Sea Tel Side Exit User manual

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page1of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

1. BriefSummary:

Troubleshootingdocumentfordiagnosingafaultwithandreplacingthelevelcageassembly.

2. Checklist:

VerifyRemoteTilt

VerifyInitialization

VerifySensorOutputsusingDacRemP

AzimuthandRelativeTargeting

DriftandSensorMonitoring

3. TheoryofOperation:

Thelevelcagecontains4sensors,afluidfilledtiltsensorwhichisusedasthesystemshorizonreference(levelposition)

aswellaslongtermstabilizationreference,and3solidstateratesensors;oneforeachaxiswhichactastheantennas

shorttermstabilizationreference.Afaultysensorinsidethelevelcagewillcausetheantennatolosestabilityand

mispointfromthesatelliteunderdynamicconditions.However,thesystemmayappeartobeoperationalintheport

whenthereisnomotiontocounteract.Thisdocumentwillrunthroughtestingthesensorsinsidethelevelcage,

replacingthelevelcageassemblyandcalibratingthesystemsremotetiltsetting.

4. VerifyRemoteTilt:

Ifthepedestalishavingstabilityproblems,firstly,checktheremotetiltsettingbylookingatthelevelbubbleontopof

thelevelcage(note:oldersystemsdidn’thaveabubbleinstalledontopofthelevelcage).Itisonlypossibletodoso

whenthevesselisstationary.Ifthebubbleisn’tasclosetocentralaspossible,theremotetiltsettingisn’tcorrectly

calibratedmeaningtheratesensorswon’tbecorrectlyalignedwiththeiraxis.Thiswillcausetheratesensorstooutput

incorrectfeedbackintothePCU’scontrolloop,potentiallycausingastabilizationissue.Calibratetheremotetiltsetting

aspertheinstructionsattheendofthisdocumentandcontinuetotestthelevelcageusingthefollowprocedures.

5. VerifyInitialization:

Powercyclethepedestal

1. Brakesrelease(ifapplicable)

2. Levelcagedrivestoitsendstopandthenbacksoffexactly45degrees.Elistrackedbasedonstepsissued

bytransistorsinthePCU.

3. Elevationaxisdrivesto45degreesbasedonfeedbackfromthelevelcagestiltsensor.

4. Crosslevelaxisdrivestolevel,againbasedonfeedbackfromthetiltsensor.

5. Unlimitedazimuthsystemsdriveclockwiseuntilthehallaffectsensor/switchseesthehomeflag(magnet

ornotch)ontheAZdrivepulley.

6. Limitedazimuthsystemsdriveclockwiseintotheend‐stopthendrivesCCWawayfromthestop.Ifa

6003A/6004system,theRELwouldatthispointbe580.0degrees.

Ifanyofthesestepsfail,ortheACUreportsmodel"xx03/xx97",theantennasN0parameterneedscalibrating.Once

entered,verifythattheparameterhassavedcorrectlytothePCU’sNVRAM.Amotordriveissueorpedestalerror

requiresfurthertroubleshooting.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page2of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

6. VerifyStabilization:

Usingthebelowprocedurewewillphysicallymovethesystemsaxisunderstaticconditions,thusintroducinganerror

intothePCU’scontrolloop.Thiswillallowustoverifythatthesystemisabletoreturntoitslevelposition(stabilizeitself)

efficiently.WeareabletomonitorthesensoroutputsonDacRemPtoobservewhatishappening,orwecanjustwatch

thepedestalandobservehowitresponds.

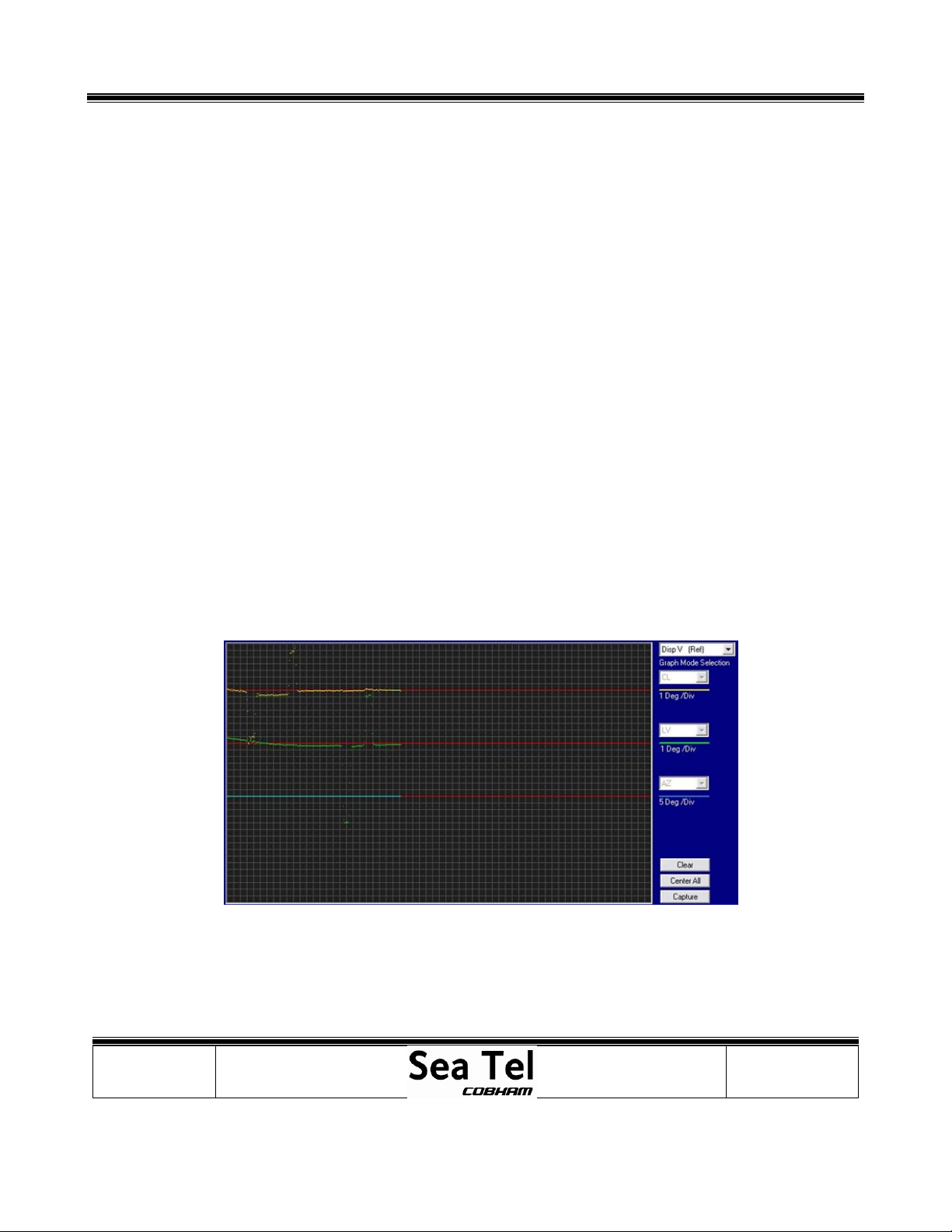

1. Turndishscanandtrackingoff.SelecttheDISP_VchartofDacRemP;youwillseethecurrentoutputfromthetilt

sensoringraphform.Oncearemotetilthasbeensetandwheninstableconditions,thetraceshouldbestableand

nomorethan+/‐4divisionsfromtheredreferenceline.Ifoutsidethislimitthenre‐checktheremotetiltandthenif

necessary,replaceandre‐calibratethelevelcage.

2. VerifyCrossLevelresponse:

Pushthecrosslevelbeamdowntotheleft(CCW)andholditinposition.VerifythattheCLtraceonDacRemP

movesdownanequalamounttothemovementexertedontheaxis.ReleasetheCLbeamandverifythatthe

DacRemPtracereturnsbacktoitsoriginalposition,withoutdeviatingortakingtimetosettle.Nowpushthecross

levelbeamdowntotherightandholditinposition.ThistimeverifythattheCLtraceonDacRemPmovesupan

equalamounttothemovementexertedontheaxis.ReleasetheAxisandverifytheDacRemPtraceandcrosslevel

beamreturnbacktotheiroriginalpositions,withoutdeviatingortakingtimetosettle.

3. VerifyLevel(Elevation)response:

PushthereflectorupinElevationandholditinposition.VerifythattheLVtraceonDacRemPmovesdownanequal

amounttothemovementexertedontheaxis.ReleasetheaxisandverifytheDacRemPtracereturns(orthe

systemsaxisreturns)backtoitsoriginalposition,withoutdeviatingortakingtimetosettle.Pushthereflectordown

inelevationandholditinposition.VerifythattheLVtraceonDacRemPmovesupanequalamounttothe

movementexertedontheaxis.ReleasetheaxisandverifytheDacRemPtracereturns(orthesystemsaxisreturns)

backtoitsoriginalposition,withoutdeviatingortakingtimetosettle.

IfusingDacRemPthetraceshouldlooksimilartotheimagetotheleft.Notehowaftereachmovementthesystem

returnstoitslevelpositionefficientlywithouttakingtimetosettle.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page3of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

7. RateSensorMonitoring:

RatesensoroutputscanalsobemonitoredusingtheDISP_WscreenofDacRemPtoverifyanydeviationsunderstatic

conditions.Thetracesshouldremainconsistent.Anydriftingorspikesareanindicationthesensorsvoltageoutputis

changingandthesensorisdefective(providednoforcesarebeingexertedonthesystem).Normaltraceis+/‐1division

fromredline.

8. AzimuthTargeting:

Shouldtheantennahaveissuestargetinginazimuth,suchasnotaccuratelyfindingthesatelliteorrepeatedlyfindingthe

satelliteindifferentazimuthpositions,thenit’simportanttodiagnoseifthesystemismispointinginazimuthorrelative.

RelativefeedbackfromtheAZencodercanbeverifiedbyinitializingthesystem,verifyingitcalibratesitselfcorrectlyand

thendrivingthepedestalclockwisein90degreeincrementsovera360degreerotation.Makenotethatthesystem

pointscorrectly(bow,starboard,aft,port,bowandstarboard)andthatnoAZreferenceerrorisflaggedbythePCU.A

mechanicalproblemsuchasthebeltslippingonthepulleycouldalsocausethiskindoferror,ascouldsomeother

mechanicalissue.Skewingtheantennainazimuthbyholdingtherightorleftarrowkeytodrivetheantennaslowlymay

alsopresentanissue.

Ifthesystemkeepsfindingthesatelliteatdifferentazimuthpositionsbutatthesamerelative,theencoderisfunctioning

correctlyandoneofthereferenceinputs(Levelcage,gyro)tothePCUiscausingtheantennatomispoint.

9. Drift:

Anotherfailurewhichcanoccurisifaratesensorstartsdrifting;thismeansthesensorsvoltageoutputdeviatesfrom

whatthePCUisexpectingunderstablecondition(2.50VDC).Thisfaultwillintroduceanerrorintothecontrolloop.Itis

morecommontoseethisintheAzimuthaxisastheCLandELaxishavethetiltsensorastheirlongtermreference

(althoughshouldtheratesensorsdriftbelargeenoughtooverpowerthetiltsensoryouwouldseethesystemdriving

intooneoftheCLorELendstops).Thisismorenoticeablewithtrackingturnedoff.

ToverifyifthesystemisdriftinginAzimuth,firstturnofftrackingandthenmonitortherelativeposition.Understatic

conditions(thevesselsheadingisn’tchanging)therelativeshouldremainstill.Iftherelativevaluebeginsto

increase/decreasefromitsnominalpositionthentheazimuthratesensorisdrifting,creatinganerrorintothePCU’s

controlloop.ThiswillcausethePCUtobelievethevesselsheadingischangingandinturndrivetheazimuthaxisinthe

oppositedirectiontocompensate.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page4of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

10. Diagnostics:

Anyincorrectreadingsfromtheabovetestswouldrelatetoanerrorintheantennascontrolloopcausingthesystemto

notstabilizecorrectly.Themostlikelycauseofthisisadefectivesensorinthelevelcage.Thenextstepwouldbeto

replaceandre‐calibratethelevelcage.Nowrepeatthefailedtesttoverifythatthesystemisnowfunctioningcorrectly.

Shouldtheproblemremain,anotherpossiblecausemaybeafaultwiththereferenceharnessbetweenthelevelcage

andPCU.ThePCUitselfshouldnotberuledoutasfaultyeither.Evenso,thelevelcageisthemostlikelycomponentto

becausingthisissue,thereforereplacingitisthefirststepwhentroubleshooting.

Oncetheproblemhasbeenrectified,itisgoodpracticetorefittheoriginallevelcageandseeifthefaultreturns.Itis

possiblethatcorrosiononthepinsofthereferenceharnessand/orconnectorsofthePCU/levelcagecausedtheinitial

fault.Byconnectingthereplacementlevelcage,itislikelythatanypincorrosionmayhaverubbedoff,creatingacleaner

electricalcontact.Youmayhavebeenundertheimpressionthatreplacingthelevelcagerectifiedthefaultwhenin

actualfact;theissuewasapoorelectricalcontactcausingvaryingresistance.

11. FurtherInformation:

Shouldthesystemfailtotargetthecorrectelevation(physicallypointingatadifferentpositiontothereadingonthe

DAC),orhaveissuesdrivingpastacertainelevationpositionthenthemostlikelycauseisadefectivelevelcagemotor.

Ifthesystemisdisplayingapedestalerror(error8),thereisadriveissuewiththeantennaandattentionwillneedtobe

paidtothemotorandmotordriver(servoamp)fortherelevantaxis.Thereisnoerrorcodethatdirectlytellsyouifthe

levelcageorlevelcagesteppermotorhasfailed,however,apointingorstabilizationissueisagoodindication.

Anotherpotentialissuewhichcouldcausetheantennatolosethesatelliteisifthevesselsgyrocompassisdrifting.This

accumulatingerroristhenfedintothecontrolloop.ThiscanbeverifiedbyrunningaDacRemPlogfileatseatomonitor

thepedestalsreadingswhentheAGCdrops,orbyputtingthesystemintosatellitereferencemodetouncouplethegyro

feedfromtheazimuthstabilizationloop.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page5of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

12. ReplacingtheLevelCageAssembly:

12.1. Tools.

2mmFlatBlade(Terminal)Screwdriver

#1PhillipsScrewdriver

½”Wrench/Spanner

12.2. Procedure.

Procedureforreplacingthelevelcageassembly,SeaTelkitpartnumber:135344(levelcageassemblypartnumber:

122208‐1)andtensioningthelevelcagebelt.

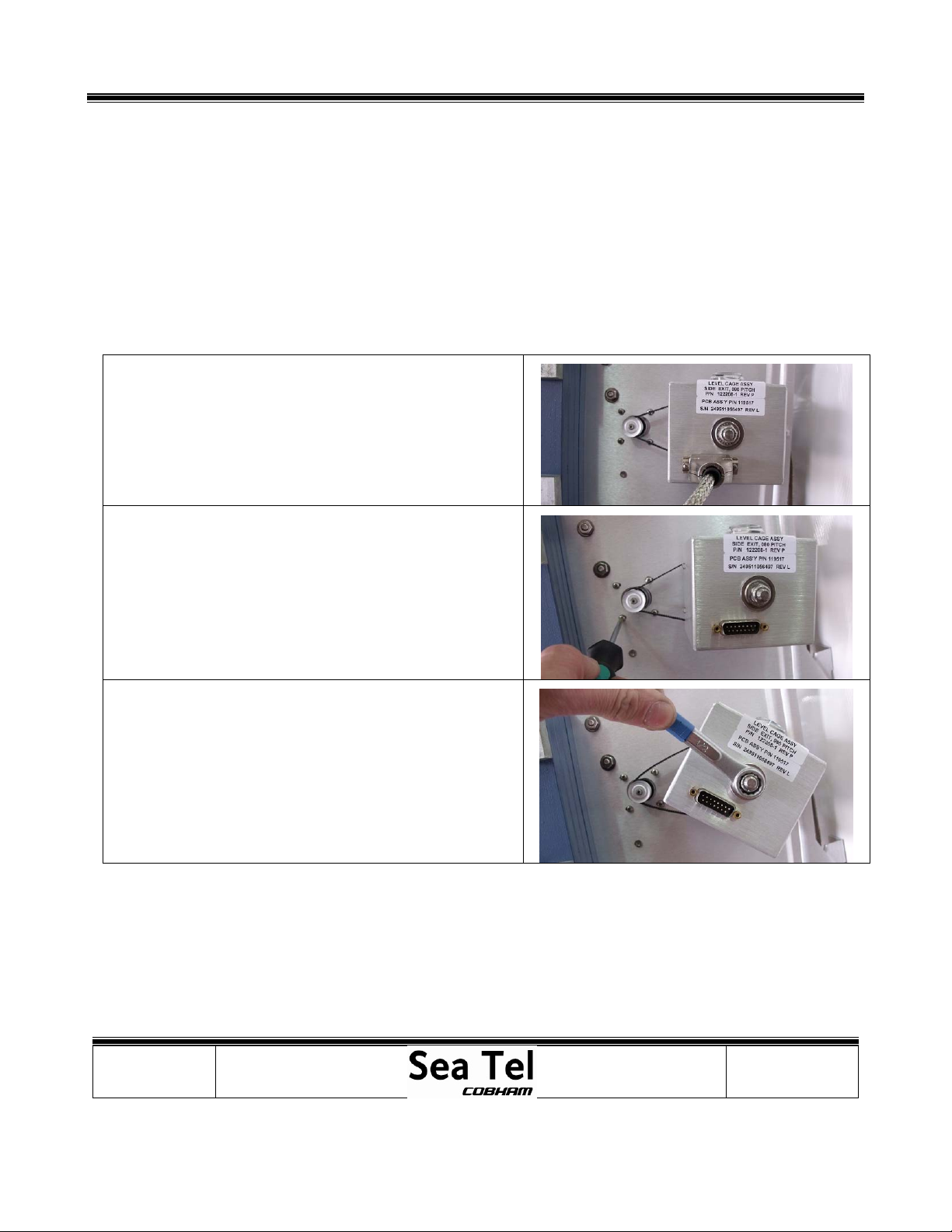

*CAUTION:Powerdownthepedestalbeforefollowingthis

procedure.

1.Usinga2mmflatbladescrewdriver,loosenthescrews

securingthereferenceharnessD‐Subconnectortolevelcage.

2.Usinga#1Phillipsscrewdriver,loosenthefourscrews

attachinglevelcagemotortotheELpan(donotfully

remove).

3.Usinga½”socketorspanner,removetheNylocknut

securingthelevelcagetothespindle.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page6of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

4.Slidethemotortowardsthelevelcagetoallowenoughslack

onthebelttoremoveitwithoutstressingit.

5.Removethedefectivelevelcage,takingcarenottoremove

thestandoffspacerfromthespindle.

6.Installthereplacementlevelcageontothespindle,slipping

thebeltoverthelevelcagepulleyandmakingsureitsend

stopsarealignedcorrectly.

7.Secureitwiththe1/2”Nylocknut.Whentight(sothatthere

isnohorizontalplayalongthespindle)addanadditional½a

turnforagoodground.Rotatethelevelcagebyhandand

verifyithas90degreesofmotionandthatthecagerotates

freely,ensuringthestopsdonotrubagainsttheELpan.

8.Tensionthebeltbyslidingthemotorassemblybyhand

awayfromlevelcageandthentightenthefourscrews.

9.Acorrectlytensionedbeltwillallow¼turnwithyourfingers.

Ifthebelttensionistootight/looseadjustuntilcorrect.

10.Ifthebelttensionisincorrectloosenthescrewsandre‐

tension.NoLoctiteisrequiredaslockwashersareusedonthe

securingscrews.

11.Re‐connectthereferenceharnesstothelevelcageand

tightentheretainingscrews,againnoneedtouseLoctiteas

lockwashersareinstalledontheconnectorshell.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page7of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

13. CalibratingtheRemoteTiltSetting:

Thisprocedureisrequiredtocalibratethelevelcagesothatallthesensorswillbeaccuratelyalignedtotheiraxis.The

fluidfilledtiltsensorprovidesatwodimensionalhorizonreference.Thesystemisnotabletoautomaticallycalculatethe

exactcentervalue,thereforeitisnecessarytoperformthisproceduretomanuallyenteranyoffsetrequiredtomakesure

thePCUreceivesatruehorizonreference.

1. Turndishscanoff:

EnterintotheSetupMenubypressingandholdingthearrowstogetheruntiltheELTrimorAutoTrim

parameterisdisplayed.

Usethearrowkeytoscrollthroughthemenuuntilthedishscanwindowisdisplayed.

Pressthearrowtoactivatethewindowandthenpressthearrow,followedbythebuttontoturn

dishscanfromontooff.

*Note:Whenyoupressthearrowtoturndishscanoffyouwon’tseethedisplaychangeuntilyoupressthe

button.

(Steps2‐7requiresassistancetoobserveandoperateantennasimultaneously)

2. EnterintotheSetupMenubypressingandholdingthearrowstogetheruntiltheELTrimorAutoTrim

parameterisdisplayed.

3. PushthearrowkeyuntiltheRemoteTiltwindowisdisplayed.

4. PushthearrowkeytoactivatetheRemoteTiltsetting.

5. Usethearrowkeystopositionthebubbleasclosetothecenteraspossible.Eachpressofanarrowkeyonthe

directionalpadwillmovetheRemoteTilt½adegree.Itisadvisedthatyouonlypressthebuttononceandwaitfor

theaxistomovebeforepressingitagain.

Whenstandingbehindtheantennalookingatthebubble,ifthebubbleisovertotheright,youneedtopressthe

(right)arrowtobringthebubbleintothecenter.Ifthebubbleisdowntowardsyou,youneedtopressthe

(down)arrowtobringittowardsthecenter.Ifthebubbleistotheleft,youneedtopressthe(left)arrowandif

thebubbleisuptowardsthetop,youneedpressthe(up)arrowtomoveittowardsthecenter.

Procedure, Field Replacement, Level Cage Kit, Side Exit

Page8of8

Document No

135265 Rev B

Copyright © Sea Tel, Inc 2011 - The information contained in this document is proprietary to Sea

Tel, Inc.. This document may not be reproduced or distributed in any form without prior written

consent of Sea Tel, Inc.

Whencorrectthebubbleshouldbeasclosetothecenterofthefluidaspossible

6. WhenthebubbleisascentralaspossiblepressthebuttontodeactivatetheRemoteTiltsetting.

7. Turndishscanon:

EnterintotheSetupMenubypressingandholdingthearrowsuntileithertheELTrimorAutoTrim

parameterisdisplayed.

Usethearrowkeytoscrollthroughthemenuuntilthedishscanwindowisdisplayed.

Pressthearrowkeytoactivatethewindowandthenpressthearrowkey,followedbythebuttonto

turndishscanfromofftoon.

*Note:Whenyoupressthearrowtoturndishscanonyouwon’tseethedisplaychangeuntilyoupressthe

button.

8. SavetheRemoteTiltsettinginthePCU:

PressthearrowkeyuntiltheRemoteParameterswindowisdisplayed.

Pressthearrowkeytoactivatethewindowfollowedbythebutton(you’llseeaconfirmationonthe

displaysaying“Saved”).

9. AsgoodpracticemakeanoteofyourN4andN5parametersonceyouhavecorrectlysettheremotetilt.TheN4and

N5parametersareanumericreadoftheremotetilt.Todothisgototheremotecommandwindowandkeyin

N4999toreadtheCLsetting,followedbyN5999toreadtheELsetting.

Table of contents