RTD TRANSMITTER

(eld-congurable) MODEL B3FR

INSTRUCTION MANUAL

BEFORE USE ....

Thank you for choosing M-System. Before use, please check

contents of the package you received as outlined below.

If you have any problems or questions with the product,

please contact M-System’s Sales Office or representatives.

■PACKAGE INCLUDES:

Signal conditioner......................................................... (1)

■MODEL NO.

Confirm Model No. marking on the product to be exactly

what you ordered.

■INSTRUCTION MANUAL

This manual describes necessary points of caution when

you use this product, including installation, connection and

basic maintenance procedures.

POINTS OF CAUTION

■CONFORMITY WITH UL

•ThisequipmentissuitableforuseinaPollutionDegree2

environment.

•DONOT connecttheRTDtocircuitsgreaterthan30V

rmsand42.4Vpeakor60VDC.

•Thisequipmentistobeusedwiththemaximumoperat-

ingvoltage30Vrmsand42.4Vpeakor60VDC.

•Theequipmentmustbemountedinsideasuitablereen-

closure.

•Operatingtemperature:-40to+55°C(-40to+131°F)

•Altitudeupto2000meters.

■CONFORMITY WITH EU DIRECTIVES

•Functionalinsulationismaintainedbetweensignalinput

and output.

•Theequipmentmustbemountedinsideapanel.

•Installlightningsurgeprotectorsforthosewiresconnected

to remote locations.

•Insertanoiselterforinputandoutputconnectedtothe

unit.TDKNoiseFilterModelZCAT3035-1330orequiva-

lent is recommended.

•The actual installation environments such as panel con-

figurations, connected devices, connected wires, may affect

the protection level of this unit when it is integrated in a

panel system. The user may have to review the CE require-

ments in regard to the whole system and employ additional

protective measures to ensure the CE conformity.

■SAFETY PRECAUTION

Before you remove the unit or mount it, turn off the power

supply and input signal for safety.

■ENVIRONMENT

•Indooruse

•Whenheavydustormetalparticlesarepresentintheair,

install the unit inside proper housing with sufficient ven-

tilation.

•Donotinstalltheunitwhereitissubjectedtocontinuous

vibration.Donotsubjecttheunittophysicalimpact.

•Environmentaltemperaturemustbewithin-40to+85°C

(-40to+185°F)withrelativehumiditywithin0to95%RH

in order to ensure adequate life span and operation.

•Besurethattheventilationslitsarenotcoveredwithca-

bles, etc.

■WIRING

•Do not install cables close to noise sources (relay drive

cable, high frequency line, etc.).

•Do not bind these cables together with those in which

noisesarepresent.Donotinstalltheminthesameduct.

■AND ....

The unit is designed to function as soon as power is sup-

plied,however,awarmupfor10minutesisrequiredforsat-

isfying complete performance described in the data sheet.

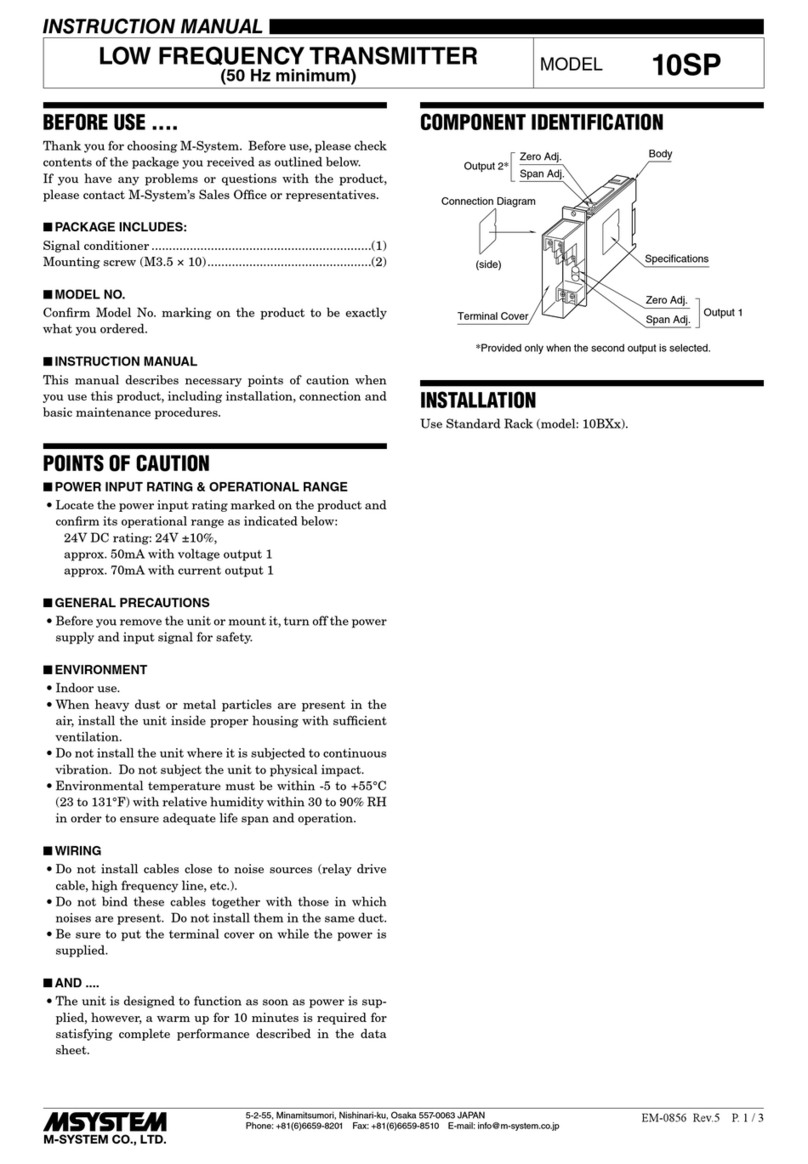

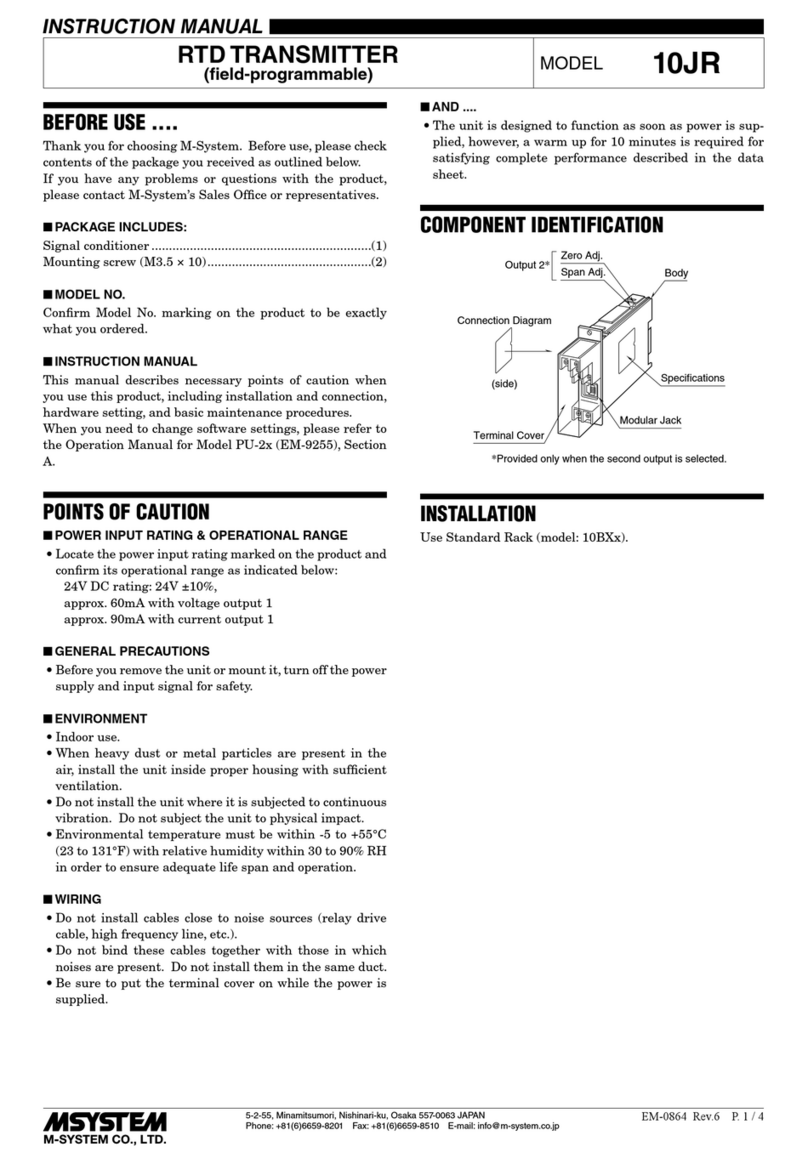

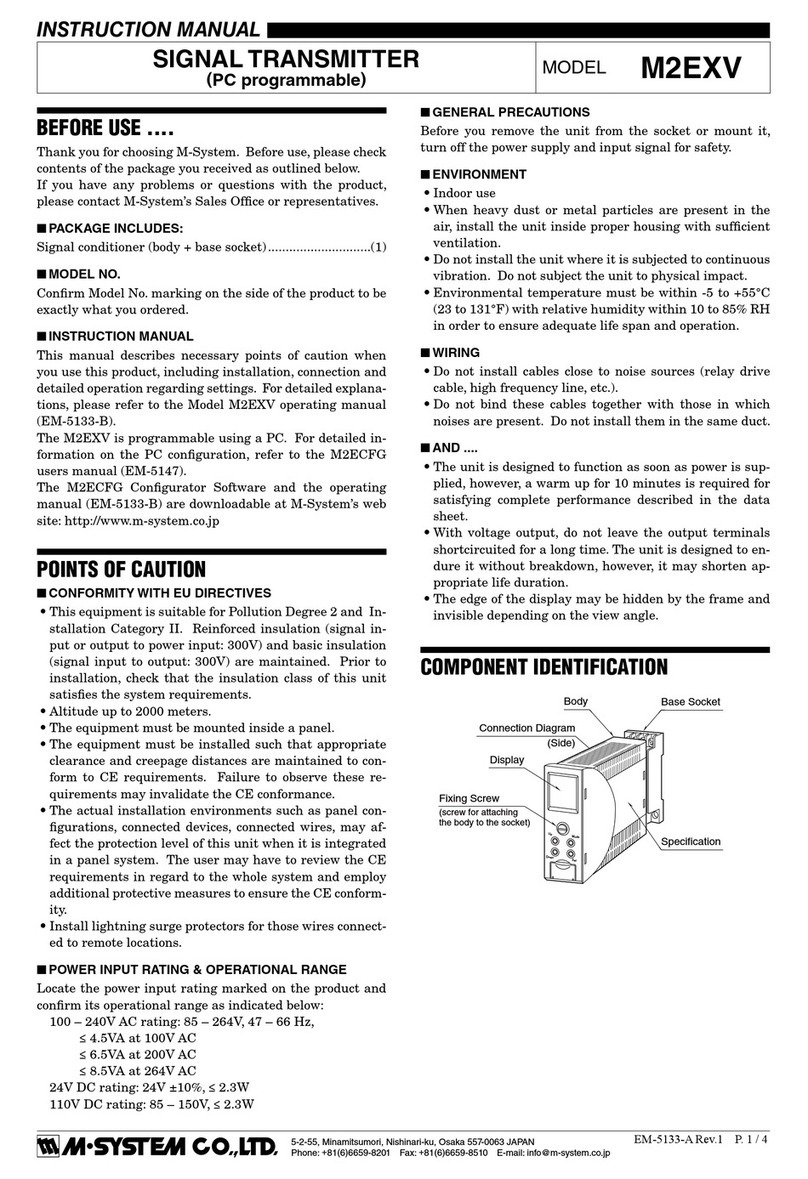

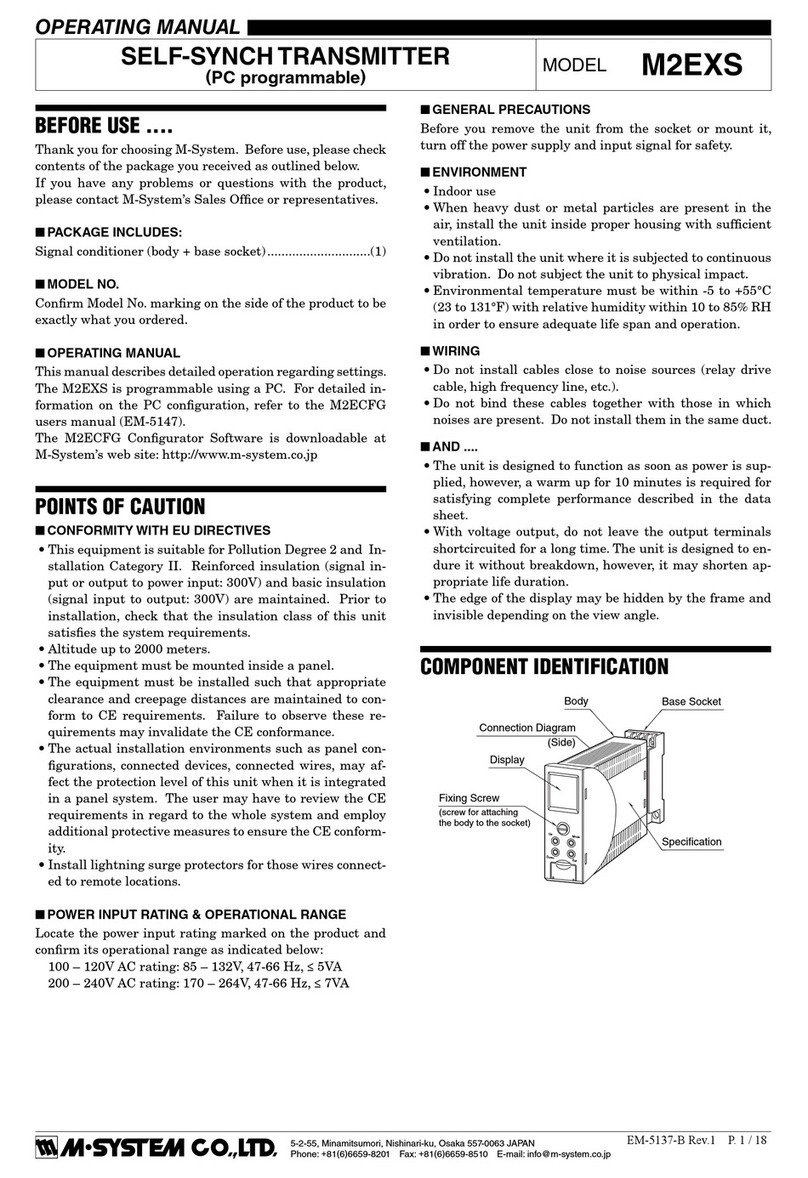

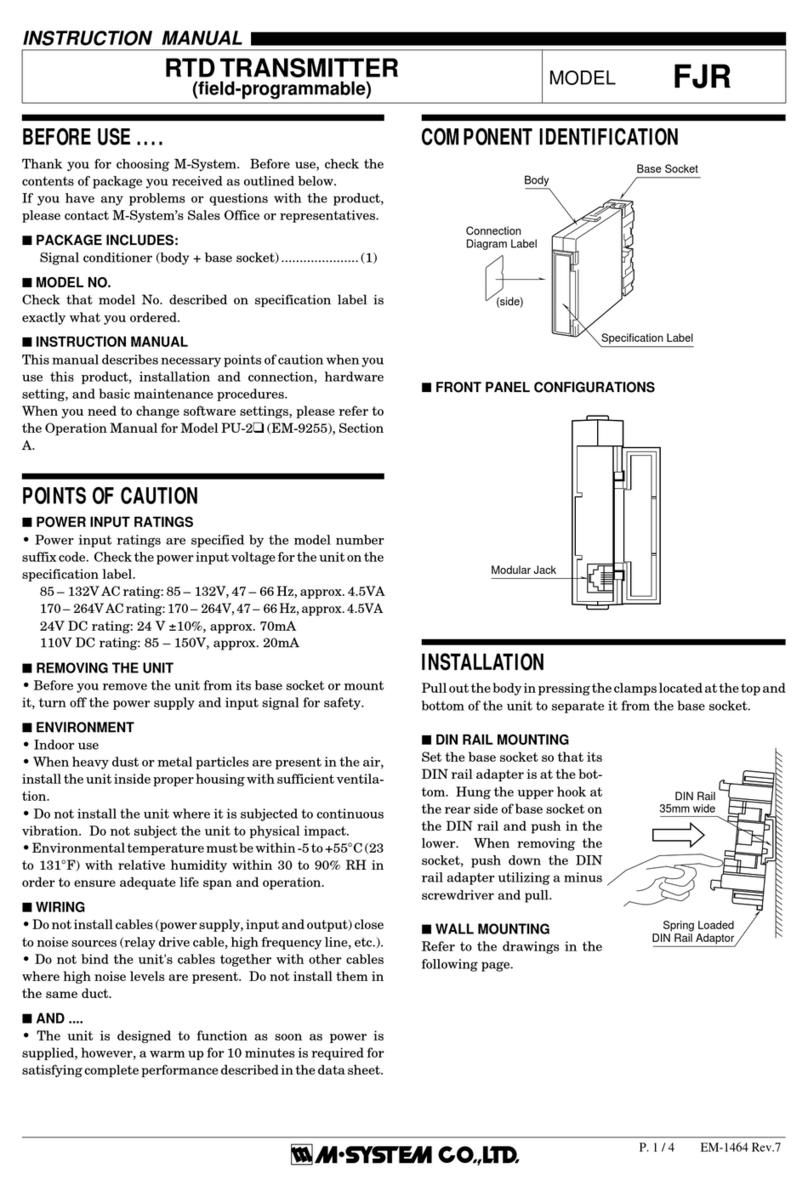

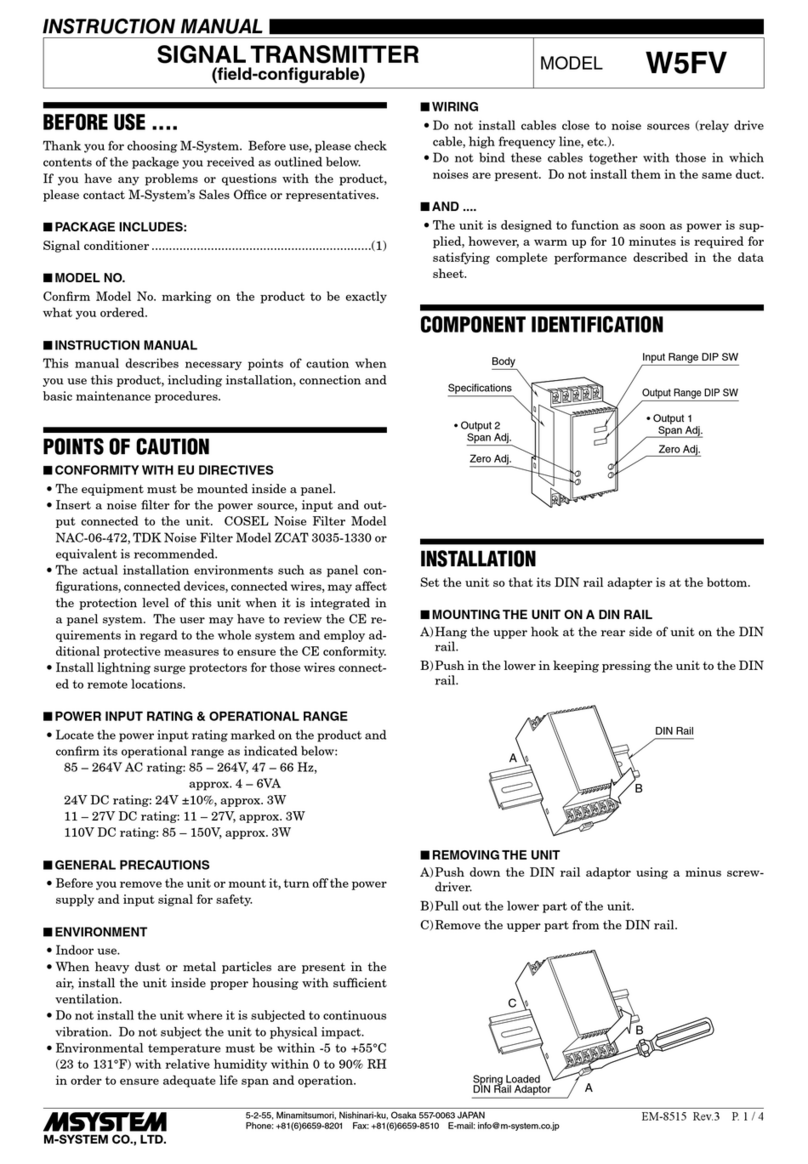

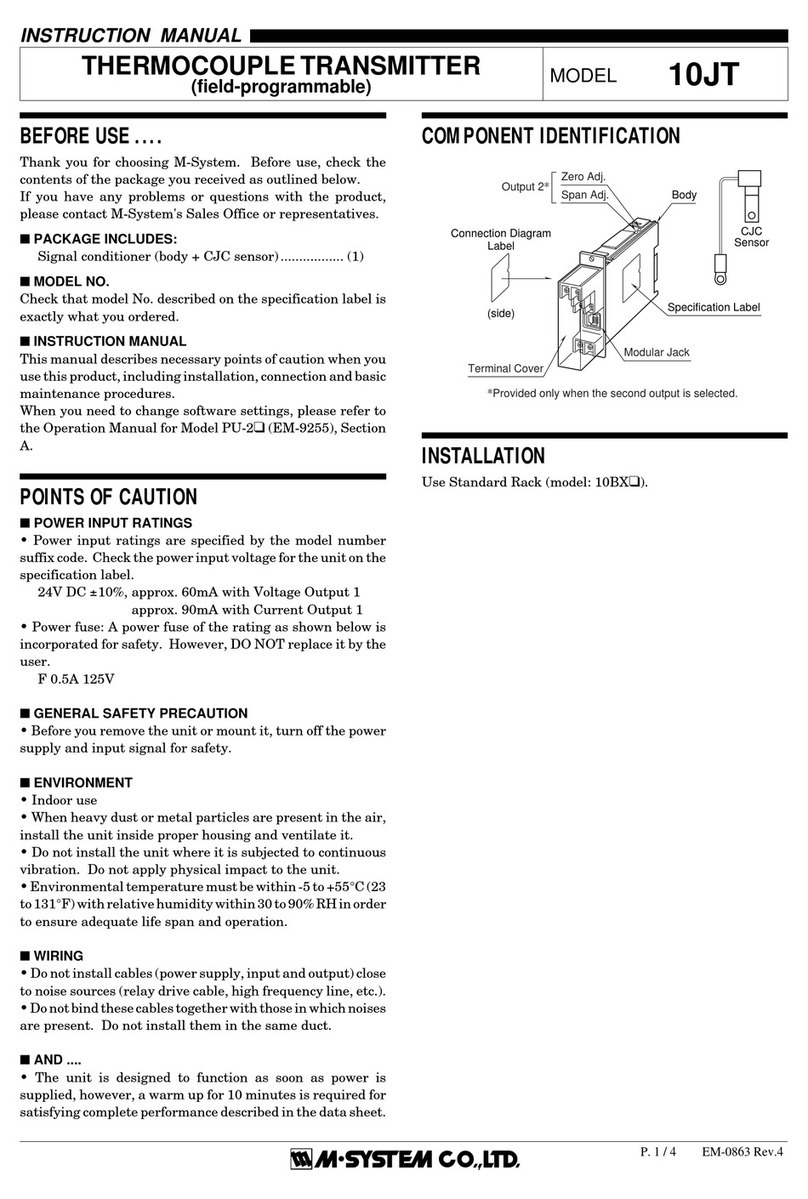

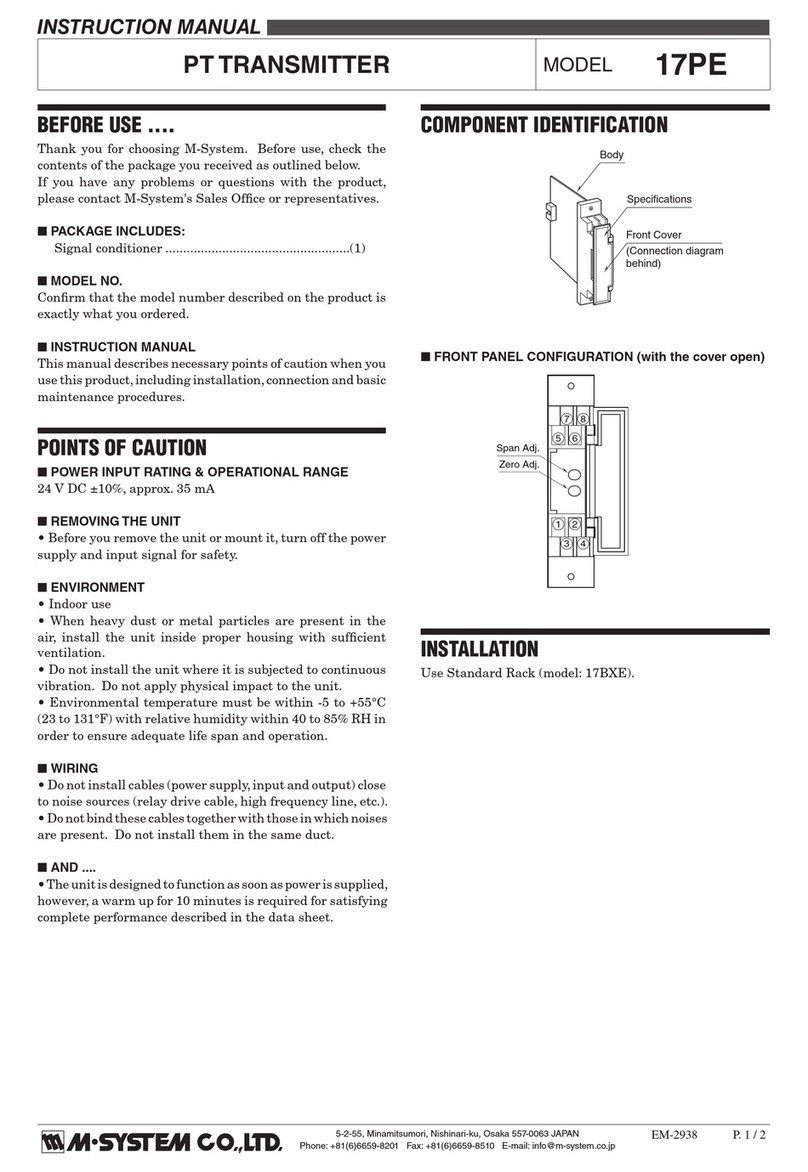

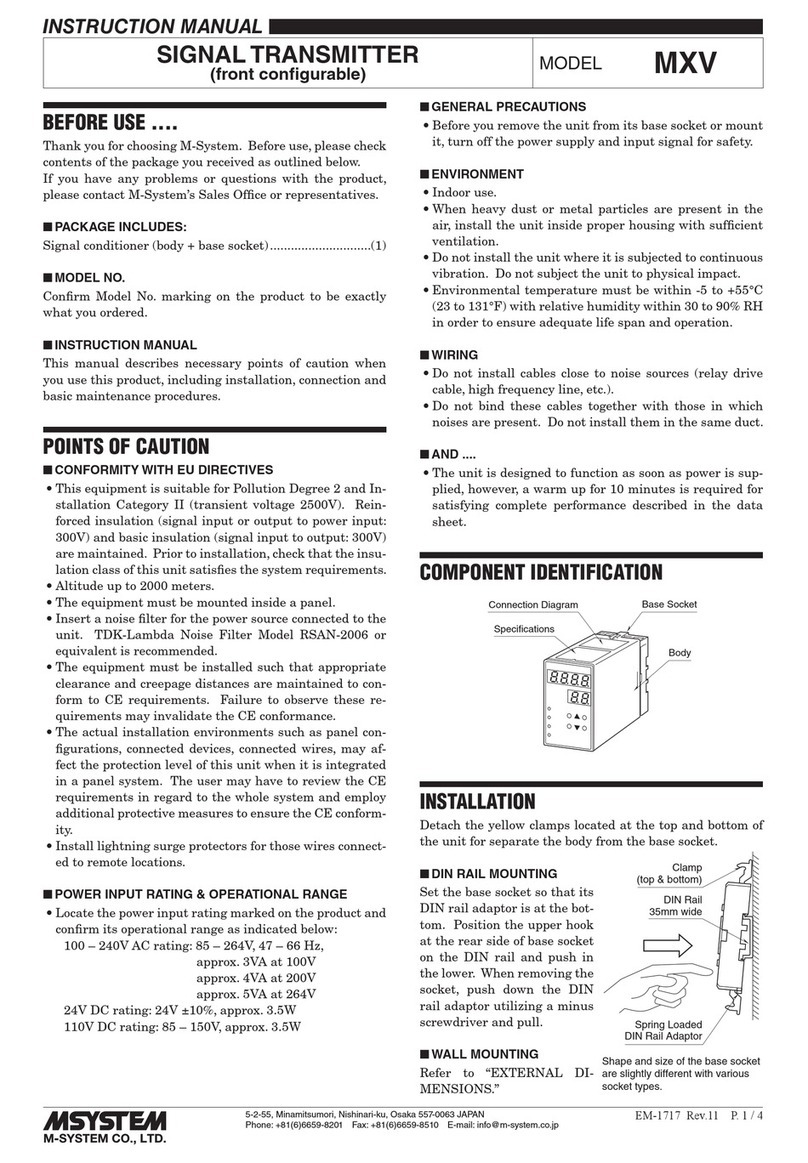

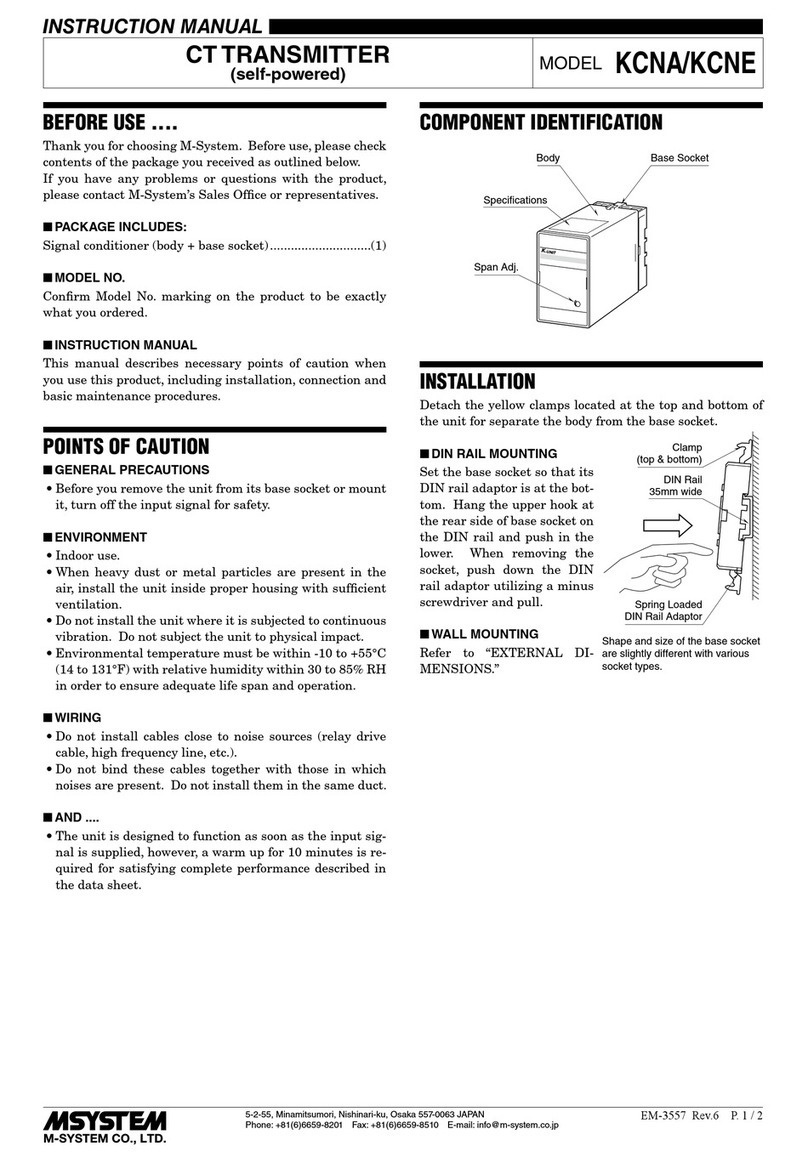

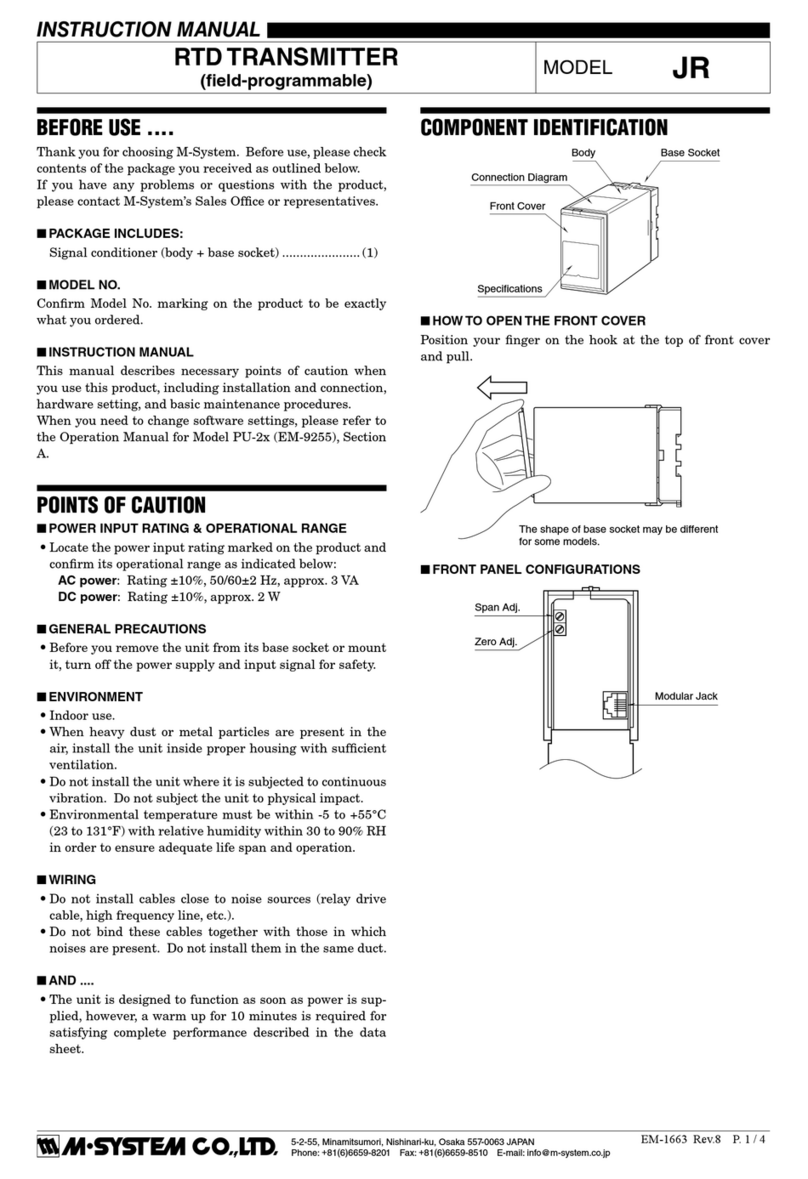

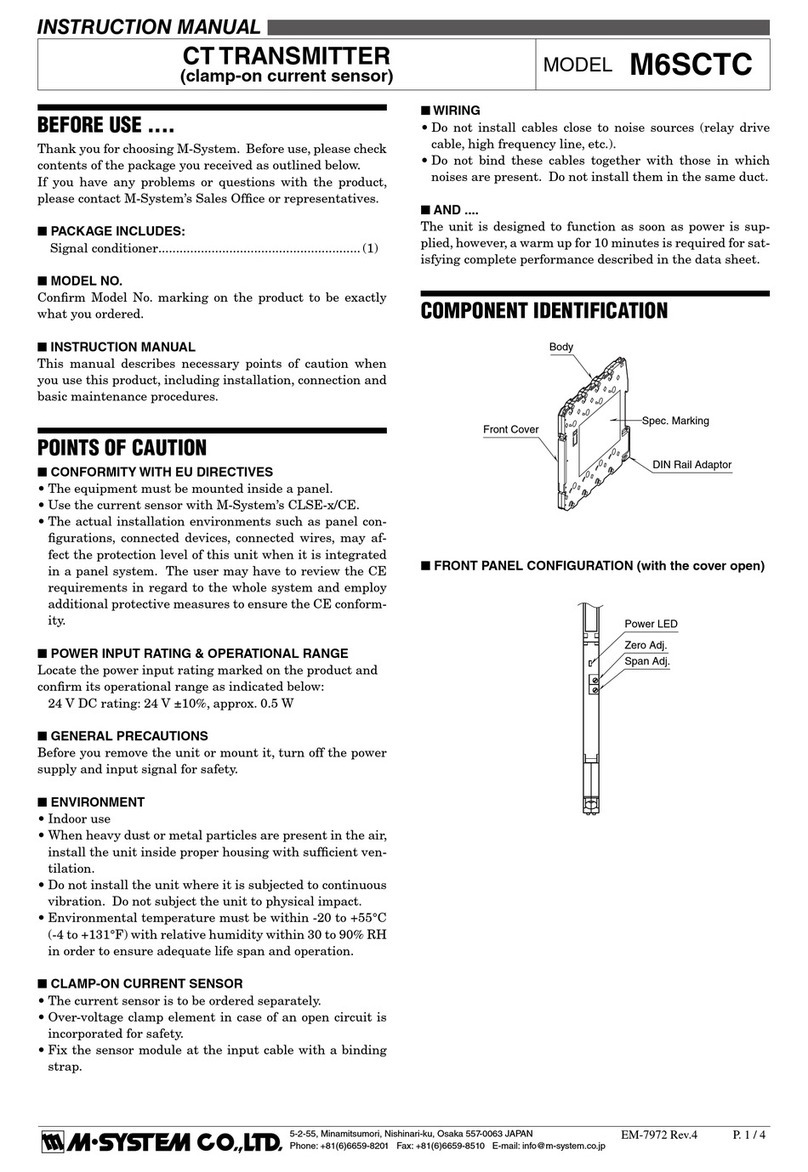

COMPONENT IDENTIFICATION

■HOW TO OPEN THE COVER WHEN SETTING DIP SW

Holdatthetopandbottomoftheunitasshownbelowand

slide the housing cover gently to open until it hits the latch-

ing inside the unit.

Body

SW Configuration

Zero Adj.

Span Adj.

Specifications

(side)

• Housing Cover Fully Opened

Caution: DO NOT PULL beyond where the housing cover is latched.

The plastic housing may be damaged.