SEA USA GATE 1 DG R2BF User manual

GATE 1 DG R2BF GATE 1 DG R2EF GATE 1 DG R3BF

67412252 REV. 00 - 06/2022

QUICK START

FULL MANUAL

(Rev. 15)

&

SAFETY

INFORMATION

SEA USA Inc.

10850 N.W. - 21st - unit 160 - Doral - MIAMI - Florida (FL) - 33172 - USA

Telephone - Toll free: : ++1-305.594.1151 ++1-305.594.7325 800.689.4716

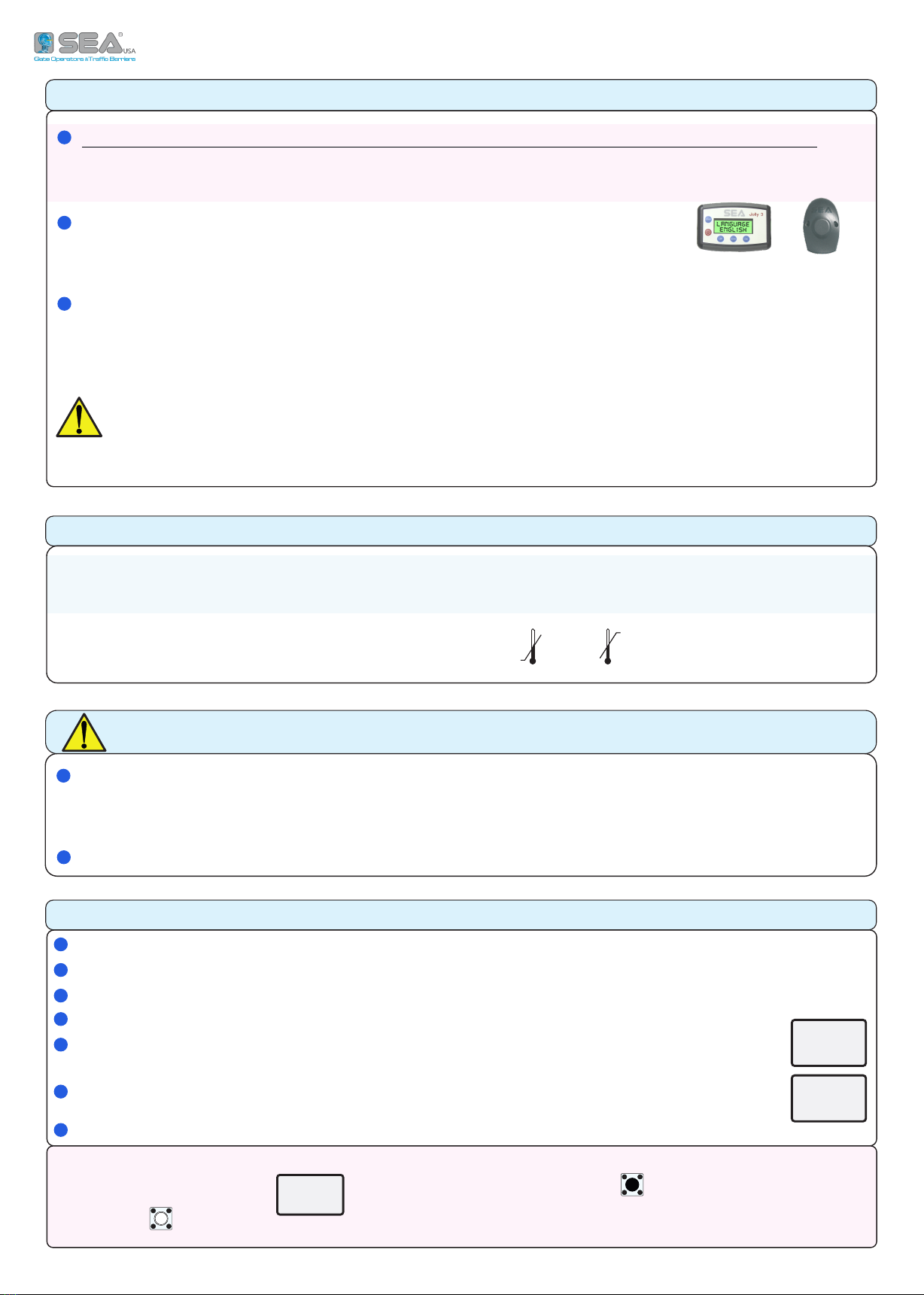

JOLLY 3 SEACLOUD

T

JOLLY 3

SEACLOUD

T GATE 1 DG (

7);

!

F

; ,

A (, )

;

PRELIMINARY

TECHNICAL INFORMATION

-

230V - 50/60 H

115V - 50/60 H

30 mA

-20° C +50°C

( )

IP 55

GATE 1 DG R2BF (SOFTWARE REV. 03.04)

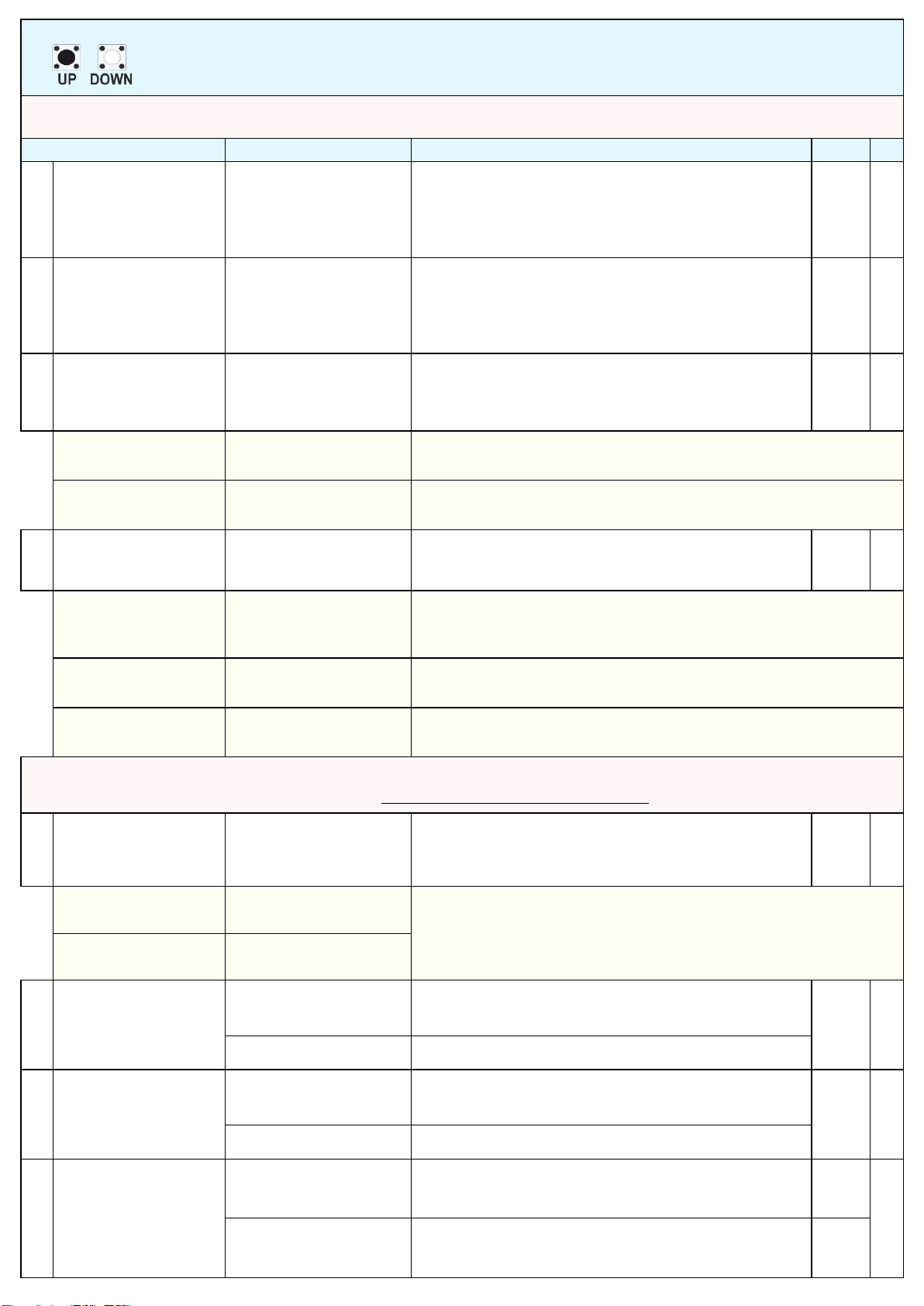

QUICK START

F « 1 3» : ,

;

a

, ,

192

MOVE

GATE UP

DOWN

7

TIMER TO

CLOSE

3

MOTOR

M ( OFF): ,

DO NOT N.C. ( .. )

P ( 5)

O - «» ( 6)

S 7 «» ( )

«-» ( )

C 3 ( )

S 7

IMPORTANT SAFETY INFORMATION - RESET BUTTON

GATE 1 DG « » UL STANDARDS (UL325).

A , BUZZER .

T B , « »

C « » , 5 6 CN1

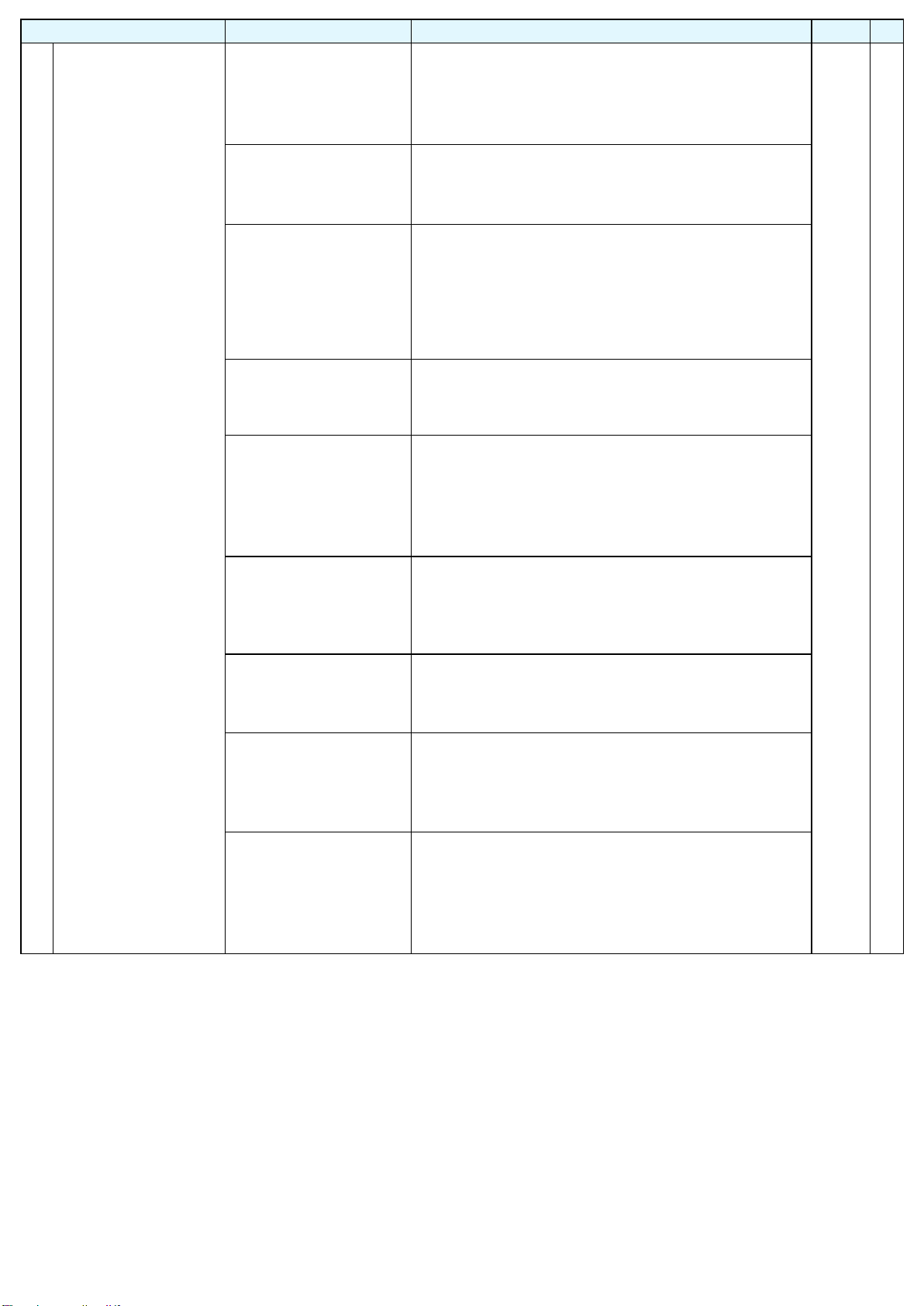

GATE 1 DG R2EF (SOFTWARE REV. 03.04) GATE 1 DG R3BF (SOFTWARE REV. 00.01)

2

1

Common

Light (-)

*24VAUX 500mA max.

-

UP DOWN OK

BLACK WHITE RED

+

EXTERNAL MODULE

CONNECTOR

JOLLY3/SEACLOUD

CONNECTOR

RF RECEIVER

CONNECTOR

PRIMARY

SECONDARY

CONNECTOR

OPEN

(Firmware update)

RF FIX RECEIVER

CONNECTOR

PROGRAMMING

BUTTONS

* A 24V 500mA, 24V

, (30 mA)

ANT COM START STPD STOP COM PH1 PH2 EDGE1 24VAUX COM 24V(FL) FL(-)

ANT COM START STPD STOP COM PH1 PH2 EDGE1 24VAUX COM 24V(FL) FL(-)

OPTIONAL JUMPERS

AUTOMATIC RECOGNITION OF THE

N.C. INPUTS NOT IN USE - NO JUMPER IS

REQUIRED ON THE N.C. CONTACTS

UP DOWN OK

TR1

98

7

6

5

4

3

2

110 13

12

11

CN1

98

7

6

5

4

3

2

110 13

12

11

CN1

CN1 CN2

JOLLY

CLOUD

CNS

CNS

CN4

CNA

DISPLAY

CMS

PRIMARY

SECONDARY

EXP

--------

--------

- - - - - - - -

- - - - - - - -

NL

CNP

CN7

CN6

CN5

20

19

18

17

16

15

14

20

19

18

17

16

15

14

CN2

CN3

F2

R1

R2

F1

T1

155 mm

85 mm

+

-

*24V 500mA max.

(accessories)

98

7

6

5

4

3

2

110 13

12

11

THE INPUTS EXCLUDED DURING THE

WORKING TIMES PROGRAMMING CAN BE

RESTORED THROUGH THE «INPUTS

MANAGEMENT» MENU (CHAPTER 7).

NO NEED TO SET UP THE UNIT AGAIN

NL

Courtesy light (phase)

Courtesy light (neutral)

Motor 1 opening

Motor 1 capacitor

LIGHT LIGHTN MCL MN MOP CAPACITOR

Motor 1 closing

Motor 1 neutral

M

CN3

Neutral

Line

CN4

24Vac *

Max. 150 mA

CN5

CN6

Red/Brown

Blue/White

Black/Green

CONNETTORE

ENCODER

1

Opening limit switch (green)

Closing limit switch (yellow)

Common (white)

* 24V (red)

Opening limit switch (green)

Closing limit switch (yellow)

CN7

CNP

T1

R1

R2

F1

F2

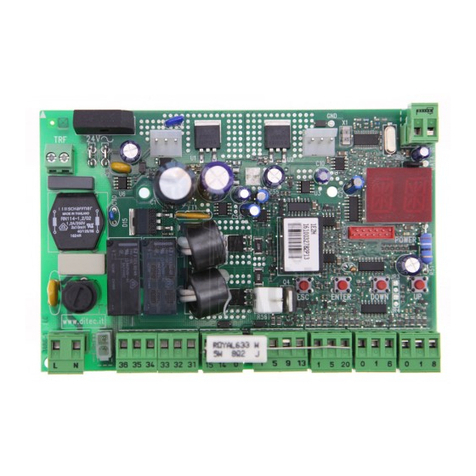

TR1

EXP JOLLY/CLOUD

CMS

CNA CNS

=

=

=

=

=

=

MOTOR CONTROL TRIAC

MOTOR AND COURTESY LIGHT RELAY

MOTOR EXCHANGE RELAY

FUSE 6.3AT (230V) OR 10AT (115V)

FUSE ACCESSORIES 1A

POWER TRANSFORMER

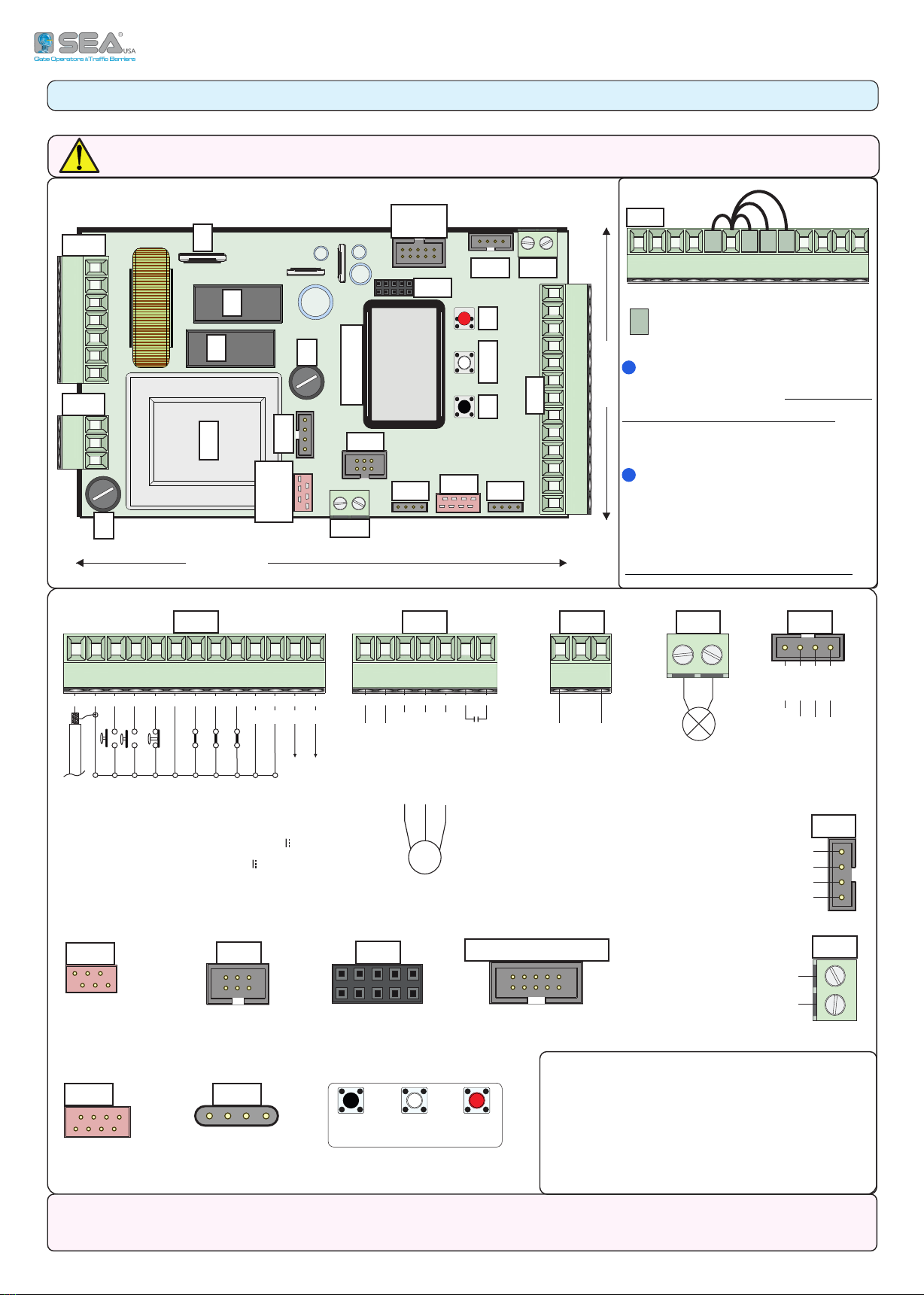

1 - CONNECTIONS

WARNING: CONNECT ALL DEVICES WHEN THE CONTROL UNIT IS SWITCHED-OFF

Start

Stop

Common

Antenna

Common

Photocell 1

Photocell 2

Partial START

Safety edge

3

2 - MAIN WIRINGS

EXAMPLES OF LIMIT SWITCH WIRINGS

EXAMPLE OF ENCODER WIRING

EXAMPLE OF

ANTENNA

START

PARTIAL START

STOP

PHOTOCELLS

WIRINGS

1

CN6

RED

RED = 24V

BLACK

YELLOW

YELLOW = CLOSING LIMIT SWITCH

13

12

11

10

9

CN1 CN7

GREEN

GREEN = OPENING LIMIT SWITCH

WHITE

WHITE = COMMON

CN5

1

2 1

OFF

DIP SWITCH 1 = OFF

DIP SWITCH 2 = OFF

P11

D1

P01

POTENTIOMETER

EXAMPLE OF POTENTIOMETER WIRING via «LSE» UNIT

M1

1 2 4 56 73

8

9 10 11

M2

DS1

2 1

ON

CN1

POT

ENC

CNP

+

-

P01 P02

GND

I3

D1 P11 D2 P12 I1 I2 I4

LSE

8

7

6

5

4

3

2

1

CN1

TX1

TX2

CN1

RX1

RX2

Start

Stop

Antenna

13

12

11

910

24V (+)

Common

Common

Common

Photocell 1

Photocell 2

Partial Start

YELLOW

GREEN

PRE-WIRED

LIMIT SWITCH

NON

PRE-WIRED

LIMIT SWITCH

(EXAMPLE)

BLACK

ENCODER NEW MODEL: BLACK - BLUE - RED

ENCODER OLD MODEL: GREEN - WHITE - BROWN

BLUE

RED

BLACK (WHITE) D1

BLUE (GREEN) P01

BROWN P11

98

710 12

11

CN1

Common

Edge 1

24V (+)

98

710 12

11

CN1

Photo 1

Photo 2

Common

CN1

13

12

11

10

9

-

+

BUZZER

Lamp FL(-)

7 8

24V (+)

EXAMPLES OF 10K PHOTOCELLS WIRINGS

10K PHOTOCELL

10K PHOTOCELL

UP TO 4 10K PHOTOCELLS

24V (+)

EXAMPLE OF 10K PHOTOCELL

AND BUZZER WIRINGS

EXAMPLE OF SAFETY EDGE AND

WARNING LAMP WIRINGS

Common

Edge 1

GATE 1 DG R2BF

GATE 1 DG R2EF

GATE 1 DG R3BF

YELLOW = CLOSING LIMIT SWITCH

GREEN = OPENING LIMIT SWITCH

BLACK = COMMON

13

12

11

10

9

24V (+)

SAFETY EDGE

Edge 1

Common

Lamp FL(-)

CN1

(EXAMPLE)

4

3 - OPERATOR WIRING ON CONTROL UNIT

CN2

20

19

18

17

16

15

14

MCL MN MOP CAPACITOR

a

OK UP

3

OK

4 - CONTROL UNIT POWER SUPPLY

NL

CN3

-

-

5 - INPUTS STATUS

00111110

1 2 3 4 5 6 7 8

9 10 11 12 13 14 15 16

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

11000000

-

-

-

-

01

00111110

11000000

START

(N.O.)

START

(N.C.)

10111110

11000000 11000000

00111110

11000000

00101110

= MCL - M1 CLOSING

= MN - M1 NEUTRAL (WHITE)

= MOP - M1 OPENING

= CAPACITOR

16

17

18

19 - 20

M

~

*

*

MOTOR 1 (115V)

BLUE 230V

(EXAMPLE)

CAPACITOR

O

A ,

3

SLIDING

MOTOR

(EXAMPLE)

T !

F 16AT 230V~

F 16AT 115V~

U 10A

F

I ,

UPS .800VA

E ,

E : (0) - (1)

N.O. - N.C. -

START

PARTIAL START

STOP

PHOTOCELL 1

PHOTOCELL 2

SAFETY EDGE 1

SAFETY EDGE 2

NOT IN USE

MOTOR 1 OPENING LIMIT SWITCH

MOTOR 1 CLOSING LIMIT SWITCH

NOT IN USE

NOT IN USE

NOT IN USE

NOT IN USE

NOT IN USE

NOT IN USE

PHOTOCELL 1

(N.C.) PHOTOCELL 1

(N.O.)

S P S N.O. (0) - A N.C. (1)

5

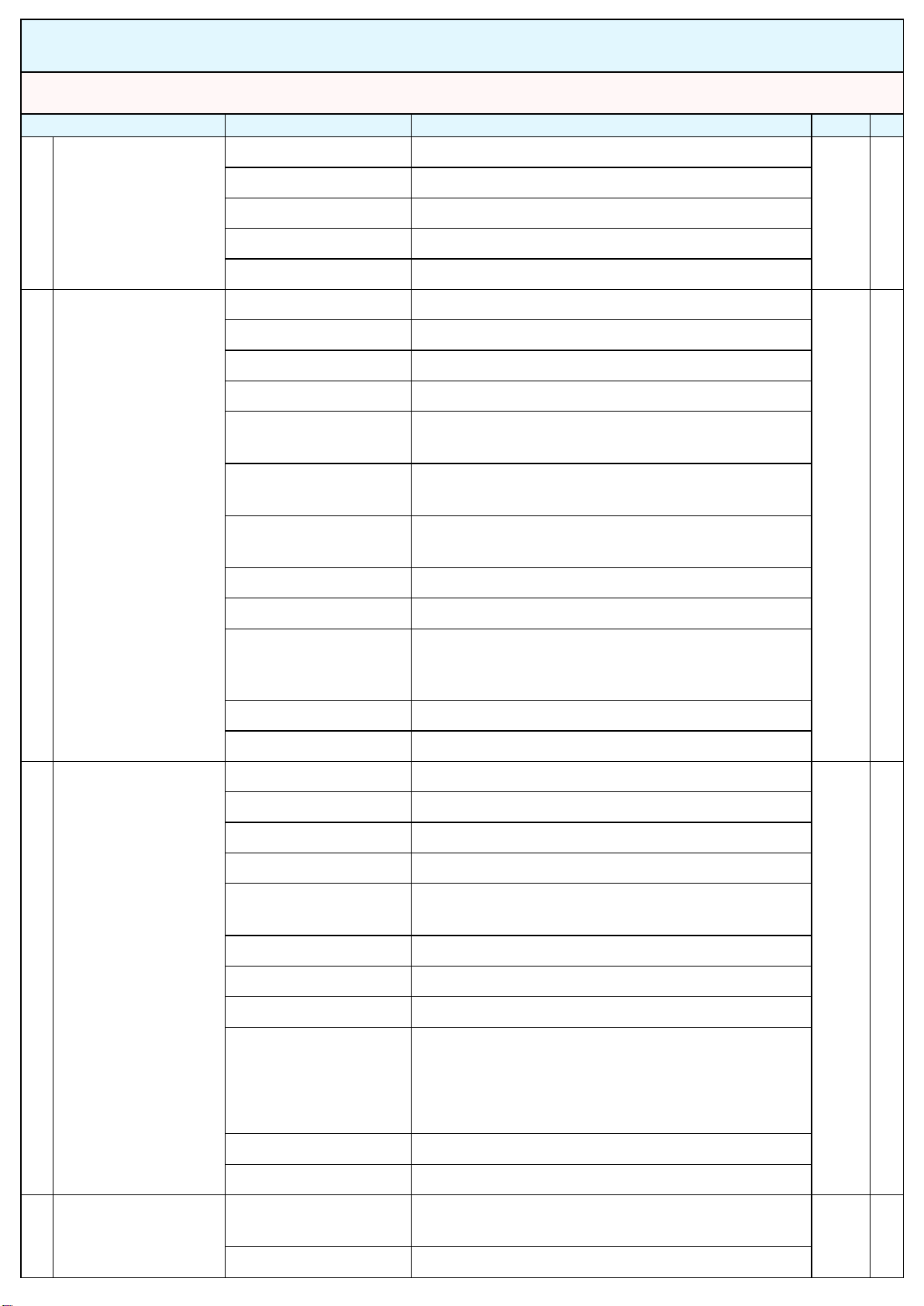

7 - WORKING TIMES LEARNING

ON

POWER ON

UP

TENERE PREMUTO

5 SECONDI

CHIUDE

APRE

CHIUDE

00111110

11000000

5

WORKING TIMES LEARNING PROCEDURE - MORE DETAILS ON TECHNICAL MANUAL

ON

POWER ON

00111110

11000000

DOWN OK

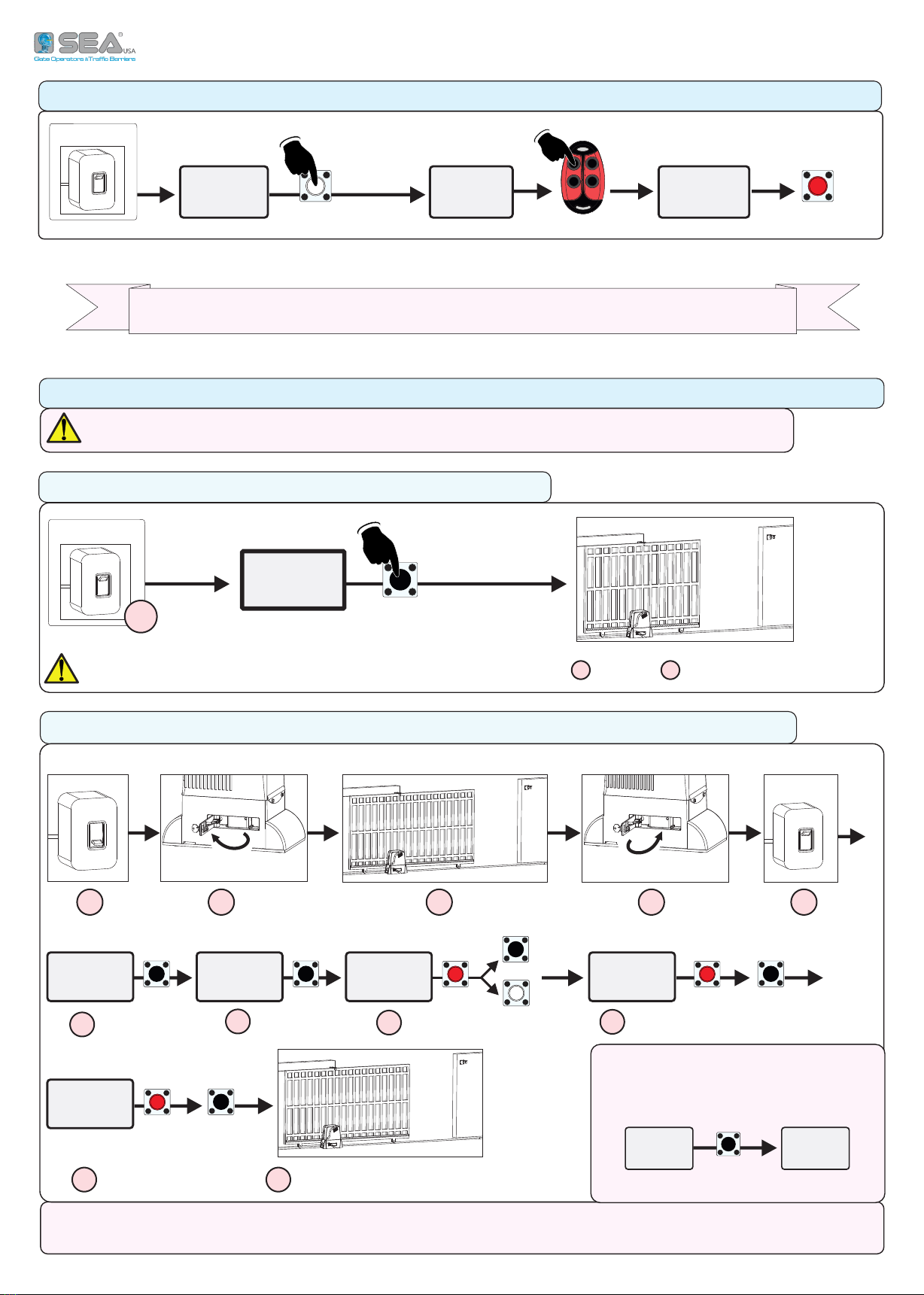

6 - «START» COMMAND QUICK LEARNING ON THE TX

a

HOLD PRESSED

5 SECONDS

EXIT

PRESS

BUTTON

STORED

HAVE A QUALIFIED SERVICE PERSON TO CARRY OUT THE OPERATIONS IN SAFE CONDITIONS

QUICK START - ONLY FOR SEA SLIDING OPERATORS

1

OFF

POWER OFF

23 4

POWER ON

ON

5

UP

11000000

00111110

03.04

UP OK

UP

DOWN

OK

OK

UP

UP

9

789

10

6

11

CLOSE - OPEN - CLOSE

UP

ON

5

a

UNLOCK LOCK

(EXAMPLE)(EXAMPLE)

LEAVES ON HALFWAY

(EXAMPLE)

3

MOTOR

1-HYDRAULIC

(EXAMPLE)

(EXAMPLE)

CHOOSE THE MODEL

PROGRAM-

MING

(EXAMPLE)

I

,

5:

REVERSE

MOTOR

T ;

F ,

! 1 5

F ,

!

6

SET DESCRIPTION DEFAULT NOTES

Italiano

Italian

English

English

Français

French

Español

Spanish

Dutch

Dutch

Start

Start

Partial opening

Partial opening

External module

External module

Stop

Stop

Bistable Stop

Pressed once, it stops the gate.

Pressed twice, it reactivates the START input

Latch opening

One impulse opens and keep open.

A second impulse restore the movement

Latch closing

One impulse closes and keep closed.

A second impulse restore the movement

Unlock

To store a command for unlocking the electric brake

Delete a transmitter

To delete a single transmitter (TX)

Move to EEP

Menu available on model

R3BF only

To transfer the transmitters stored on the control unit to

the external EEPROM (MEM), if connected

Clear memory

To delete the full transmitters memory on the receiver

End

To exit the menu "transmitters"

1- Hydraulic

Hydraulic operators

2- Sliding Sliding operators

3- Reversible Sliding Reversible sliding operators

4- Mechanic Swing

Electro-mechanic swing operators

5- Three-phase

and Bollards

Three-phase operators

Bollards

6- Magnetic Sliding Sliding operators with magnetic limit-switch

7- Barrier Barriers

12- B-200 Sliding operator

13- Chain sliding operator

Sliding chain operator

Slowdown OFF

deceleration 70%

Buzzer in ON

PHOTO 2 as shadow loop

14- B-200 chain Sliding chain operator

15- Erg Garage door operator

On

To reverse the opening with the closing and vice-versa

(both motors and limit-switches are reversed)

Off Off

3

MOTOR

Mechanic

1

LANGUAGE

English

2

TRANSMITTERS

Start

Partial

Opening

5

REVERSE MOTOR

Off

MENU

GATE 1 DG (R2BF) - (R2EF) - (R3BF) MENU FUNCTIONS TABLE

THE DESCRIBED FUNCTIONS ARE VALID FOR ALL GATE 1 DG VERSIONS, EXCEPT WHERE EXPRESSLY STATED

7

SET DESCRIPTION DEFAULT NOTES

Automatic

Automatic logic - automatic reclosing enabled

Open-stop-close-stop-open

Step by step type 1

Open-stop-close-open

Step by step type 2

2 button

Two buttons

Safety

Safety

Dead man

Dead man

Off

Semi-automatic logic enabled

(a START command opens and another START closes the

gate - automatic reclosing disabled)

1 240

To set a pause time (from 1 second to 4 minutes) before

the automatic reclosing

Off

The Start command is not accepted during pause

On

The Start command is accepted during pause

9

PROGRAMMING Off On To start the working times self-learning Off

10

TEST START Off On To give a Start command for testing the automation Off

13

LATCH PAUSE

Menu available on

model R3BF only

Off On

If "ON" the operator complies with the pause time set

when the function "LATCH OPENING" is disabled. When

"OFF" the pause time set is not respected

Off

14

RESET

192

MOVE GATE 1 *

Menu available on

model R3BF only

- - - -

15

END

16

SPECIAL MENU

MENU

6

LOGIC

Auto-

matic

7

TIMER TO CLOSE

Off

8

START IN PAUSE

Off

Press OK to return to the display of the firmware version

and to the one of inputs state

Press OK to enter the special menu

A count-down of 5 seconds will start by holding the UP button; at its end "INIT" will appear on the

display as confirmation of the control board reset

Allows the movement of the gate in a temporary "dead man" mode

(for example to test the correct running of the motor)

HOLD UP PRESSED = THE GATE OPENS

HOLD DOWN PRESSED = THE GATE CLOSES

* The command is accepted only at the end of the cycle or after a STOP command; it is not accepted during the cycle and

during the pause

8

SET DESCRIPTION DEFAULT NOTES

28

OPENING TORQ 1 10 100

Motor 1 opening torque:

by increasing the torque, more strength will be required

to execute the inversion in case of obstacle.

with hydraulic motors the torque will be on 100%

It

depends

on

model

29

CLOSING TORQ 1 10 100

Motor 1 closing torque:

by increasing the torque, more strength will be required

to execute the inversion in case of obstacle.

with hydraulic motors the torque will be on 100%

It

depends

on

model

32

ENCODER On

ON = Encoder enabled

OFF = Encoder disabled

(when OFF, the working times learnt are only shown)

Off

47 ENCODER PAR.

M1

xxx.

48 ENCODER TOT.

M1

xxx.

32

ENCODER Potentiometer

To enable the reading of the potentiometer

(only with LE or LSE management unit)

Off

51 I.PAR. M1 *- - - - - - - -

52 I.AP. M1

From the value learned

to ± 100 pulses

53 I.CH. M1

From the value learned

to ± 100 pulses

32

ENCODER Off

ON = Encoder enabled

OFF = Encoder disabled

(when OFF, the working times learnt are only shown)

Off

65 OPENING TIME M1 xxx.s

66 CLOSING TIME M1 xxx.s

10% (Fast intervention)

99% (Slow intervention)

To adjust the Encoder or Potentiometer intervention time

on Motor 1 in opening

Off (Intervention excluded) Disabled

10% (Fast intervention)

99% (Slow intervention)

To adjust the Encoder or Potentiometer intervention time

on Motor 1 in closing

Off (Intervention excluded) Disabled

10% (Fast intervention)

99% (Slow intervention)

To adjust the amperometric sensitivity in slowdown

Function available only on electro-mechanic operators

Off

With potentiometer

To set the inversion time in slow-down from 0to 5

seconds (= 99%) - Only with potentiometer enabled

It

depends

on model

Impulses read by Encoder during operation (Motor 1)

Impulses stored during programming (Motor 1)

To show the current position of the potentiometer on the leaf moved

by Motor 1. This parameter is useful to see if the potentiometer is

correctly read

To show the impulses stored by the control unit when the leaf moved

by Motor 1 is fully open

To show the impulses stored by the control unit when the leaf moved

by Motor 1 is fully close

To display the learnt value during the working times self learning, in

opening and closing (Motor 1) . With UP or DOWN it is possible to

increase or reduce the working times

33

OPENING SENSITIVITY

MOTOR 1

Off

37

SLOWDOWN

SENSITIVITY MOTOR

SPECIAL MENU

SPECIAL MENU

PRESS AT THE SAME TIME FOR 5 SECONDS TO ENTER OR TO EXIT THE SPECIAL MENU

34

CLOSING SENSITIVITY

MOTOR 1

Off

THE DESCRIBED FUNCTIONS ARE VALID FOR ALL GATE 1 DG VERSIONS, EXCEPT WHERE EXPRESSLY STATED

* While the partial impulses are displayed, it is possible to OPEN (by pressing UP) or CLOSE (by pressing DOWN) the operator

to verify the correct reading of the potentiometer - Function available only on model R3BF

9

SET DESCRIPTION DEFAULT NOTES

38

POTENTIOMETER

THRESHOLD

OPENING 1

39

POTENTIOMETER

THRESHOLD

CLOSING 1

42

POTENTIOMETER

SLOWDOWN THRESHOLD

OPENING 1

43

POTENTIOMETER

SLOWDOWN THRESHOLD

CLOSING 1

Total

In case of obstacle or safety edge it totally reverses the

movement during closing. If the automatic reclosing is

enabled (automatic logic) , it is attempted for 5 times

Partial

In case of obstacle, safety edge or potentiometer, it

partially reverses direction (of about 30 cm) then stops

59

OPENING

SLOWDOWN 1

Off (*) 50 Adjustable from OFF to the 50% of the stroke

It depends

on model

60

CLOSING

SLOWDOWN 1

Off (*) 50 Adjustable from OFF to the 50% of the stroke

It depends

on model

63

DECELERATION 0 %

100%

To adjust the change from normal speed to slowdown

speed

It depends

on model

64

ACCELERATION 0 %

100%

Acceleration ramp.

To adjust the motor start

It depends

on model

70

OPENING POSITION

RECOVERY

0 20 seconds

To retrieve the inertia of the motor in opening after the

Stop or the reversing

1s

71

CLOSING POSITION

RECOVERY

0 20 seconds

To retrieve the inertia of the motor in closing after the

Stop or the reversing

1s

72

OPENING TOLERANCE

MOTOR 1

0 100

To adjust the Motor 1 tolerance between the stop and

the obstacle, in opening

0

73

CLOSING TOLERANCE

MOTOR 1

0 100

To adjust the Motor 1 tolerance between the stop and

the obstacle, in closing

0

Time

Pushing Off - 3 sec

Stroke

Before opening, the motor starts in closing for the time

set, in order to simplify the lock release

Repeat

Lock Off – On

Release

If ON, the lock will be released both before and after the

pushing stroke

End

To exit the menu

Only opening

Only closing

Opening and closing

Off

For menu 47 and 48 see menu 32- ENCODER = On

For menu from 51 to 53 see menu 32- ENCODER = Potentiometer

* For motors with hydraulic brake (CF) or double hydraulic brake (2CF) this parameter must be on Off

0 100

To adjust the threshold of the potentiometer intervention

in slowdown. By default this value is set on 10. but can be

manually increased on the condition that the set value is

higher than the value shown in VP1 (instantaneous

speed values which can be shown by accessing the

DEBUG menu)

It

depends

on

model

79

ANTI INTRUSION

If the gate is forced manually, the control unit starts the

motor and restores the state of the gate before forcing

(function only available if limit switches are installed)

Off

76

PUSHING STROKE

Off

0 1000

To adjust the threshold of the potentiometer

intervention. This parameter self-determines during the

working times learning but can also be adjusted later, on

the condition that the set value is higher than the value

shown in VP1 (instantaneous speed values which can be

shown by accessing the DEBUG menu). NOTE: The lower

the threshold value, the slower will be the response of

the potentiometer.

It

depends

on

model

46

CLOSING INVERSION

It

depends

on

model

For menu from 65 to 66 see menu 32- ENCODER = Off

SPECIAL MENU

10

SET DESCRIPTION DEFAULT NOTES

Off

Opening and closing

Only closing

Only opening

81

PERIODICAL PUSHOVER Off 8

To activate the repetition of the pushover function at a

distance of time adjustable from 0to 8 hours, at hourly

intervals

Off

Opening 1 Off - 3 s

Closing 1 Off - 3 s

Opening 2 Off - 3 s

Closing 2 Off - 3 s

End

83

EXTRA TIME 0.0 s 10 s

If the limit switches are installed, it is possible to add an

extra time (max. 10 seconds) to the movement of the

operator after the reading of the limit switches

Note: If an Encoder is installed, the space can be set by

impulses (from 0 to 100)

0.0 s

84

BRAKE Off 100% To adjust the braking on the limit switch 0

Only closing

To enable the pre-flashing only before closing

(to access: press DOWN button when 0.0 value is shown)

0.0 10 s

To set the pre-flashing duration

Normal

Normal

Light

Warning lamp function

Always

Always ON

Buzzer

Buzzer

Off

The flashing light will be OFF with enabled timer and open

gate

On

The flashing light will be ON with enabled timer and open

gate

Off

Disabled

1 240

Adjustable from 1 second to 4 minutes

In cycle

Courtesy light only in cycle

89

TRAFFIC LIGHT

RESERVATION

Off On

To get the priority in entry or exit. The function is

available only with SEM management unit and by the

use of the partial opening contact

Off

90

PARTIAL OPENING 20 100 Adjustable from 20 to 100 100

= Start

The pause in partial opening is the same as in total

opening

Off

Disabled

1 240

Adjustable from 1 second to 4 minutes

Off

On photo2

On partial input

Off

Disabled

On Photo2

The function can be enabled on the Photocell 2 input

On partial input

The function can be enabled on the partial opening Start

input

82

MOTOR RELEASE

SPECIAL MENU

80

PUSHOVER

The gate leaf makes an extra movement at the maximum

torque to ensure the tightening of the gate

Off

Normal

87

FLASHING LIGHT AND

TIMER

Off

92

TIMER

The selected input will be turned into an input (on CN1)

to which connect an external clock

Off

91

PARTIAL PAUSE

= Start

20

If different from OFF, the operator slightly reverses its

direction at the end of the cycle

Off

(hydraulic)

0.1

(mechanic)

85

PRE-FLASHING

Off

Off

FIRE SWITCH

93

88

COURTESY LIGHT

86

FLASHING LIGHT

11

SET DESCRIPTION DEFAULT NOTES

Always

AUX output always powered

In cycle

AUX output powered only during cycle

Opening

AUX output powered only during opening

Closing

AUX output powered only during closing

In pause

AUX output powered only during pause

Phototest

AUX output powered for safety devices testing

In cycle and phototest

AUX output powered only during cycle and for safety

devices testing

Positive brake

management

(connected through relay)

Positive Electric-brake - connected through relay

(AUX output powered only with stationary gate)

Negative brake

management

(connected through relay)

Negative Electric-brake - connected through relay

(AUX output powered during cycle and 1 second before

starting the movement)

Negative brake

(connected through relay)

Photocell management

Negative Electric-brake (AUX output powered during

cycle and 1 second before starting the movement; AUX

output disabled when the photocell is activated)

Open gate

warning light

1 flash per second during opening

2 flashes per second during closing

Steady lit in "Stop" or "Open" status

Lock

(connected through relay)

The AUX output allows the connection of a relay for the

management of a lock Note: to connect the lock, a relay

and an external power supply are necessary

Opening and open AUX output powered during opening and with open gate

Courtesy light

(connected through relay)

The AUX output allows the connection of a relay for the

management of a courtesy light which will work as per

Menu-88 settings

Start 3 s

(connected through relay)

AUX output powered at every Start input or at every

photocells or safety edge intervention, for 3 seconds

(ie. management of lights connected through the relay)

Barrier Led lights

Closed barrier - the light is switched-on

Open barrier - the light is switched-off

Moving barrier - the light blinks

Photo 1

Self-test enabled only on photocell 1

Photo 2

Self-test enabled only on photocell 2

Photo 1 and 2

Self-test enabled on photocells 1 and 2

Off

Disabled

Edge

Self-test enabled only on safety edge

Photo 1 and Edge

Self-test enabled on photocell 1 and safety edge

Photo 2 and Edge

Self-test enabled on photocell 2 and safety edge

All

Self-test enabled on photocell 1 and 2 and safety edge

Always

95

FOTOTEST

Off

SPECIAL MENU

94

24V AUX

(Max. 500 mA)

The AUX output allows

the connection of a relay

for the additional

accessories management

12

SET DESCRIPTION DEFAULT NOTES

Closing

If the photocell is occupied during closing, the gate

reverses the movement; If the photocell is occupied

during the pause, it prevents the gate reclosing

Opening and closing

If the photocell is occupied during opening or closing, it

stops the gate movement; when the photocell is released,

the movement continues

Stop

If the photocell is occupied before the Start input, the

Start will be ignored. If the photocell is occupied after the

Start input, the photocell will be ignored. If the photocell

is occupied during closing, the gate will reopen

Stop and close

If the photocell is occupied during closing, it stops the

gate movement; when released, the closing movement

continues

Close

The photocell stops the gate until it is occupied in both

opening and closing; when released, the photocell gives a

closing command (the gate closes one second after the

photocell release)

Pause reload

If the photocell is occupied during opening or closing, it

stops the gate movement; when released, the movement

continues. If the photocell is occupied during the pause, it

recharges the pause time set

Shadow loop

When the gate is open, the shadow loop prevents the

reclosing until it is occupied. The Shadow loop is switched

off during closing

Delete pause time

If the photocell is occupied during opening, pause or

closing, the gate reopens completely and closes without

observing the pause time set

Shadow loop RP

(pause reloading)

When the gate is open, the shadow loop prevents the

reclosing until it is occupied. When released, the gate

repeats the pause time set, then it closes. The Shadow

loop is switched off during closing

97

PHOTOCELL 1

SHADOW LOOP 1

Closing

SPECIAL MENU

13

SET DESCRIPTION DEFAULT NOTES

Closing

If the photocell is occupied during closing, the gate

reverses the movement; If the photocell is occupied

during the pause, it prevents the gate reclosing

Opening and closing

If the photocell is occupied during opening or closing, it

stops the gate movement; when the photocell is released,

the movement continues

Stop

If the photocell is occupied before the Start input, the

Start will be ignored. If it is occupied after the Start input,

the photocell will be ignored. If the photocell is occupied

during closing, the gate will reopen

Stop and close

If the photocell is occupied during closing, it stops the

gate; when released the closing movement continues

Close

The photocell stops the gate until it is occupied in both

opening and closing; when released, the photocell gives a

closing command (the gate closes one second after the

photocell release)

Pause reload

If the photocell is occupied during opening or closing, it

stops the gate movement; when released, the movement

continues. If the photocell is occupied during the pause, it

reloads the pause time set

Pause reload

Photo closing

If the photocell is occupied during the pause, it reloads

the pause time set. If the photocell is occupied during

closing, the gate reverses the movement

Shadow loop

When the gate is open, the shadow loop prevents the

reclosing until it is occupied. The Shadow loop is switched

off during closing

Delete pause time

If the photocell is occupied during opening, pause or

closing, the gate reopens completely and closes without

observing the pause time set

Shadow loop RP

(pause reloading)

When the gate is open, the shadow loop prevents the

reclosing until it is occupied. When released, the gate

repeats the pause time set, then it closes. The Shadow

loop is switched off during closing

Stop and open

If the photocell is occupied during opening, the gate will

stop; when released, the gate continues the opening

movement. The photocell is ignored during closing

Stop N.O. Stop connection on ERG push-button panel

Safety edge 2

It is possible to connect a second safety edge;

Only with the "R3BF" model: is it possible to select the

type of safety edge through menu 101;

For all models: it is possible to choose the working

direction of the second safety edge through menu 103

Opening

and

Closing

SPECIAL MENU

98

PHOTOCELL 2

SHADOW-LOOP2

14

SET DESCRIPTION DEFAULT NOTES

Normal

Normal N.C. contact

8K2

Safety edge protected by a 8K2 resistor enabled

8K2 Double

Two safety edges protected by a 8K2 resistor enabled

Photo 1 10K

Photocell protected by a 10K resistor enabled

Photo 1 10K Double

Two photocells protected by a 10K resistor enabled

Normal Normal N.C. contact

8K2 N.C. Safety edge protected by a 8K2 resistor enabled

8K2 N.C. Double Two safety edges protected by 8K2 resistor enabled

8K2 RES Resistive edge protected by 8K2 resistor enabled

8K2 RES Double Two resistive edges protected by 8K2 RES enabled

Normal Normal N.C. contact

8K2 N.C. Safety edge protected by a 8K2 resistor enabled

8K2 N.C. Double Two safety edges protected by 8K2 resistor enabled

8K2 RES Resistive edge protected by 8K2 resistor enabled

8K2 RES Double Two resistive edges protected by 8K2 RES enabled

Opening and closing

Safety edge enabled in opening and closing

Only opening

Safety edge enabled only in opening

Only closing

Safety edge enabled only in closing

Opening and closing

Safety edge enabled in opening and closing

Only opening

Safety edge enabled only in opening

Only closing

Safety edge enabled only in closing

Automatic

Automatic detection of the limit switch

Only opening

Limit switch enabled only in opening

Only closing

Limit switch enabled only in closing

Motor internal

To be enabled if the operator is equipped with an inner

limit switch that stops the motor phase

Primary

To set the control unit as PRIMARY on applications with

two operators in primary/secondary mode

Secondary

To set the control unit as SECONDARY on applications

with two operators in primary/secondary mode

Off Disabled

106

DIAGNOSTICS 1 10 To display the last event (See alarms table)

107

MAINTENANCE CYCLES 100 240000 Adjustable from 100 to 240000 cycles 100000

108

PERFORMED CYCLES 0 240000

To display the executed cycles.

Hold pressed OK to reset the cycles

0

109

THERMOMETER On Off

To enable the probe for measuring the piston oil

temperature; The temperature probe must be connected

via the LE or LSE management circuit

Off

103

SAFETY EDGE 2

DIRECTION

Menu available only if

the menu 98 is set on

"SAFETY EDGE 2"

Opening

and

Closing

104

SELECT LIMIT SWITCH

Automatic

105

Opening

and

Closing

101

SAFETY EDGE 2

DIRECTION

Menu available on

model R3BF only and if

the menu 98 is set on

"SAFETY EDGE 2"

102

SAFETY EDGE 1

DIRECTION

PRIMARY/SECONDARY

(MASTER/SLAVE)

SPECIAL MENU

SAFETY EDGE 1

Menu available on

models R2BF and R2EF

only

Normal

100

Normal

SAFETY EDGE 1

Menu available on

model R3BF only

15

SET DESCRIPTION DEFAULT NOTES

110

LOWER THRESHOLD

TEMPERATURE

From -20° to +50°

To adjust the temperature threshold to enable the oil

heater (This menu is shown only if the menu 109-

Thermometer is set to ON)

-10°

111

UPPER THRESHOLD

TEMPERATURE

From -20° to +50°

To adjust the temperature threshold to disable the oil

heater (This menu is shown only if the menu 109-

Thermometer is set to ON)

0°

112

PASSWORD

Note: "0000" setting is

not allowed

To enter a password for blocking the control unit

parameters modification

- - - -

Off Disabled

Last opening

In case of power failure, as soon as the battery charge

drops below 22V, the gate opens one last time and

remains open until the power is restored

Last closing

In case of power failure, as soon as the battery charge

drops below 22V, the gate closes one last time and

remains closed until the power is restored

117 ALWAYS CLOSE Off 240 seconds

In case of power failure, if the gate has been manually

open, it closes only after the set time has elapsed (from 0

to 240 sec.) as soon as the power is restored

Off

Off Disabled

Opening

The gate opens and stay open till a new Start input.

The latch function uses the "Partial Opening" N.O. input

(the "Partial Opening" function is so disabled)

Closing

The gate closes and stay closed till a new Start input.

The latch function uses the "Partial Opening" N.O. input

(the "Partial Opening" function is so disabled)

119

DISPLAY WRITING

SPEED From 30% to 100% See Note 2 at the end of the table 80%

120

BASIC MENU

Normal Standard photocell without 10K control

Photo 1 10K Photocell with 10K control

Photo 1 10K DOUBLE Double photocell with 10K control

Normal Standard photocell without 10K control

Photo 2 10K Photocell with 10K control

Photo 2 10K DOUBLE Double photocell with 10K control

Normal

In case of a power failure or in case of obstacle, the

operator restarts at the normal speed set

Deceleration

In case of a power failure or in case of obstacle, the

operator restarts at a lower speed than the normal speed

set

190

BASIC MENU

On model R3BF only

SPECIAL MENU

Note 1: after initialization, the parameters set on menu 3 - MOTOR and 104 - SELECT LIMIT SWITCH always remain set to the

value chosen during the programming operation

Note 2: if the menu 119 - DISPLAY WRITING SPEED is set to the minimum value of 30%, the display writing speed will be low. On

the contrary, if it is set to the maximum value of 100%, the writing speed will be very high

Please note: the writing speed will not change on the JOLLY 3 programmer

Off

Press OK to exit the special menu.

The special menu switches off automatically after 20 minutes

118

LATCH

121

PHOTO 1 TYPE

Menu available on

model R3BF only

Normal

113

EMERGENCY

Off

122

PHOTO 2 TYPE

Menu available on

model R3BF only

Normal

189

HOMING

Menu available on

model R3BF only

Normal

Press OK to exit the special menu.

The special menu switches off automatically after 20 minutes

16

NOTES

NOTES

SEA USA Inc.

10850 N.W. 21st - unit 160 - DORAL - MIAMI

Florida (FL) 33172

Phone: ++1-305.594.1151

Toll Free: 800.689.4716

www.sea-usa.com

This manual suits for next models

2

Table of contents

Popular Control Panel manuals by other brands

FAAC

FAAC 455 D Supplemental installation instructions

Autronica

Autronica AutroSafe BS-60 Commissioning Handbook

Satel

Satel PERFECTA-32-SET-A/IT Installer manual

jcm-tech

jcm-tech CONT-R15 user manual

Helo

Helo Elite Free Installation guide and quick start guide

DITEC

DITEC Entrematic HomeLink E2H installation manual