·,·.· ....'4..-.....~

~,o.~ .•..,:.•.••:.•.•.\...

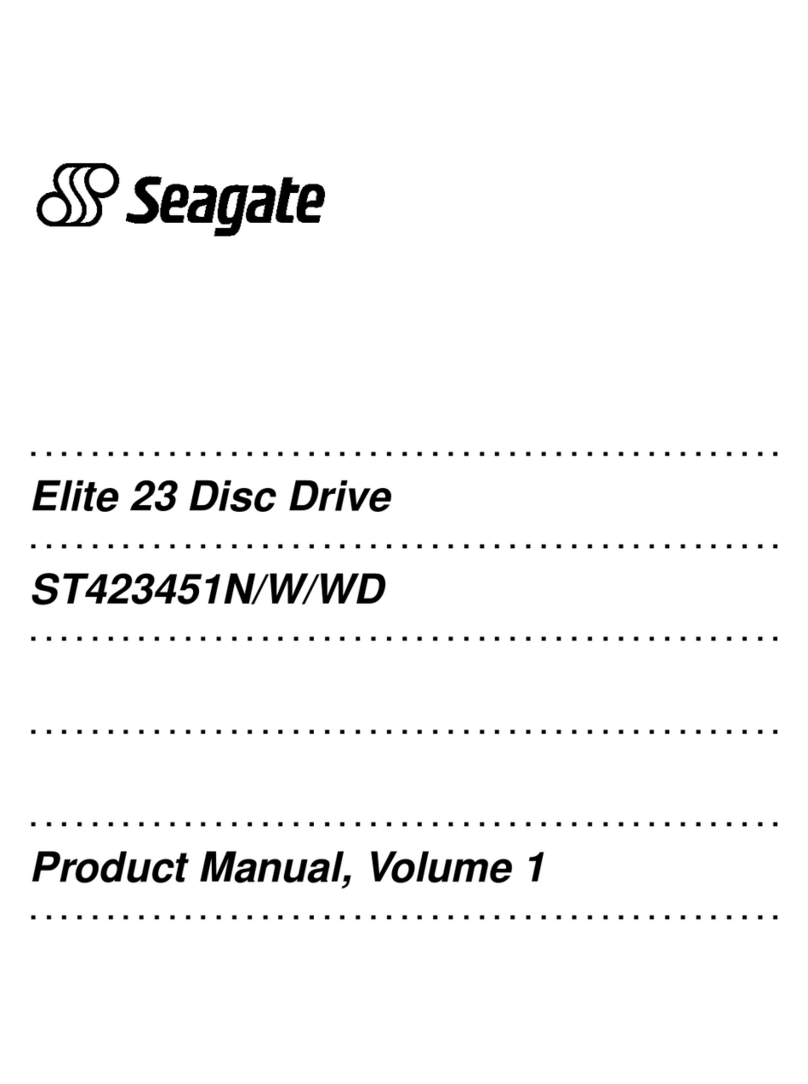

Appendix 1:32 Sector, 256 Byte/Sector Format Example

~ ~fLOO

A:~I·I·I·I·I·I·I·I·I·H;tJ·~1·1·1·1+1·1·1·1·1·1·'jj~~

-1 •..'.•IftCIPCI••••

I\-.cIIIt IIfO ent_

-....

IdHNn N_1N<r fleW

N•• 1N<r eI.,ln s.rnt

I:'WTRODUcriON •.••••••••.••••••••••••••••••••••••.••••••.••••• 'On

i.OSi'ECiHCATiOS SUMMARY •••••••••••••••••••••••••••••••••.• 8

1.1 Perrormance Specificalions ........•.•.••••..••.•.•...•...•••....• i

1.1.1 Access Time Ddinition and Timins .•.••..•.•..•.•..•...•..••.. I

1.2 Funclional Specifica.ions .••.•.•••.••.••••.•.•..•..••.•.•.•.••••. I

1.3 Physical Specificalions ...•..........•.••••.•..•..••..•....•••... !

1.4 RtiiabililY Specificalions ..........•...••••..•.•.•.•..•••..•.•••.. 2

1.4.1 Read Error Rales ....•.......•.•..•••••.•••.•....••..•.•..... 2

1.4.1.1 Bil Jiner •....•.....•......••..••....•.•.•...•..•......•. 2

1.4.2 Media DereCIS ••••........••.•.••••.•..•.......••••..•••.... 2

I.S Environmental Specifications ...........•••...........••.••.•.••.. 2

1.5.1 Ambien. Temperalure ..........•..••.•...•..••.••••..••....•. 2

1.5.2 TemperaiUre Gradi.ni. ......•...•...••..••..•..........•.••.• 2

1.5.3 Relalive HumidilY ......•..•.••......••.•.•.•.•..........•••• 3

I.SA Ahilude Limi.s .........••......•••.••..••......•...••.•.••• 3

I.S.S Optrating Shock ....•....••.....••••..••......•.••••••.•.... 3

1.5.6 Operaling Vibralion ........•.....•...•.••......••...•..•..•• 3

1.5.7 Nonope,ating Shock ..•...•.•......•......•.......•..•..•.•.. 3

!.S.8 Nonoperaling Vibralion ...........••.......••....••••••••.•.. 3

1.6 DC Power Requiremenls ...•.....•..•..••..•.•..•..•....•••...•.• 3

1.6.1 Inpu. Noise Ripple •....•..•.•....•.....•.•••.•.....•.••..•.. 4

1.6.2 Inpu. Noise Frequency •..•..•....•••••...•.......•.•..•.••••• 4

1.6.3 H.al Dissipation ••...•••..•.•..••.•.••.•••..•...••.••.•...•. 4

1.7 Mounling Requirements ...•.....••.••.•.•.••••.•.•.•••...••••... 5

1.7.1 Shock Mounring Recommendalion .•••....••...•.•....••.•••... 5

1.7.2 Handling and Slatic·Discharge Precautions .••.••......••.•.•••.• 6

1.7.3 Shipping Zone .•.....•......•..••.••...••••.....••..•.•..•.• 6

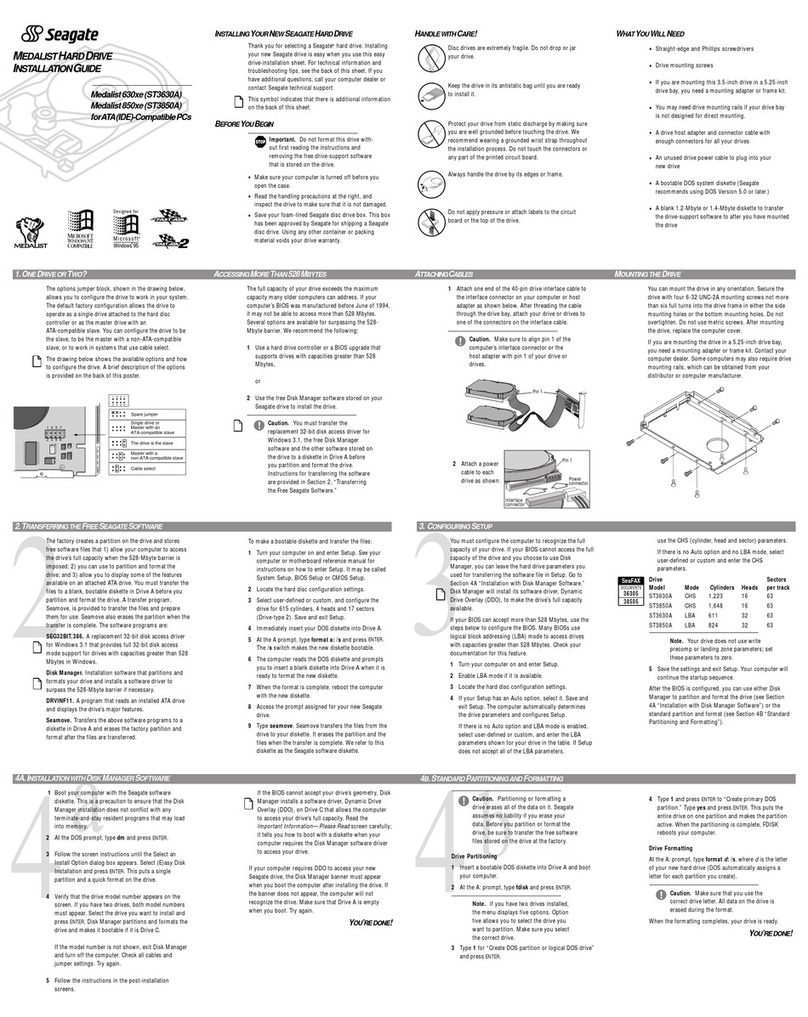

USn25 HOST/DRiVE INTERFACE ••••••••••••••••••••••••••••••• 7

2.1 Conlrol/Slatus Signals: PCB Edge·Connector. JI .•..•...•••••.•....• 7

2.2 Dala Signals; PCB Edge·Conneclor, J2 ...•••..•...••.•...••••..••.• 9

2.3 DC Power Connector, J3 .•••.....•..••.•..•.•.•...•.....••....•.. II

3.0 DRIVE CONfiGURATION ••••••••••••••••••••.•• , ••••••••••••• 13

3.1 Drive Configuralion Shunt. J7 ..••••.•••••.••••••...•.•.••....••.. 13

3.2 Drive Seleci Configuralion .•••.......•.•••••..•..•.•.•.•.••..••.. 13

3.2.1 Daisy.Chain •...•••.•...••.•..•.•.•...••...•.•...••.•••..... 13

3.3 Radial ..•...•...••....•.•..•.•..•.•...•••••.••.•.•••.••.•..•.. 14

3.4 Write Fault ....••.•••...•.•.•...•.•.••••.•..•••..•...•••...•••• 14

3.5 lire Test. ...•.•••...•....•••..•.....••••...••..•••.••••.•.••••. 14

3.6 Recovery Mode ••.•.•........•....••..•..•..•..•...••••.•.••.... IS

4.0 CONTROL INi'UYSiGNALS ••••••••••••••••••••••••••••••••••• 16

4.1 Head Seleci 2", 2'. 2'. 2' ..•...•.....•....••.••••.....••..•...••..• i6

4.2 Wrile Gale •.......•....•......•.••..••..•.•......•.•••••..•... 16

4.3 Slep ....•.....••...•....•••.•..•••••••.•.••.•....•....•••••••• 17

4.3.1 Burrered Seek ..•..•.•.•.•..•..•..••••.••••.•.•.•.•••••.••••. 18

4.3.2 Slow·Slep (Track-Io-Tr:ack) .••..••••.••••.••••.••.••..••.•••.•. 18

4.3.3 AUlo·Truncation •.. , •....•...•.•..••.•.••••..•.•.••.••.•.••• 19

4.4 Direclion In •....••.•• , •.••..•..•..•••••..••.••..•.••.••.•..... 19

4.5 Drive Select. ......•.•••....••......•••.•.•....•....•..•..•.•••. 20

4.6 Recovery Mode ...••••......•......••••.•.••••..•.•..•.••.•..... 21

5.0 CONTROL OUTPUT SiGNALS ••••••••••••••••••••••••••••••••• 22

5.1 Drive Selected ....•..•••...••.....•...••.....••••.•....••••••.•. 22

5.2 Index ..•..•.•...•••••.•....•....••..•.•••.••..••..•.•••.••..•. 22

5.3 Track" .....•..•.......•.•......•••••••••.•....•.••.•.•••••..• 22

5.4 index and Track" Scnsinl ..•..•...••.••••.•.............•..•••.• 22

5.5 Ready .•..•.•...••.•.•..•••.••..••..••...•.•....•••....••.•... 23

5.6 Seck Complete ...••.•..•....•.....•..•••.•.••.•.•...••.••.•.••• 23

5.7 Writc f~uli ....•................•..•••••..••••........••.••••.. 23

S.7.1 Wriie fault Signll <lener.iion ......••••.••••...••...•..•..••.• 23

5.7.1.1 Wrile Curreni imerrupiioli .......•....•...•..........••.•. 23

TABLE OF CONTENTS

,

•..

.~

~

~o

o~

--

.•.• -..

...•..

"'::' ""::'"

,3tI

tI ••

tI

".

"

MTA f1ELD

A nu••••ric21•• 1•• in Hex dtfinin. lhe hoad ••lcc1ed

floW Dnnl" •••

A field or .1I,etOS 10sync lhe VfO for lhe 10

••AI" H•• wilh • dropptd clock 10nOliry lhe conlrol •••.lhal dal. "IIOWI

"Fr Hex dtfinin. Ih.1 10 Mid dal. follows

A nu••••ric.1 •• Iu. in Hex dtfinin. lhe dtl.nl posilion or lhe lCualor

A num.rical •• Iu. in H•• d.finin. lhe •••• or rot Ihi, ••••ion of 1M

rotation

Cyclic Redundancy (1)<ck inrormalion uoed 10••riry lhe ••Iidily of Ih.

10 fieldinrorm'lion juS! •••d

lam wrinen durin, format to isolale the ViniC' !Plitt (~;litd. Thii

field a$SUm ••Iid ••adin. of field numhor 7 .nd .11owslhe IJ 1»1<5

r<quirtd ror Dal. VfO lock.

A field of .11'''0110 sync 1M VFO rot lhe d••• fitld

"AI" H•• wilh • dropped clock 10 notiry lhe con,roIk, lhal dall rollow>

"fA" H•• dtfinin. lhai UKrclata rollow,

This am .,waibbk for UKrIbl,;

Cyclic Redu••••ncy Check inrorm.,ion uKd 10 •.nry lhe •• Iidityof

the UKr data Mid informillion JUst read

Z••OI wriuon durin. updol' to i••I.lo tho writ. splitt eft.,td. This

field '$SUm •• Iod••:odin. IIr field oumher lJ.nd .11owslhe IJ

byl•• '«Iuired rot VfO lock rot ,he ID fitld of lhe ••• 1KC'ot.

A fitld of.II •••.01 which acts II•bulf•• Ioti"un ••••0<110.11_

for ~ "'arialion

315 Ims TOTAL

tI I' I'• It tI

....,

-:Ol~

II

=1=

IJ ID \'FO LOCK

I SY:-IC BYTE

I ADDRESS

MARK

42CYU:-IDER

ADDRESS

HE.-\D

NUMBER

6 I SECiOR

NUMBER

CRC

WRITE

Tt: RS·ON

GAP

9 IJ OAH SYNC

\'FO LOCK

10 I SYSC BHE

II I ADDRESS

MARK

12 256 O-\T..••

IJ 2CRC

14 J WRITE

Tl: R:-I'()ff

G-\P

" " 1:o;rER·RECORD

GAP

'::

:=1--;;

-..•

..-

JI mlS OEM/!lIf'I. F

,..•.~-•..... ".

TJJkO/C_mu iil