SEAGUARD Digital Corrosion Tester PRO User manual

03MAN00021 V2 139.7*215.9mm

USER MANUAL

DIGITAL CORROSION TESTER

PROFESSIONAL MODEL

USER MANUAL

SEAGUARD DIGITAL CORROSION TESTER

PROFESSIONAL MODEL

© 2017 Canada Metal (Pacic) Ltd. All rights reserved.

The information contained in this document is the sole property of Seaguard

International – a division of Canada Metal (Pacic) Ltd. Any reproduction

in part or whole without the written permission of Seaguard International

is prohibited. Seaguard International will not be liable for errors contained

herein or for incidental or consequential damages in connection with the

furnishing, performance, or use of this document. The information contained

in this manual is subject to change without notice.

This product complies with EU directives.

Danger

• Please do not use or store this product near explosive materials, strong

magnetic elds, or a combustible gas environment, otherwise it may cause

a re or explosion.

• To avoid being shocked, do not use this product when the tested object

has electrical power.

Warning

• Please do not repair, dismantle, or modify this product by yourself.

• If any abnormal situation occurs, such as smoke or abnormal noise, stop

using this product immediately.

Note

• If do not use this product for a long period, take out the batteries.

2

Table of Contents

1. Introduction........................................................................4

2. Operation...........................................................................5

2.1 Test Setup........................................................................5

2.2 Pro Model –Features........................................................5

2.3 Pro Model – Operation Screens.......................................5

2.3.1 Turning on the tester.....................................................5

2.3.2 Making selections in the tester screens........................6

2.3.3 Using the Selection Window..........................................6

2.3.4 Choosing the boat material...........................................6

2.3.5 Change the potential limit..............................................6

2.3.6 Taking measurements...................................................7

2.3.7 Reviewing saved data...................................................7

2.3.8 Clearing all the saved data...........................................8

2.3.9 Resetting to factory settings..........................................8

3. How to Connect and Measure...............................................8

3.1 General.............................................................................8

3.2 Sterndrive.........................................................................9

3.3 Inboard.............................................................................9

3.4 Outboard...........................................................................9

3.5 Others...............................................................................9

4. Maintenance.......................................................................9

5. Troubleshooting................................................................10

6. Specifications...................................................................10

7. For more information........................................................10

3

1. Introduction

This manual gives instructions for operating the Seaguard Digital

Corrosion Tester to test boats and other marine structures in

seawater. The professional model is designed to be used by

marina operators, shipyard workers and service technicians with

silver / silver chloride reference cell (SSC).

Measuring corrosion

Vessels in seawater produce galvanic reactions just like an electric

battery does. Electrical current will ow through the hull when the

hull contains different metals. This happens even in wooden hulls

with motors attached. The most active metal discharges electrical

current to the other metal, cycling the current back through the

seawater. The most active metal becomes corroded.

If a metal part is greater than 0.2 volts negative to its natural

potential, it will not corrode. If the part is positive to its natural

potential then we know that it is connected to a different type of

metal and it will cause corrosion.

One of the most effective protection methods is to add sacricial

electrodes called anodes to make the hull become a cathode,

where the current ows from one to the other.

To measure the actual corrosion process we measure the

electrical potential of the hull. If the voltage reading is too high, it

means the hull is not protected. If the voltage is too low, we say it

is “over-protected.” Over-protection will cause the hull coating to

lose its bond to the hull and peel off (“disbondment”). So checking

the electrical potential is very important.

The Seaguard Digital Corrosion Tester is a high-impedance

voltage meter with a reference cell. The tester is specially designed

to check the electrical potential of the hull at different locations on

the hull while the boat is in seawater. Each reading is color coded

to indicate whether the boat is protected (PASS, green), under-

protected (FAIL, red), or overprotected (OVER, yellow).

The following parts are included:

• Corrosion tester handheld device

• Ag/AgCl reference cell (SSC) with 20 feet long cable (Pro Model)

• Test probe with alligator clip and 6 feet long cable

4

2.2 Pro Model - Features

2. Operation

WARNING! – The corrosion tester is a sensitive instrument

used to measure the electrical potential of a boat hull or

submerged structures. Please operate it according to these

instructions.

2.1 Test Setup

Open the battery cover and install provided 3 AAA batteries.

Note the orientation of the batteries.

Connect the reference cell.

Connect the alligator test probe. You are ready to use.

5

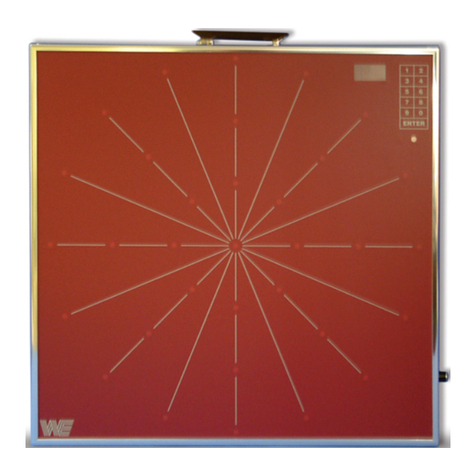

78

6

1. Display screen

2. Power button

3. Key pad

4. Lanyard

5. Port for reference cell

6. Port for alligator clip

7. Alligator clip

8. Ag/AgCl reference cell

9. Selected material indicator

10. Number of stored reading

11. Type of reference cell

12. Power indicator

13. Upper limit

14. Corrosion protection value

15. Lower limit

16. Right function indicator

17. MENU/Save/Back/Update(Upd) indicator

18. Left function indicator

11 12

13

14

15

16

17

18

9

10

1

2

3

4

Figure 1 Pro Model

2.3.1. Turning on the tester

Press the power button. The tester will display

the Welcome Screen (Figure 2) and then the

Corrosion Measuring Screen (see Figure 6).

If the battery power is too low, the tester will not

turn on.

Figure 2 Welcome

screen

2.3 Pro Model – Operation Screens

5

2.3.3. Using the Selection Window

From the Potential Measuring Screen, press the

button to display the Main Menu Screen

(Figure 4).

From the Menu Screen you can review stored

measurement data, modify the potential limit

settings for a material type, clear your stored

data, and reset the tester to factory settings.

2.3.4. Choosing the boat material

Before measuring, rst identify the material of the hull or xture

that you want to measure. From the Corrosion Measuring

Screen, press Up/Down keys to select the right material. The

material options are Steel alloy, Aluminum alloy, Copper alloy

and others.

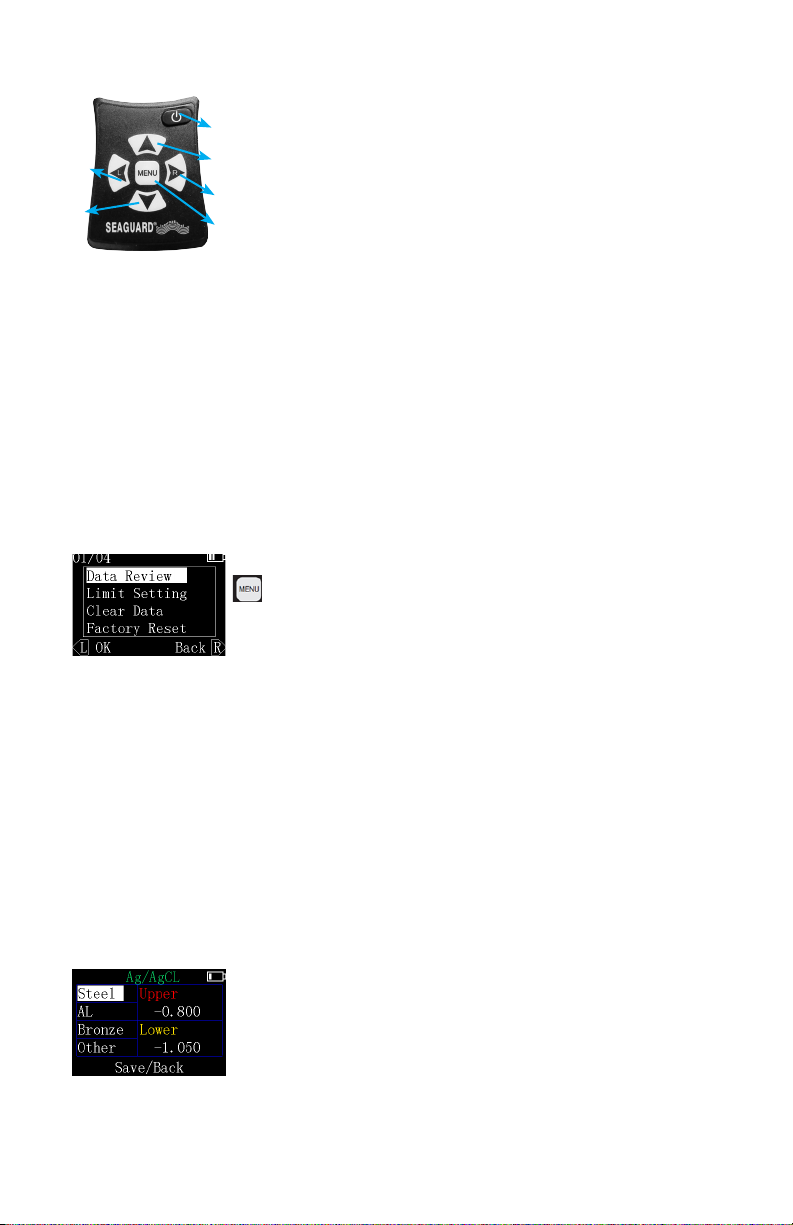

2.3.2 Making selections in the tester screens

Use the hand buttons to perform all functions

of the tester.

Using the selection buttons

1. Power button

2. Move up, or increase number

3. Right “soft key” on the display

4. Go to the Selection Screen, or middle soft

key on the display

5. Left “soft key” on the display

6. Move down, or decrease number

To make selections, press the buttons on the tester (Figure

3). The words displayed along the bottom of each screen

are “soft keys” that represent the functions of the left key, the

central menu key, and the right key. The functions will change

depending on which screen you are viewing. For examples,

see the screen images below.

1

2

3

4

6

5

Figure 3 e keypad

Figure 4 e Menu

Screen

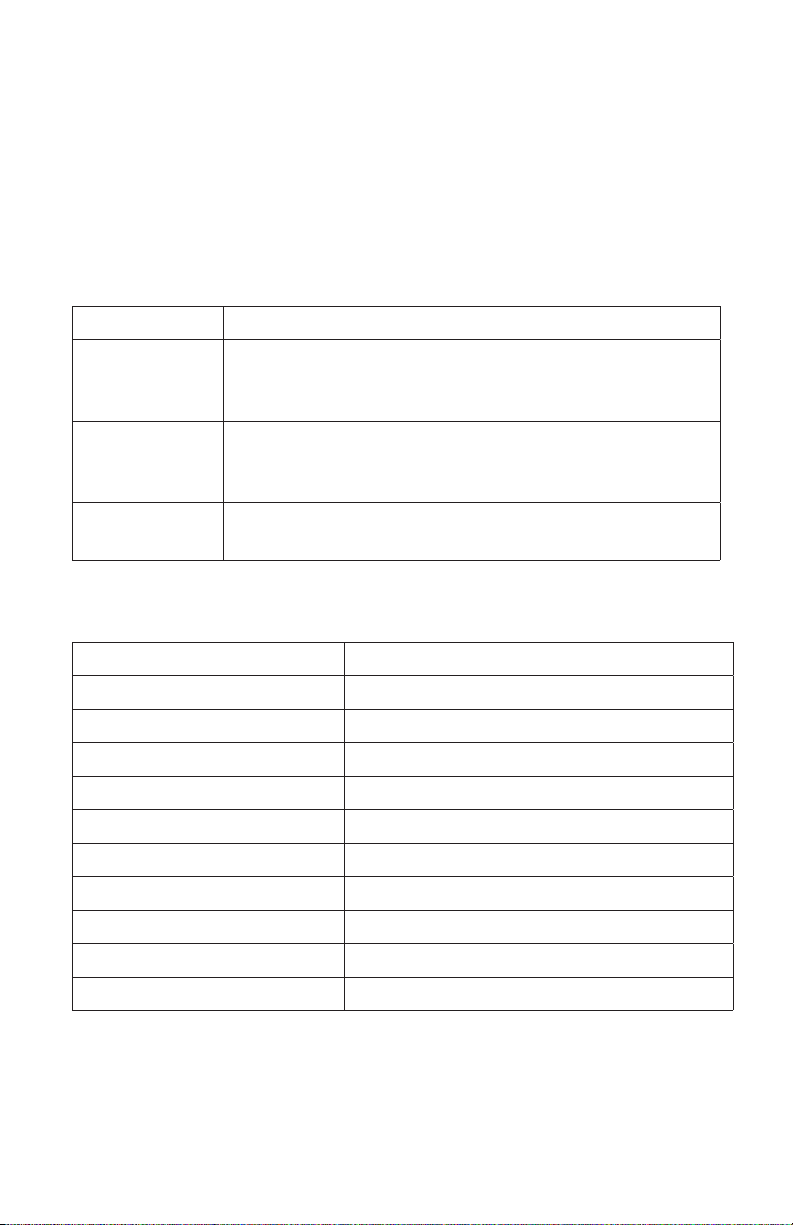

2.3.5. Change the potential limit

For advance user, you can customize all potential

limits for different materials in Limit Setting Screen.

To customize the Limit Settings for uncommon

materials:

Figure 5 Limit Setting Screen

6

1). Choose “Others” material.

2). Select the Upper or Lower setting value for that material.

3). Press or to increase or decrease the value.

4). Save the new Limit Settings. You will be taken back to the

Measuring Screen.

In the same way, you may change the values for steel, aluminum,

and bronze as well, based on your knowledge about corrosion.

For your reference, Table 1 lists the potential factory setting values

for protected, under-protected, and over-protected conditions for

each type of boat material.

Table 1 - Potential Limit Factory Settings for the Seaguard

Digital Corrosion Tester (Ag/AgCl reference cell - SSC)

Hull Material Under

protection Safe Protected Over

protection

Steel alloys > -0.800V -0.800V to -1.050V < -1.050V

Aluminum alloys > -0.900V -0.900V to -1.100V < -1.100V

Copper alloys > -0.500V -0.500V to -0.700V < -0.700V

Others > -0.500V -0.500V to -0.700V < -0.700V

The “<” symbol means “less than” the given limit, in the negative

direction. The “>” symbol means “greater than” the given limit, in

the positive direction. The default setting is steel.

2.3.6. Taking measurements

Your Potential readings are displayed directly on

the Corrosion Measuring Screen (Figure 6).

To save the current measurement value, press the

left button (Save). A window will appear for you to

conrm that you do want to save, yes or no.

Figure 6 Corrosion

Measuring Screen

Important – For correct interpretation, note the polarity of the

voltage reading (+ or -).

2.3.7. Reviewing saved data

The example of the Data Review Screen (Figure 7) shows

7

readings for over-protected steel (in yellow),

measured relative to the corrosion tester’s Ag/

AgCL reference cell (SSC). To delete a saved

measurement, select it using the Up/Down keys,

then press the left key (Del).

To display a highlighted measurement in the

Measuring Screen, press the Menu key “Upd”. As

shown in Figure 8, you can now view the static

saved measurement along with the upper and

lower limits, to compare them. To return to the Data

Review Screen press the MENU key (Back).

2.3.8. Clearing all the saved data

From the Menu Screen (Figure 4), choose Clear Data. A window

will pop up for you to conrm that you do want to save, yes or no.

2.3.9. Resetting to factory settings

From the Menu Screen (Figure 4), choose Factory Reset. A

window will pop up for you to conrm that you do want to reset the

data, yes or no.

Figure 7 Saved Data

Figure 8 Update

Saved Data

3. How to Connect and Measure

WARNING! - Do not put the reference cell or test probe

into water that is contaminated with oil, diesel, gas, or

pollutants. This can cause contamination of the reference

cell and erroneous readings.

3.1 General

Lower the reference cell into the water so that it is at least a foot

below the water surface, near to the boat. If there is wave action,

lower the reference cell deeper.

Secure the test lead using alligator clip to a point above water on

the metal being tested.

Make an effective connection. The metal surface will often be

covered by paint, dirt, oil, or rust. Make sure that the probe has

effective electrical contact directly with the metal. Probe several

times in different locations on the same material. If good contacts

are made, the readings will be stable and very similar in the

different locations. When taking measurements from a xture

attached to the hull, make sure that the xture has been properly

bonded. Search for a contact point until the measurement is

stable.

8

CLIP TO BOLT

HOLDING ENGINE

3.4 Outboard

3.5 Others

Any other structure that is steel, aluminum or copper which

is in water can be measured.

CLIP TO BOLT

ON OUTDRIVE

CLIP TO GROUND STRAP

OR TO COPPER WIRE

CONNECTING ITEMS SHOWN

3.2 Sterndrive 3.3 Inboard

9

4. Maintenance

Ag/AgCl reference cell (SSC) is maintenance free.

After using the tester:

1). Rinse the reference cell and test probe in fresh water.

2). Dry all parts after use and keep them in the box.

3). Store in a dry, safe place.

5. Troubleshooting

Problem Possible solution

No display Check that the test probe lead and reference

cell are plugged into the correct place. The

battery is dead. Replace the battery.

Reading is

inaccurate

Check the wire of the reference cell. Replace

it if there is any damage. Clean the surface of

Zinc reference cell using ne sand paper.

Any damage Contact Seaguard International for

replacement.

6. Specications

Measurement range -2.500 to +2.500 volts

Measurement accuracy 0.5%

AD resolution 16 bits

Input impedance >108 Ω

Display TFT LCD 1.8”, 320x220

Power 3 AAA Batteries

Auto shutdown No button action for 2.5 minutes

Manual shutdown Press power button >2 seconds

Data stored Maximum 50 measurement values

Working temperature -10°C to 50°C

Dimensions 142 mm x 63 mm x 32 mm

7. For more information

For more information, please check out our website

seaguardinternational.com

10

Table of contents

Popular Test Equipment manuals by other brands

Apera Instruments

Apera Instruments GroStar GS2 user manual

Maurer Elektromaschinen

Maurer Elektromaschinen Captest 1225 V2 Operation manual

Teledyne

Teledyne HDO8000A Getting started guide

Keysight

Keysight U1610A user guide

Klein Tools

Klein Tools RT210 user manual

Lifeloc

Lifeloc Phoenix 6.0BT Operation manual