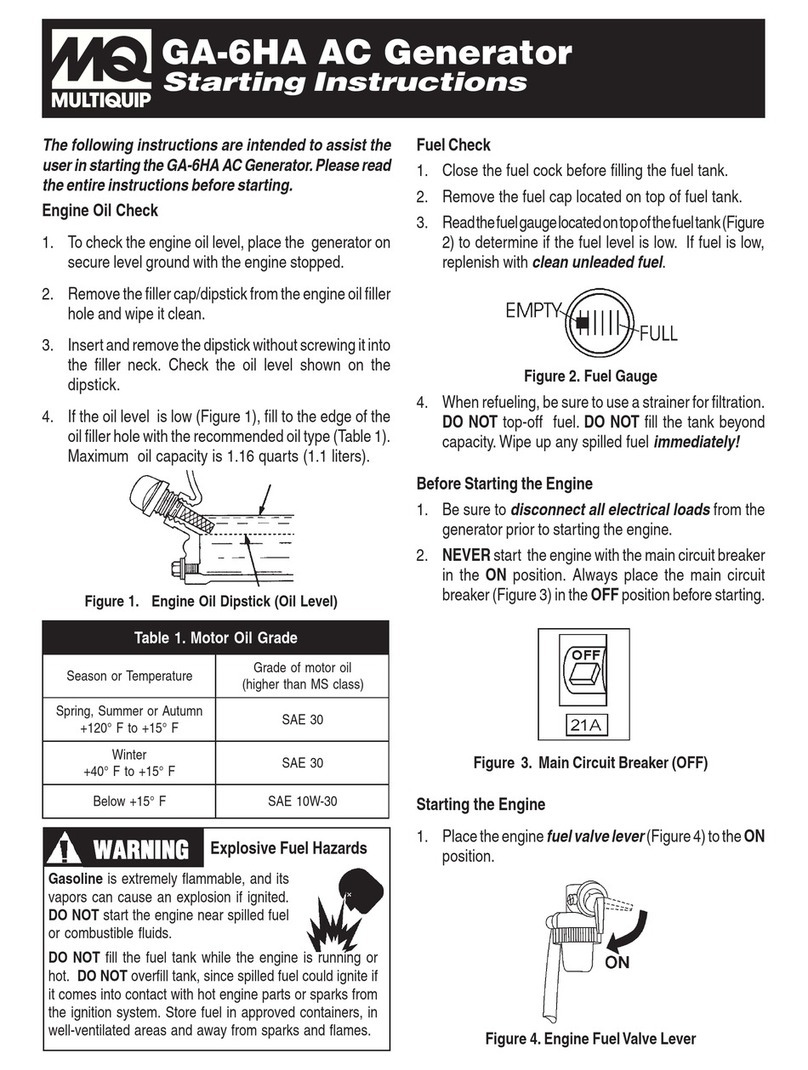

2.1.1 Nameplate explanation

When the products arrive:

Please check the appearance to confirm whether there are any scratches or dirt on the

inverter. Damage caused during product transportation is not covered by our warranty. In case

of damage to the product during transportation, please contact the shipping company

immediately.

Please confirm whether the model of the inverter is consistent with the ordered product.

You can refer to the “MODEL” column on the nameplate which on the side of the inverter

Nameplate:

Fig. 2-1 Nameplate

MODEL :

INPUT :

OUTPUT :

S/N:

Shenzhen SCOV Electric Technologes Co.,Ltd.

SV800-7R54G/114PB

3PH AC 400V 50/60HZ

7.5/11KW 17/24A

SV800 INVERTER

Inverter model

Rated input

Rated output

Serial NO. 802518301021

2 Product Introduction SV800/SV800A User Manual

6

2.1.2 Designation Rules of SV800/SV800A models

Fig. 2-2 Description of the model

SV800/SV800A 7R5 4 G / 11 4 P B

-

Inverter Series

2

4

Code

2R2

4R0

5R5

7R5

11

15

18R5

22

30

37

45

55

2.2KW

4.0KW

5.5KW

7.5KW

11KW

15KW

18.5KW

22KW

30KW

37KW

45KW

55KW

P:Fan or Pump Type

Adapted Motor

Code

G:General Type

B:Built-in Braking Unit

Voltage Grade

AC 230V

3PH AC 480V

5

3PH AC 480V

-S

S:Single phase input

SV800/SV800A User Manual 2 Production Introduction

7

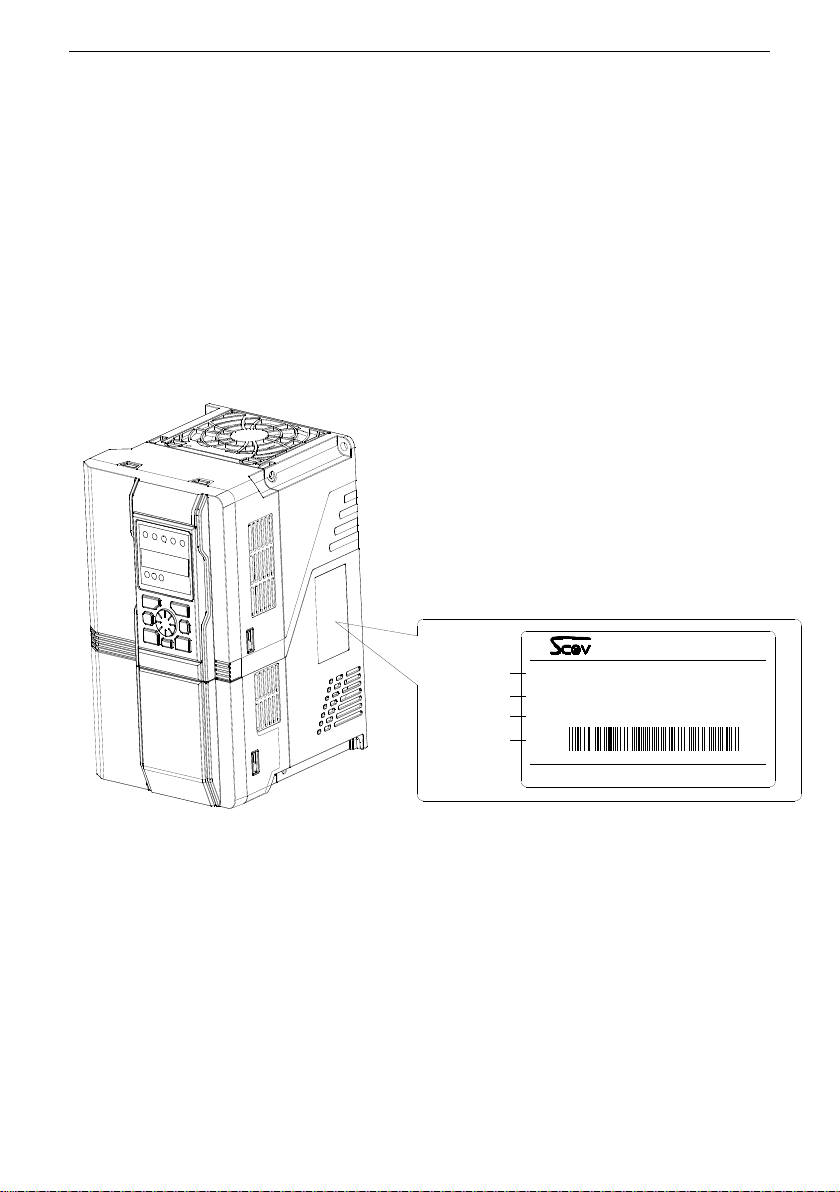

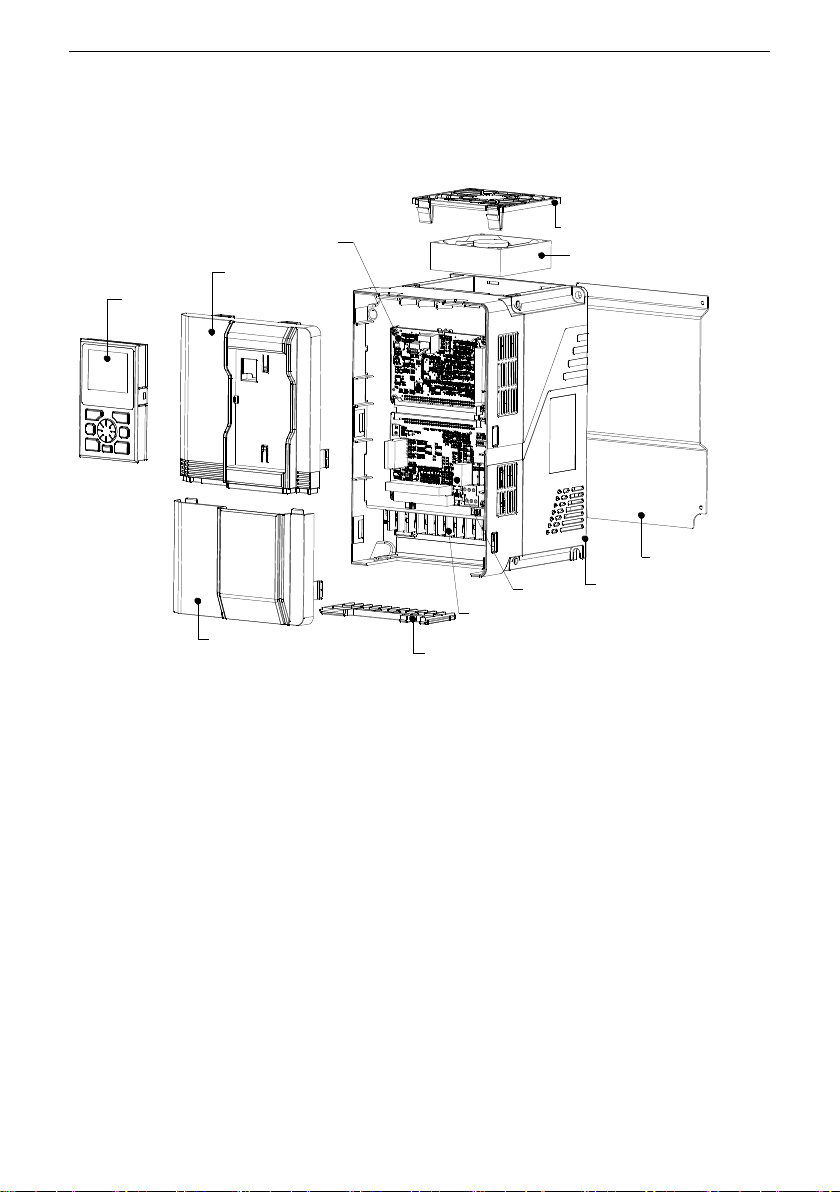

2.1.3 Components name of the frequency inverter

This section describes the components names of the inverter.

Plastic housing model

Fig. 2-3 Components names of the plastic housing model

Keyboard Upper fornt cover

Cabling board

Power terminals

TB BoardCasing

Metal bottom plate

Fan

Main control board Fan cover

Lower front cover

2 Product Introduction SV800/SV800A User Manual

8

Sheet metal housing model

Fig. 2-4 Components names of the sheet metal housing model

Shell

Fan

Fan cover

Lower front cover

Upper front cover

Keyboard

Power terminals

Keyboard

Holder

SV800/SV800A User Manual 2 Production Introduction

9

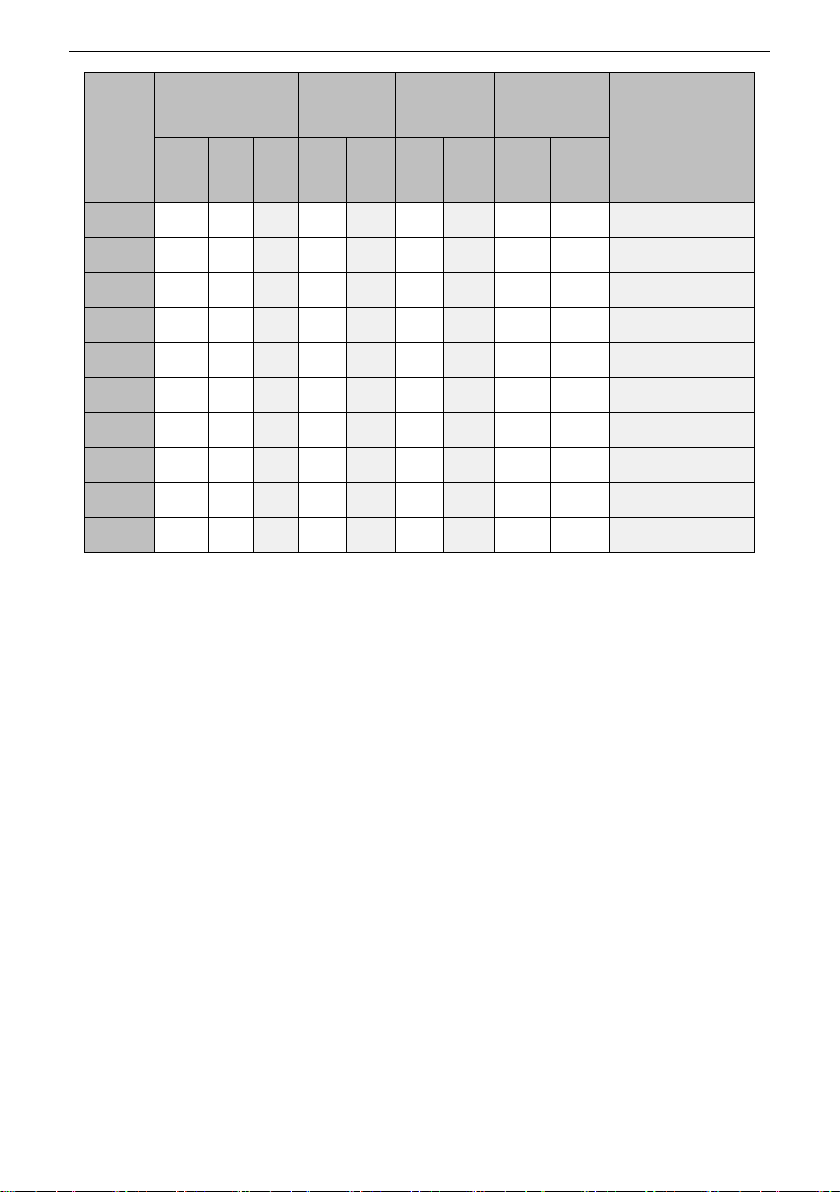

2.1.4 Product models and specifications

The model and specifications of the SV800 series are shown in below Table 2-1. The input

voltage is three-phase three-wire system (400V±15% 50/60Hz±5%), and the output voltage

varies with the input voltage; the output power PNis valid at the rated voltage UN=380V.

Table 2-1 Models and Specifications

Code

Rated load

Heavy load

High heavy

load

Carrier frequency

range

Model name

IN

A

IMax

A

PN

kW

IHd

A

PHd

kW

IHH

A

PHH

kW

Min

kHz

Max

kHz

2R24

5.5

8.3

2.2

4.0

1.5

2.4

0.75

1.0

15.0

SV800-2R24GB

4R04

10

15

4.0

5.5

2.2

4.0

1.5

1.0

15.0

SV800-4R04G/5R54PB

5R54

13

19.5

5.5

10

4.0

5.5

2.2

1.0

15.0

SV800-5R54G/7R54PB

7R54

17

25

7.5

13

5.5

10

4.0

1.0

15.0

SV800-7R54G/114PB

114

24

35

11

17

7.5

13

5.5

1.0

15.0

SV800-114G/154PB

154

32.5

48

15

24

11

17

7.5

1.0

15.0

SV800-154G/18R54PB

18r54

38

57

18.5

32.5

15

24

11

1.0

15.0

SV800-18R54G/224PB

224

46

69

22

38

18.5

32.5

15

1.0

15.0

SV800-224G/304PB

304

62.5

93

30

46

22

38

18.5

1.0

15.0

SV800-304G/374P

374

75.5

113

37

62.5

30

46

22

1.0

15.0

SV800-374G/454P

454

92.5

138

45

75.5

37

62.5

30

1.0

15.0

SV800-454G/554P

554

111

166

55

92.5

45

75.5

37

1.0

15.0

SV800-554G/754P

754

146

219

75

111

55

92.5

45

1.0

15.0

SV800-754G/904P

904

169

253

90

146

75

111

55

1.0

15.0

SV800-904G/1104P

1104

210

315

110

169

90

146

75

1.0

15.0

SV800-1104G/1324P

1324

246

369

132

210

110

169

90

1.0

15.0

SV800-1324G/1604P

1604

300

450

160

246

132

210

110

1.0

15.0

SV800-1604G/1854P

1854

350

525

185

300

160

246

132

1.0

15.0

SV800-1854G/2004P

2004

370

555

200

300

160

246

132

1.0

15.0

SV800-2004G/2204P

2204

415

623

220

350

185

300

160

1.0

15.0

SV800-2204G/2504P

2504

460

690

250

370

200

300

160

1.0

15.0

SV800-2504G/2804P

2 Product Introduction SV800/SV800A User Manual

10

Code

Rated load

Heavy load

High heavy

load

Carrier frequency

range

Model name

IN

A

IMax

A

PN

kW

IHd

A

PHd

kW

IHH

A

PHH

kW

Min

kHz

Max

kHz

2804

510

765

280

415

220

350

185

1.0

15.0

SV800-2804G/3154P

3154

600

900

315

460

250

370

200

1.0

15.0

SV800-3154G/3554P

3554

660

990

355

510

280

460

250

1.0

15.0

SV800-3554G/4004P

4004

740

1110

400

600

315

460

250

1.0

15.0

SV800-4004G/4504P

4504

820

1230

450

660

355

600

315

1.0

15.0

SV800-4504G/5004P

5004

920

1380

500

740

400

660

355

1.0

15.0

SV800-5004G/5604P

5604

990

1485

560

820

450

740

400

1.0

15.0

SV800-5604G/6304P

6304

1160

1665

600

920

500

740

400

1.0

15.0

SV800-6304G

7504

1380

2070

750

1160

630

920

500

1.0

15.0

SV800-7504G

10004

1840

2760

1000

1380

750

1160

630

1.0

15.0

SV800-10004G

Note: <1>Under vector control, the frequency inverter can drive motors with the power are three to four

times smaller than the inverter power. Standard V/F control does not have this limitation.

<2> The carrier frequency range means that the control algorithm can operate stably under the maximum

carrier frequency, but the motor needs to be de-rated when the carrier frequency is larger than the factory

default value.

2.1.5 Heavy load application and de-rating use of frequency inverter

For rated load application:

The motor is allowed to output a maximum of 1.5 times of the rated torque; INin Table 2-1 is

the rated current that can be used continuously when the inverter is not overloaded; PNis the

typical motor power adapted when there is no overload; IMax is the maximum overload current

allowed by the inverter, allowing continuous operation for 1 minute / 5 minutes at 40 ℃.

For heavy load application:

The inverter should be derating used by one grade and the motor is allowed to output more than

1.5 times of the rated torque; IHd in Table 2-1 is the rated current of the continuously running

motor. The motor overload protection is set by P0-03 (motor overload protection setting) and

P0-04~P0-06 (motor over-torque protection); The output current of the inverter is limited by

IMax and allowed to run continuously for 1 minute / 5 minutes at 40℃; PHd is the typical motor

power adapted for heavy load applications.

For high heavy load applications:

The inverter should be de-rating used by two grades and the motor allows output greater than

twice times of the rated torque; In table 2-1, IHH is the rated current of the continuously running

motor. The motor overload protection is set by P0-03 (motor overload protection setting) and

SV800/SV800A User Manual 2 Production Introduction

11

P0-04~P0-06 (motor over-torque protection); The output current of the inverter is also limited

by IMax, allowing continuous operation for 1 minute / 5 minutes at 40 ℃; PHH is the typical

motor power adapted for high heavy load applications.

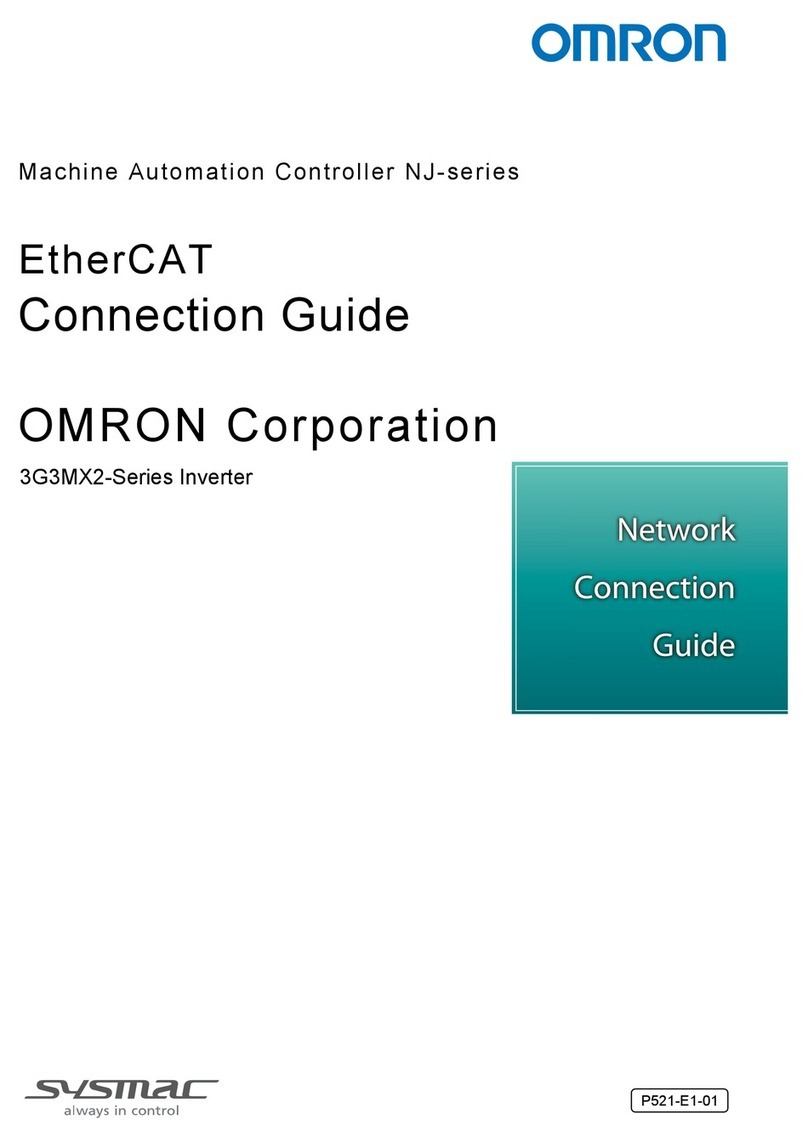

Fig.2-5 Overload protection diagram

Overload protection:

Both the inverter and the motor will perform overload protection and over-torque protection.

The motor protection parameters can be set in the inverter. When the inverter output current is

1.5 times of the rated current (or IMax), it is allowed to run for 1 minute / 5 minutes at 40 ℃, as

shown in Figure 2-5.

The guidance of derating using:

When the user needs the motor to output more than 1.5 times of the rated torque, the inverter

should be derated used as described above in the heavy load application. When the ambient

temperature of the inverter, altitude and other factors changed or the carrier frequency of the

inverter is greater than the factory default value, derating using (passive) is required; In addition,

when the motor is required to run at a very low speed for a long time, the carrier frequency must

be reduced or the inverter must be derated. Derating method as shown in Table 2-2 or you can

consult the manufacturer.

Table 2-2 The guidance of inverter derating using

Derating factors

Derating guidance

Temperature

The rated value of the inverter is measured at 40 °C. If the ambient temperature rises, the capacity should

be reduced by 3%/1 °C and the maximum ambient temperature is 50 °C.

Altitude

After the altitude is higher than 1000 meters, derating 1% for each 100 meters.

Carrier

frequency

When the carrier frequency of the inverter is higher than the factory default value, in principle, the inverter

should be derated used by one grade or consult the manufacturer directly.

Current or oL%

t/min

1.5IN

1.05IN

1 2 3 4 5

oL%=100%

Overload counting curve

Current amplitude

2 Product Introduction SV800/SV800A User Manual

12

Derating factors

Derating guidance

When it needs to run at very low speed with rated output, please consult the manufacturer or derating use

the inverter by one grade.

Note: The factors affecting the output capability of the inverter are not limited to the above factors, if any

questions, please consult the manufacturer or supplier.

Table of contents

Other SCOV Inverter manuals