Sea Clear Watermakers G-20 User manual

INSTALLATION MANUAL

System Diagram ................................................... Page 23

What’s Included InYour Kit .................................... Page 24

Control Panel Installation ...................................... Page 25

Pre-filter Installation............................................. Page 26

High Pressure Pump Installation ............................ Page 27

Membrane Installation ..........................................Page 29

Seawater Lift Pump Installation.............................Page 29

Running Tubing and Hoses..................................... Page 30

Initial System Start-up .......................................... Page 33

Sea Clear Watermakers™ Manual -Version 1.1-G Page 22

SYSTEM DIAGRAM

Sea Clear Watermakers™ Manual -Version 1.1-G Page 23

WHAT’S INCLUDED INYOURKIT

Standard Kit (Model G-20):

• (1) 40” reverse osmosis membrane with

housing

• (1) 1HP 115V/230V AC pump

Premium Kit (Model G-40):

• (2) 40” reverse osmosis membranes with

housings

• (1) 2HP 115V/230V AC pump

Both Standard & Premium Kits:

• (1) Control panel

• (1) Seawater lift pump

• (1) Starter switch

• (1) Pre-filter housing with wrench

• (1) Pre-filter

• 25’ of high pressure tubing

• 10’ of 1/4” low pressure hose

• 50’ of 1/2” low pressure hose

• 10’ of 3/4” low pressure hose

• Sodium metabisulfite (pickling chemical)

Optional Features

• Other membrane options

• Water tester

• Pump repair kit

• O-ring kit for membrane housing

ItemsYou Will Need

• Minimum 4000 watt generator (5000 watt preferred) or larger

• Intake through-hull

• Brine discharge through-hull

• Stainless steel hose clamps

• PVC cleaner and glue

• Membrane housing mounting brackets

Sea Clear Watermakers™ Manual -Version 1.1-G Page 24

CONTROL PANEL INSTALLATION

►►►Prior to mounting the Control Panel, connect 1/4” hose to the Pre-filter Gauge on the back of the

Control Panel. Leave the hose loose for connection to the Pre-filter Housing later.

❶Mount the Control Panel in a convenient location;

the panel should be easily accessible and you

should have a clear view of the gauges when

you’re running the watermaker. It should be as

close as possible to the Membrane and to the High

Pressure Pump.

►►►Make sure the panel is mounted securely to

a solid surface.

❷Mount the Wiring Harness near the Control Panel (but not below the panel, as it will be obscured by

hoses).

❸Run 12-gauge wire from a dedicated 10 amp breaker to the red wire on the barrier strip.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 25

On many boats, a convenient location for the Control Panel is a cockpit locker bulkhead.This

provides easy access to controls and hose runs to the bucket are kept short.

PRE-FILTER INSTALLATION

The Pre-filter Housing should be located for easy access, away

from any electronics or other surfaces that cannot get wet.

❶Mount the Pre-filter Housing to a bulkhead using the

supplied bracket.

►►►Be sure to leave enough room below the housing to

allow for Pre-filter changes.

❷Glue PVC fittings with PVC glue as required per your

installation.

❸Run a 1/2” hose from the intake side of the Pre-filter Housing to the hose barb on the Control Panel

labeled “To H.P. pump.”

❹During the Control Panel installation, you attached a 1/4” hose to the back of the Control Panel and

left it loose. Connect this hose to the 1/4” hose barb on the output side of the Pre-filter Housing.

❺Run a 1/2” hose from the output side of the Pre-filter Housing to the input hose barb on the High

Pressure Pump.

❻Place the 5-micron Pre-filter that was included with your kit into the Pre-filter Housing. Screw the

Pre-filter Housing back into place.

❼The first time the Seawater Lift Pump is started or when the Pre-filter is changed, you must release

the air from the Pre-filter. Push and hold the red button on top of the Pre-filter Housing and turn on

the Seawater Lift Pump. Continue to hold the button until air stops being released. As soon as water

is seen, release the button.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 26

HIGH PRESSURE PUMP INSTALLATION

High Pressure Pump RPM

Minimum Maximum Recommended

1250 1800 1725

*Decreasing the RPM of the pump will simply decrease the production of fresh water.

To determine your generator’s operating RPM, refer to the AR North America chart below.

►►►Go back to page 6 and write your generator’s RPM in the gold-colored box for future reference..

Sea Clear Watermakers™ Manual -Version 1.1-G Page 27

Bracket Requirements

Before installing the high pressure pump, you’ll need a bracket to mount it to the generator.

• The pump must be mounted as level as possible with the oil dipstick on top of the unit.

• The pump can be turned in either direction.

• The bracket should be made of mild steel and painted prior to installation.

• The bracket should include a method for tensioning the belt.

►►►It is recommended that a qualified metal fabricator or mechanic build and install the

bracket.

Once the pump has been mounted and the belt has

been installed, you’re ready to make the electrical

and plumbing connections for the High Pressure

Pump.

❶Fill the pump with 9.81 oz. ISO 100 - NA 30 weight

hydraulic oil.

❷Connect the [+] wire from the magnetic clutch to

the wiring harness on the Control Panel using 12-gauge tinned wire.

❸If the generator is not grounded to the [-] terminal of the battery, you will need to run an additional

wire from the pump to your [-] battery buss. (In most cases, this will not be required.)

High Pressure Pump Fittings

See “Swagelok High Pressure Fitting Installation” on page 29.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 28

MEMBRANEINSTALLATION

The Membrane should be installed horizontally within a reasonable

distance of the Control Panel and the High Pressure Pump. When

selecting a location for the Membrane, be sure to account for the

additional space required for hose fittings.

►►►The Membrane should not be near sources of heat,

such as the generator or refrigeration.

The Membrane requires 2 mounting brackets.These brackets should be padded with rubber and should

be firmly, but not too tightly, clamped around the high pressure vessel.

SEAWATER LIFT PUMP INSTALLATION

The Seawater Lift Pump may be installed on a bulkhead with the

bracket that was included with your watermaker or it may be threaded

directly onto the through-hull fitting. If you are mounting it on a

bulkhead, the pump must be installed a minimum of 2” below the

waterline, as close to the through-hull as possible.

❶Once the pump has been mounted, run the brown wire to the wiring

harness on the panel and run the black wire to the [-] buss.

❷Run a 3/4” hose from the output of the Seawater Lift Pump to the

hose barb on the panel labeled “Seawater Intake.” Secure using

stainless steel hose clamps.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 29

The membrane is shipped with plugs in the end caps where the hose fittings will be installed.

Do not remove these plugs until you are prepared to install the hose. If the plugs are removed

and the membrane is allowed to dry out, you will need to purchase a replacement membrane.

Brine

Product Input

RUNNINGTUBINGANDHOSES

High Pressure Tubing

When planning your installation and high pressure tubing runs, be aware

that the maximum bend radius for the tubing is 12”.

►►►When running high pressure tubing in bilges or near heat sources,

it is recommended that you install 3/4” reinforced hose over the

high pressure tubing.

►►►While running tubing, you may use a heat gun to assist in bending

it. However, be very careful not to overheat an area and crimp the

tubing.

❶Once you’ve identified where the tubing will be run, start by

running the high pressure tubing from the output port on the

High Pressure Pump to the inlet port on the membrane (see

Figure 2). Be sure when cutting the tubing to length to leave

some extra. Install end fittings per the “Swagelok High Pressure

Fitting Installation” instructions.

►►►When cutting the tubing make sure the ends are

square and clean. A plastic tubing cutter with scoring

action, which can be found in most hardware stores, is

recommended. This tool can be used to cut PVC tubing as

well. Do not use a hacksaw.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 30

Your watermaker comes with 25’ of high pressure tubing and 4 Swagelok field-attachable

fittings. If your installation will require more than 25’ of tubing, please contact us.

FIGURE 2

❷Blow the tubing clear to eliminate any chips or dust created by cutting.

❸Once you’ve installed ends fittings on the high pressure tubing, connect tubing to the High Pressure

Pump and Membrane using Teflon tape to seal the threads.

❹Install the high pressure tubing from the Membrane to the port on the Control Panel labeled “H.P.

In.” Install end fittings per the “Swagelok High Pressure Fitting Installation” instructions. Connect

and tighten fittings.

Swagelok High Pressure Fitting Installation

❶Fully insert the tube into the fitting and against the

shoulder; rotate the nut finger-tight. Fig. 1.

High-Pressure Applications and High Safety-Factor

Systems:

Further tighten the nut until the tube will not turn by hand

or move axially in the fitting.

❷Mark the nut at the 6 o’clock position. Fig. 2.

❸While holding the fitting body steady, tighten the nut one

and one quarter turns to the 9 o’clock position. Fig. 3. Note:

For 1/16, 1/8, and 3/16 in.; 2, 3, and 4 mm tube fittings,

tighten the nut three-quarters turn to the 3 o’clock position.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 31

Low Pressure Hose

❶Install a 1/2” hose run from the output of the Pre-filter Housing to the inlet

of the High Pressure Pump, securing with hose clamps.

❷Install a 1/2” hose run from the Brine Dump port on the Control Panel to

the through-hull.

❸Install a second hose run from the second Brine Dump port on the Control

Panel to the pressure relief valve located on the High Pressure Pump.

Product Water Hose

Install a 1/2” hose run from the product port on the Membrane (see Figure 2 on page 28) to the port on

the Control Panel labeled “From R.O.M.” and secure with hose clamps.

Through-Hull (not supplied)

The boat’s designated intake through-hull should be located in an area that will always be in the water

when the boat is used under normal running conditions. This through-hull must not be located near

discharge lines that could introduce foreign materials, such as head or generator exhaust.

• Because it is important that the product water line never become blocked, we discourage

the use of shut-offvalves in the product water tubing.

• We recommend that the product water from your watermaker be connected to its own fill

on your water tank. However, as we understand this is not always possible and because all

installations are different, any solution that will not block the flow of water is acceptable.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 32

Though it may be necessary to “T” into another drain for the Brine discharge, it is preferable

that a new through-hull be installed specifically for the watermaker. This through-hull should

be located above the waterline and in a spot where flow can be verified from on deck.

INITIAL SYSTEM START-UP

Now that you have completed installation, you are almost ready to start the watermaker for the first

time.

❶Starting with the Seawater valve in the “Seawater Intake” position and the Fresh Water valve in the

“To Flush Tank” position, place the hose labeled “To flush tank” into a clean 5 gallon bucket.

❷Start the generator and bring it to operating temperature and RPM.

❸Turn on the Seawater Lift Pump using the switch on the Control Panel labeled “Seawater Lift Pump.”

❹Verify water is flowing out the Brine Dump through-hull.

►►►Take a moment to check for leaks.

❺Turn on the High Pressure Pump using the switch on the Control Panel labeled “H.P. Clutch.”

❻Take a moment to check for leaks again and verify additional flow through the system.

❼Let the system run for 5 minutes and then increase the pressure by turning the Pressure Adjustment

Needle Valve clockwise until it reaches 700 psi.

❽Do another quick check for leaks.

Pre Start-up Checklist

□All hose fittings are secured with hose clamps.

□Through-hulls are open.

□All wiring connections are secure.

□Breaker is on.

□Belt tension on High Pressure Pump is adjusted.

□Verify Pressure Adjustment Needle Valve is turned counterclockwise to reduce pressure.

□Purge Pre-filter of air by pushing and holding the red button on top of the Pre-filter Housing

and turning on the Seawater Lift Pump. Continue to hold the button until air stops being

released; as soon as water is seen, release the button.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 33

Setting The Pressure Relief Valve

❶Slowly increase pressure to 950 psi by turning the Pressure Adjustment Needle Valve on the Control

Panel clockwise.

❷Using an Allen wrench, adjust the pressure relief valve until it opens.You should see water flow into

the clear bypass hose and a slight drop in pressure on the Membrane Pressure Gauge.

❸Reduce pressure by turning the Pressure Adjustment Needle Valve counterclockwise to operating

pressure of 850 psi.

❹Verify output flow to 5 gallon bucket.

❺Let system operate, discarding water for 15 minutes before testing, checking one last time for leaks.

❻At the end of 15 minutes, fill 5 gallon bucket with product water.

WARNING: Be sure that the High Pressure Pump needle valve is turned fully counterclockwise

to the minimum PSI.

Sea Clear Watermakers™ Manual -Version 1.1-G Page 34

This manual suits for next models

1

Table of contents

Popular Water Filtration System manuals by other brands

Ruwac industriesauger

Ruwac industriesauger NA 7-11 instruction manual

Ultrafilter

Ultrafilter Ultra Drain UAD S012 Installation and operating manual

Ceasa

Ceasa MIAWA operating instructions

Water Channel Partners

Water Channel Partners AIF10 Installation, operation, maintenance & repair parts

Pure Company

Pure Company Carbon Filter Water Decanter instructions

Teesa

Teesa TSA0103 owner's manual

GE

GE Merlin Installation and maintenance manual

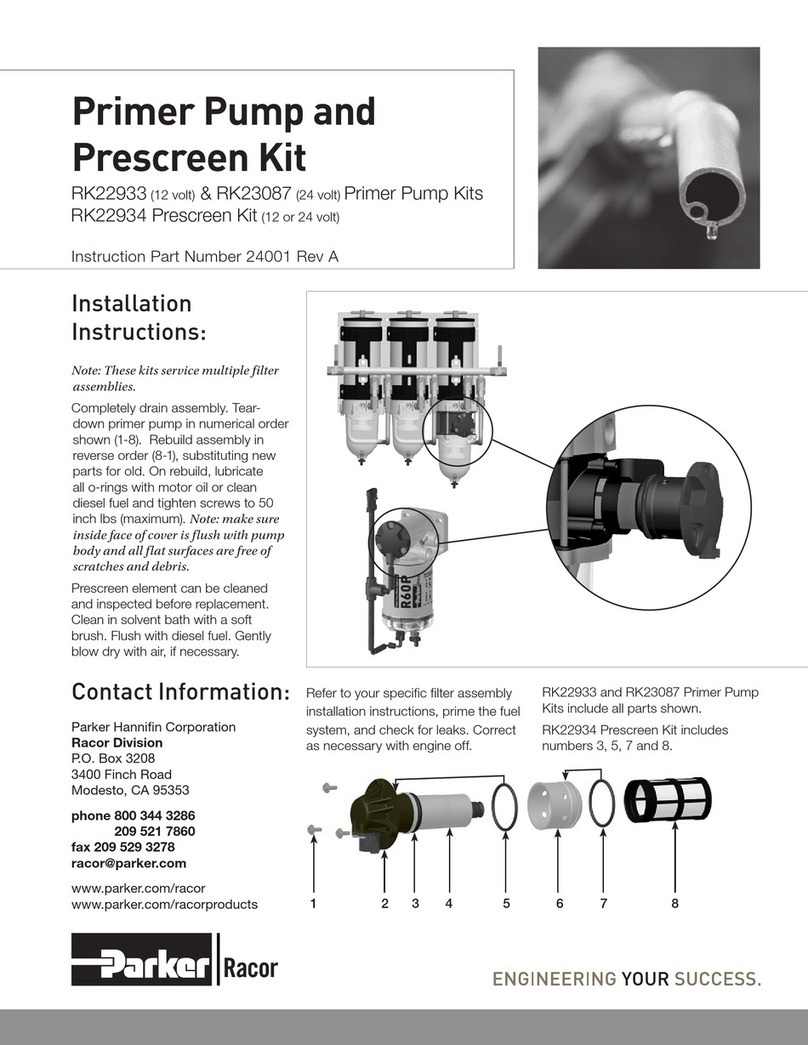

Parker

Parker Racor RK22933 installation instructions

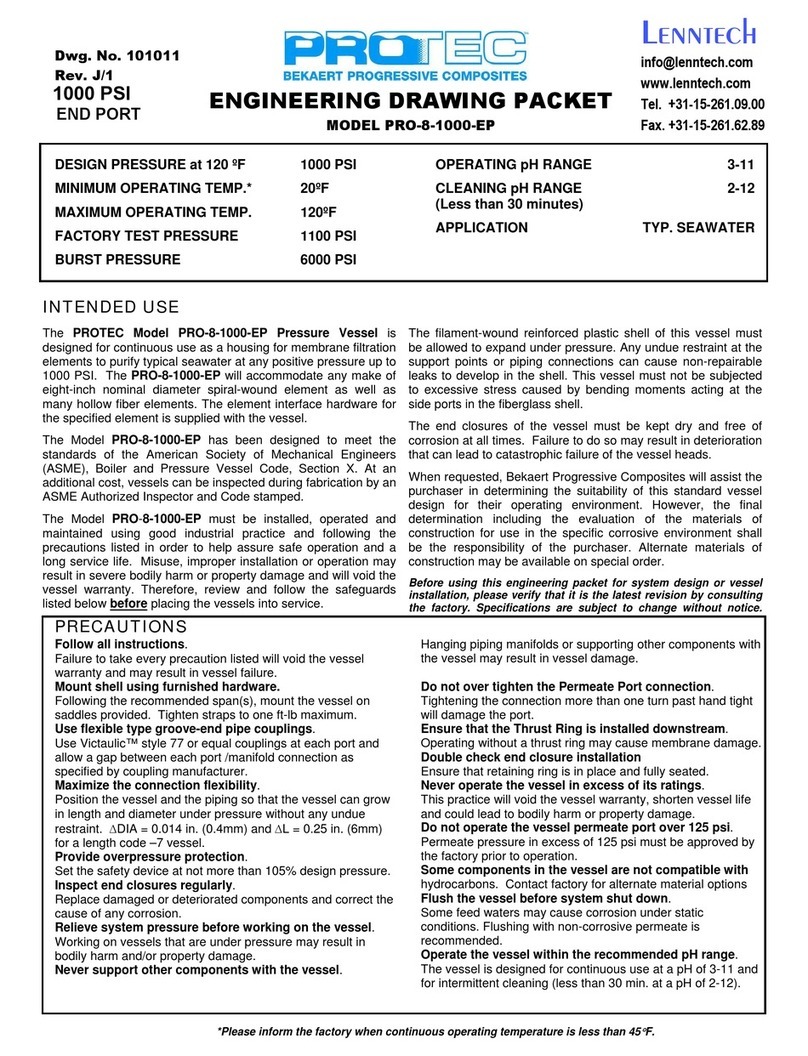

Pro-tec

Pro-tec PRO-8-1000-EP manual

Delta

Delta Ecodrip Series Care and operation instructions manual

Compu Pool Products

Compu Pool Products Compu-Chlor CPA Series owner's manual

Seaside

Seaside C22 quick guide