ML538 | v8 i

System Specification .................................................................................................................1

MiniPurge® Control Unit Data .................................................................................................2

Pressure Relief/Outlet Valve with Integral Spark Arrestor .......................................................3

Quick User Guide .......................................................................................................................3

Installation ...............................................................................................................................3

Operation of the System ..........................................................................................................3

Application Suitability ................................................................................................................4

Description and Principle of Operation ....................................................................................5

Main Components ......................................................................................................................6

Air Supply Filter / Regulator .....................................................................................................6

Logic Air Supply Regulator ......................................................................................................6

Minimum Pressure Sensor ......................................................................................................6

Purge Flow Sensor ..................................................................................................................6

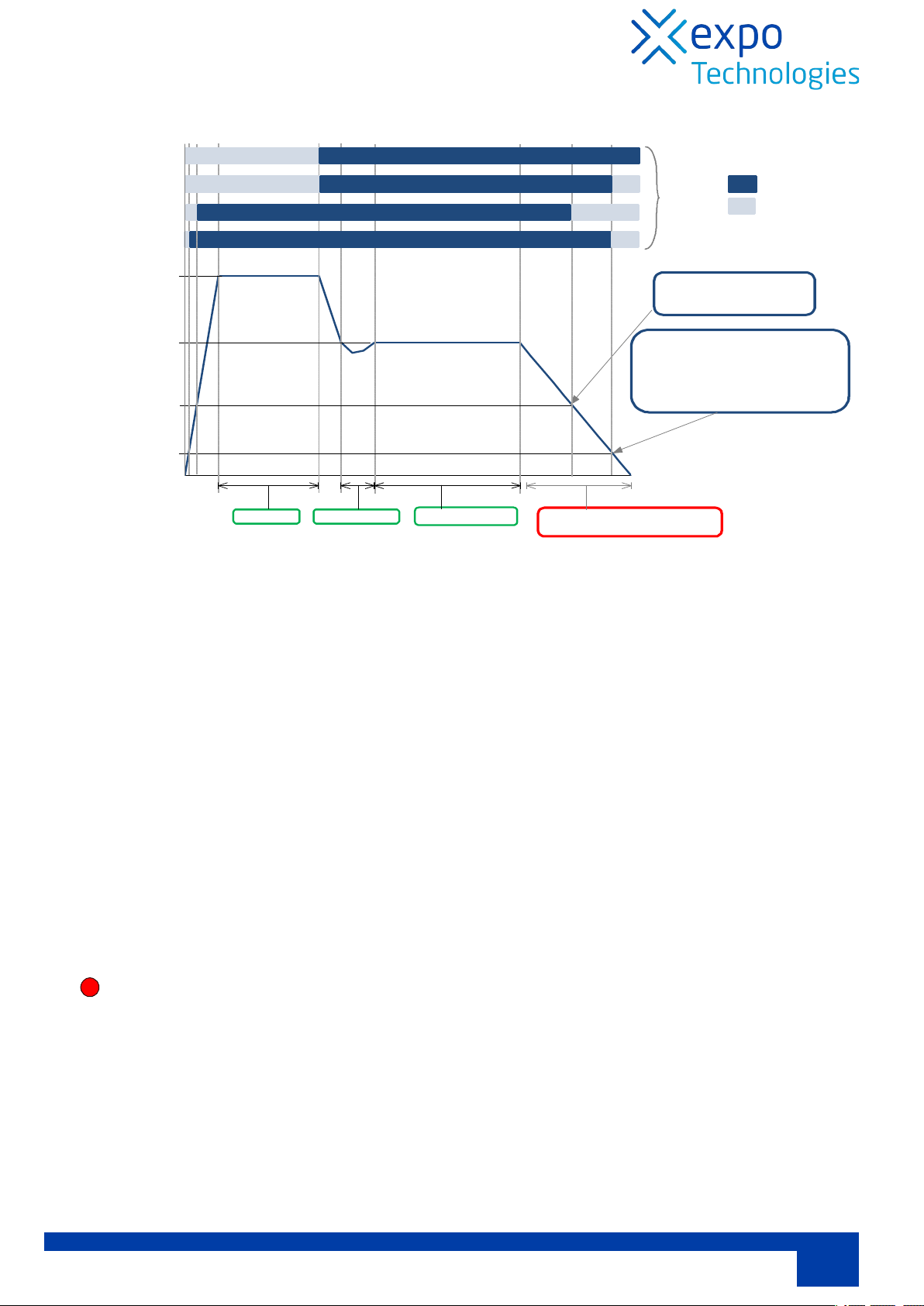

Electronic Purge Timer ............................................................................................................7

Purge Complete Valve .............................................................................................................7

Purge Inhibit Sensor ................................................................................................................7

OR Gate ..................................................................................................................................7

Alarm Only Circuit (/AO) ..........................................................................................................7

Power Interlock Switch ............................................................................................................7

Alarm / Pressurized Switch ......................................................................................................8

System Purging Switch (Optional) ...........................................................................................8

Purge Valve .............................................................................................................................8

Purge Flow Restrictor ..............................................................................................................8

CLAPS Sensor ........................................................................................................................8

CLAPS Regulator ....................................................................................................................8

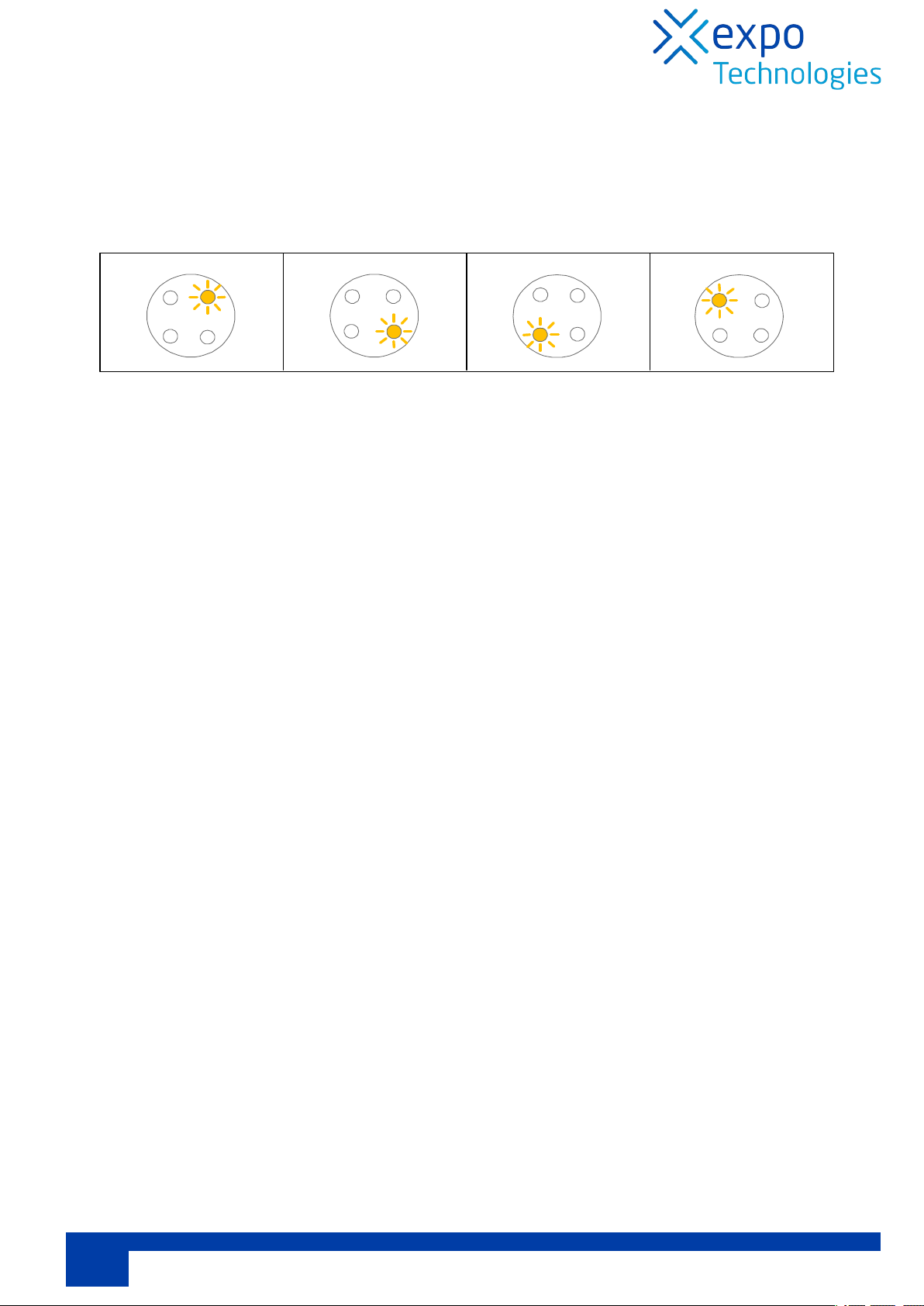

Visual Indicators ......................................................................................................................8

Relief Valve Unit ......................................................................................................................8

/PA Terminal Box .....................................................................................................................9

Installation of the System ..........................................................................................................9

Relief Valve Unit ......................................................................................................................9

Air Supply Quality ....................................................................................................................9

Pipe Work ..............................................................................................................................10

Multiple Enclosures ...............................................................................................................10

Provision and Installation of Alarm Devices ..........................................................................10

Power Supplies and their Isolation ........................................................................................10

Power Interlock Switch ..........................................................................................................11

Commissioning ........................................................................................................................11

Commissioning the System ...................................................................................................11

Maintenance of the System .....................................................................................................13

General maintenance ............................................................................................................13

Additional maintenance checks .............................................................................................14

Maintenance of Electronic Timer ...........................................................................................14

Re-calibration of the Relief Valve Unit ...................................................................................15

Re-calibration of the Pressure Sensors .................................................................................15

Fault Finding ............................................................................................................................16

General Information ...............................................................................................................16

System purges correctly but trips and auto re-purges at the end of the purge time ..............16

Relief Valve opens (continuously or intermittently) ................................................................17

System enters purging but purge indication does not occur ..................................................17

Recommended Spare List .......................................................................................................17

Glossary ....................................................................................................................................18

Drawings and Diagrams ..........................................................................................................18

Certificates ................................................................................................................................18