SDL Atlas M233B User manual

www.sdlatlas.com

M233B

AutoFlamm Tester

INSTRUCTION

MANUAL

Ver. 2.1(2023.02.13)

AutoFlamm Tester

i

GENERAL EQUIPMENT SPECIFICATIONS

This page is a record of your equipment specifications. This information is found on

the stamped nameplate of your instrument. Please fill in the blanks below when you

receive your SDL Atlas instrument.

When contacting the sales or service department to order parts or obtain information,

refer to this page. This will allow us to respond quickly and accurately to your request.

MODEL NO.

SERIAL NO.

VOLTS CYCLES PHASE

NUMBER REV. NO. DATE

MAIN FUSE. 把

SINGLE PHASE AMPERES

MODEL: M233B RE

TYPE: AutoFlamm Tester

AutoFlamm Tester

ii

SAFETY INSTRUCTIONS

READ THESE INSTRUCTIONS BEFORE USE

Due to the potential hazards associated with any electrical equipment it is important

that the user is familiar with the instructions covering the capabilities of, and the

operation of this instrument. The user should ensure that all reasonable safety

precautions are followed and if any doubt exists, should seek professional advice

before proceeding.

This instrument is designed for use by suitably trained, competent personnel in a

controlled working area, and is intended to be used as a flammability tester only.

This instrument have moving parts and while all reasonable steps have been taken to

protect personnel associated with these moving parts, incorrect or mis-use of the

equipment could result in injury. Consideration should be given to the nature of these

moving parts when installing and setting up the equipment. This equipment should be

installed by fully trained, competent personnel. This instrument is intended for use in

a residential, commercial and light industrial environment as laid down in EN 50081-1.

SDL Atlas cannot be held responsible for any unauthorized modifications to the unit.

Due to the potential hazards associated with the use of Propane and Butane, it is

important that the user take all necessary safety precautions when using these items.

WARNING

This unit contains moving parts and hazardous live voltages. Under no circumstances

should the user try to prevent / restrict the movement of the burner or gain access to

the internal circuitry, personally or with the aid of a foreign body. All ventilation slots

must be kept clear.

AutoFlamm Tester

iii

PROVISION FOR LIFTING AND CARRYING

When unpacking or moving this instrument, extreme care is required owing to its

physical construction and weight.

It is recommended that accepted lifting and carrying procedures are employed

and that personnel wear the appropriate protective equipment e.g. safety shoes. If

the unit is to be moved an appreciable distance/height, it is recommended that it is

moved via a suitable vehicle e.g. a fork lift truck.

EQUIPMENT WARRANTY

SDL Atlas warrants for twelve (12) months from first use or fifteen (15) months from

date of shipment, whichever occurs first, that this SDL Atlas instrument has passed

our inspection and tests; that it is free from defects in materials and workmanship;

and that it will perform according to the applicable published SDL Atlas specifications

if installed and operated according to our instructions. This warranty is in lieu of any

other warranty expressed or implied. In no event will SDL Atlas be liable for special or

consequential damages as a result of any alleged breach of this warranty provision.

The liability of SDL Atlas hereunder shall be limited to repairing or exchanging, at its

option, any defective part FOB, SDL Atlas plant. Equipment or parts that have been

subjected to abuse, misuse, accident, alteration, neglect, unauthorized repair or

installation are not covered by warranty. SDL Atlas shall have the right of final

determination as to the existence and cause of the defect.

When parts are repaired or exchanged, the warranty on said part shall continue in

effect for the remainder of the original equipment warranty period or for six (6)

months following the date of shipment by SDL Atlas, whichever period is longer.

SDL Atlas reserves the right to make changes and improvements in its products

without obligation to install these changes in products theretofore manufactured.

AutoFlamm Tester

iv

PARTS WARRANTY

Parts and material supplied by SDL Atlas are inspected and tested to ensure that

they are free from defects and will operate properly when correctly installed and

operated in equipment produced by SDL Atlas. Parts (excluding consumable

components such as light sources, optical components, crock cloth, etc.) are under

warranty for a period of six (6) months from date of shipment. This warranty is in lieu

of any other warranty expressed or implied. In no event will SDL Atlas be liable for

special or alleged breach of this warranty provision.

The liability of SDL Atlas hereunder shall be limited to repairing or exchanging, at its

option, any defective part FOB, SDL Atlas plant. Parts that have been subject to

abuse, misuse, accident, alteration, neglect, unauthorized repair or installation are

not covered by warranty. SDL Atlas shall have the right of final determination as to

the existence and cause of the defect.

SDL Atlas reserves the right to make changes and improvements in its products

without obligation to install these changes in products theretofore manufactured.

AutoFlamm Tester

CONTENTS

1.0 INTRODUCTION.................................................................................................. 1

2.0 SPECIFICATION.................................................................................................. 2

3.0 INSTALLATION ................................................................................................... 3

3.1 Uncrating the Instrument.................................................................................. 4

3.2 List of Materials (Standard Accessories).......................................................... 4

3.3 Optional Accessories ........................................................................................ 8

3.4 Setup................................................................................................................. 9

4.0 OPERATION...................................................................................................... 24

4.1 Setup for Testing............................................................................................. 24

4.2 Standard Testing Method (see related standard for details) ........................... 25

4.3 Test Results.................................................................................................... 43

5.0 MAINTENANCE................................................................................................. 59

5.1 Cleaning the Specimen Holder ....................................................................... 59

5.2 Cleaning the Machine Frame.......................................................................... 59

5.3 Repair of Specimen Holder............................................................................. 59

6.0 REVISION .......................................................................................................... 60

AutoFlamm Tester

1

1.0 INTRODUCTION

The SDL Atlas M223B AutoFlamm Tester determines the flammability resistance of

fabrics and soft fabric toys, it measures the flame-spreading time and speed of

specimens burnt at the vertical or other orientations that under controlled flame-

impingement conditions.

The AutoFlamm must work with the supplied computer software. It is equipped with a

solenoid operated gas burner and micro-switch operated trip threads, fully motorized

burner assembly with ignition position memory function for different testing standards.

Test results can be directly saved in the computer, data can be re-called, edited, and

stored in test report. The report can also be exported to third party software

application (such as MS Word).

The M233B meets requirements to perform varies test standard as below:

•BS EN 13772: 2003

•BS EN ISO 6940: 2004

•BS EN ISO 6941: 2003

•BS EN ISO 6941: 1995

•BS EN ISO 6940: 1995

•BS EN ISO 15025: 2016

•BS EN 1103: 2005

•BS EN 1101: 1996

•BS EN 1102: 1996

•BS EN 532: 1995

•BS 5438: 1989

•BS 5438: 1976 –Test 1

•BS 5438: 1976 –Test 2

•BS 5438: 1976 –Test 3

•BS EN 71-2: 2011

AutoFlamm Tester

2

2.0 SPECIFICATION

PHYSICAL:

Length

65 cm

width

51 cm

Height

120 cm

Weight

70 kg (Approx.)/154.3Lbs

ELECTRIC:

Power

230 Vac, 50/60 Hz, Single Phase

Fuse

5 Amp 250 Vac

INSTRUMENT

Control

PC

Interface

USB (cable connection) or Bluetooth (wireless connection)

Marker Thread

6 horizontal markers and 2 vertical markers (+/- 1 mm)

Specimen Holder

7 sets of frames with templates (Dimension +/- 0.5 mm)

Timer

+/- 0.05 s

Gas Supply

Commercial Butane or Propane with regulator (not supplied

by SDL Atlas)

AutoFlamm Tester

3

COMPUTER (Not Included)

Intel Core i3 processor or above installed with MS Win 10 operation system

2 GB RAM or higher

20 GB free hard disk space.

Any suitable monitor

USB port

Remark: The computer that connects to AutoFlamm must be solely use for the

machine control purpose only, it is not supposed to use for other sharing functions.

ENVIRONMENTAL: (refer to ISO, EN or other standard for exact details and

requirements)

Indoor use with ventilation facility

Air movement less than 0.2 m/s during test

Ambient Temperature: 15 to 30 C

Relative Humidity: 45-65% (for details refer to test standard)

Mains Supply Voltage Fluctuations: 10% of the nominal voltage

Over voltage Category: II

Meets EU (European Union) requirements for safety. CE

stands for Conformité Européenne (European

Conformity).

AutoFlamm Tester

4

3.0 INSTALLATION

3.1 Uncrating the Instrument

When you receive your AutoFlamm Tester, inspect the crate for damage that may

have occurred during shipping. Carefully unpack the instrument and thoroughly

inspect the instrument components for any damage or shortages. Report any

instrument damage to the carrier and/or shortages to SDL Atlas Customer Service.

3.2 List of Materials (Standard Accessories)

The AutoFlamm is shipped with the following items:

•AutoFlamm

•Connecting Cable

•Bluetooth Receiver (for wireless connection)

•Removable Stainless steel Debris Tray

•Pack of Marker Thread

•7 sets of Pin Frames (specimen holders) with Templates

•M233A/10 Gas Burner

•M233A/11 Gas Burner

•Burner Spacer (17 mm)

•Burner Spacer (20 mm)

•25mm Flame gauge

•USB for Instruction Manual & Software

•Power Cable

•5 Amp fuses

AutoFlamm Tester

5

Seven Sets of Pin Frames (Specimen Holders) and Templates to

Comply to following Standards

⚫M233A/1 - BS EN 1101, BS EN ISO 6940:1995, BS EN 13772:2003

⚫M233A/2 - BS EN 6941:1995, BS EN 6941:2003, BS EN 1102, BS EN 1103

⚫M233A/3 - BS EN ISO 6940:1995, BS EN ISO 6940:2004, BS EN 1101:1995

⚫M233A/4 - BS EN 532, BS EN ISO 15025:2002, BS5438: 1989

⚫M233A/5 - BS EN 5438 Part 1 and 2:1976 (shown in picture below)

⚫M233A/6 - BS EN 5438 Part 3:1976

⚫M233A/14- EN71-2: 2011 Part 5.4

AutoFlamm Tester

6

Gas Burner

Debris Tray

AutoFlamm Tester

7

Burner Spacer 17 mm 20 mm

Marker Thread

25mm Flame Gauge

AutoFlamm Tester

8

3.3 Optional Accessories

The following optional accessories are available for the AutoFlamm:

⚫M233B/2 Radiator Assembly with Filter Paper for BS EN 13772

⚫M233A/7 Filter Paper for BS EN 13772, BS EN 15025 & BS EN 1102

⚫M233A/8 Filter Papers for BS EN 1103

⚫M233A/9 45 Tex White Mercerized Cotton Marker Thread

⚫M233A/10 Burner for BS EN Standard

⚫M233A/11 Burner for BS 5438: 1976

⚫M233A/12 White Plain Weave Bleached Cotton Ignition Fabric

⚫M233A/13 Calibrations Kit for EN 13772

Standard

Test

Frame

Filter

paper

Marker

Thread

Radiator

Burner

Gas

BS EN ISO 6941:2003

M233A/2

M233A/9

M233A/10

Propane/Butane

BS EN 13772:2003

M233A/7

M233B/2

Propane

BS EN 1102:1996

BS EN 1103:2005

M233A/8

BS EN ISO 6940:2004

M233A/3

Propane/Butane

BS EN 1101:1996

Propane

BS 5438:1989

M233A/4

Butane

BS EN 532:1994

Propane

BS EN ISO 15025:2016

M233A/7

Propane

BS EN 71-2:2011 Part5.2

Propane/Butane

BS EN 71-2:2011 Part5.3

BS EN 71-2:2011 Part5.4

M233A/14

M233A/9

BS EN 71-2:2011 Part5.5

BS 5438:1976 Test1

M233A/5

M233A/11

Butane

BS 5438:1976 Test2

BS 5438:1976 Test3

M233A/6

M233A/9

AutoFlamm Tester

9

3.4 Setup

3.4.1 Machine Layout

Manual Control

Panel

Right Side

Panel

Right Vertical Marker

(5 & 15 mm)

150 mm Marker

(5 & 15 mm)

300 mm Marker

(5 & 15 mm)

600 mm Marker

(5 & 15 mm)

Left Vertical Marker

(5 & 15 mm)

Pin Frame with

Template

First Marker

220 mm (1 & 5 mm)

Second Marker

370 mm (1 & 5 mm)

Third Marker

520 mm (1 & 5 mm)

Gas Regulator

Burner Assembly

Radiator Assembly

(optional)

Upper Beam

Middle Beam

Lower Beam

AutoFlamm Tester

10

Right Side Panel

Manual Control Switch

Run/Set:

1. When burner assembly is at the origin, short press the button and burner move to

the preset position of the selected standard.

2. When Burner is not at the origin, press the button and Burner returns to the origin.

3. When Burner is not at the origin, hold the button for 5 seconds until the light

flashes, the device will set the current position to the preset position of the selected

standard, and the Burner assembly will then return to the origin.

Manual ignition and

Gas Value button, light

on when working.

Manual Radiator

button, light on when

working.

AutoFlamm Tester

11

3.4.2 Software Setup

The AutoFlamm is supplied with software that control the device to perform tests

and process test results and reports. Computer is not supplied; please refer to

section 2 “Specification” for the detailed requirements of the computer system.

1. Before installation, close any other programs that Windows is running. This

will stop them from interfering with the installation process.

2. Insert the supplied USB drive and then double click the “Setup.exe”.

3. The setup screen will prompt up, to continue, the default folder for software is

“C:\Program Flies\AutoFlamm”. (By clicking on the “Browse” the user is able

to select a different drive and/or folder to install software.) Then press

“Next”. ,click on the “Next”, or click on the “Cancel” to exit the application.

AutoFlamm Tester

12

4. Creat a desktop shortcut or not, then click “Next”install the software.

5. The software is ready to be installed. Press “Install” to install the software”.

AutoFlamm Tester

13

6. Press “Next” to install the Device Driver.

7. The Driver will be completely installed and ready for use.

AutoFlamm Tester

14

8. The software will be completely installed and ready for use.

Table of contents

Popular Test Equipment manuals by other brands

Metrix

Metrix MX 407 user manual

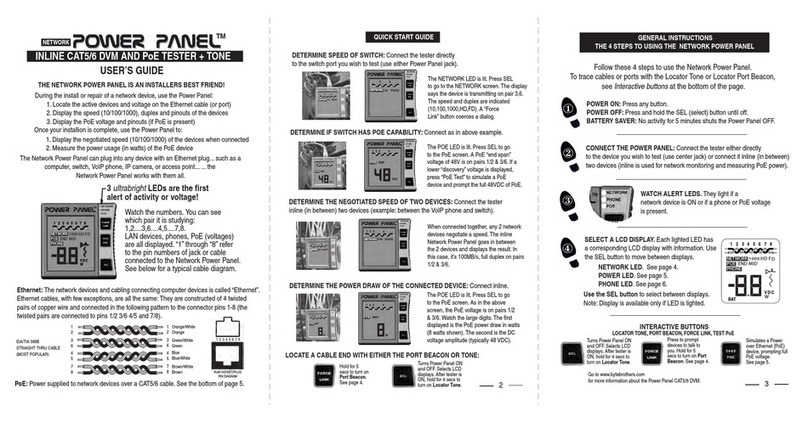

Byte Brothers

Byte Brothers POWER PANEL quick start guide

Tinker & Rasor

Tinker & Rasor VC-2 Product instructions

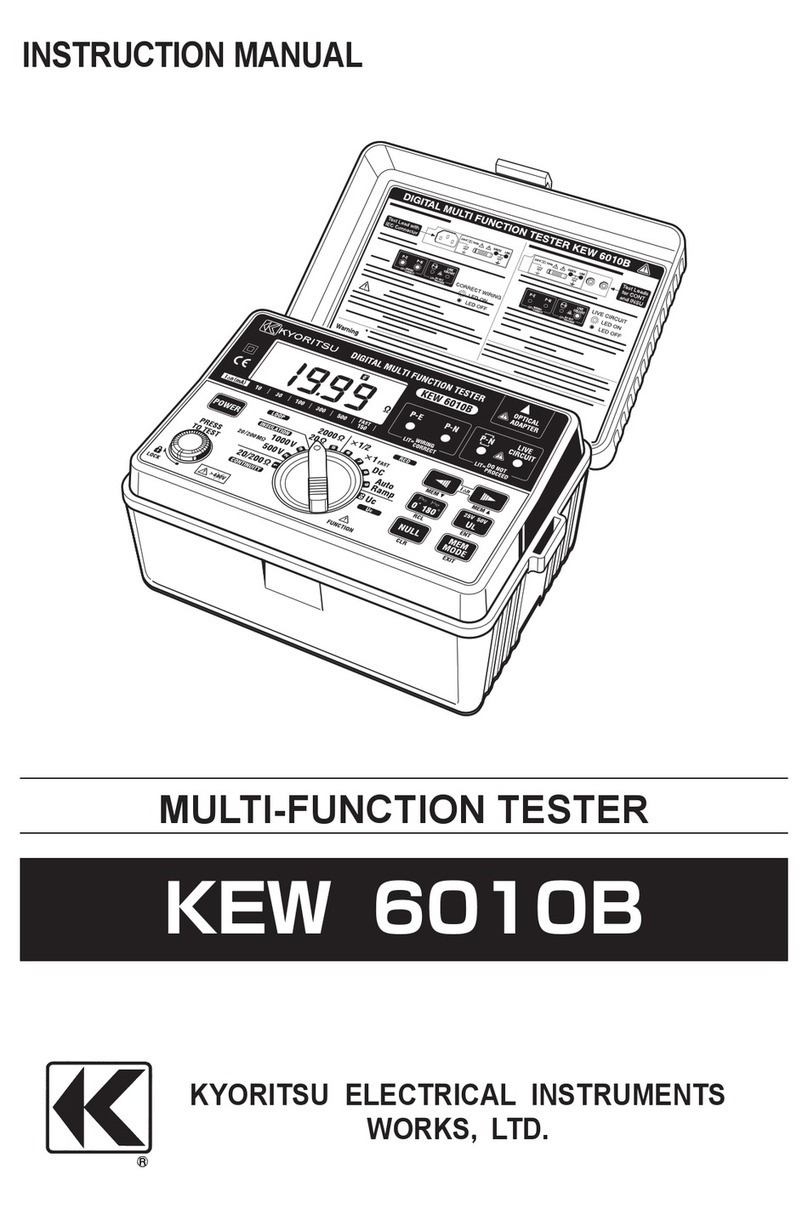

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. KEW 6010B instruction manual

Unit

Unit UT712 operating manual

easymaxx

easymaxx 08165 instructions

Isotech

Isotech 875 User maintenance manual/handbook

Socket & See

Socket & See PDL 234Plus Instruction manual & specification

Edgetech

Edgetech RH CAL Operator's manual

Pro-tec

Pro-tec PROpolN LCD 2.0 operating instructions

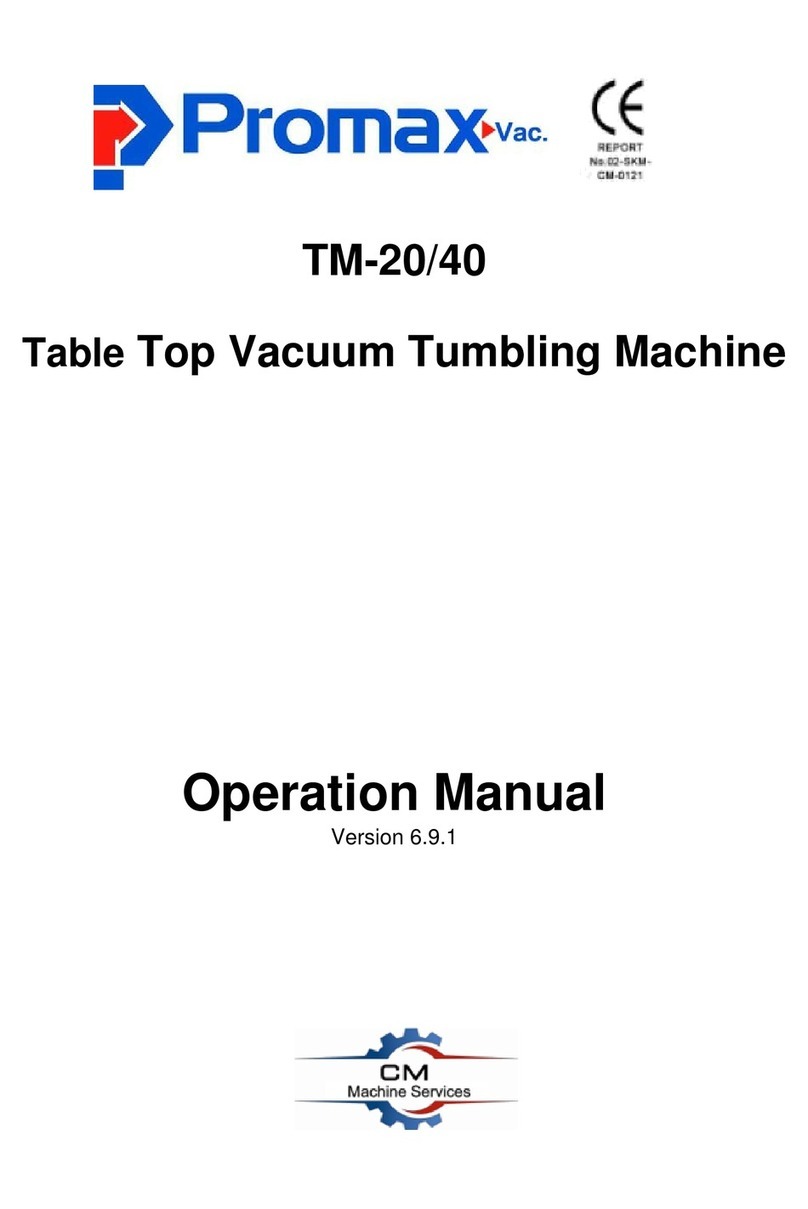

Promax

Promax TM-20 Operation manual

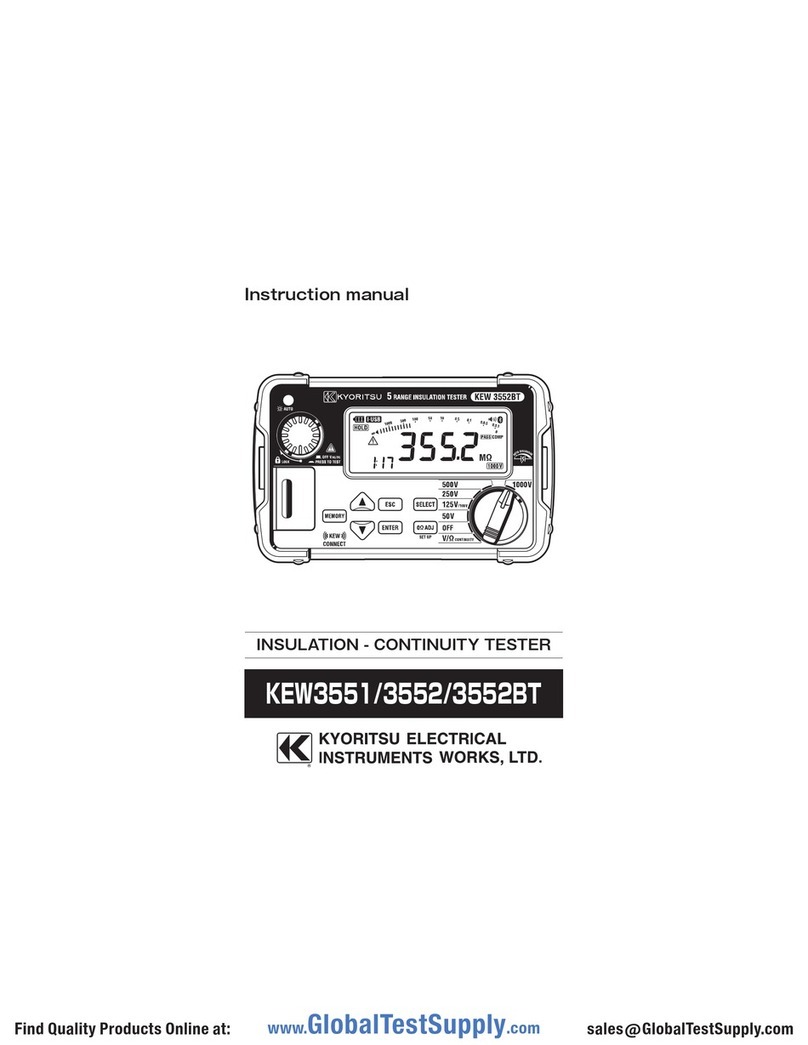

Kyoritsu Electrical Instruments Works, Ltd.

Kyoritsu Electrical Instruments Works, Ltd. KEW3551 instruction manual