Sullair 65 II Guide

UTILISATION - ENTRETIEN F

USE - MAINTENANCE E

BEDIENUNG - WARTUNG D

USO - MANUTENZIONE I

UTILIZACION - MANUTENCION SP

PIECES DE RECHANGE

SPARE PARTS

ERSATZTEILBESTELLUNG

PIEZZI DI RICAMBIO

PIEZAS DE REPUESTO

PARTES DE SUBSTITUIÇÃO

UTILIZAÇÃO - MANUTENÇÃO P

65 II

UPDATE 04/11/200568724241

A partir du N° de série 13000

From serial Nb 13000

1

E

S65 II

TABLE OF CONTENTS

CHAPTER 1 - SAFETY

1.1 GENERAL...........................................................................................................................2

1.2 TOWING .............................................................................................................................2

1.3 PRESSURE DANGERS......................................................................................................3

1.4 FIRE AND EXPLOSION......................................................................................................3

1.5 MOVING PARTS.................................................................................................................3

1.6 HOT SURFACES, SHARP EDGES AND SHARP CORNERS...........................................3

1.7 TOXIC AND IRRITATING SUBSTANCES..........................................................................3

1.8 ELECTRICAL SHOCK........................................................................................................4

1.9 LIFTING ..............................................................................................................................4

1.10 ACCIDENTAL ENTRAPMENT............................................................................................4

1.11 JUMP STARTING...............................................................................................................4

CHAPTER 2 - TECHNICAL DATA

2.1 SPECIFICATIONS..............................................................................................................5

2.2 LOCATION OF COMPONENTS.........................................................................................5

2.3 DIMENSIONS .....................................................................................................................6

2.4 COMPRESSOR IDENTIFICATION.....................................................................................6

2.5 ENGINE AND COMPONENT IDENTIFICATION................................................................6

CHAPTER 3 - DESCRIPTION

3.1 WORKING PRINCIPLE ROTARY SCREW COMPRESSOR.............................................7

3.2 DESCRIPTION OF COMPONENTS...................................................................................7

3.3 AIR END COMPRESSOR UNIT FUNCTIONAL DESCRIPTION........................................7

3.4 COMPRESSOR COOLING AND LUBRICATION SYSTEM...............................................7

3.5 COMPRESSOR DISCHARGE SYSTEM FUNCTIONAL DESCRIPTION ..........................7

3.6 REGULATING SYSTEM.....................................................................................................8

3.7 SAFETY DEVICES .............................................................................................................8

CHAPTER 4 - USE

4.1 TRANSPORT......................................................................................................................9

4.2 PARKING OR LOCATING COMPRESSOR.......................................................................9

4.3 PREPARING THE BATTERY FOR SERVICE....................................................................9

4.4 PRECAUTIONS TO BE TAKEN PRIOR TO STARTING....................................................9

4.5 FILLING FUEL TANK........................................................................................................10

4.6 CONTROL PANEL............................................................................................................11

4.7 STARTING........................................................................................................................11

4.8 UTILIZATION....................................................................................................................11

4.9 SHUTTING DOWN ...........................................................................................................11

CHAPTER 5 - MAINTENANCE

5.1 MAINTENANCE - First 50 hours.......................................................................................12

5.2 MAINTENANCE 10 HOURS (or daily)..............................................................................12

5.3 MAINTENANCE 100 HOURS...........................................................................................12

5.4 MAINTENANCE 500 HOURS...........................................................................................13

5.5 MAINTENANCE 1000 HOURS (or Yearly)......................................................................14

5.6 TABLE OF MAINTENANCE OPERATIONS.....................................................................14

CHAPTER 6 - ELECTRIC CIRCUIT

6.1 SCHEMA...........................................................................................................................15

6.2 ELECTRIC CIRCUIT OPERATION...................................................................................15

CHAPTER 7 - TROUBLESHOOTING ..................................................................................................16

CHAPTER 8 - RECOMMENDATIONS FOR SPARE PARTS ..............................................................17

The technical data given in this manual is for information purposes only and we reserve

the right to make anymodifications or implovements we consider necessary

without having to modify this manual.

Without authorization the partial or total reproduction of the information contained in this manual is forbidden.

S65 II

2

E

1. SAFETY

1.1 GENERAL

SULLAIR manufactures all of its products so they can be operated safely.

However, the responsibility for safe operation rests with those who use

and maintain our products. The following safety precautions are offered

as a guide which, if conscientiously followed, will minimize the possibility

of accidents throughout the useful life of this equipment.

This compressor should be operated only by those who have been

trained and delegated to do so, and who have read and understand the

Operator’s manual. Failure to follow the instructions, procedures and

safety precautions in the manual may increase the possibility of accidents

and injuries.

Never start this air compressor unless it is safe to do so. Do not attempt

to operate the air compressor with a known unsafe condition. Tag the air

compressor and render it inoperative by disconnecting and locking out all

power at source or otherwise disabling its prime mover so others who

may not know of the unsafe condition cannot operate it until the condition

is corrected.

Install, use and operate this air compressor only in full compliance with all

pertinent ISO regulations and all applicable. Local codes, standards and

regulations.

Do not modify this compressor and/or controls in any way, except with

written factory apporval.

While not specifically applicable to all types of compressors with all types

of prime movers, most of the precautionary statements contained herein

are applicable to most compressors, and the concepts behind these

statements are generally applicable to all compressors. Carry out a daily

compressor control and check for leaks, loose or missing components

and for any damaged or misadjusted parts.

Personal protective equipment:

Prior to installing or operating this compressor, owners, employers, and

users should become familiar with, and comply with, all applicable regu-

lations, and any other applicable Local codes, standards, and regulations

relative to personal protective equipment, such as eye and face protec-

tive equipment, respiratory protective equipment, equipment intended to

protect the extremities, protective clothing, protective shields and barri-

ers, and electrical protective equipment, as well as noise exposure ad-

ministrative and/or engineering controls and/or personal hearing

protective equipment.

Before any high pressure cleaning, electrical parts must be protected.

1.2 TOWING

A. PREPARING TO TOW

1. Inspect the ball hitch, pintle eye, coupling device and drawbar and

chains (if requested) and also the coupling device of the towing vehi-

cle and if to be used, the chain attachment points: then check for any

defects such as wear or excessive corrosion, or cracked, bent,

dented or otherwise deformed or degraded parts as well as for loose

nuts and bolts or other fixings the compressor and towing vehicule

must be in horizontal position.

Do not tow until all these problems have been solved.

2. Reverse the towing vehicle to the compressor and position it in prep-

aration for coupling with the compressor set the tow bar in order that

the coupling device of the compressor is horizontal.

3. Verify that the coupling device is fully engaged, closed and locked.

4. If chains are requested, pass each chain through its attachment point

on the towing vehicle, then hook each chain to itself by passing the

grab hook over (not through) a link.

5. Make sure that the coupling device and adjacent structures on the

towing vehicle and also, if requested, the chain adjustments, brake

and/or electrical interconnections do not interfere with or restrict the

movement of the compressor, including its coupling device, with

respect to the towing vehicle, when maneuvering over any antici-

pated terrain.

6. If requested, ensure that the chain lengths, brake and electrical cir-

cuit interconnections provide sufficient slack to prevent strain when

maneuvering or negotiating a bend. Make sure however that they are

sufficiently supported so they cannot drag or rub on the road, terrain

or towing vehicle surfaces which might cause wear and render them

inoperative.

7. Fully retract the front screw jack. If a castor wheel is provided,

remove the lock pin and fold and raise the castor wheel; then make

sure the pin is re-engaged and secures the castor wheel in full up and

locked position with the wheel horizontal.

8. Make sure that tyres are in good condition, of the correct size (load

range), and inflated to the correct pressure. Never change the type of

size of tyre. Check that the pivots, fixing screws and wheels are tight-

ened to correct torque.

9. If provided, make sure that the dual stop, tail, fog, directional and

clearance lights function correctly and that their lenses are clean and

functional. Also check that all reflectors and reflecting surfaces are

clean.

10.Make sure that all service air hoses (not air brake hoses) are discon-

nected or are fully stowed and secured on hose reels if provided.

11.Check that all access doors and tool box covers are closed and

latched. If the compressor is large enough to hold a man, make sure

all personnel are out before closing and latching access doors.

12.Make sure that the towing vehicle’s parking brake is set, or that its

wheels are chocked or blocked or that it is otherwise stopped from

moving. Then release the compressor parking brakes if provided.

13.Make sure that the compressor wheels are not chocked or blocked

and that any fixings are free.

14.Test overrunning brake operation, including the emergency brake

functioning, if provided, before attempting to tow the compressor at

permissible speed.

15.Do not carry loose or badly stowed tools, equipment or supplies on or

in the compressor.

B. TOWING

1. Observe all motor vehicle regulations in force, including those speci-

fying speed limitations.

2. Under ideal conditions, tow at the speeds recommended or lower.

Reduce speed according to road signs, weather, road or terrain con-

ditions.

3. Remember that portable air compressors may approach or exceed

the weight of the towing vehicle. Therefore increase braking dis-

tances accordingly.

4. Avoid gradients in excess of 27% (15°).

5. Avoid pot-holes, rocks and other obstructions, and soft shoulders or

unstable terrain.

6. Manoeuvre in a way that will not exceed the freedom of motion of the

compressor’s draw-bar and/or coupling device in or on the towing

vehicle’s coupling device and/or the adjacent structures, whether

towing forward or backward, regardless of the terrain being tra-

versed.

7. Do not allow personnel to ride on the compressor.

8. Make sure before maneuvering that no personnel or obstructions are

behind or under the compressor.

9. Do not allow any personnel to stand or ride on the drawbar, or to

stand or walk between the compressor and towing vehicle.

C. PARKING OR LOCATING COMPRESSOR

1. Park or locate the compressor on level ground if possible. If not, park

or locate it across the gradient so the compressor does not tend to

roll downhill. Never park or locate the compressor on gradients

exceeding 27% (15°).

2. Check that the compressor is parked on a firm surface that can sup-

port its weight.

3. Park the compressor so that the wind, if any, tends to carry the

exhaust gases and radiator heat away from the compressor air inlet

openings and so that the compressor is not exposed to excessive

dust from the work site.

4. Set parking brake and disconnect the emergency switch cable as

well as all other electrical interconnections and/or brake circuit con-

nections, if provided.

5. Check or block both sides of each wheel.

6. If provided, unhook the chains and remove them from the chain

attachment points of the towing vehicle. Then hook the chains onto

the ball on the drawbar or wrap chains around the drawbar and hook

them to themselves to stop the chains resting on the ground, which

may cause rusting.

1. SAFETY

S65 II

3

E

7. If provided, lower the screw jack or stabilizer legs. Make sure the

contact surface has sufficient load bearing capacity to support the

compressor weight.

8. Move the towing vehicle well clear of the parked compressor, and

erect danger indicators, barricades and/or lighted markers (at night)

when the compressor is parked on or adjacent to public roads. Park

to avoid traffic interference.

* Many of these recommendations also apply to mobile air compressors

mounted on feet, even though they are not towed in the true sense of the

word.

1.3 PRESSURE DANGERS

A. Open the pressure relief valve at least once per week to ensure it is

neither blocked, closed, obstructed or otherwise damaged.

B. Do not use tools that are rated below the maximum rating of this com-

pressor. Select tools, air hoses, pipes, valves, filters and other fittings

accordingly. Do not exceed manufacturer’s rated safe operating pres-

sures for these items.

C. Secure all hose connections by wire, chain or other suitable retaining

devices to prevent tools or hose ends from being accidentally discon-

nected.

D. Open fluid filler cap only when compressor is not running and is not

pressurized. Shut down the compressor and bleed the sump (receiv-

er) to zero internal pressure before removing the cap.

E. Vent all internal pressure prior to opening any line, fitting, hose, valve,

drain plug, connection, or other components, such as filters and line

oilers, and before attempting to refill optional air line anti-icer systems

with antifreeze compound.

F. Keep personnel out of line with and away from the discharge opening

of hoses, tools, or other points of compressed air discharge.

G. Use air at pressures less than 207kPa (2 bar) for cleaning purposes,

and then only wih effective chip guarding and personal protective

equipment.

H. Do not engage in horseplay with air hoses, as death or serious injury

may result.

I. Wait until the radiator has cooled down. Then unscrew the cap slowly

to its stop to relieve any excess pressure, and check that the coolant

is not boiling prior to removing the cap completely.

1.4 FIRE AND EXPLOSION

A. Refuel at a service station or from a fuel tank designed for that pur-

pose. If this is not the case, ground the machine to the dispenser be-

fore refuelling.

B. Clean up spills-of lubricant, or other combustible substances immedi-

atly when such spills occur.

C. Shut off the air compressor and allow it to cool. Then keep sparks,

flames and other sources of ignition away and do not permit smoking

in the vicinity when checking or adding lubricant, or when refilling air

line anti-icer systems with antifreeze compound.

D. Do not permit liquids, including air line anti-icer system antifreeze

compound or fluid film to accumulate on bottom covers or on, under or

around acoustical material, or on any external surfaces of the air com-

pressor or on internal surfaces of the enclosure. Wipe down using an

aqueous industrial cleaner or steam clean as required. If necessary,

remove acoustical material, clean all surfaces and then replace

acoustical material. Any acoustical material with a protective covering

that has been torn or punctured should be replaced immediately to

prevent accumulation of liquids or fluid film within the material do not

use flammable solvents for cleaning purposes.

E. Disconnect and lock out all power at source prior to attempting any re-

pairs or cleaning of the compressor.

F. Keep electrical wiring, including all terminals and other pressure con-

nectors in good condition. Replace any wiring that has cracked, cut,

abraded or otherwise degraded insulation ; or terminals that are worn,

discolored, or corroded. Keep all terminals and pressure connectors

clean and tight.

G. Switch off the battery charger or break the connections to it, before do-

ing any repair work or cleaning.

H. A conducting object like a iron tool can create a short circuit through

contact between (+) (eg: terminal (+) of the battery) and the earth, that

could provoke an electric arc with burns and fire risk.

I. Replace damaged tanks or fuel lines immediately, rather than trying to

weld or otherwise repair them. Do not store or try to run the compres-

sor if there are any known leaks in the fuel system.

J. Before a welding repair operation, remove any acoustical material or

other material that may be damaged by heat or that may support com-

bustion and is in close proximity prior to attempting weld repairs.

K. Keep a suitable full charged class BC, ABC or the ones requested in

your country fire extinguisher, or extinguishers, nearby when servicing

and operating the compressor.

L. Keep oil rags, trash, leaves litter or other combustibles away from the

compressor.

M. Open all acces doors and let vent the compressor prior to starting in

order to avoid possible presence of vapor.

N. Do not operate the compressor under low branches and ensure that

the leaves are not in contact with hot exhaust system surfaces when

operating in forested areas.

O. The anti-freeze used in certain air line anti-ice systems contains meth-

anol, which is inflammable. Only use and refill these systems with an-

tifreeze in well ventilated areas, away from heat, bare flames or

sparks. Do not expose any part of these systems or the antifreeze to

temperatures above 66°C. The antifreeze vapours are heavier than

air. Do not store this product or discharge treated air in confined or un-

ventilated areas. Do not store containers or antifreeze in direct sun-

light.

P. Storeallfluids andinflammablematerials wellaway from your work ar-

ea. Know where fire extinguishers are placed, how to use them and

for what type of fire they are intended. Check the condition of fire fight-

ing systems and detectors if so equipped.

1.5 MOVING PARTS

A. Keep hands, arms and other parts of the body and also clothing away

from fans, and other moving parts.

B. Do not attempt to operate the compressor with the fan or other guards

removed. ( belt guards).

C. Wear snug fiting clothing and confine long hair when working around

the compressor, especially when exposed to hot or moving parts.

D. Keep access doors, if any, closed except when making repairs or ad-

justments.

E. Make sure all personnel are out of and/or clear of the compressor prior

to attempting to start or operate it.

F. Shut off engine before adding fuel, oil, coolant, lubricants and airline

antifreeze or battery electrolyte or before replacing ether starting aid

cylinders.

G. Disconnect the grounded negative battery connection before carrying

out any repairs or adjustments to avoid accidental engine operation.

Tag the battery connection so that others won’t unexpectedly recon-

nect it.

H. Keep hands, feet, floors, and walking areas clean and make sure they

are free from oil, water, antifreeze or other liquids, to minimize the

risks of slips and falls.

1.6 HOT SURFACES, SHARP EDGES AND SHARP

CORNERS

A. Avoid bodily contact with hot fluid, hot coolant, hot surfaces and sharp

edges and corners.

B. Keep all parts of the body away from all points of air discharge.

C. Wear personal protective equipment, including gloves and head cov-

ering, when working in, on, or around the compressor.

D. Keep a first aid kit handy. Seek medical assistance promptly in case

of injury. Don’t ignore small cuts and burns as they may lead to infec-

tion.

1.7 TOXIC AND IRRITATING SUBSTANCES

A. Do not use air from the compressor for respiration (breathing) except

in full compliance with CEE Standards and any other Local codes or

regulations.

B. Operate the compressor only in open or well ventilated areas.

1. SAFETY

S65 II

4

E

C. Locate the compressor or provide a remote inlet so that it is not likely

to ingest exhaust fumes or other toxic, noxious or corrosive fumes or

substances.

D. Locate the compressor so that the exhaust gases cannot be carried

towards the personnel, air intakes servicing personnel areas or to-

wards the compressor’s air intake.

E. Motor fuel, oils, coolants, lubricants and electrolyte use are typical of

the industry. Ensure that no accidental ingestion or contact with the

skin occurs. If ingestion occurs, make sure that the correct medical

treatment is given immediately. If fuel is ingested do not provoke vom-

iting. If there is skin contact wash with soap and water and, if neces-

sary contact a doctor immediately.

F. When servicing a battery, always wear an acid resistant apron and a

face shield or goggles. If acid spills on skin or clothing, immediately

flush with large volumes of water.

G. Wear protective goggles or a complete face shield, when inspecting

either starting aid systems or when adding antifreeze to the air line an-

tifreeze systems. At start up, keep valve openings, tube or atomizers

of the ether starting aid system pointed away from yourself or other

personnel.

H. If air line anti-icer system antifreeze compound enters the eyes or if

fumes irritate the eyes, they should be washed with large quantities of

clean water. A physician, preferably an eye specialist, should be con-

tacted immediately.

I. Do not store ether or antifreeze for the air line anti ice systems in the

operators’ cabs or in an enclosed area.

J. The antifreeze compound used in air line anti-icer systems contains

methanol and is toxic, harmful or fatal if swallowed. Avoid contact with

the skin or eyes and avoid breathing the fumes. If swallowed, have pa-

tient lay down and cover eyes to exclude light. Call a physician imme-

diately.

1.8 ELECTRICAL SHOCK

A. Ensure that the towing vehicle or equipment carrier compressor, hos-

es, tools and all personnel are kept at a distance of at least 3 meters

from the power lines and buried cables.

B. Keep all parts of the body and any hand tools or any other conductive

objects away from exposed live parts of the electrical system. When

carrying out adjustments or repairs keep feet dry, stand on insulating

surfaces and make sure that no parts of the compressor come in con-

tact with exposed live parts of the electric system.

C. Attempt repairs only in clean, dry well lighted and ventilated areas.

D. Stay clear of the compressor during electrical storms. It can attract

lightning.

1.9 LIFTING

A. If the compressor is provided with a lifting bail, then lift by the bail pro-

vided. If no bail is provided, then lift by sling. Compressors to be air

lifted by helicopter must not be supported by the lifting bail, but by

slings instead. In any event, lift only in full compliance with European

Transport Regulation.

B. Inspect lifting bail and points of attachment for cracked welds and for

cracked, bent, corroded or otherwise degraded members and for

loose screws or nuts proir to lifting.

C. Make sure that the entire lifting, rigging and support structure has

been inspected: check that it is in good condition and its rated capacity

is at least equal to the net weight of the compressor plus an additional

10% allowance for the weight of snow, ice, mud or transported tools

and equipment. If you are unsure of the weight, weigh the compressor

before lifting.

D. Make sure lifting hood has a functional safety latch or equivalent, and

is fully engaged and latched on the bail.

E. Use guide ropes or equivalent to prevent twisting or swinging of the

compressor once it has been lifted clear of the ground.

F. Do not attempt to lift in high winds.

G. Keep personnel out from under, and away from, the compressor when

it is suspended.

H. Lift compressor no higher than necessary.

I. Keep lift operator in constant attendance whenever compressor is

suspended.

J. Set down the compressor on a level surface capable of supporting at

least its own weight plus additional 10% allowance for snow, ice, mud

or equipment and tools carried.

K. If the compressor has parking brakes, make sure they are set. In any

event, block or chock the two sides of all running wheels prior to dis-

engaging the lifting hook.

L. The hoisting eyebolt does not use like a fasteneing device for air stor-

age.

1.10 ACCIDENTAL ENTRAPMENT

A. Make sure all personnel are out of the compressor before closing and

latching the access doors. If the compressor is large enough to hold a

man, and if it is necessary to enter it to carry out maintenance or ad-

justment, inform other personnel before doing so.

1.11 JUMP STARTING

A. Observe all safety precautions mentioned elsewhere in this manual.

B. The batteries might produce hydrogen gas, which is inflammable and

explosive. Keep flames, sparks and other ignition, sources away.

C. The batteries contain acid which is corrosive. take care that it does not

come in contact with eyes, skin, fabrics or painted surfaces since se-

rious personnel injury or property damage could occur. Flush any con-

tacted areas thoroughly with water immediately. When carrying out a

jump start, always wear an acid resistant apron and a face shield.

D. Remove all vent caps from the battery or compressor batteries. Stop

any dirt or other foreign bodies entering the open cells.

E. Check electrolyte level. If it is too low, top up to correct level prior to

attempting a jump start.

F. Only attempt to jump start with a vehicle having the same electrical

voltage system with a negative grounding, and which is equipped with

a battery or batteries of comparable size or larger than that of the com-

pressor battery. Do not attempt a jump start using motor generating

sets, welders or other DC power sources,as serious damagecould re-

sult.

G. Only use jump cables which are clean, in good condition and heavy

enough to handle the starting current.

H. Avoid any accidental contact with the jump cable terminal clips or

clamps and any metallic part of either the compressor or the starting

vehicle, to minimize the risk of uncontrolled arcing which could act as

an ignition source.

I. The positive battery terminals are usually identified by a plus (+) sign

on the terminal, and by the initials POS adjacent to it. The negative

battery terminals are usually identified by a minus (-) sign on the ter-

minal and by the initials NEG adjacent to it.

J. Start the compressor in accordance with normal procedure. Avoid a

prolonged start-up phase.

K. Warm up the compressor. When warm and operating smoothly at nor-

mal idle rmp, disconnect the jumper cable from the engine block on

the compressor, and then disconnect the other end of this same cable

from the negative grounded terminal (NEG) (-) of the starting vehicle’s

battery. then disconnect the other jumper cable from the positive

(POS) (+) terminal of the compressor battery. Remove and carefully

dispose of the dampened cloths. Because they might be contaminat-

ed with battery acid. Replace the vent caps.

5

E

S65 II

2. TECHNICAL DATA

2.1 SPECIFICATIONS

Compressor

Asymetric rotary screw with oil injection.

Engine

KUBOTA 4 cylinder model V 2203 E water cooling, indirect injection,

electric starter and diesel fuel circuit vent.

Capacity control system

Progressive control system which adjusts the compressor output to

match the air demand by regulating the engine speed.

Body work

This consists of:

- A thermoformed composite plastic lift-up hood,

- The compressor unit is mounted on shock absorbers on a steel

sheet chassis.

Axle / Drawbar

Sprung axle.

Articulated towbar with or without inertia braking.

Compressor 65 II

• Delivery rated pressure * (l/min/cfm).......................... 3700

• Maximum pressure (bar/psi) ...................................... 7,5

• Working pressure (bar/psi)) ....................................... 7

• Minimum separator pressure (bar/psi)....................... 4

• Safety valve opening pressure(bar/psi) ..................... 9

(*) According to ISO 1217 ± 5%

Diesel engine

• Maximum operating speed (rpm)...............................

• Minimum operating speed (rpm)................................ 1450

• Engine oil sump capacity, about (l)............................ 9,5

• Fuel tank capacity (l).................................................. 55

• Battery 12 V (Ah) ....................................................... 12x75CC350Ah

Separator tank

• Total capacity (l)......................................................... 20,5

• Total oil capacity (l).................................................... 7,5

• Air outlet cocks........................................................... 2

Orifice Ø 1’................................................................. 1

Unit

• Sound level

(EEC Code) - dB(A).................................................. < 98

•Tyres:

- dimensions (minimum) ........................................ 155R13

- inflation pressure (bar)......................................... 2,7

• Total weight ready for use

- total authorized loaded weight (kg)

braked version..................................................... 727

Non-braked version............................................. 698

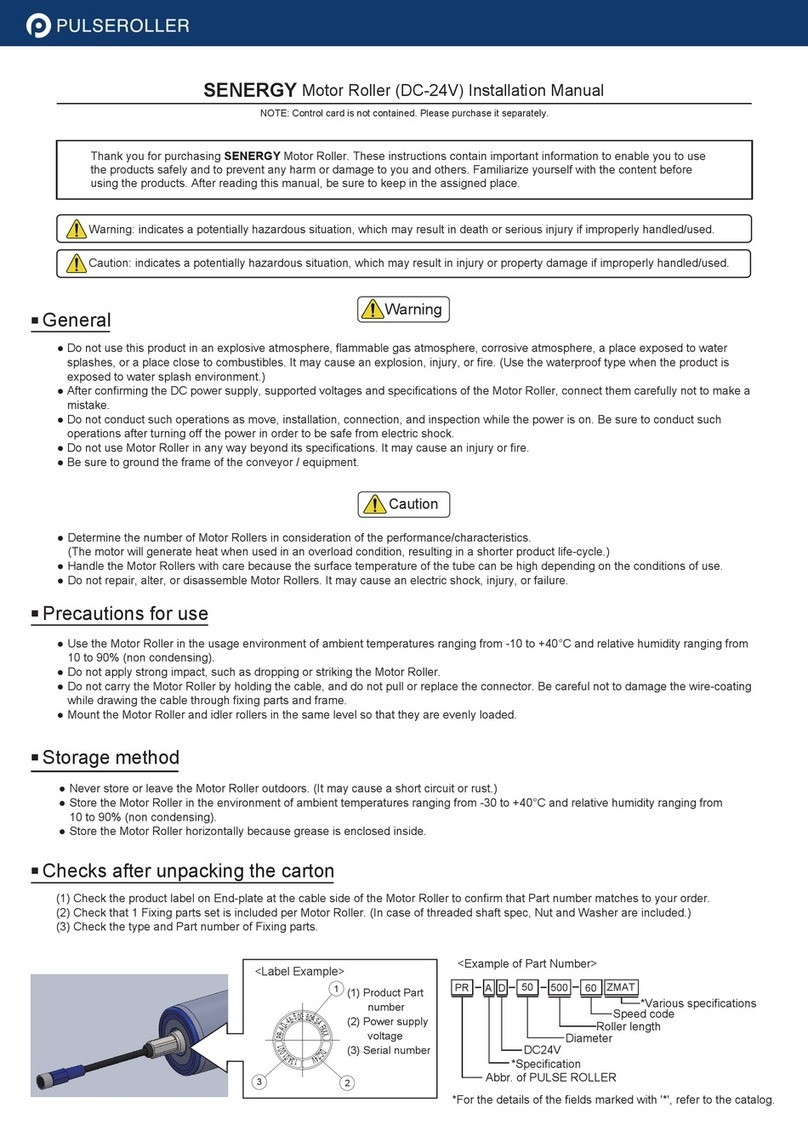

2.2 LOCATION OF COMPONENTS

1 - Hoisting eyebolt

2 - Compressor oil filter

3 - Compressor air filter

4 - Compressor cooler and motor

5 - Battery

6 - Inlet valve

7 - Separator

8 - Compressor

9 - Compressor oil filling point

10 - Engine oil filling point

11 - Pressure expansion chamber

12 - Engine air filter

13 - Fuel tank filling point

14 - Engine speed control cylinder

15 - Engine oil dipstick

16 - Engine oil filter

17 - Fuel filter

18 - Electro-stop.

2200 +50

+0

2

1

14

12

10 1

1517 1813 162

11

68

7

9

3

4

5

3

Braked version

2. TECHNICAL DATA

S65 II

6

E

2.3 DIMENSIONS

IMPORTANT

Instruction stickers fixed on the machine should be respected. They

should be replaced if damaged.

2.4 COMPRESSOR IDENTIFICATION

The compressor is designated with a serial number, which is stamped on

the manufacturer’s plate located on the front of the chassis.

This number is to be quoted when requesting information or ordering

parts.

2.5 ENGINE AND COMPONENT IDENTIFICATION

Components such as the engine and rotary screw are provided with a

Manufacturer’s identification plate.

4

Non-braked version

Plate

EC Signboard, plate

EC sound level sticker

Serial number

Total authorized loaded weight

Maximum axle load

Maximum tow hook load

Year of manufacture

Gross weight of machine

Maximum pressure

Engine power

Machine type reference

Maximum tow hook load

Engine rotation speed

Serial number

7

E

S65 II

3. DESCRIPTION

3.1 WORKING PRINCIPLE

ROTARY SCREW COMPRESSOR

3.2 DESCRIPTION OF COMPONENTS

The package includes a compressor unit, diesel engine, compressor inlet

system, compressor cooling and lubrication system, compressor dis-

charge system, capacity control system, a fuel tank, instrument panel and

electrical system. The compressor is also supplied with sound insulation

to lower noise emissions to a legally acceptable level.

The rigid tiltable canopy gives complete access to all components.

The airend compressor unit is driven by an industrial engine designed to

provide enough horsepower for more than adequate reserve at rated con-

ditions. Refer to the Engine Operator’s manual for a more detailed de-

scription of the engine.

The engine cooling system is comprise of a radiator, high capacity fan,

engine fluid cooler and thermostats. The fan draws air through the radia-

tor, keeping the engine at the proper operating temperature.

Another an is used to cool the fluid usedin thecompressorlubricationand

cooling system.

The engine drives the air end compressor via trapezoidal belts. The com-

pressor’s fuel tank has sufficient capacity for a full day’s operation.

3.3 AIR END COMPRESSOR UNIT

FUNCTIONAL DESCRIPTION

The air end compressor unit (1) is a single-stage, positive displacement,

fluid lubricated-type compressor. This unit provides continuous pulse-

free air to meet your needs and it does not require any maintenance of

inspection of its internal parts.

Fluid is unjected into the compressor unit, at each compression cycle and

mixes directly with the air as the screws turn.

The fluid has three main functions:

• As coolant, it controls the rise of air temperature associated with the

heat of compression.

• Seals the leakage paths between the rotors and the stator and also be-

tween the rotors themselves.

• Acts as a lubricating film between the rotors allowing one rotor to direct-

ly drive the other, which is an idler.

After the air/fluid mixture is discharged from the compressor unit, the fluid

is separated from the air. At this time, the air flows to your service line (13)

and the fluid is cooled in preparation for reinjection.

3.4 COMPRESSOR COOLING AND LUBRICATION

SYSTEM

The compressor cooling and lubrication system is designed to provide

adequate lubrication as well as maintain the proper operating tempera-

ture of the compressor.

• The fan (3) draws air through the cooler (4) to remove heat produced by

air compression.

• The fluid filter (2) stops impurities entering the air end compressor unit

(1).

In operation, fluid circulates from the separtor (5) to the cooler (4). This

circulation is caused by the pressure difference between the separator

(high pressure) and the low pressure zone of the air end compressor unit.

It is a radiator type cooler. The fan (3) sucks in air and discharges it

through the cooler, therby removing heat generated due to fluid compres-

sion. The fluid is then returned to main fluid filter (2) where it is filtered pri-

or to being re-injected into the compression chamber and bearings of the

compressor unit where it functions as a lubricant.

3.5 COMPRESSOR DISCHARGE SYSTEM

FUNCTIONAL DESCRIPTION

The air end compressor unit discharges compressed air/fluid mixture into

the separator.

The separator has four functions:

• It primary fluid separation system.

• Serves as the compressor fluid tank.

• Houses the air/fluid separator.

• Air reseve for the régulation.

The compressed air/fluid mixture enters the separator and is directed

against the side wall.

By change of direction and reduction of vellocity, larger droplets of fluid

fall to the bottom of the sump. The fractional percentage of fluid remaining

in the compressed air collects on the surface of the final separator car-

tridge (6) as the compressed air flows through it .

As more and more fluid collects on the cartridge surface the fluid de-

scends to the bottom of the separator. A return circuit (or plunger pipe 7)

links the bottom of the separator cartridge to the air end compressor inlet.

Fluid collecting on the bottom of the separator cartridge is returned to the

compressor by the pressure difference between the area surrounding the

separator cartridge and the compressor inlet. The return line includes an

orifice (14) which ensures proper flow.

The separator is CEE code rated at 1310 kPa (13 bar) working pressure.

A calibrated port (17), located downstream from the separator, helps

maintain a minimum receiver pressure of 350 kPa (3,5 bar) under all con-

ditions. This pressure is necessary for proper air/fluid separation and

proper fluid circulation.

A non return valve (19) is installed at the tap inlet to prevent compressed

air in the sevice line from bleeding back into the receiver on shutdown

when the compressor is being run in parallel with other compressors

linked to a large air system.

A pressure relief valve (9) located on the separator is set to open if the

sump pressure exceeds 900 kPa (9 bar). A temperature switch will shut-

cown the compressor if the discharge temperature reaches the admissi-

ble maximum temperature.

A

R

ADMISSION

The spacing of the lobes in front of the intake

port (A) creates a partial vacuum, enabling am-

bient air to enter the groove of the rotary

screws.

COMPRESSION

The meshing of the rotary screws traps the in-

take air, which is progressively compressed by

the rotation.

DELIVERY

The compressed air is progres-sively routed to

the exhaust port (R).

3. DESCRIPTION

S65 II

8

E

3.6 REGULATING SYSTEM

3.6.1 Starting

The pressure in the separator (5) is zero, the engine speed control cylin-

der (9) retains the engine speed control level in the full speed position.

When the ignition is switched on and the starter is activated:

- The safety devices are disconnected during the start-up phase by

means of a relay (see ch. 6).

- The engine starts and drives the compressor.

3.6.2 Operation of compressor set according to air consumption

There are three possible air consumption configurations:

A. High consumption: >= to the compressor delivery.

The pressure in the separator (5) never reaches the maximum pressure

and the compressed air does not active the controller (10) of the REGU-

LAIR unit. The cylinders (16) and (9) are therefore not supplied with air.

The inlet valve (A) fully opens and the engine runs at maximum speed.

B. Average consumption: < to the compressor delivery.

The pressure in the separator (5) reaches the working pressure. The con-

troller (10) of the regulair unit opens and supplies the cylinder (16) which

slightly closes the inlet valve (A), the pressure also pushes on the engine

speed control cylinder piston (9) which reduces the engine speed. The

lower the air consumption, the higher the pressure in the separator (5) is.

The governor (10) continues to supply the cylinder (16 & 9) at a higher

and higher pressure ; this tends to close the inlet valve (A) end reduce the

engine speed which in turn reduces the compressor output.

The positions of cylinders (16 & 9) are stabilized by a slight leak through

the controller (10 & 15).

In this configuration, the compressor rotates at a speed proportional to

the consumption.

C. Zero consumption: outlet valves (11) closed.

The pressure in the separator (5) is maximum. Cylinder (16), supplied at

this maximum pressure by the controller (10), closes the inlet valve (A).

Cylinder (9), which is also supplied, adjusts the engine to run at idling

speed. Only a very small quantity of air is compressed to ensure the lu-

brication system functions correctly. The excess compressed air can es-

cape through the bleeder valve (12) and the nozzle (15).

3.6.3 Shutting down: when the ignition is switched off

The solenoid (ref.18 photo 1) is disconnected and stops the engine.

The compressor stops feeding air. The inlet valve (A) is no longer under

depression and closes immediately due to its return spring and the back

pressure of the separator.

The bleeder valve (12) commanded by the remaining compressor’s pres-

sure connects the separator to the compressor’s air intake.

This action allows for quick re-start if necessary.

The control cylinder (16) is then released and the engine speed control

cylinder (9) places control lever in the full speed position.

3.7 SAFETY DEVICES

• Pressure relief valve (8) on the separator.

3 safety devices are provided to shut down the engine by an electro stop

(e) (see section 6) when a fault occurs.

The battery charge lamp on the instrument panel then lights up.

The safety devices protect the engine and compressor against the risks

of :

• Engine oil pressure drop: Pressure switch (g).

• Compressor overheating: Thermal switch (T2).

• Engine overheating: Water thermal switch (T1).

Oil

Compressed air/fluid mixture

Compressed air

Max. speed end stop Idling end stop

9

E

S65 II

4. USE

4.1 TRANSPORT (photo 5)

• Adjust the drawbar for the correct height and check the tyre inflation

pressure.

• Connects the light cables into the socket on the front of the chassis

(standard 7 pin socket ref.1) and check the lights.

• For non-braked compressors, attach the safety chains to the two rings

provided on the compressor chassis and to the towing vehicle. These

chains must be kept as short as possible without however affecting the

maneouvring of the towing vehicle.

• For braked compressors, attach the safety cable, integral with the park-

ing brake (ref.2) , to the towing vehicle to ensure automatic braking of

the unit if the coupling breaks.

Release, the parking brake if necessary.

NOTE:

These braked compressor units have an automaticreversingdevice mak-

ing it possible to reverse with the towing vehicle without damaging the

drawbar. This is possible because of an integrated system which stops

the brake shoes blocking.

This system requires a strong action on the parking brake lever to make

sure that the non-coupled unit is blocked. In this case, make sure that the

unit is completely blocked after using the lever.

• Place the front wheel or the drawbar stand to the «towing» position.

Handling with lifting ring (photo 6)

To use the lifting ring (1), open the cover to let the sling pass through the

hole. Lift the unit after making sure that the capacity of the hoisting equip-

ment is sufficient.

After handling, re-close the cover.

4.2 PARKING OR LOCATING COMPRESSOR

The compressor set must always be positioned on a stretch of flat and

level ground.

The maximum permissible transverse and longitudinal gradient is 15°

(see drawing).

If necessary, insert chocks under the wheels.

To conform with the sound level regulations pertaining to Public Works

equipment, the compressor should be operated with the "canopy closed",

the cooling of the compressor set is only ensured when the canopy is

closed.

In a very dusty environment, install the compressor set in the least pollut-

ed area.

The set should be operated in a ventilated place and should never be op-

erated in an enclosed area unless the latter is of sufficient dimensions

and provided with suitable ventilation for the discharge of hot air and ex-

haust gases and the supply of fresh air.

A flexible hose with a minimum diameter of 100 mm is to be provided for

the discharge of the engine exhaust gases. This hose should be insulated

to avoid any risks of fire.

To avoid any risk of recycling hot air, never place the fresh air suction

ports, hot air discharge ports and exhaust outlet too close to an obstacle.

4.3 PREPARING THE BATTERY FOR SERVICE

- Connect the battery terminals without overtightening the nuts.

- Start the engine and allow to run for at least 10 minutes.

To ensure proper operation, it is recommended to give the battery a boost

charge for at least 2 hours at a 1/10 of its capacity and to use the com-

pressor for a long enough period after installation of the new battery.

4.4 PRECAUTIONS TO BE TAKEN PRIOR

TO STARTING

NOTE:

For all engine procedures consult the engine manual.

Contact the SULLAIR specialist prior to starting a compressor set which

has not been used for a long period (more than six months) or has not

been specially prepared for long shut down periods.

CHECK:

• The compressor set internal cleanliness (oil, fuel, cloths, etc…).

• The compressor air filter cleanliness if working in a very dusty atmos-

phere (see clogging indicator ref.1 photo 7). Pinch dust valve drain

(ref.2).

• The engine oil level: Dipstick (ref.1 photo 8).

Check the engine oil level before starting the engine or more than five

minutes after it has been stopped.

Lift out the oil level dipstick, wipe it clean, reinsert it, take it out again, and

check the oil level. (A) engine oil level within this range is proper.

If the oil level is too low, remove the oil filler plug (see ch. 2.2), and supply

new oil to the prescribed level.

Never overfill above the dipstick maximum mark.

• Check the engine coolant in the reserve tank (ref.1 photo 9). If must be

within the range between «full» and «low», and in the event of insuffi-

cient coolant, fill the radiator with special coolant.

Never top up the coolant level with water.

5

12

6

1

15° 15°

4. USE

S65 II

10

E

IMPORTANT

• Be sure to tighten the radiator pressure cap (ref.2 photo 9) securely af-

ter filling up.

• The separator oil level: Keep the level at maximum (fig S).

The maxi level is determined by the filling hole thus it cannot be over-

filled.

• The battery electrolyte level: should be from 10 to 15 mm above the

plates. Top-up with distilled water if necessary.

• Fuel pre-filter cleanliness (part 2, photo 14). The filter should not contain

water or dirt. If necessary change it.

To ensure that the oil levels are stabilized, they should always be

checked when the compressor set is cold.

Use only the oils recommended in the maintenance section.

4.5 FILLING FUEL TANK

- Correctly close the filler cap (ref.1 photo 10) after refueling.

- Clean all overflow diesel fuel.

- Do not smoke.

- Use a strainer when filling the fuel tank, or dirt or sand in the fuel

may cause trouble in the fuel injection pump.

- Keep the engine away from fire when filling.

Ensure that only clean diesel fuel conforming to engine constructor spec-

ifications (below), is used - especialy in cold weather:

• DIN 51-601.

• ASTM D 975-81: 1-D and 2-D

• Codes OTAN F 54, F 75 and F 76

• VV-F-800a: DF-A, DF-1 and DF-2

• BS 2869: A1 and A2

(For A2 comply with sulphur content)

• Do not draw fuel from a drum if it has not been decanted. Never use the

fuel remaining at the bottom of a drum.

• Fill the fuel tank in the evening to avoid water condensate formation

during the night.

7

8

1

2

1

11

10

Maxi: Threading bottom

Mini: bottom of bend

9

S

1

2

1

1

4. USE

S65 II

11

E

4.6 CONTROL PANEL

1 - Manometer

2 - Hours meter

3 - Battery charge lamp

4 - Preheat lamp

5 - Starter selector switch (COM)

4.7 STARTING (photo 12)

Starting should not be attempted until all the operations detailed in the

previous section have been accomplished.

IMPORTANT

In very cold weather respect imperatively the engine maker’s instructions.

1. Open the air outlet valves: No load Start.

Turn on the COM selector switch (5) : the battery charge lamp (3)

lights up.

2. Position 2 on COM (5) : Preheating. Hold down until PRE lamp (4)

goes out.

3. Turn to position 3 to engage the starter then release as soon as the

engine starts.

NOTE:

The start-up position also feeds the preheating spark plugs.

4. Do not try for more than 10 seconds in very cold weather. Recom-

mence step 2.

5. Allow the compressor set to warm up for about 5 minutes and pro-

gressively close the outlet valve, to obtain a stabilized pressure

between 6 and 7 bars. The compressor runs at regulating system.

4.8 UTILIZATION

Connect the supply hoses to the valves (not connected) and progressi-

vely open the valves to purge them. Never open the valves abruptly, to

avoid dirt projection and hose whiplashing which could cause an acci-

dent.

Then shut the valves before connecting the tools and reopen them pro-

gressively to use the tools.

NOTE:

Do not forget to apply the manufacturer’s instructions for pneumatic tools

before connecting to the compressor.

4.9 SHUTTING DOWN

- Close the air valves and let the compressor set idle for 1 ou 2 minu-

tes to avoid a sudden stop, especially after intensive use in cold

weather.

- Switch off the ignition switch (5).

NOTE:

In case of long shut down (more than 6 months) contact your SULLAIR

specialist to insure the “Long Period” shut down treatment to avoid star-

ting difficulties later.

12

21 3

45

S65 II

12

E

5. MAINTENANCE

IMPORTANT

The maintenanceoperations indicated in thismanual are given for normal

conditions. In difficult conditions, extreme temperatures, high relative hu-

midity, polluted or dusty environment, high altitude etc… certain opera-

tions must be carried out more frequently and certain precautions must

be taken. Consult the engine maker’s manual and your local SULLAIR

specialist.

Also respect elementary safety rules to avoid accidents (See ch.1).

Waste disposal:

Drained ingredients like oil, fuel, grease, cooling fluid, battery acid and

detergents should not penetrate the soil. They should be collected in suit-

able containers and be disposed according to environment-friendly pre-

scriptions. This applies to all filter cartridges and spare parts as well.

WARNING!

DO NOT remove caps, plugs, or other components

when compressor is running or pressurized. Stop com-

pressor and relieve all internal pressure before doing

so.

RUNNING IN

The compressor set must be closely monitored during the running in pe-

riod. Besides the daily operations (or 10 hourly operations), the following

specific operations must be done after 50 hours:

5.1 MAINTENANCE - First 50 hours

5.2 MAINTENANCE 10 HOURS (or daily)

- Check the engine coolant level:

The engine coolant level with reserve tank must be within the range

between «full» and «low» (see ch.4.5).

- Check the engine oil level:

Compressor set standing on level ground with the engine shut down

and cold. The oil level should be between the MAXI and MINI marks

on the dipstick (see ch.4.5).

- Check the diesel fuel level:

Top up if necessary to avoid filling up during running and to avoid

the risk of running out of diesel. Use only clean water-free diesel

fuel observing the instructions in chapter. 4.6.

- Check the separator oil level:

With the compressor set in same conditions as above, the oil level

should be between maxi and mini marks (see ch.4.5).

- Check the battery electrolyte level:

The level should be between 10 and 15 mm. above the plates. It

may be sufficient to perform this check about every 50 hours.

NOTE:

Topping up should always be done with the products recommended in

the following maintenance section. In very dusty environments, the air fil-

ters should be cleaned as well (see ch.4.5).

5.3 MAINTENANCE 100 HOURS

5.3.1 Engine oil draining and changing oil fiter

(see engine manual)

The compressor set should be standing stopped on level ground with the

engine warm. An extension piece makes it possible to bring the drain plug

under the chassis (photo 13).

Put a drain pan under the engine to avoid spillage, and permit subse-

quent processing of the oil.

Engine oil filter (rep.1 photo 13)

NOTE:

Amultigrade15W 40 oil is used for theinitial filling in the works. If climatic

conditions dictate, replace this oil by one of appropriate viscosity.

5.3.2 Change the diesel fuel filter

(see engine manual)

• Change cartridges (ref.1 and 2 photo 14)

5.3.3 Draining off water in diesel fuel tank

• Unscrew plug (ref.1 photo 11) fitted under the chassis.

• Let water flow out until diesel fuel flows clean and replace the plug and

tighten.

This operation should be done every 3 months.

COMPRESSOR SET:

• check the battery electrolyte level......................... ch.5.2

• check tyre pressure and tighteness bolts

or wheel nuts......................................................... ch.5.3.12

• purge the fuel tank and circuit............................... ch. 5.3.3

• check fuel pre-filter................................................ ch.4.5

• check tighteness of all bolts

• grease articulations............................................... ch. 5.3.11

ENGINE: (see engine manual)

• check and clean the air filter

• drain the sump

• change the oil filter cartridge

• change fuel filter cartridge

and prefilter (if necessary)

• check fan belt (tension)

• check valve clearance

COMPRESSOR:

• check and clean the air filter ................................. ch.5.3.4

• change the oil filter................................................ ch.5.4.1

• check drive belt (tension)...................................... ch.5.3.8

• clean the dip tube strainer..................................... ch.5.3.6

• check the control functioning

(speed and pressure)

13

1

14

1

2

1

5. MAINTENANCE

S65 II

13

E

5.3.4 Cleaning and checking compressor air filter

• Uncouple and dismount the filter (photo 15).

• Remove primary cartridges (ref.1).

- Blow on them, gently, from the inside towards the outside, if they

are too sealed, change them.

- Check their condition, if they are too sealed, change them.

NOTE: the filter has a de-dusting valve.

5.3.5 Cleaning coolers and fans

(photo 16 - 11)

The cleaning frequency depends on the operating conditions.

Do not aim the high pressure cleaning jet directly onto the cooling fins.

5.3.6 Cleaning the separator

return line

• Unscrew the hose (1) located on

the dip tube.

• Check that the nozzle (2) is clean.

5.3.7 Engine belt tension

(see engine manual)

An improperly adjusted fan belt can

cause engine overheating and insuf-

ficient battery charging.

5.3.8 Compressor belts tension

must be done

by a SULLAIR specialist

• Check belts tension.

If necessary retension by loosening

the fixing screws (ref.1 photo 17) and acting on the tension screw

(ref.2). Arrow under load of 4kg.

• Re-tighten the compressor fixing screws (ref.1).

IMPORTANT:

It is obligatory to use the belts kit.

Never replace only one belt.

5.3.9 Tighteness of compressor oil filter cartridge

• Check the cartridge is fully screwed in (ref.1 photo 18).

5.3.10Battery charge

• Check the electrolyte level, if necessary, top up with distilled water.

• Check the acid specific gravity, charge the battery if necessary.

5.3.11Lubrication of hinge points

• Bodywork hinge.

• Control cylinder rod (ref.14 photo 1).

5.3.12Wheels - tyres - axle

• Check the tighteness of the wheel nuts and the tyre pressure (when

cold).

• Grease the axle.

5.4 MAINTENANCE 500 HOURS

5.4.1 Compressor oil filter

• Change the filter at the same time as draining the separator.

• Remove the cartridge and discard (ref.1 photo 18).

• Lightly oil joint then install a new cartridge.

5.4.2 Change compressor air filter cartridge

(see ch.5.3.4)

5.4.3 Engine radiator

(see engine manual)

Prescribed coolant volume: see page 17.

15 16

1

1 2

19

18

17

1

1

2

5. MAINTENANCE

S65 II

14

E

5.5 MAINTENANCE 1000 HOURS (or Yearly)

5.5.1 Engine valve clearances

Must be done by a kubota specialist.

5.5.2 Draining separator (arrow photo 19)

• Put a drain pan under the separator.

• Loosen the filling cap.

• Unscrew the drain plug and drain.

After replacing and tightening up the drain plug, fill up to the maxi level

which is indicated by the filling orifice (ch. 4.5 - fig.S).

Recommended oil: Summer / Winter

Temperate climate ............................ A.W.F.

Oil conforms to the DIN 51506 VDL 46 or ISO DAH norm.

In the case of extreme temperatures, consult your SULLAIR agent.

IMPORTANT:

The 1000 hours frenquency maintenance is applicable for normal working

conditions. If used in a very humid or hot conditions reduce maintenance

frequency to every 500 hours.

5.5.3 Separator cartridge

The separator cartridge must be replaced when it is no longer efficient

(presence of oil in the air during operation).

NOTE:

No attempt should be made to clean this cartridge as it would be com-

pletely useless and dangerous.

Removal of the cartridge:

• Remove cover (3) of the separator, being careful not to bend the dip

pipe fixed in the cover.

• Remove the cartridge (4) and check the cleanliness of the inside of the

separator (5).

Assembly of new cartridge:

• Clean the contact faces.

• Install the new cartridge with stapled gaskets.

• Replace cover and dip tube having taken the opportunity to clear the

nozzle beforehand (ch.5.3.6).

• Tighten the separator cover (8m/kg).

NOTE:

Do not remove the ground staples on the new cartridge, as they ensure

electrical continuity and avoid any electrostatic phenomena.

5.6 TABLE OF MAINTENANCE OPERATIONS

1

23

4

5

OPERATION CHAP.

Daily

• Check fuel tank level

• Check oil level (engine and compressor)

• Check radiator coolant level

• Check dust drain valve, air filters

• Check diesel fuel prefilter

• Check battery

5.2

5.2

5.2

5.3.4

4.5

5.2

First 50-100 hours

• See engine and compressor instruction manual 5.1

Every 100 hours

• Clean complete compressor set

• Clean engine radiator and compressor cooler

• Clean compressor air filter

• Check diesel fuel cartridge

• Clean the return line nozzle

• Drain off water in diesel fuel tank

• Control fan belt tension

• Control fan belt tension

• Tighteness of compressor oil filter cartridge

• Check battery charge

• Lubrication of hinge points

• Check tyre pressure and tightness of wheel nuts

5.3.5

5.3.4

5.3.2

5.3.6

5.3.3

5.3.7

5.3.8

5.3.9

5.3.10

5.3.11

5.3.12

Every 200 hours

• Drain engine and change the oil filter 5.3.1

Every 500 Hors or 6 months

• Clean complete compressor set

• Change air filter cartridges

• Change compressor oil filter

• Check cooling circuit

• Check max. speed and idle speed

5.3.4

5.4.1

5.4.3

Every 1 000 Hours

or yearly

• Clean the return line nozzle

• Change separator oil

• Change separator cartridge

• Check regulating system

5.3.6

5.5.2

5.5.3

15

E

S65 II

6. ELECTRIC CIRCUIT

6.1 SCHEMA

f1 fuse 60 A

f2 fuse 10 A

COM key switch

VC load/contact indicator light

VPRE preheat indicator light

TEMP time delay unit

RS safety relay

RE safety device blanking relay

ES electro-stop

PGO gas oil electric pumpl

Sd starter solenoid

a alternator

M engine

h hour meter

g engine oil pressure switch

T1 engine coolant temperature switch

T2 air/oil mixture discharge temperature switch

6.2 ELECTRIC CIRCUIT OPERATION

1. Start up

Position 1 on key switch (COM) 8-15/54

The + 12V battery supplies:

- the load indicator light (VC)

- the gas-oil electric pump (PGO)

- the safety relay (RS)

Position 2 on key switch (COM) 8-15/54/19

The + 12V battery supplies:

- The preheating spark plugs and the time delay unit (TEMP), which

determines the preheating time until the indicator light (VPRE) goes

out.

Position 3 on key switch (COM) 8-15/54/19/17/50

The + 12V supplies:

- the starter

- the safety device blanking relay (RE)

- the solenoid (ES) in call position

2. The engine starts

The key switch (COM) returns to position 1

- the load indicator light goes out

- the hour meter (h) and hold-on solenoid (ES) are supplied by the sa-

fety relay (RS).

3. Normal shutdown

When the key switch (COM) is turned off, the complete circuit is de-ener-

gized and the electro-stop (ES) shuts the motor off. The hour meter (h)

stops counting and the load indicator light goes out.

4. Shut down via safety system

There are 3 safety devices:

- Engine oil pressure drop: pressure switch (g).

- Abnormal engine coolant temperature rise: temperature switch

(T1).

- Abnormal oil/air temperature rise at the compressor unit’s dischar-

ge: temperature switch (T2).

They function by closing their contacts at earth which energize the safety

relay (RS). The latter opens its contact and cuts off the electro-stop (ES)

which in turn cuts the engine injection (even with a passing fault).

The engine stops. The air circuit is decompressed. The load indicator li-

ght lights up. The hour meter stops counting.

S65 II

16

E

7. TROUBLESHOOTING

SYMPTOM PROBABLE CAUSE REMEDY

1. Compressor will not

start. 1. No fuel.

2. Plugged fuel filter.

3. Low battery voltage.

4. Plugged air filter.

5. Engine problems may have developed.

6. Defective engine oil pressure switch.

7. Blown fuse in wiring harness.

8. Faulty electro-stop.

Check fuel level and add fuel if necessary.

Replace the filter cartridge and its secondary filter.

a. Check electrolyte level and add water if necessary. Recharge or replace if necessary.

b. Loose battery cable, tighten cables.

c. Dirty battery cables, clean thoroughly.

Clean or replace the element.

Refer to engine operators manual.

Check continuous flow and replace if necessary.

Check continuity and replace if necessary.

Check and replace if necessary.

2. Compressor shuts

down with air demand

present.

1. No fuel.

2. Compressor discharge temperature

switch is open.

3. Defective engine oil presure switch.

4. Blown fuse in wiring harness.

5. Faulty electro-stop.

Check fuel gauge and add fuel if necessary.

a. Cooling air flow is insufficient. Clean cooler and check for proper ventilation.

b. Low fluid sump level. Add fluid.

c. Compressor fluid too dirty: change fluid.

d. Fluid filter clogged: change cartridge.

e. Defective discharge temperature switch. Check for a short or open circuit to the engine

fuel rack solenoid. should this check out normal, it is possible that the temperature

switch itself is defective.

Check continuity and replace if necessary.

Check continuity and replace if necessary.

Check and replace if necessary.

3. Compressor will not

build up full discharge

pressure.

1. Air demand is too great.

2. Dirty air filter.

3. Pressure regulator out of adjustment.

Check service lines for leaks or open valves.

Check the filter indicator and change or clean element if required.

Adjust regulator according to control adjustment instructions in th Maintenance section.

4. Improper unloading,

with excessive pres-

sure buid-up causing

pres-sure relief to

open.

1. Pressure regulating valve is set too high.

2. Inlet valve jammed.

3. Restriction in the control system.

4. Clogged regulating connected.

5. Defective pressure regulating valve.

6. Defective cylinder.

Readjust.

Free or replace valve.

Check all control lines and components. Ice and other contaminants could cause restric-

tions.

Check and replace if necessary.

Inspect membrane and replace if necessary (repair kit available).

Check its condition, change if necessary

5. Insufficient air delivery. 1. Plugged air filter.

2. Plugged air/fluid separator.

3. Defective pressure regulator.

4. Engine speed too low.

5. Leak in control system causing loss of

pressure signal.

6. Defective cylinder.

Clean or replace.

Replace separator element and also change compressor fluid and fluid filter at this time.

Adjust or repair.

Readjust engine speed.

Check all control lines.

Check its condition, change if necessary

6. Excessive compressor

fluid con-sumption. 1. Clogged return line.

2. Leak in lubrication system.

3. Separator element damaged or not func-

tioning properly.

4. Fluid separator too full.

Clean orfice and return line strainer.

Check all pipes, connections and components.

Change separator element.

Drain to correct level.

7. Compressor overheat-

ing. 1. Loose or broken compressor belt.

2. Dirty fluid cooler core.

3. Plugged fluid cooler tubes (internal).

4. Low sump fluid level.

5. Plugged compressor fluid filter.

6. Clogged return line.

7. Hot air return.

Tighten or change belt.

Clean core thoroughly.

Clean them thoroughly.

Fill up.

Change element.

Clean orfice and return line strainer.

Check cowling lock and internal compartment leaks.

8. Engine overheating. 1. Loose or broken fan belt.

2. Dirty radiator core.

3. Low water level.

4. Low fluid level.

5. Faulty water pump.

6. Plugged radiator.

7. Faulty thermostat.

Tighten or change belt.

Clean thoroughly.

Refill.

Refill.

Change pump.

Clean thoroughly.

Change thermostat element.

17

E

S65 II

8. RECOMMENDATIONS FOR SPARE PARTS

Who should you contact ?

You must contact our Agent,Trader or Subsidiary Company which repre-

sents us in your country.

Only this network is able to provide you with original parts, namely top

quality components.

What information should you give ?

To make out an order correctly, give all the following informations:

- type or model of machine and serial number.

- the part number, designation and quentity of parts or sub-assem-

blies you have referenced in the catalogue.

- if necessary, the catalogue edition.

Précautions

In order to obtain a maximum utilization of your compressor, we recom-

mend you always keep a lot, of the following spare parts:

This list can be adapted to your particular circumstances.

* In accordance with use conditions

** belt tension 4 mm under 4 kg

Engine oil sump capacity 9,5 l

Engine coolant volume 8,5 l

Separator fluid capacity 7,5 l (total)

RECOMMENDED SPARE PART LIST

Reference Q KIT Description Replacement and maintenance

68560938 2 B Safety cartridge, engine and compressor air filter every 4 primary cartridge changes

68560937 2 A primary cartrige, engine and compressor air filter clean every week and change / 500 h *

02250098-048 1 compressor fluid AWF (4 x 3,8 L) 1000h or 1 year, first reached

68560439 1 B separator cartridge with gaskets 1000h or 1 year, first reached

68819388 1 B 2 compressor belts kit checkevery week and change / 1000 h

68521824 1 A compressor oil filter 500 h

68780281 1 A diesel fuel secondary filter 200 h

68415814 1 A diesel fuel filter 100 h

68415000 1 A engine oil filter 100 h, then every 200 h

68529883 1 regulator, pressure

68520357 2 relay, safety

68415047 1 engine oil pressure switch

68415032 1 water thermo - switch

68520697 1 thermo-switch compressor

68563100 1 cylinder

68415023 1 solenoid

68563125 1 key switch

68563222 1 fuse 60 A

68416154 1 altenator belt

68822400 2 fuse 10 A

68780293 1 KIT "FILTRATION" includes parts A

68780294 1 KIT "1 YEAR" includes A and B

Table of contents

Other Sullair Industrial Equipment manuals