Sealed Air Instapak 901 User manual

Instapak®901/970

Foam-in-Place Packaging System

User's Guide

Original instructions.

Instapak®901/970 System User's Guide Table of Contents

TABLE OF CONTENTS PAGE

IMPORTANT SAFETY PRECAUTIONS i

1.0 OVERVIEW 1 - 1

1.1 System Description 1 - 1

1.2 System Operation 1 - 1

1.3 Electrical Requirements 1 - 2

1.4 Space Requirements 1 - 2

2.0 OPERATION 2 - 1

2.1 The Console Control Panel 2 - 1

2.2 System Start-Up 2 - 3

2.3 Control Settings 2 - 3

2.3.1 Timer Modes 2 - 4

2.3.2 Setting Flow Rate 2 - 7

2.3.3 Setting Temperatures 2 - 7

2.4 Additional Features 2 - 9

2.4.1 The Shot Sequence Mode 2 - 9

2.4.2 Shot Storage Feature 2 - 12

2.4.3 Language Selection 2 - 16

Table of Contents

3.0 PACKAGING SUGGESTIONS 3 - 1

3.1 Foam-in-Place Packaging Method 3 - 1

3.2 Pre-Molding Packaging Method 3 - 5

4.0 MAINTENANCE 4 - 1

4.1 Preventive Maintenance Schedule 4 - 1

4.2 Holster Maintenance 4 - 2

4.3 Cartridge and Dispenser Maintenance 4 - 3

4.4 Chemical Container Replacement 4 - 14

5.0 TROUBLESHOOTING 5 - 1

5.1 Equipment/System Issues 5 - 1

5.1.1 Efficient Use of Foam 5 - 1

5.2 Troubleshooting Charts 5 - 2

6.0 APPENDIX 6 - 1

Accessories 6 - 1

Supplies 6 - 1

Parts 6 - 1

Customer Service Locations 6 - 2

Instapak®901/970 System User's Guide Safety

i

IMPORTANT SAFETY PRECAUTIONS

Read and thoroughly understand this guide.

Warning Symbols:

This "bolt of lightning" indicates uninsulated material within

your unit that may cause an electrical shock. do not remove

the product cover.

This "exclamation point" calls attention to features for which

you should read the enclosed literature closely to prevent

operating and maintenance problems.

Before operating your Instapak®system, read and understand

the "RECOMMENDATIONS FOR THE SAFE USE

AND HANDLING OF INSTAPAK®FOAM-IN-PLACE

CHEMICALS" bulletin, and the Material Safety Data Sheets

(MSDSs) provided for Instapak®products.

If additional copies of the "RECOMMENDATIONS FOR

THE SAFE USE AND HANDLING OF INSTAPAK®

FOAM-IN-PLACE CHEMICALS" bulletin or MSDSs are

needed, please contact your local Sealed Air®sales or account

representative.

WARNING: To avoid overexposure to MDI vapors, never

dispense Instapak®"A" chemical unless making Instapak®

packaging foam. If system is not in normal operating

condition, DO NOT USE.

This "goggles" symbol calls attention to the need to wear

protective eyewear with side shields while performing

operating, maintenance, and repair procedures.

Be sure to turn the console OFF before performing main-

tenance procedures on the Instapak®901/970 system.

Safety

ii

Do not remove the covers. The covers should be removed only

by authorized Sealed Air®service personnel. Opening the cov-

ers exposes dangerous electrical shock hazards.

before operating, make sure that:

• Theoperatorhasreceivedfulltrainingbyauthorized

Sealed Air®personnel.

• Thesystemispluggedintoaproperlyrated,groundedoutlet.

(Refer to Section 1.3 of this guide)

Failure to properly ground the system could create an electrical

shock hazard.

Inspect the Instapak®901/970 system at regular intervals to

ensure that:

a. Component hoses and cables are not cut, broken or damaged.

b. No components of the dispenser, console or pumps are loose.

c. All controls and indicators function properly.

If operation of the system differs from the descriptions in this

guide, turn the system off and disconnect the main power until

the unit can be inspected by a Sealed Air®representative.

We strongly recommend that customers use only Instapak®

chemicals with Instapak®systems. We can assume no responsi-

bility when other chemicals are used in Instapak®systems, and

we reserve the right to refuse to service any Instapak®systems

if non-Instapak®chemicals or parts have been used. Service

includes, without limitation, providing repairs and maintenance

services, supplies and parts.

Do not attempt to repair or modify the Instapak®901/970

system other than the procedures contained in the

troubleshooting section of this guide. All repairs must be

done by authorized Sealed Air®service personnel.

Instapak®901/970 System User's Guide Safety

iii

In accordance with the provisions of the EC Machinery Directive (2006/42/

EC), EC Low Voltage Directive (2006/95/EC) and EC Electromagnetic Directive

(2004/108/EC) the following applicable standards documents were used:

For all 901 and 970 systems:

EN 60204-1, EN 13849-1, EN 14121,

EN ISO 12100-1, EN ISO 12100-2,

EN ISO 13857, EN 349, EN 953-1,

EN 55011, EN 61000-4-2, EN 61000-4-3,

EN 61000-4-4, EN 61000-4-5, EN 61000-4-6,

EN 61000-4-11, EN 61000-6-2, EN 61000-6-4

SHOULD YOU ENCOUNTER A PROBLEM WITH YOUR

INSTAPAK®901/970 SYSTEM THAT YOU CANNOT FIX

WITH THE HELP OF THIS MANUAL, PLEASE CALL

SEALED AIR FOR TECHNICAL ASSISTANCE.

Safety

iv

NOTICE

© Copyright 2006 by Sealed Air Corporation (US). All rights reserved.

This document is copyrighted. The material contained herein is protected under

the US Copyright Act of 1976. This document, in whole or in part, may not

be copied, photocopied, reproduced, translated or reduced to any electronic

or machine-readable form without the prior written permission of Sealed Air

Corporation (US).

AIRBORNE NOISE EMISSION

For all 901 and 970 systems, the continuous A-weight sound pressure level does

not exceed 70 dB(A) during normal operations.

Instapak®901/970 System User's Guide Overview

1 - 1

1.0 OVERVIEW

The Instapak®901/970 foam packaging system dispenses a mixture of

Component "A" and Component "B". When mixed, the "A" and "B"

components react with each other to produce high quality polyurethane

packaging foam.

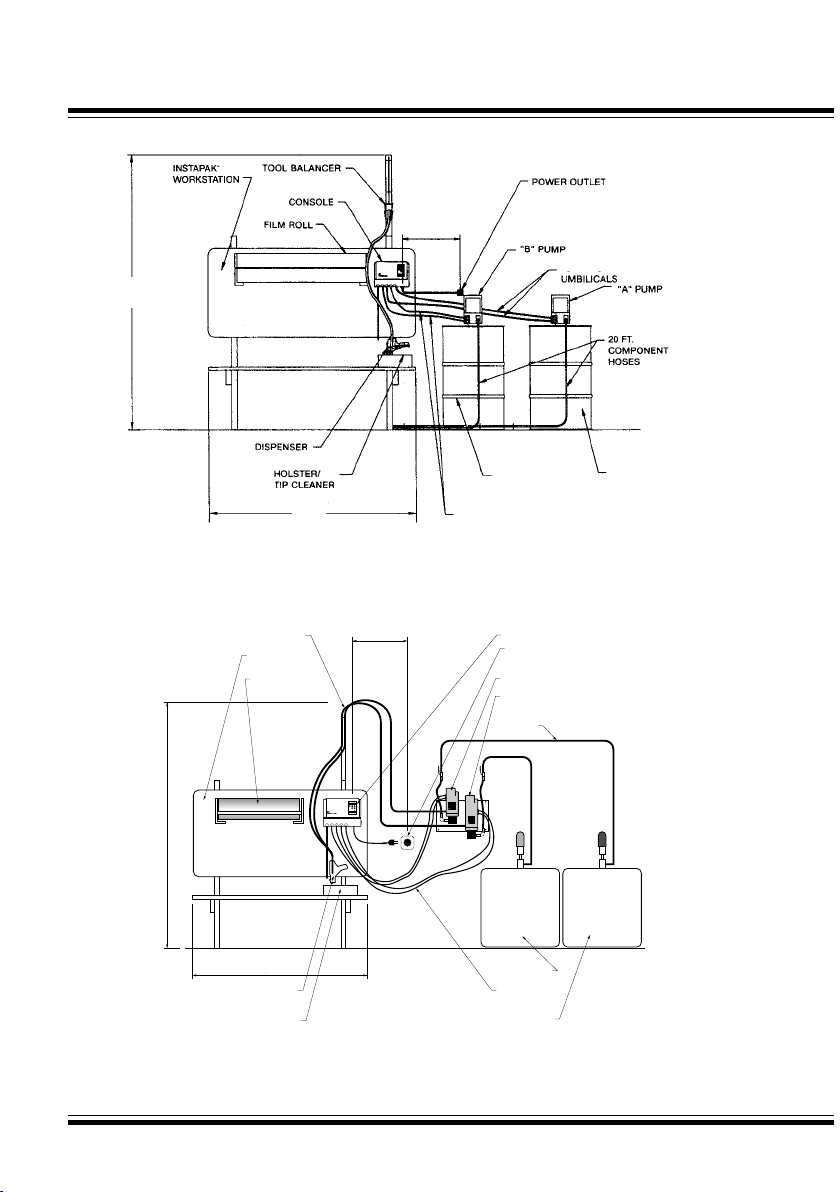

1.1 SYSTEM DESCRIPTION

The Instapak®901/970 system is made up of 4 major parts. Refer to

Figure 1-1, page 1-3.

1) Set of two electric pumps.

2) Electrically operated dispenser.

3) Computer operated console.

4) Heated component hoses.

1.2 SYSTEM OPERATION

The "A" and "B" components are pumped from the supply containers by

the "A" and "B" pumps into the heated hoses and through the dispenser.

The dispenser is supplied with a holster that keeps the tip clean and

ready for use. The hoses are suspended from a tool balancer that

supports their weight and allows them to be maneuvered easily.

Overview

1 - 2

1.3 ELECTRICAL REQUIREMENTS

NOTE: The Instapak 970 system requires 7 bar clean dry shop air at the

chemical container location.

1.4 SPACE REQUIREMENTS

The location selected for the Instapak®system should meet the following

criteria:

• Easilyaccessiblespaceforthe"A"and"B"componentcontainers.

The containers must be located within 1.5 m of the console, and

within 3 m of the dispenser.

• Asuitablewallspacetoaccommodatethecontrolconsole.Thepower

outlet for the console must be within 1,5 m of the console, and easily

accessible to the operator. The console should be fastened to the wall

approx. 1,5 m from the floor to the center of the console, to allow

easy access by the operator.

• Astructureatleast3,5mhigh,strongenoughtohangthetool

balancer and component hoses.

• AnInstapak®workstation is also available for ease of

installation. Ask your Sealed Air®account representative for details.

SYSTEM RECEPTACLE

TYPE A/C VOLTAGE PHASE CURRENT

Instapak®901/970

Instapak®901Y/970Y

Instapak®901D/970D

NEMA L6-30R

CEE type CT

516/6h

CEE type CT

432/9h

200 - 240 VAC,

50/60Hz

380 - 415 VAC,

50/60Hz

220 - 240 VAC,

50/60Hz

Single

Phase

3 N PE

3 PE

30 Amperes

16 Amperes

20 Amperes

Instapak®901/970 System User's Guide Overview

1 - 3

Fig 1-1 Typical Layout of the Instapak®901 System

Fig 1-2 Typical Layout of the Instapak®970 System

A

CHEMICAL

Instapak

®

900

Reset +

-

+

-

AB

AB

12

B

CHEMICAL

A

Instapak

B

Instapak

Instapak®

Workstation

Tool Balancer 5 Ft. Max.

13 Ft. Pump

Umbilicals

"A" Pump

Chemical

Lines

"B" Pump

Power

Outlet

Console

Film Roll

Dispenser

Holster/

Tip Cleaner

6 Ft.

8 Ft.

"A" Bulk Tank

"B" Bulk Tank

COMPONENT "B"

DRUM

COMPONENT "A"

DRUM

4 m PUMP

UMBILICALS

1,5 m

2,45 m

1,5 m MAX

4 m PUMP

1,5 m

1,5 m

2,45 m

4 m Pump

Overview

1 - 4

NOTES

Instapak®901/970 System User's Guide Operation

2 - 1

2.0 OPERATION

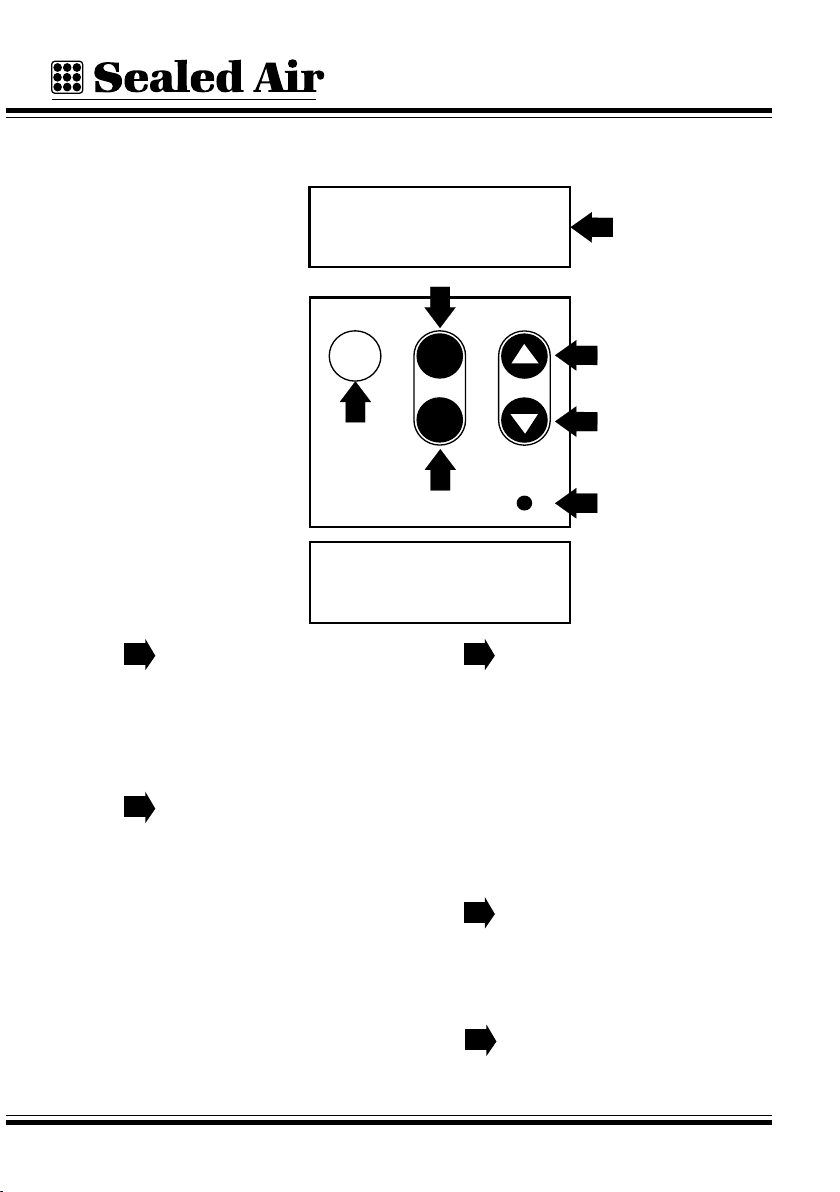

2.1 THE CONSOLE CONTROL PANEL

To operate the Instapak®901/970 system, push the main power switch

(1), on the right side of the console, to the "ON" position.

The Instapak®901/970 System Control Console

I

O

ON

OFF

Main Power Switch

Instapak

®

901

Reset

+

-

1

Operation

2 - 2

Instapak® 901

Reset

+

-

3

3

2

5

2

4

1

The controls are located on the front of the console. See the figure

below.

The Display.

This window displays messages

from the system and a number of

options you can change within the

system.

The Menu UP ▲ and Menu

DOWN ▼ keys.

These keys allow you to change the

window being displayed. Push the

Menu UP ▲ key to change to the

next window and push the Menu

DOWN ▼ key to change to the

previous window shown.

The Adjust PLUS + and

Adjust MINUS - keys.

These keys allow you to change

settings. Use the PLUS (+) or

the MINUS (-) key to increase or

decrease the value by one unit.

Hold down a key, and the value

will continue to change at a faster

rate.

The RESET key.

Push the RESET key to restart the

901/970 system after a shut-down

has occurred.

The LED.

This will light up when the system

is on.

1

2

3

4

5

SYSTEM STATUS WARM-UP

DISPENSER: OK

A DRUM: 3/4 FULL

B DRUM: FULL

Instapak®901/970 System User's Guide Operation

2 - 3

2.2 SYSTEM START-UP

When the system is first turned on, the displays will read all zeros, then

change to all ones. Then the display will read:

The display will show this message until the system has reached the

proper operating temperature and pressure. Then, the display will read:

NOTE: "A" and "B" drum level will not be shown on 970 systems.

You are now ready to dispense Instapak®foam.

• Removethedispenserfromtheholster.

• Squeezethetriggertodispensefoam.

• Releasethetriggertostopdispensingfoam.

• Placethedispenserbackintotheholster.

2.3 CONTROL SETTINGS

This section explains how to adjust basic settings: Timer, Flow Rate, and

Temperatures.

The settings are made by observing the display and then using the keys

on the control console to make selections or change numerical values.

The display shows a series of menus or "windows." Moving from one

window to another is accomplished by using the Menu UP ▲ and Menu

DOWN ▼ keys.

CAUTION

SAFETY GLASSES WITH SIDES MUST BE WORN WHILE

OPERATING INSTAPAK®EQUIPMENT.

SYSTEM STATUS WARM-UP

DISPENSER: OK

A DRUM: FULL

B DRUM: FULL

SYSTEM STATUS READY

DISPENSER: OK

A DRUM: FULL

B DRUM: FULL

Operation

2 - 4

2.3.1 TIMER MODES

You can choose between two modes, Manual Shot and Single Shot.

2.3.1.1 Manual Shot Mode

In Manual Shot mode the shot will last as long as you pull the trigger.

Use Manual Shot mode when you wish to manually control the foam

dispensing process. The system is configured to operate in the Manual

Shot mode after start-up. No adjustment to the system is necessary to

permit manual operation.

However, in Manual Shot mode you can, if you wish, determine the

length of any shot you have made. This information may be helpful for

programming timed shots into the system. To determine the length of a

manual shot, begin at the SYSTEM STATUS WINDOW:

NOTE: "A" and "B" drum level will not be shown on 970 systems.

•PresstheMenuUP ▲ key to show the TIMER MODE WINDOW:

•PresstheMenuUP▲ key again to show the LAST SHOT WINDOW:

SYSTEM STATUS READY

DISPENSER: OK

A DRUM: FULL

B DRUM: FULL

TIMER MODE

*MANUAL SHOT*

USE (+) OR (-) KEY

TO SELECT

LAST SHOT WAS

0.00 SECONDS

Instapak®901/970 System User's Guide Operation

2 - 5

•Squeeze the trigger on the dispenser. Foam will be dispensed and the

timer will count up from 0.00 seconds until you release the trigger. The

actual time of the shot will be shown in the LAST SHOT WINDOW,

for example:

The timer will automatically reset to 0.00 and time the next shot when

the trigger is squeezed.

2.3.1.2 Single Shot Mode

In Single Shot mode, when you squeeze the trigger, the shot will last as

long as the timed setting. Use this mode when you have a repetitive task

requiring the same amount of foam each time.

To set the length of a single timed shot, begin at the SYSTEM STATUS

WINDOW:

NOTE: "A" and "B" drum level will not be shown on 970 systems.

•PresstheMenuUP ▲ key to show the TIMER MODE WINDOW:

SYSTEM STATUS READY

DISPENSER: OK

A DRUM: FULL

B DRUM: FULL

TIMER MODE

*MANUAL SHOT*

USE (+) OR (-) KEY

TO SELECT

LAST SHOT WAS

2.33 SECONDS

Operation

2 - 6

•PressthePLUS(+)orMINUS(-)keytoselectSingleShotMode:

•PresstheMenuUP ▲ key and the display will read:

•PressthePLUS(+)orMINUS(-)keytosetthedesiredlength(in

seconds) of the single shot.

You can now dispense a timed shot. When you pull the trigger on the

dispenser, foam will be dispensed and the display will count down to

0.00 seconds. The shot will stop automatically at that time. The shot

will also automatically stop if you let go of the trigger.

At the end of the shot, the display will reset to the same number of

seconds. All subsequent shots will change automatically to the new set

point until the timer setting is changed again.

TIMER MODE

*SINGLE SHOT*

USE (+) OR (-) KEY

TO SELECT

TIMER SET FOR:

5.00 SECONDS

USE (+) OR (-) KEY

TO ADJUST

Instapak®901/970 System User's Guide Operation

2 - 7

2.3.2 SETTING FLOW RATE - THE FLOW RATE

WINDOW

The flow rate should be set to suit your particular packaging applica-

tions. A small box will use a slower flow rate; a large box will use a

faster rate.

•FromtheSYSTEMSTATUSWINDOW,presstheMenuUP ▲ key

THREE times and the display will read:

•PressthePLUS(+)orMINUS(-)keytochangetherateatwhichfoam

is dispensed. The higher the number, the faster foam is dispensed

(kilogram per minute).

2.3.3 SETTING TEMPERATURES - THE TEMPERATURE

WINDOWS

The temperature windows are used to control the temperatures of the

foam components in the hoses.

2.3.3.1 The "A" Temperature Window

•FromtheFLOWRATEWINDOW,presstheMenuUP ▲ key to move

to the "A" TEMPERATURE WINDOW.

•PressthePLUS(+)orMINUS(-)keytoadjustthe"A"component

temperature value.

FLOW RATE:

3.0 kg/m

USE (+) OR (-) KEY

TO ADJUST

A TEMPERATURE 60°C

USE (+) OR (-) KEY

TO ADJUST

Operation

2 - 8

2.3.3.2 The "B" Temperature Window

•Fromthe"A"TEMPERATUREWINDOW,presstheMenuUP ▲ key

to move to the "B" TEMPERATURE WINDOW.

•PressthePLUS(+)orMINUS(-)keytoadjustthe"B"component

temperature value.

B TEMPERATURE 60°C

USE (+) OR (-) KEY

TO ADJUST

This manual suits for next models

5

Table of contents

Other Sealed Air Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

Minipack-Torre

Minipack-Torre Pratika 56 CS Series Installation, operation and maintenance

Dispens-a-Matic

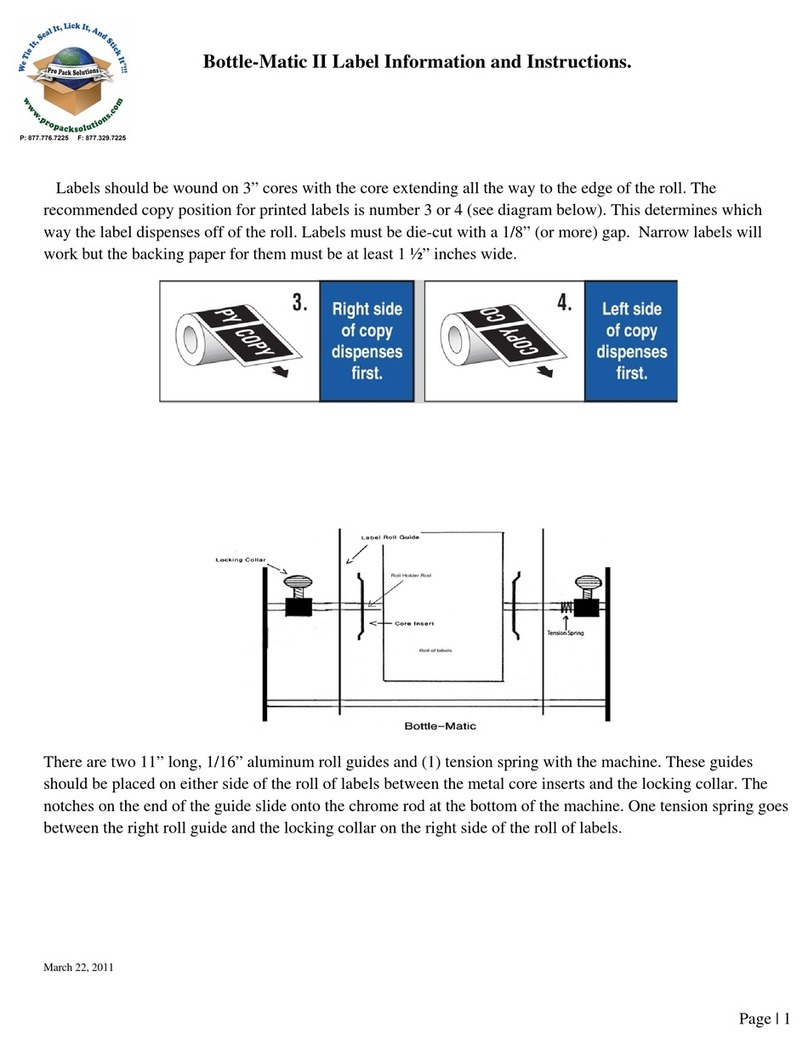

Dispens-a-Matic Bottle-Matic II Information and instructions

U-Line

U-Line H-7241 user manual

Greenbridge

Greenbridge PC1500 Operation manual & spare parts list

Proceq

Proceq ZAA 2600.HA instruction manual

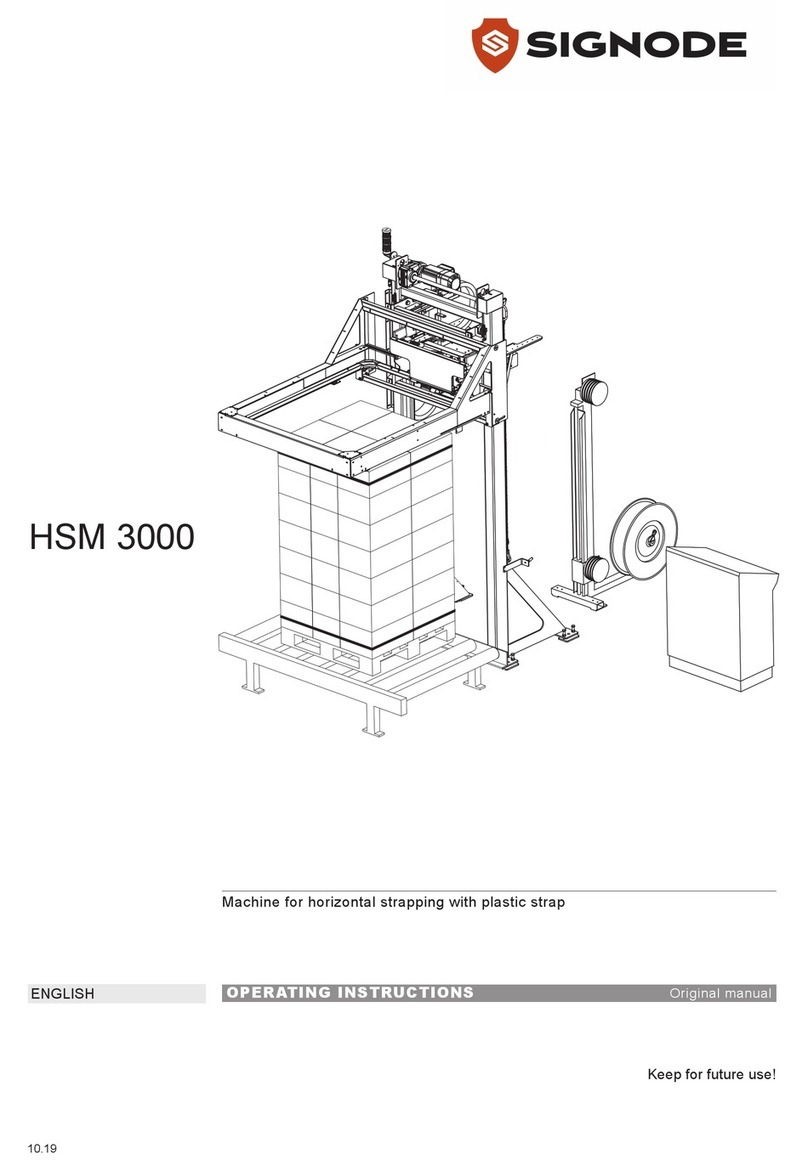

Signode

Signode HSM 3000 operating instructions