Water Channel Partners AIF10 Use and care manual

Model AIF10

Automatic Iron and

Hydrogen Sulfide Filter

AUTOMATIC WAT R FILTRATION

with High-Flow 1” Valve

Installation

Operation

Maintenance

Repair Parts

Manufactured and warranted by

Water Channel Partners

1890 Woodlane Drive

Woodbury, MN 55125 7320079 (Rev. S 3/26/20)

2

TABLE OF CO TE TS

Page

Inspect Shipment / Safety Guides . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Specifications & Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Before Starting Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Typical Installation Illustrations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Installation Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-9

Programming the lectronic Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10-11

Customizing Features / Options . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12-14

Adding Potassium Permanganate Powder to Feeder Tank . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Cleaning the Nozzle & Venturi . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16-19

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Schematic . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

xploded View & Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20-23

WATER FILTER WARRA TY

Warrantor: Water Channel Partners, 1890 Woodlane Drive, Woodbury, M 55125

Warrantor guarantees, to the original owner, that:

One Year Full Warranty:

● For a period of one (1) year from the date of purchase, all parts will be free from defects in materials and workman-

ship and will perform their normal functions.

Limited Warranties:

● For a period of ten (10) years from the date of purchase, the fiberglass mineral tank, excluding mineral, will not rust,

corrode, leak, burst, or in any other manner, fail to perform their proper functions.

● For a period of three (3) years from the date of purchase, the electronic control board and valve body will be free of

defects in materials and workmanship and will perform their normal functions.

If, during such respective period, a part proves to be defective, Warrantor will ship a replacement part directly to your

home, without charge.

General Provisions

Damage to any part of this water filter because of misuse, misapplication, neglect, alteration, accident, installation or oper-

ation contrary to our printed instructions, or damage caused by any unusual force of nature such as, but not limited to,

freezing, flood, hurricane, tornado, or earthquake is not covered by this warranty. In all such cases, regular parts and serv-

ice charges will apply.

We assume no warranty liability in connection with this water filter other than specified herein. This warranty is in lieu of all

other warranties, expressed or implied, including warranties of fitness for a particular purpose. We do not authorize any

person or representative to assume for us any other obligations on the sale of this water filter.

Should a defect or malfunction occur, contact your contractor. If you are unable to contact your contractor, return the part,

freight prepaid, directly to the factory at the address below. nclose with the part a full description of the problem, with

your name, full address, date purchased, model and serial numbers, and selling contractor's name and address. We will

repair or replace the part and return it to you at no cost if our repair department determines it to be defective under the

terms of the warranty.

This warranty gives you specific legal rights and you may have other rights which vary from state to state.

This water filter is manufactured by

Water Channel Partners, 1890 Woodlane Drive, Woodbury, MN 55125

Customer Information Telephone No. 1-800-972-0136

Inspect Shipment

The filter is shipped in one carton, including the

potassium permanganate feeder assembly. The filter

is completely assembled at the factory, except as

required at installation. The filter’s mineral tank is

loaded with the proper quantity of manganese green-

sand, gravel and sand.

Thoroughly check the filter system for possible ship-

ping damage and parts loss. Also inspect and note

any damage to the shipping carton.

Remove and discard (or recycle) all packing materials.

To avoid loss of small parts, we suggest you keep the

small parts in the parts bag until you are ready to use

them.

Recommended maximum allowable inlet water

pressure is 80 psi. Use a pressure reducing valve if

necessary. Be sure the addition of a pressure reduc-

ing valve will not reduce the flow to less than the 5

gallons per minute needed for backwash.

The filter works on 24V DC electrical power, supplied

by a direct plug-in power supply (included). Be sure

to use the included power supply, and plug it into a

nominal 120V, 60 Hz household outlet that is in a dry

location only, grounded and properly protected by

an overcurrent device such as circuit breaker or fuse.

This system is not intended to be used for treating

water that is microbiologically unsafe or of unknown

quality without adequate disinfection before or after

the system.

uropean Directive 2002/96/ C requires all

electrical and electronic equipment to be

disposed of according to Waste lectrical

and lectronic quipment (W ) require-

ments. This directive or similar laws are in

place nationally and can vary from region to

region. Please refer to your state and local

laws for proper disposal of this equipment.

Safety Guides

Follow the installation instructions carefully. Failure to

install the filter properly voids the warranty.

Before you begin installation, read this entire manual.

Then obtain all the materials and tools you will need

to make the installation.

Check local plumbing and electrical codes. The

installation must conform to them.

Use only lead-free solder and flux for all sweat-sol-

der connections as required by state and federal

codes.

Use care when handling the filter. Do not turn upside

down, drop, or set on sharp protrusions.

Do not locate the filter where freezing temperatures

occur. Do not attempt to filter water over 120°F.

Freezing, or hot water damage voids the warranty.

Avoid installing in direct sunlight. xcessive sun heat

may cause distortion or other damage to non-metallic

parts.

The filter requires a minimum water flow of 5 gallons

per minute at the inlet for backwash.

3

4

Specifications & Dimensions

Automatic Iron Filter AIF10

Model Code HIF10

Type of Mineral Greensand Plus

Amount of Mineral 1.0 cu. ft.

Amount of Gravel Base 17 lbs.

Amount of Filter Sand 10 lbs.

Inlet Water Pressure Limits (min./max.) 40 - 125 psi

Nominal Mineral Tank Size 10” dia. x 47” tall

Water Temperature Limits (min./max.) 40 - 100 °F

Minimum Inlet Water Flow 7 gal./min.

Service Flow Rate* 2 - 5 gal./min.

Backwash Flow Rate 5 gal./min.

Inlet/Outlet Pipe Size 1”

Maximum Iron Removal 20 ppm

Supply Water Minimum pH 7

Capacity Rating

270 gal. with 10.6 ppm Hydrogen Sulfide (H2S)

620 gal. with 10.4 ppm Ferrous Iron (FeSO4)

1900 gal. with 2.01 ppm Manganese (MnSO4)

*Well pump must be able to provide the minimum flow for 30+ minutes.

14"

OUTLET

INLET

INLET -

OUTLET

3-3/4"

58-1/8" 10-1/2"

49-3/4"

18"

11"

DIA.

FIG. 1

3-3/4”

INL T

OUTL T

INL T -

OUTL T

14”

58-1/8”

49-3/4”

10-1/2”

18”

11”

DIA.

Contaminant Removal

Clear and/or

Red Water Iron Removes up to 15 ppm

Hydrogen Sulfide

(rotten egg smell) Removes up to 2 ppm

Manganese Removes up to 5 ppm

5

Befo e Sta ting Installation

WHERE TO I STALL THE FILTER

= Place the filter as close as possible to the pressure

tank (well system) or water meter (city water).

= Place the filter as close as possible to a floor drain,

or other acceptable drain point (laundry tub, sump,

standpipe, etc.). The drain point must be able to

discharge the backwash flow rates shown on page

3.

= Connect the filter to the main water supply pipe

UPSTR AM OF the water heater. DO NOT RUN

HOT WAT R THROUGH TH FILT R. The tem-

perature of water passing through the filter must be

less than 120°F.

= Keep outside faucets on unfiltered water to con-

serve filtering capacity.

= Do not install the filter in a place where it could

freeze. Damage caused by freezing is not covered

by the warranty.

= Put the filter in a place water damage is least likely

to occur if a leak develops. The manufacturer will

not repair or pay for water damage.

= A 120V, 60 Hz electrical outlet, to plug the included

power supply into, is needed near the filter. Be

sure the electrical outlet and power supply are in an

inside location, to protect from wet weather.

= If installing in an outside location, you must take the

steps necessary to assure the filter, installation

plumbing, wiring, etc., are as well protected from

the elements, contamination, vandalism, etc., as

when installed indoors.

= Keep the filter out of direct sunlight. The sun's heat

may soften and distort plastic parts.

TOOLS, PIPE & FITTI GS,

OTHER MATERIALS YOU WILL EED

= Plastic inlet and outlet fittings included with the filter

allow water flow equivalent to 1 inch nominal pipe.

To maintain full valve flow, 1” pipes to and from the

filter fittings are recommended. Do not reduce the

pipes to less than 3/4” size. Follow local codes.

= Use copper, brass, or galvanized pipe and fittings.

Some codes may also allow CPVC plastic pipe.

= ALWAYS install the included bypass valve, or 3

shut-off valves. Bypass valves let you turn off

water to the filter for repairs if needed, but still have

water available to the house pipes.

= Drain hose, 5/8” inside diameter minimum, with a

garden hose connection on one end, is needed for

the valve drain. See step 5 on page 8.

= If a rigid valve drain is needed, to comply with

plumbing codes, you can buy the parts needed (see

page 6) to connect a 1/2” minimum copper tubing

drain.

= Potassium permanganate is needed for regenera-

tion of the filter mineral. It is available from most

dealers of water conditioning equipment. This filter

uses from 2 to 5 ounces of potassium perman-

ganate each regeneration.

PLA HOW YOU WILL I STALL THE FILTER

You must first decide how to run in and out pipes to

the filter. Look at the house main water pipe at the

point where you will connect the filter. Is the pipe sol-

dered copper, glued plastic, or threaded brass/galva-

nized? What is the pipe size?

Now look at the typical installation illustration on page

6. Use it as a guide when planning your particular

installation. Be sure to direct incoming, unfiltered

water to the filter valve inlet fitting. The valve ports are

marked IN and OUT.

6

Typical Installation Illust ations

FIG. 4

Drain

Fitting

Valve

Drain

Hose

Valve

Drain

Hose

1-1/2”

Air Gap

1-1/2”

Air Gap

1-1/2”

Air Gap

1-1/2” Air Gap

LAU DRY

TUB

SUMP

STA D

PIPE

FLOOR

DRAI

To standpipe, sump, laundry

tub or other suitable drain.

1/2” I.D.

(minimum)

copper tube

Push in for

Bypass Clip

Drain Fitting

CO ECTI G A RIGID VALVE DRAI TUBE

To adapt a copper tube to the filter, buy a compression fitting (garden hose thread to

1/2” I.D. minimum tube and necessary tubing from your local hardware store.

Adaptor, garden hose

thread to compression

Pull out for

filtered water

“Service”

FIG. 3FIG. 2

I STALLATIO USI G 3-VALVE BYPASS

MAIN WAT R PIP

MAIN WAT R PIP

I STALLATIO USI G I CLUDED BYPASS VALVE CROSS-OVER

Use if water supply flows from the left.

Include single or 3-valve bypass.

Filtered

Water OUT

Unfiltered

Water I

Unfiltered Water

to Outside Faucets

120V,

60 Hz

Outlet

FILT R D

WAT R

TO FILT R

INL T

UNFILT R D

WAT R

FROM FILT R

OUTL T

BYPASS

Valve

OUTL T

Valve INL T

Valve

1” NPT

Adaptor (2)

not included

Clip (2)*

O-Ring Seal (2)*

1” NPT Installation

Adaptor (2)*

Valve

I LET

For filtered water S RVIC :

-Open the inlet and outlet

valves

For unfiltered BYPASS:

-Close the inlet and outlet

valves

-Open the bypass valve

* Included with filter - Pipe and

fittings supplied by installer.

1” NPT

Adaptor (2)

not included

1” NPT Installation

Adaptor (2)*

Bypass Valve*

Clip (4)*

O-Ring Seal (2)*

Power

Supply

7

Installation Inst uctions

1. TUR OFF WATER SUPPLY

a. Close the main water supply valve near the well

pump or water meter.

b. Shut off the electric or fuel supply to the water

heater.

c. Open high and low faucets to drain all water from

the house pipes.

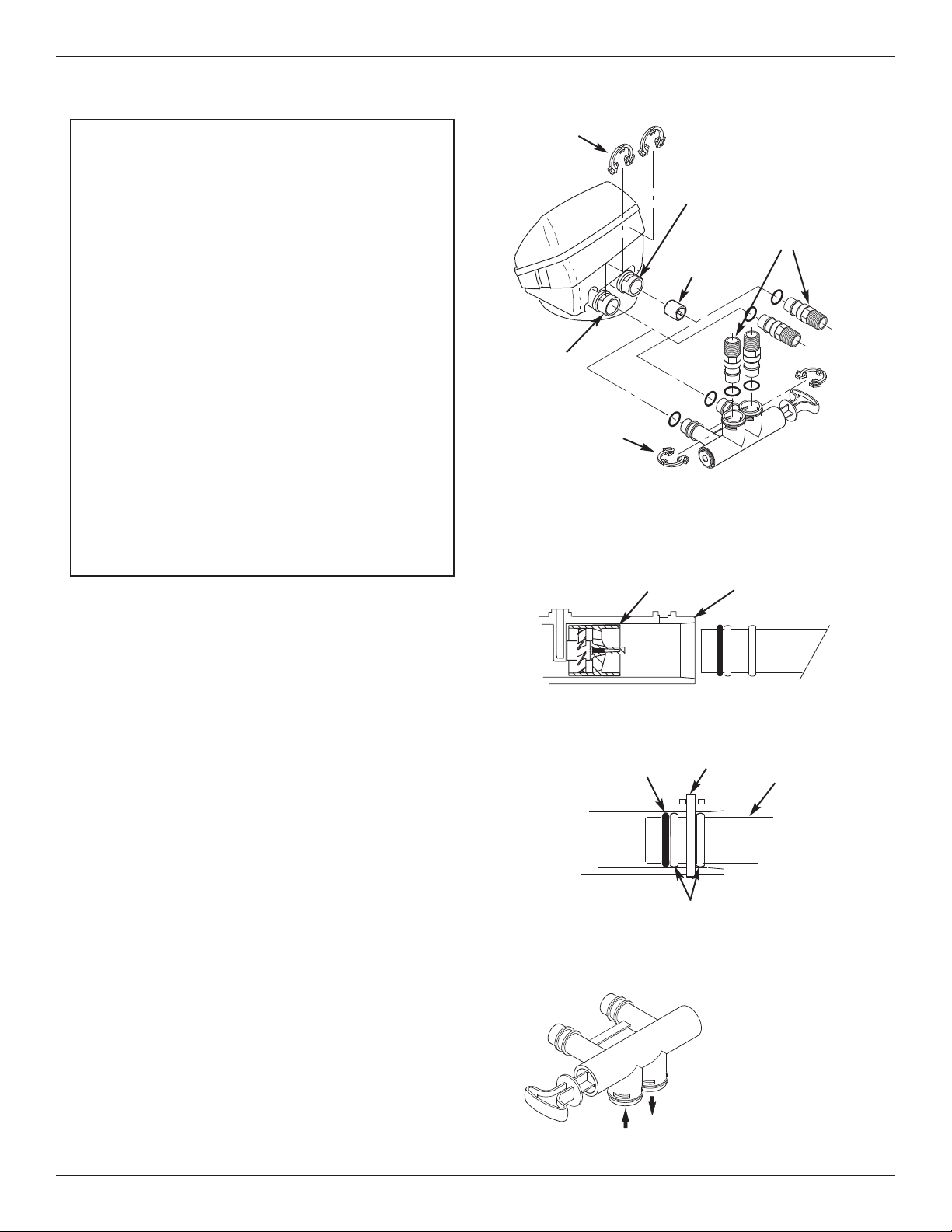

2. I STALL BYPASS VALVE A D/OR

PLASTIC I STALLATIO ADAPTORS

a. If installing a single bypass valve, push the bypass

valve, with lubricated o-ring seals in place, into the

valve inlet and outlet ports (See Figures 2 & 5).

- OR -

b. If installing a 3-valve bypass system, slide plastic

installation adaptors, with lubricated o-ring seals in

place, into the valve inlet and outlet ports (See

Figures 3 & 5).

c. Make sure the turbine support is in place in the

valve outlet, as shown in Figure 6.

d. Snap the two large plastic clips in place on the inlet

and outlet ports, from the top, down (See Figure 7).

Be sure they snap into place. Pull on the bypass

valve, or installation adaptors, to make sure they

are held securely in place.

Turbine

Support

Valve

Outlet

FIG. 6

FIG. 7

O-ring Clip

Cross section of

valve inlet or outlet

Bypass valve or

plastic adaptor

Snap clips into place between

larger diameter rings

FIG. 8

Turn the bypass

valve downward if

connecting to floor

level plumbing

I LET

OUTLET

FIG. 5

I LET

OUTLET

Clip (2)

Bypass

Valve

Clip (2)

Turbine

Support

Plastic installation

adaptors (install in

filter valve or

bypass valve)

IMPORTA T SA ITIZI G PROCEDURES

Care is taken at the factory to keep your water filter

clean and sanitary. Materials used to make the fil-

ter will not infect or contaminate your water sup-

ply, and will not cause bacteria to form or grow.

However, during shipping, storage, installing and

operating, bacteria could get into the filter or

media. For this reason, sanitizing as follows is

suggested* when installing.

a. Pour about 1 ounce of the following disinfectant

into the valve inlet fitting:

=Calcium hypochlorite, available in granular

or tablet form, under trade names such as

Perchloron or HTH - OR -

=Common 5.25% household bleach (Clorox

or other brands).

b. Complete the sanitizing procedures in steps 7

and 10, below.

*OTE: Sanitizing is recommended by the Water Quality

Association for disinfecting. On some water

supplies, they suggest periodic sanitizing.

8

Installation Inst uctions

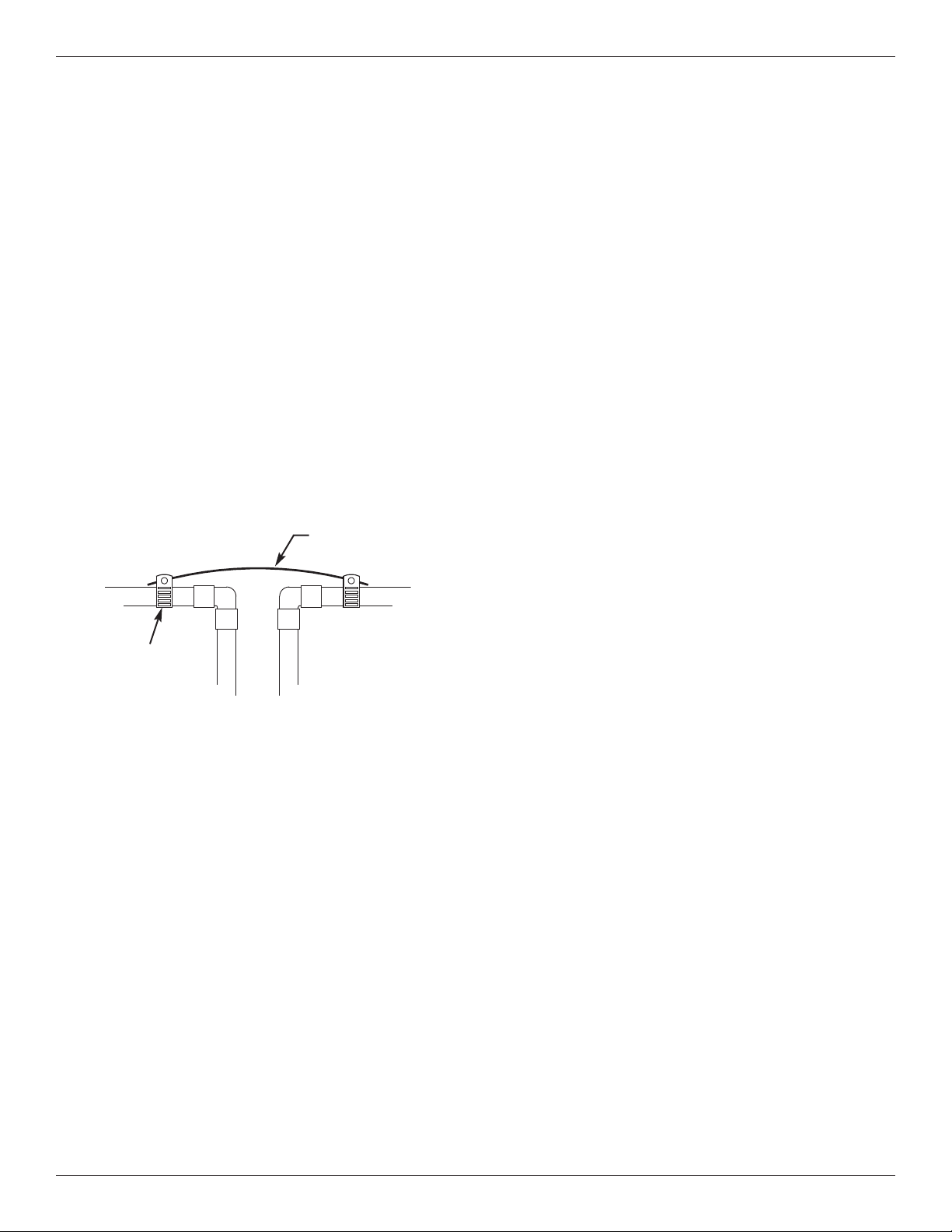

4. COLD WATER PIPE GROU DI G

CAUTIO : The house cold water pipe (metal only) is

often used as a ground for the house elec-

trical system, The 3-valve bypass type of

installation, shown in Figure 3, will maintain

ground continuity. If you use a plastic

bypass valve at the unit, continuity is bro-

ken. To restore the ground, do the follow-

ing:

a. Install a #4 copper wire across the removed section

of main water pipe, securely clamping it at both

ends (See Figure 9) - parts not included.

OTE: Check local plumbing and electrical codes for

proper installation of grounding. The installa-

tion must conform to them. In Massachusetts,

plumbing codes of Massachusetts shall be

conformed to. Consult with your licensed

plumber.

5. I STALL VALVE DRAI HOSE

a. Take a length of 5/8” inside diameter garden hose

and attach to the valve drain fitting (See Figure 4 on

page 6).

b. Locate the other end of the hose at a suitable drain

point (floor drain, sump, laundry tub, etc.). Check

and comply with local codes. Refer to Figure 4 on

page 6 if codes require a rigid pipe drain run.

IMPORTA T: Use high quality, thick wall hose that will

not easily kink or collapse. The filter will

not backwash properly if water cannot

exit this hose during recharges.

c. Tie or wire the hose in place at the drain point.

Water pressure will cause it to whip during the back-

wash and fast rinse cycles of recharge. Also pro-

vide an air gap of at least 1-1/2” between the end of

the hose and the drain point. An air gap prevents

possible siphoning of sewer water, into the filter, if

the sewer should back up.

d. If raising the drain hose overhead is required to get

to the drain point, do not raise higher than 8 feet

above the floor. levating the hose may cause a

back pressure that could reduce backwash flow and

proper mineral bed cleaning.

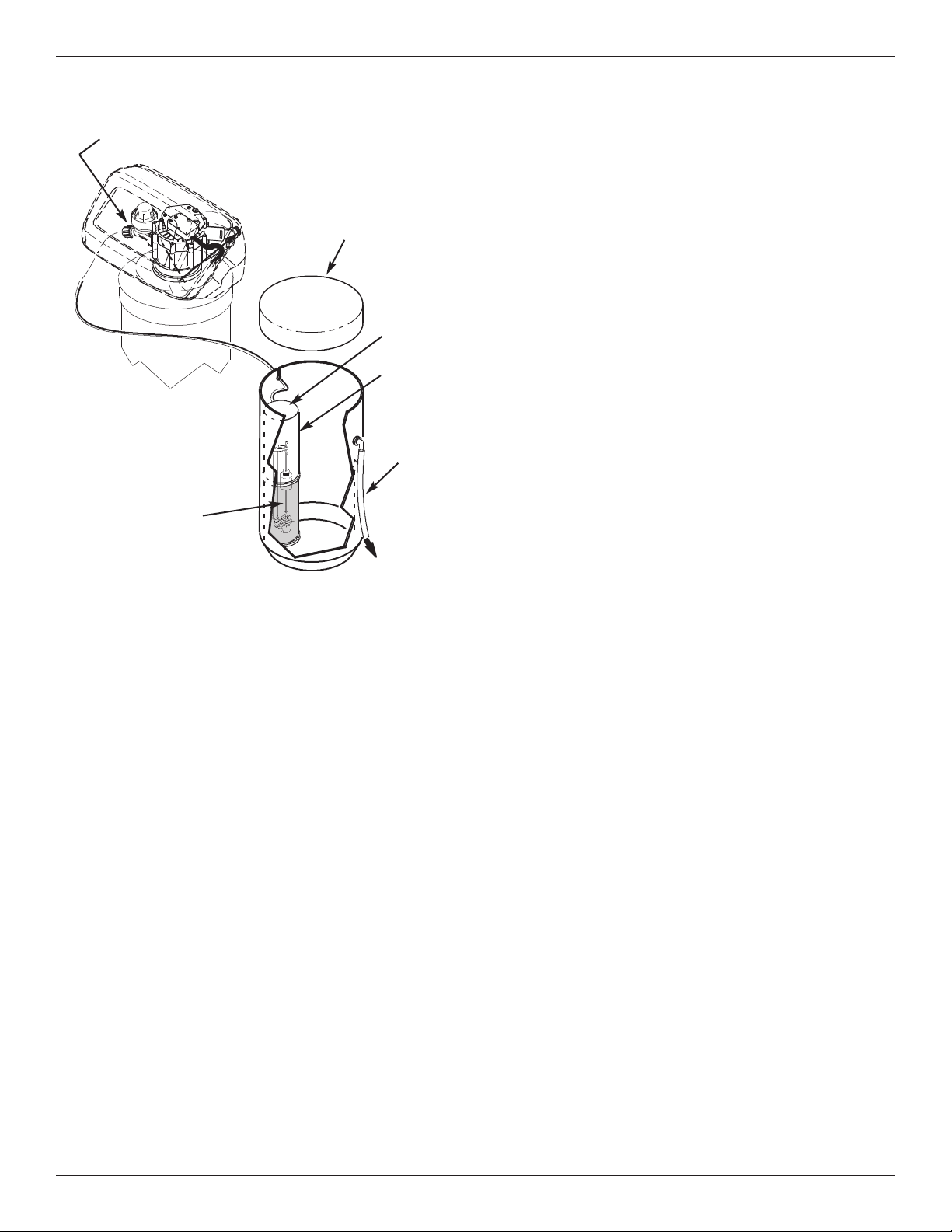

6. CO ECT THE POTASSIUM

PERMA GA ATE FEEDER

a. Run the 5/16” tubing from the brine valve to the noz-

zle assembly on the filter (See Figure 10). Use

slots in the tank and both brinewells to hold tubing

in place.

b. Attach a length of 3/8” or 7/16” I.D. drain hose (7

feet included) to the hose fitting on the tank side-

wall. Place the outlet of the hose over the floor

drain. This is a gravity drain, and must flow down-

ward. Provide an air gap as you did with the valve

drain hose.

CAUTIO : Do not omit this hose. If the feeder tank

should overfill, the drain hose carries

excess potassium permanganate solution

to the drain. This solution will deeply stain

anything it contacts.

c. With brinewell covers in place, pour the included 2

lbs. of potassium permanganate powder into the

feeder tank, then about 1/2 gallon of water. Install

the tank cover.

3. COMPLETE PLUMBI G TO A D FROM

THE FILTER

Using the “Typical Installation Illustrations” on page 6

as a guide, observe all of the following cautions while

you connect inlet and outlet plumbing:

= Be sure incoming, unfiltered water is directed to

the valve I LET port.

= Be sure to install bypass valve(s).

= If making a soldered copper installation, do all

sweat soldering before connecting pipes to the filter

fittings. Torch heat will damage plastic parts.

= Use pipe joint compound on all external pipe

threads.

= When turning threaded pipe fittings onto plastic fit-

tings, use care not to cross-thread.

= Support inlet and outlet plumbing in some manner

(use pipe hangers) to keep the weight off of the

valve fittings.

FIG. 9

Ground Wire

Clamp (2)

9

Installation Inst uctions

FIG. 10

Brine Valve

(inside brinewell)

Overflow

Drain

Hose

Brinewell

Cover

Cover

TO FLOOR

DRAI

Brinewell

Nozzle Assembly

7. FLUSH PIPES, CIRCULATE DISI FEC-

TA T, EXPEL AIR FROM FILTER, A D

TEST YOUR I STALLATIO FOR LEAKS

CAUTIO : To avoid water or air pressure damage to

filter inner parts, be sure to do the following

steps exactly as listed:

a. Fully open two cold, filtered water faucets nearby

the filter.

b. Place bypass valve(s) into “bypass” position. On a

single valve, slide the stem inward to BYPASS (See

Fig. 4 on page 6). On a 3 valve system, close the

inlet and outlet valves, and open the bypass valve

(See Fig. 3 on page 6).

c. Fully open the house main water pipe shutoff valve.

Observe a steady flow from both opened faucets.

d. Place bypass valve(s) into “service”, XACTLY as

follows. K P FILT R D WAT R FAUC TS OP N.

=Single Bypass Valve: SLOWLY, pull the valve

stem outward to ”service” position, pausing sev-

eral times to allow the filter to pressurize slowly.

=3 Valve Bypass: Fully close the bypass valve

and open the outlet valve. SLOWLY, open the

inlet valve, pausing several times to allow the fil-

ter to pressurize slowly. The sanitizing bleach

also circulates through the filter.

e. After about three minutes, open a HOT water faucet

for one minute, or until all air is expelled, then close.

f. Close both cold water faucets.

g. Check your plumbing work for leaks and, if any are

found, fix right away. Be sure to observe previous

caution notes.

h. Turn on the gas or electric supply to the water

heater. Light the pilot, if applicable.

8. CO ECT TO ELECTRICAL POWER

The filter works on low voltage electric power. The

included power supply changes standard 120V AC

house power to 24V DC. Plug the power supply into a

120V, 60 Hz electrical outlet. Be sure the outlet is

always “live” so it can not be switched off by mistake.

9. PROGRAM THE TIMER

See pages 10 & 11 for instructions to program the timer.

10. CLEA I G / SA ITIZI G PROCEDURE

a. About 20 minutes after completing step 6, use the

R CHARG NOW feature, on the timer, to start an

immediate recharge. Any remaining sanitizing

bleach is drawn through the filter and discharged to

the drain. The backwash and following fast rinse is

over in about 40 minutes.

b. After the recharge has completed, fully open a cold

water faucet downstream from the filter and allow

50 gallons of water to pass through the filter. This

should take 20 minutes. Close the faucet.

c. Cleaning/sanitizing process is complete.

10

P og amming the Elect onic Cont olle

CO TROLLER SETTI GS REQUIRED

upon installation, and after an extended power outage.

When the power supply is plugged into the electrical

outlet, a model code (HIF10) and a test number

(example: J3.8), are briefly shown in the display.

Then the words “PR S NT TIM ” appear and 12:00

PM begins to flash.

A. SET PRESE T TIME OF DAY

If the words “PR S NT TIM " do not show in the dis-

play, press the S L CT button several times until

they do.

FIG. 12

FIG. 13

1. Press the rUP or sDOWN buttons to set the

present time. Up moves the display ahead; down

sets the time back. Be sure AM or PM is correct.

OTE: Press buttons and quickly release to slowly

advance the display. Hold the buttons down

for fast advance.

2. When the correct time is displayed, press the

S L CT button, and the display will change to

show the next setup screen.

FIG. 11

UP button

DOWN

button

Display

TOUCH/HOLD

button S L CT

button

11

P og amming the Elect onic Cont olle

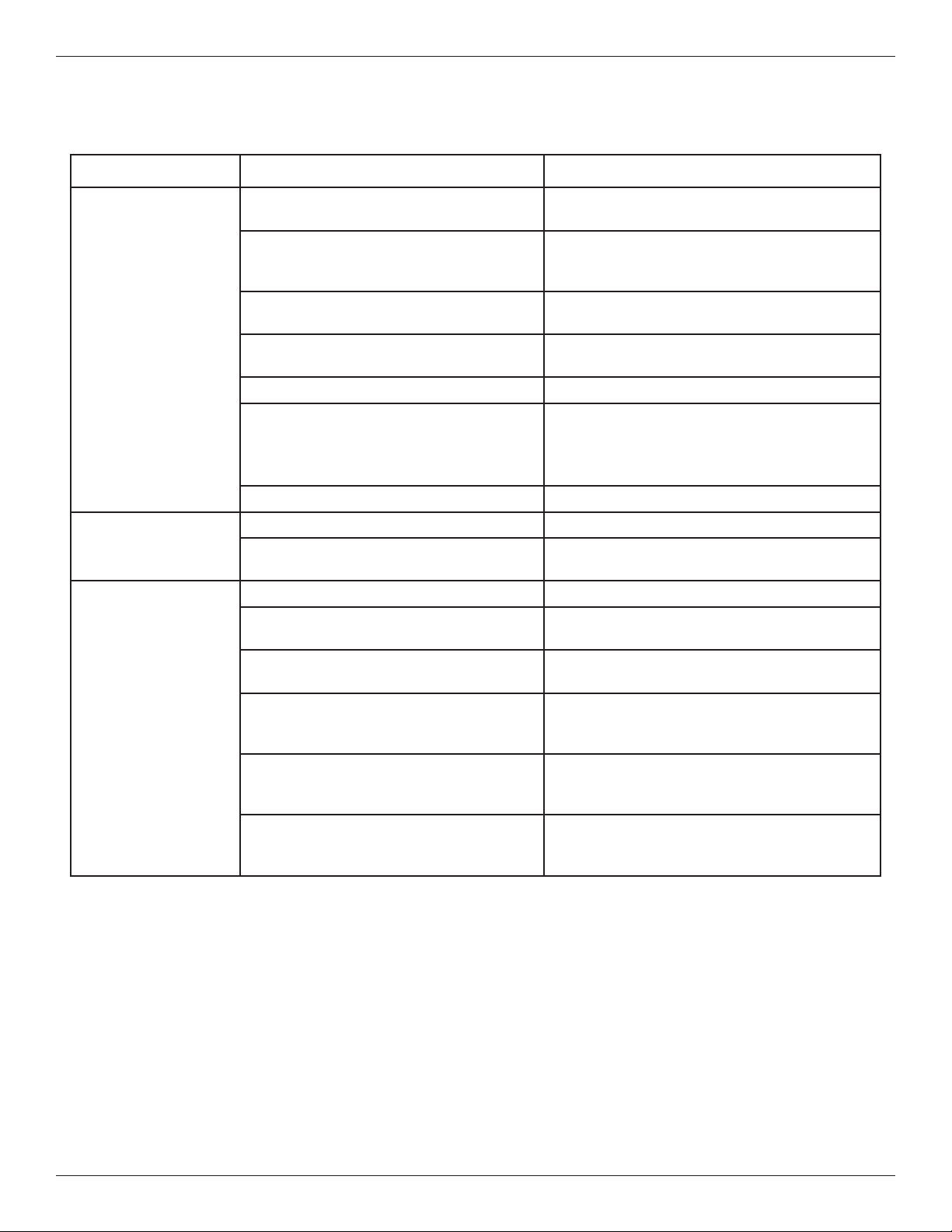

B. SET DAYS BETWEE RECHARGES

1. If you completed the previous step, the word

“R CHARG " should show in the display (See

Figure 14). Otherwise, press the S L CT button

several times until it does.

2. The default setting is 3 days. This means that the

filter will recharge every 3 days. See the chart

below to determine the frequency of recharges. To

change the number of days between recharges,

use the rUP or sDOWN buttons to adjust from

1 to 99 days.

3. When the desired number of days is displayed,

press the S L CT button, and the display will

change to show the next setup screen.

FIG. 14

OTE: If there is an iron bleed or the water supply has high turbidity (sand, silt, sedi-

ments, etc.), set the filter to regenerate more often than the table above shows.

OTE: In some extreme iron conditions, a fill setting of 2 minutes (3 ounces of

potassium permanganate used), or 3 minutes (4 oz.) could be needed

for each regeneration.

OTE: If hydrogen sulfide is present, decrease the number of days between

recharges by one or more (to a minimum setting of 1 day between

recharges) until contaminant is removed.

C. SET RECHARGE START TIME

1. If you completed the previous step, the words

“R CHARG TIM " should show in the display

(See Figure 15). Otherwise, press the S L CT

button several times until they do.

umber

of

People

Iron (parts per million)

2 4 6 8 10 15 20

17 days 6 days 5 days 4 days 3 days 3 days 2 days

26 days 5 days 3 days 3 days 2 days 1 day 1 day

35 days 3 days 2 days 2 days 1 day 1 day 1 day

44 days 3 days 2 days 1 day 1 day 1 day 1 day

54 days 2 days 1 day 1 day 1 day 1 day 1 day

63 days 2 days 1 day 1 day 1 day 1 day 1 day

73 days 1 day 1 day 1 day 1 day 1 day 1 day

82 days 1 day 1 day 1 day 1 day 1 day 1 day

2. The filter’s default recharge start time is 12:00 AM.

This is normally a time of day when water is not

being used in the household. If you have a water

softener or another filter installed, the recharge

start times should be offset to assure adequate

water flow and pressure. For example, if the water

softener is set to begin recharge at 2:00 AM, set

the filter to start recharge at 12:00 AM, or 4:00 AM.

Use the rUP or sDOWN buttons to adjust the

FIG. 15

SUGGESTED DAYS BETWEE RECHARGES

recharge start time.

3. When the desired recharge

time is displayed, press

the S L CT button, and

the display will change to

show the normal run (time

of day) display.

12

Cont olle Featu es / Options

FIG. 16

RECHARGE OW

For times when you expect to use more water than

usual, it may be desirable to perform a manually initi-

ated recharge. To manually start a recharge cycle,

press and hold the TOUCH/HOLD button for a few

seconds, until “R CHARG NOW” flashes in the dis-

play. The filter begins an immediate backwash.

Once started, you cannot cancel this recharge. Avoid

using hot water during this time, as the water heater

will refill with unfiltered water.

FIG. 17

VACATIO CO TROL

1. Before going on vacation, or other long absence,

press (but do not hold) the TOUCH/HOLD button, so

that “VAC” begins to flash in the display. The timer

continues to keep time, but recharges will not occur,

saving water.

2. When you return, press the TOUCH/HOLD button

again. This cancels the flashing “VAC” and returns

the filter to normal service. You must remember to do

this, or the filter will not recharge.

FIG. 18

ORMAL OPERATIO

During normal operation, the present time of day

shows in the display.

POWER OUTAGE MEMORY

If electrical power to the filter’s control is lost, internal

memory will maintain most settings such as the days

between recharge and recharge time. However,

unless the power outage was very brief, the clock’s

present time will need to be reset. During a power

outage, the display will be blank and the filter will not

recharge. When electrical power is restored:

1. Check the display.

2a. If the present time is displayed steadily (not flash-

ing), the controller did not lose time and you do

not need to reset the clock.

2b. If a time is flashing in the display, then the clock

needs to be reset to the correct present time.

See “Set Time of Day” on page 10. The flashing

display is to remind you to reset the clock. If you

do not reset the clock, then recharges will most

likely occur at the wrong time of day.

OTE: If the filter was recharging when power was

lost, it will finish the cycle when power returns.

13

Cont olle Featu es / Options

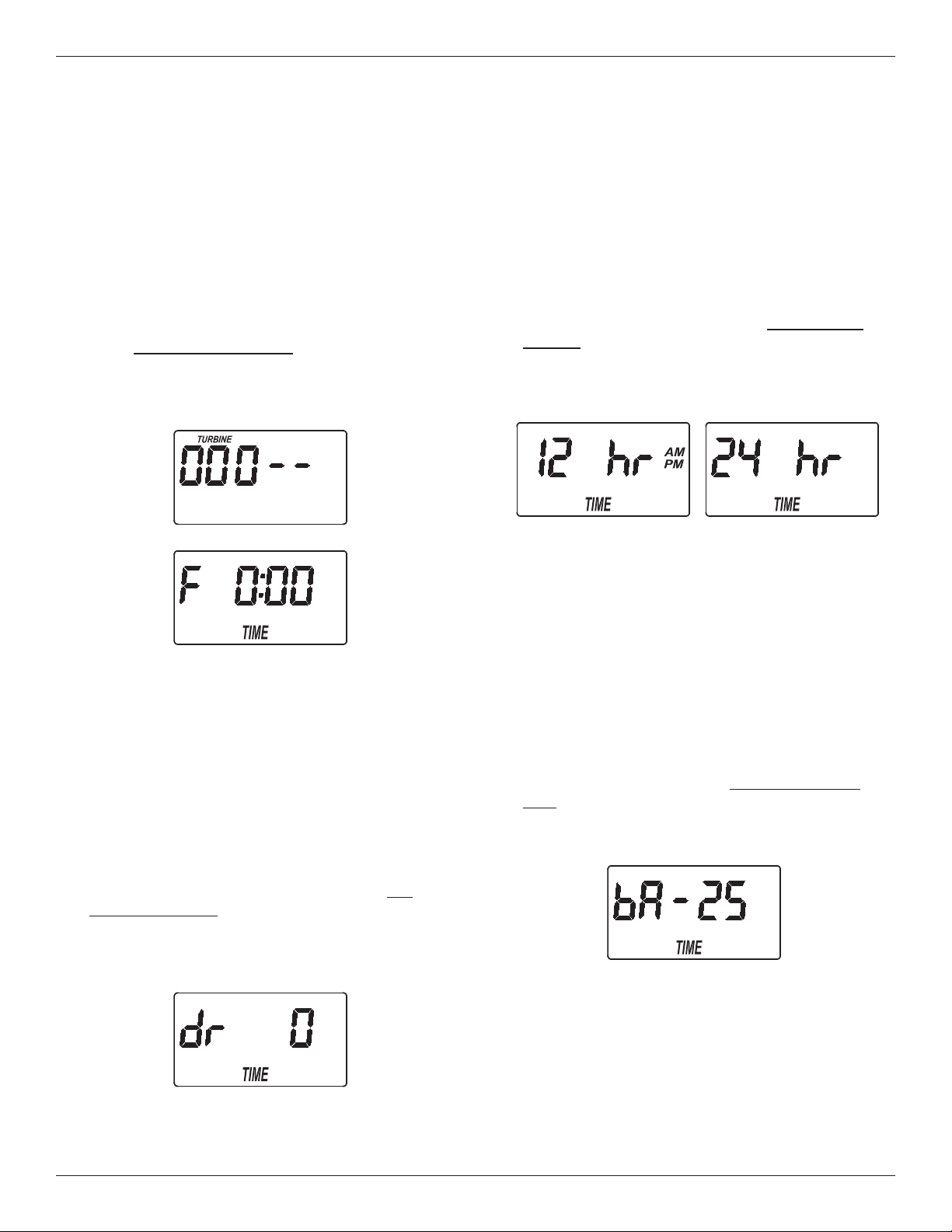

RECHARGE CYCLE TIME ADJUSTME TS

The default durations for fill (0 minutes), solution draw

/ rinse (0 minutes), backwash (25 minutes), and fast

rinse ( 5 minutes), are factory set for maximum filter

performance. Use the following procedure to check

for correct cycle times, or to change if desired.

However, only trained technicians should change the

time settings.

A. ADJUSTABLE FILL TIME

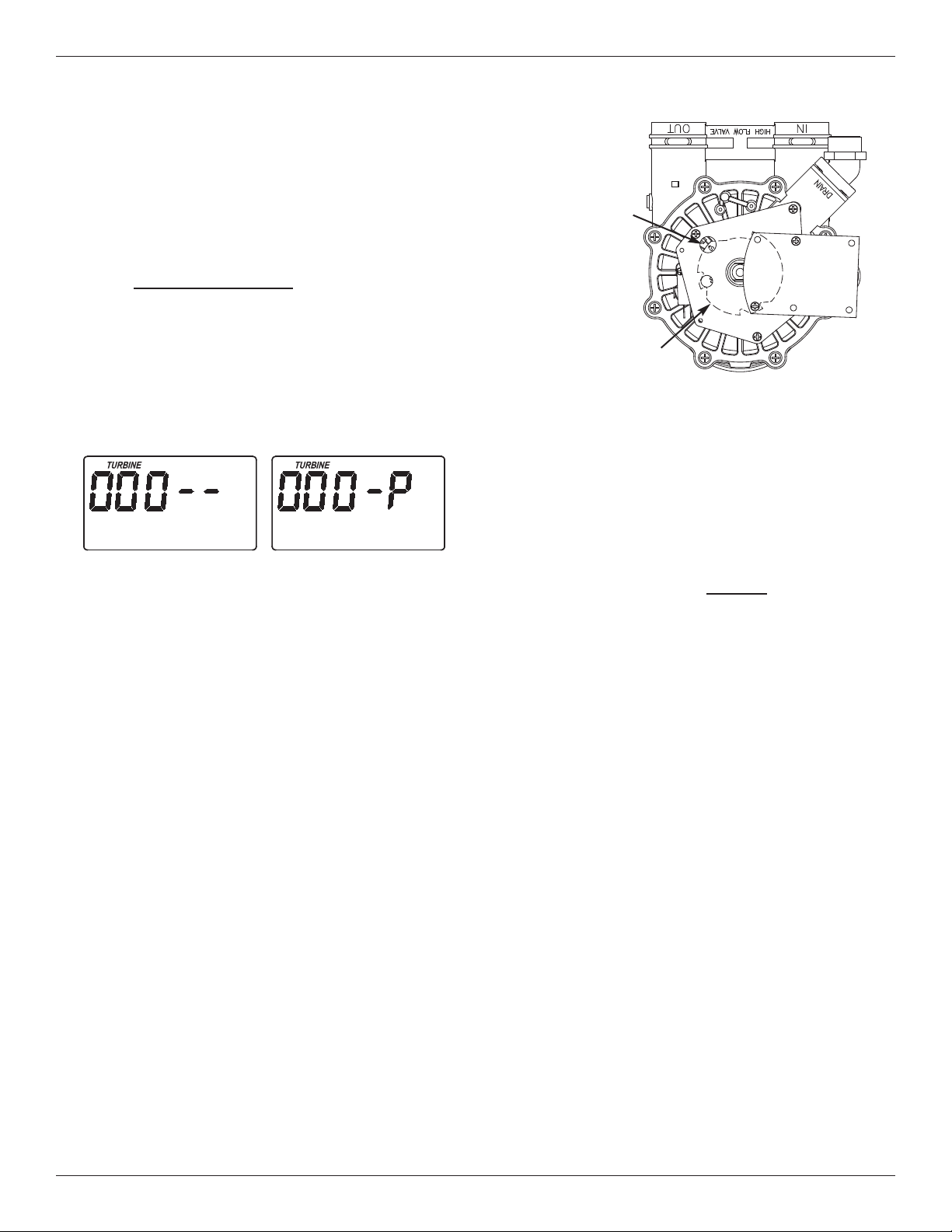

1. Press and hold for 3 seconds the S L CT button,

until the display shows “000 - -“ (See Figure 19),

then press the S L CT button again to display the

fill time adjust screen (See Figure 20).

FIG. 19

2. Use the rUP or sDOWN buttons to adjust fill

time from 0:00 minutes to 99:59 minutes.

3. When the desired fill time is displayed, press the

S L CT button, and the display will change to

show the next cycle time adjust screen.

B. ADJUSTABLE SOLUTIO DRAW /

RI SE TIME

1. If you completed the previous step, the solution

draw / rinse time adjust screen should show in the

display (See Figure 21). Otherwise, press and

hold for 3 seconds the S L CT button, until the

display shows “000 - -“, then press the S L CT

button twice to display the solution draw / rinse

time adjust screen.

FIG. 21

2. Use the rUP or sDOWN buttons to adjust solu-

tion draw / rinse time from 0 to 255 minutes.

3. When the desired draw time is displayed, press the

S L CT button, and the display will change to

show the 12 / 24 hour clock setting screen.

C. 12 OR 24 HOUR CLOCK

1. If you completed the previous step, the 12 / 24 hour

clock setting screen should show in the display

(See Figure 22). Otherwise, press and hold for 3

seconds the S L CT button, until the display

shows “000 - -“, then press the S L CT button

three times to display the 12 / 24 hour clock setting

screen.

2. All time displays are shown in 12 hour (AM/PM)

format at the default setting. If 24 hour time format

is de sired, set to “24 hr” by pressing the rUP

button.

3. Press the S L CT button, and the display will

change to show the next cycle time adjust screen.

D. ADJUSTABLE BACKWASH TIME

1. If you completed the previous step, the backwash

time adjust screen should show in the display (See

Figure 23). Otherwise, press and hold for 3 sec-

onds the S L CT button, until the display shows

“000 - -“, then press the S L CT button four times

to display the backwash time adjust screen.

2. Use the rUP or sDOWN buttons to adjust

backwash time from 0 to 99 minutes.

3. When the desired backwash time is displayed,

press the S L CT button, and the display will

change to show the next cycle time adjust screen.

continued on next page

FIG. 23

FIG. 20

FIG. 22

14

continued from previous page

E. ADJUSTABLE FAST RI SE TIME

1. If you completed the previous step, the fast rinse

time adjust screen should show in the display (See

Figure 24). Otherwise, press and hold for 3 sec-

onds the S L CT button, until the display shows

“000 - -“, then press the S L CT button five times

to display the fast rinse time adjust screen.

Cont olle Featu es / Options

1. Press and hold the S L CT button until “000 - -”

shows in the display (See Figure 25).

3. Use the rUP or sDOWN buttons to display the

desired selection, then press the S L CT button.

If you selected anything other than CF, the display

will return to the normal run (time of day) screen.

If setting to CF (Chemical Feeder), there will be

two additional settings to make for operating the

chemical feeder in Steps 4 and 5, below.

2. Use the rUP or sDOWN buttons to adjust fast

rinse time from 0 to 99 minutes.

3. When the desired fast rinse time is displayed,

press the S L CT button. Press the S L CT but-

ton several times to advance through the remaining

screens and return to the normal run (time of day)

display.

F. AUXILIARY OUTPUT CO TROL

The electronic controller’s auxiliary output may be

used to operate various types of external equipment,

such as a chlorine generator or chemical feeder. It

provides a 24V DC, up to 500 mA, current from termi-

nal J4 on the electronic control board (see Schematic

on page 17). The table below explains the choices

available for when the auxiliary output will be on dur-

ing various portions of the recharge cycle.

FIG. 24

FIG. 26

FIG. 27

FIG. 28

FIG. 25

2. Press the S L CT button six times, until “Ctrl"

flashes in the display (See Figure 26).

*A turbine and turbine cable must be added to the system if auxiliary output selections “FS” or “CF” are to be used.

The default is OFF. If you wish to change to one of

the other selections shown in the table:

4. CHEMICAL FEEDER TRIP VOLUME: If you have

set the auxiliary output control to CF (Chemical

Feeder), you will need to set the volume of water

which must flow past the turbine* before the auxil-

iary output is turned on. With the alternating

screens in Fig. 27 shown, use the rUP or

sDOWN buttons to set the trip volume, in gal-

lons. Then press the S L CT button to display the

screen shown in Fig. 28.

5. CHEMICAL FEEDER TIME: Use the rUP or

sDOWN buttons to set the length of time, in

seconds, that the auxiliary output will be turned on.

Then press the S L CT button to accept and

return to the normal run (time of day) screen.

SELEC-

TIO AME AUXILIARY OUTPUT

FU CTIO

OFF Off Remains off indefinitely.

BP Bypass On during the entire recharge.

CL Chlorine On during the brine draw portion

of the recharge.

FS Flow

Switch

On when water is flowing past

the turbine*. It will shut off 8

seconds after water flow stops.

CF Chemical

Feeder

After the set volume of water

has flowed past the turbine*,

turns on for the time set (see

Steps 4 & 5, below, to set vol-

ume and time).

FR Fast

Rinse

On during the fast rinse por-

tion of the recharge.

15

Gene al Filte Maintenance

ADDI G POTASSIUM PERMA GA ATE

POWDER TO FEEDER TA K

It is very important to always have some potassium

permanganate powder in the feeder tank. If the filter

goes too long without a regeneration with potassium

permanganate, the filtering mineral will lose its man-

ganese coating. Replacing the filter mineral bed can

be costly. Be sure to check the feeder tank every 2-4

weeks, and stir the potassium permanganate powder

to keep it from solidifying. Refill it with powder if less

than an inch remains. After filling, check the tank

overflow drain hose to be sure it is over the floor drain

(see step 6, page 8).

HOW LO G DOES THE POTASSIUM PERMA -

GA ATE LAST?

Using 2 ounces of powder each regeneration (at 1

minute fill setting), 6 pounds of potassium perman-

ganate powder will last for about 48 regenerations.

Divide 48 by the number of regenerations needed

each week. The answer is the approximate number

of weeks the potassium permanganate should last.

The 2 minute fill setting uses 3 ounces of powder,

and 3 minutes uses 4 ounces.

CLEA I G THE OZZLE & VE TURI

A clean nozzle & venturi (Fig. 29) is needed for the fil-

ter to work properly. The nozzle & venturi creates the

suction to move potassium permanganate solution

from the feeder tank to the mineral tank during regen-

eration. It will not work if it becomes plugged with

sand, silt, dirt, etc. The filter mineral will not be prop-

erly cleaned, and oxidizing capacity restored.

To get access to the nozzle & venturi, remove the fil-

ter’s top cover. Make sure the filter is in “service”

cycle (no water pressure at nozzle and venturi).

Then, while holding the nozzle & venturi housing with

one hand, unscrew the cap. Lift out the screen sup-

port and screen, then the nozzle and venturi. Wash

and rinse the parts in warm water until clean. If need-

ed, use a small brush to remove iron or dirt. Also

check and clean the gasket.

Carefully put all parts back in place in the correct

order. Be sure holes in gasket align with holes in the

housing. Lubricate the o-ring seal with silicone

grease and put in place. Install and tighten the cap,

BY HAND ONLY. DO NOT OV R-TIGHT N AND

BR AK TH CAP OR HOUSING.

UMBER OF FULL WEEKS THAT 6 LBS. OF

POTASSIUM PERMA GA ATE POWDER LASTS

umber of Regenerations

Each Week

Fill Cycle Minutes

123

148 32 24

224 16 12

316 10 8

412 8 6

5964

6854

7643

Note: The refill container has 6 pounds of potassium

permanganate powder.

PROTECT THE FILTER FROM FREEZI G

If the filter is installed where it could freeze (summer

cabin, lake home, etc.), you must drain all water from

it to prevent possible freeze damage.

FIG. 29

Screen

Support

Cap

O-Ring Seal

IMPORTA T: Be sure the

small holes in the gasket

are centered directly over

the small holes in the

nozzle & venturi housing.

Screen

Nozzle &

Venturi

Gasket

Nozzle & Venturi

Housing

*Flow Plug

*Install with numbered side

up and concave side down.

16

T oubleshooting Guide

PROBLEM CAUSE CORRECTIO

Filter will not regen-

erate

Manual plumbing bypass valve(s) in

bypass position.

Refer to figures 3 and 4 on page 6, and posi-

tion for filtered water ‘‘service’’.

Power supply unplugged at wall outlet,

fuse blown/circuit breaker popped, circuit

switched off.

Check for loss of power and correct as need-

ed. Reset the timer and use the R CHARG

NOW feature as described on page 12.

Timer set for vacation (VAC). Press the Touch/Hold button once to return

the filter to service, see page 12.

Timer not programmed for regenerations,

or time too short.

See pages 11 or 13-14 to set.

rror code shows in timer display. See next page.

Backwash flow control, drain hose

restricted or plugged, backwash flow less

than 5 gpm.

Check drain hose. Remove drain elbow on

filter valve to check flow control. See page 22

to check for correct assembly and orientation.

Backwash flow should be 5 gpm or higher.

Nozzle assembly dirty. Follow instructions on page 15 to clean.

Low water pressure

at house faucets

Well pump pressure switch set too low. Adjust to a minimum of 20 psi.

More frequent regeneration needed to

keep filter mineral clean.

See page 11 to set days between recharges.

Filtered water con-

tains iron, sediment,

dirt, etc.

See all conditions above.

Too infrequent regenerations pro-

grammed, or fill time setting too short.

See page 11 to set days between recharges,

see page 13 to adjust fill time.

Feeder tank out of potassium perman-

ganate powder.

Follow instructions on page 15 to refill.

Hot water used while filter regenerating. The water heater will refill with unfiltered

bypass water. See page 11 to set recharge

start time.

Possible increase in supply water iron

content (common with some well water

supplies).

Obtain a new water analysis and adjust the

regeneration schedule and/or fill cycle time.

Leaking faucet or toilet valve. A small leak can waste hundreds of gallons of

water in a few days time. Fix all plumbing

leaks and always fully close faucets.

CHECKLIST BEFORE YOU CALL FOR SERVICE

17

T oubleshooting

AUTOMATIC ELECTRO IC DIAG OSTICS

This filter has a self-diagnostic function for the electri-

cal system. The computer monitors electronic com-

ponents and circuits for correct operation. If a mal-

function occurs, an error code appears in the display.

The chart above shows the error codes that could

appear, and the possible malfunctions for each code.

While an error code appears in the display, all buttons

are inoperable except the S L CT button. S L CT

remains operational so the service person can per-

form the Manual Initiated lectronic Diagnostics, see

below, to further isolate the problem.

FIG. 31

Code Possible Problems

rr01 Motor, Valve Position Switch

rr03 Motor, Valve Position Switch, Wire Harness

rr04 Valve Position Switch

rr05 lectronic Control Board (PWA)

TO REMOVE A ERROR CODE:

1. Unplug the power supply.

2. Correct the problem.

3. Plug the power supply back in.

4. Wait for at least 8 minutes while the timer operates

the valve through an entire cycle. The error code

will return if the problem was not corrected.

RESETTI G TO FACTORY DEFAULTS

To reset the electronic controller to its factory default

for all settings (time, days between recharges, etc.):

1. Press the S L CT button and hold it until the dis-

play changes twice to show “COD ” and the flash-

ing model code.

2. Press the rUP button (a few times, if necessary)

to display a flashing “SoS”.

3. Press the S L CT button, and the electronic con-

troller will restart.

4. Set the present time, days between recharges,

etc., as described on pages 10 & 11.

FIG. 32

WIRI G SCHEMATIC

FIG. 30

NO

Valve

Motor

Position

Switch

NC

Power Supply

Back of lectronic Controller

(PWA)

Power

In Pos./Turbine Motor

24V DC

Auxiliary Output

J4

24V DC

120V AC

60 Hz

C

org

grn

Schematic

18

Position markers

(valve in service)

CAM

MOTOR

FIG. 34

T oubleshooting

MA UALLY I ITIATED ELECTRO IC

DIAG OSTICS

Use the following procedures to advance the filter

through the recharge cycles to check operation.

Remove the top cover faceplate assembly by unlock-

ing the tabs and lifting, to observe cam and switch

operation during valve rotation (See Figure 34).

1. Press and hold for 3 seconds the S L CT button,

until one of the screens shown in Figure 33 is dis-

played. If the valve is in service, fill, solution draw /

brining, backwash or fast rinse position (observe

markings on the valve cam), the display should

show “000 - -”, meaning the position switch is

open. When the valve is moving, the display

should show “000 - P”, meaning that the position

switch is closed.

2. Only for filter systems modified by adding a

turbine and turbine cable:

If a turbine has been installed in your filter’s valve

outlet port, the first 3 digits of the display in Figure

33 should count upward whenever water is flowing

through the system.

3. Use the TOUCH/HOLD button to manually advance

the valve into each position and check correct switch

operation.

4. While in this diagnostic screen, the following infor-

mation is available and may be beneficial for vari-

ous reasons. This information is retained by the

computer from the first time electrical power is

applied to the electronic controller.

a. Press the rUP button to display the number of

days this electronic control has had electrical

power applied.

b. Press the sDOWN button to display the num-

ber of recharges initiated by this electronic con-

trol since the model code number was entered.

5. Press the S L CT button and hold in for 3 sec-

onds until the model code shows in the display.

This code identifies the filter model. If the wrong

number shows (see table on page 4), the filter will

operate on incorrect configuration data.

6. To change the code number - Press the rUP or

sDOWN button until the correct code shows.

7. To return to the present time display, press the

S L CT button. If the model code was

changed, make all timer settings.

OTE: If the electronic control is left in a diagnostic

display (or a flashing display when setting

times or hardness), present time automatically

returns if a button is not pressed within 4 min-

utes.

FIG. 33

19

Valve Cam

FIG. 35

Position Switch

S

SERVICE

Valve Cam

FIG. 36

BR

FILL

F

BRI E DRAW

Position Switch

Valve Cam

FIG. 37

Position Switch

Valve Cam

FIG. 38

BW

BACKWASH

FAST RI SE

Position Switch

Valve Cam

FIG. 39

Position Switch

R

T oubleshooting

20

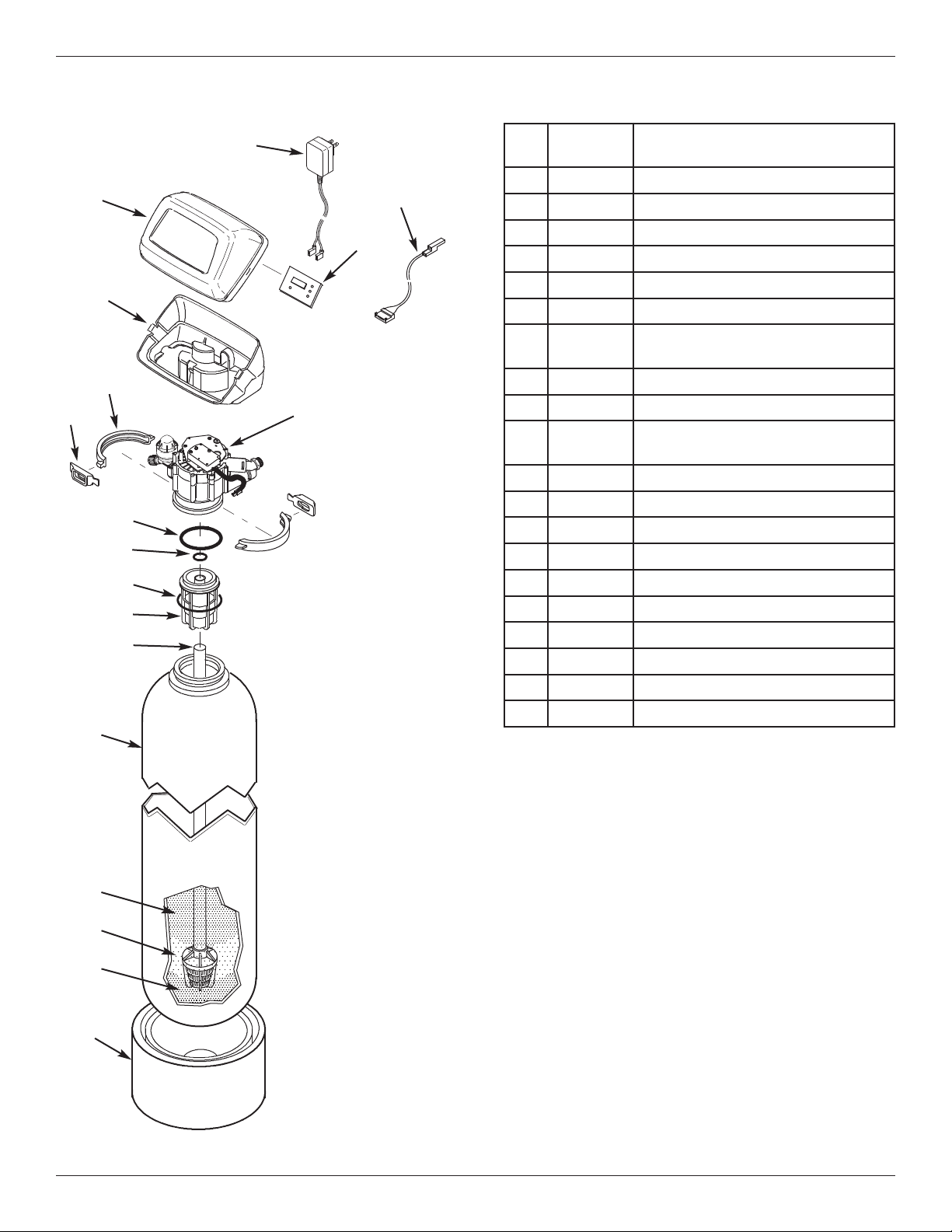

Key

No. Part No. Description

1 7351054 Power Supply, 24V DC

2 7259927 Wire Harness

3 7366677 Repl. Timer (PWA)

4 7260554 Top Cover (order decal below)

¢7285279 Decal, Filter

5 7189449 Bottom Cover

– 7331177 Tank Neck Clamp Kit

(includes Key Nos. 6 & 7)

6áClamp Section (2 req.)

7áRetainer Clip (2 req.)

– 7112963 Distributor O-Ring Kit

(includes Key Nos. 8-10)

8áO-Ring, 2-7/8” x 3-1/4”

9áO-Ring, 13/16” x 1-1/16”

10 áO-Ring, 2-3/4” x 3”

11 7088855 Top Distributor

12 7105047 Repl. Bottom Distributor

13 7092202 Mineral Tank, 10” x 47”

14 7331680 Greensand Plus, 1 cu. ft.

15 0501783 Filter Sand, 10 lbs.

16 7124415 Gravel, 17 lbs.

17 7302039 Tank Foot, 10” Tank

¢Not illustrated.

Manufactured and warranted by

Water Channel Partners

1890 Woodlane Drive

Woodbury, MN 55125

Filte Assembly Pa ts

1

2

3

4

5

7

6

8

9

10

11

12

13

17

Valve Assembly

See Pages 22 & 23

for parts

14

15

16

Table of contents

Other Water Channel Partners Water Filtration System manuals

Popular Water Filtration System manuals by other brands

Watts Premier

Watts Premier RO-TFM-4SV Installation, operation and maintenance manual

Panasonic

Panasonic TK-CS10 operating instructions

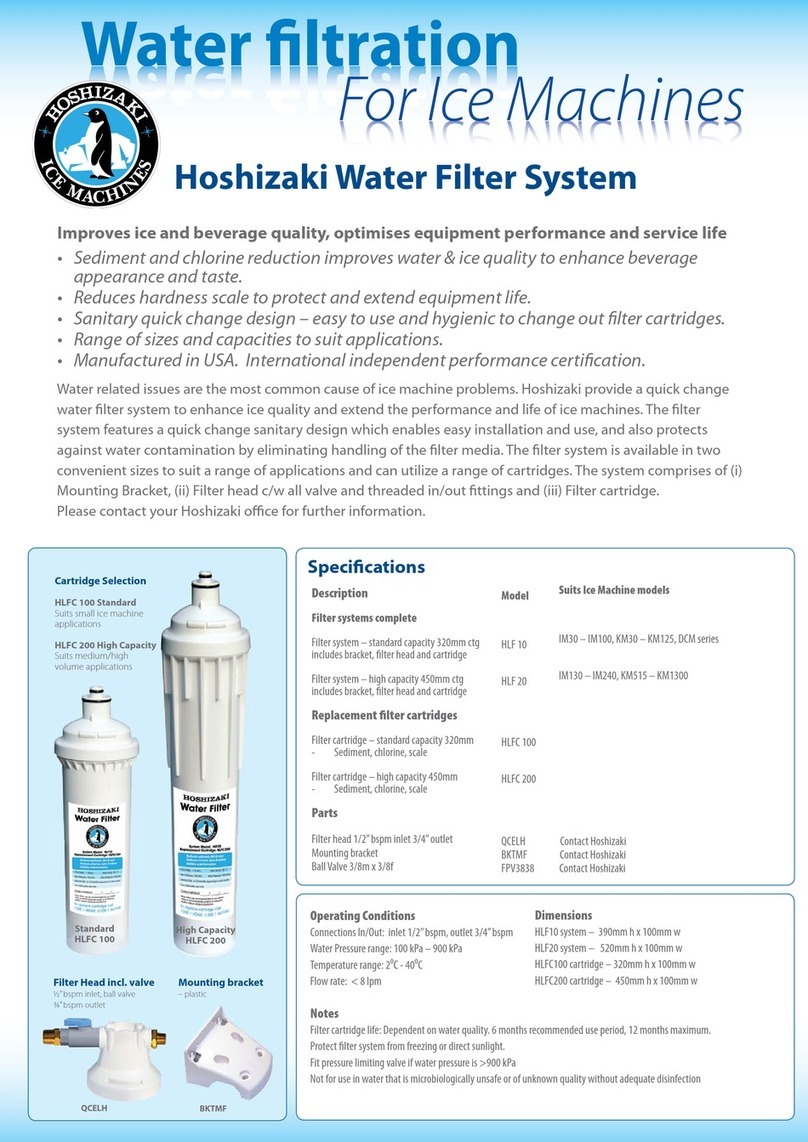

Hoshizaki

Hoshizaki HLF 10 manual

unGer

unGer HiFlo RO-Mobil Installation & operating instructions

ChemoformGroup

ChemoformGroup Summer Fun SF 122 Installation and operating instructions

Doughboy

Doughboy ECO 0-1805-180 owner's guide