TCGRx ATP Series Specifications

The ATP-series Automated Tablet Packaging Solutions

ATP-E320W

ATP-E320N

ATP OPERATOR INSTRUCTIONS

ATP Operator Instructions

2

Copyright ©2014 TCGRx. All Rights Reserved

Revised 11/05/2014

Read through this entire manual before operating the machine. Be sure to read the "Safety precautions"

This document and the information contained herein is provided on an “As Is”basis and TCGRx disclaims all

warranties, express or implied, including but not limited to any warranty that the use of the information herein will

not infringe any rights or any implied warranties of merchantability or fitness for a particular purpose.

TCGRX reserves the right to make changes to the content of this manual, at any time, without obligation to notify

any person or entity of such changes.

Those wishing to reproduce and/or use this text for purposes other than above authorized, are requested to apply

in writing or directly contact:

TCGRx

N1671 Powers Lake Road

Powers Lake, WI 53159 USA

Ph: 262.279.5307

Fax: 262.279.5360

www.tcgrx.com

Confidential Property of TCGRx

This material cannot be copied or disclosed to others without the prior written permission of TCGRx.

ATP Operator Instructions

3

Table of Contents

Chapter 1 | Introduction ................................................................................................................5

About This Instruction Manual........................................................................................................................... 5

About this Product............................................................................................................................................. 5

Privacy Policy ..................................................................................................................................................... 5

Mandatory Safety Precautions........................................................................................................................... 6

Chapter 2 | Introduction ..............................................................................................................12

Introducing the ATP-E320 ................................................................................................................................ 12

Chapter 3 | Selecting an Installation Site.......................................................................................13

Overview ......................................................................................................................................................... 13

Securing the Unit ............................................................................................................................................. 14

Chapter 4 |Installation ................................................................................................................15

Securing the Unit to the Floor .......................................................................................................................... 15

Chapter 5 | Part Names and Functions..........................................................................................17

ATP .................................................................................................................................................................. 17

Control Panel ................................................................................................................................................... 18

Tablet Canister (Canister)................................................................................................................................. 19

TC Drawer ........................................................................................................................................................ 20

UTC Tray .......................................................................................................................................................... 21

Packaging Mechanism...................................................................................................................................... 22

Power Switch ................................................................................................................................................... 24

Dispenser Preparations ....................................................................................................................27

Handling of TC Drawers.................................................................................................................................... 27

How to Refill a Tablet Canister......................................................................................................................... 27

How to Replace the Packaging Paper (by Splicing) ........................................................................................... 29

How to Replace the Packaging Paper (without Splicing)................................................................................... 31

How to Replace the Printer Ribbon.................................................................................................................. 33

Filling the UTC Tray .......................................................................................................................................... 34

Chapter 6 | Operating Method .....................................................................................................35

Checking System Conditions ............................................................................................................................ 35

From Power on to Shutdown ........................................................................................................................... 36

ATP Operator Instructions

4

Processing Alarm Messages ............................................................................................................................. 37

Chapter 7 | Maintenance .............................................................................................................39

Cleaning the Tablet Canister and Motor Base .................................................................................................. 39

How to Replace the Cutter Blade ..................................................................................................................... 40

How to Clean the Tablet Canister Drawer ........................................................................................................ 41

How to Clean the Sub Hopper.......................................................................................................................... 42

How to Clean the UTC Tray .............................................................................................................................. 44

How to Clean the Primary Shutter ................................................................................................................... 46

How to Clean the Main Hopper........................................................................................................................ 47

How to Clean the Packing Mechanism ............................................................................................................. 49

Supply for Maintenance................................................................................................................................... 51

Chapter 8 | Troubleshooting ........................................................................................................53

Automatic Tablet Packager (ATP)..................................................................................................................... 53

Tablet Canister................................................................................................................................................. 53

TCGRx Computer.............................................................................................................................................. 53

Chapter 9 | Specifications.............................................................................................................54

Dimensions ...................................................................................................................................................... 55

ATP Operator Instructions

|Introduction

5

Chapter 1 | INTRODUCTION

About This Instruction Manual

Read through this instruction manual before you attempt to operate the unit so you know how to use it

correctly.

Note that TCGRx cannot guarantee the safety of the unit if it is used in a manner other than that specified in

this manual, or used for a purpose other than intended.

Store the instruction manual in a location where it can be easily accessed for reference when needed.

The content of this manual is subject to change without prior notice due to improvements in product

performance and functions.

If you notice pages out of order or missing pages in the manual, contact your TCGRx representative.

Every effort has been made in preparing this document. Should you, however, notice any errors, have

questions or suggestions; please contact your TCGRx representative.

This instruction manual may not be reproduced whole or in part without permission.

About this Product

TCGRx does not accept any liability for damages as a result of the operator’s use of the product.

Privacy Policy

Names, addresses, telephone numbers and other personal information received when processing

warranty repairs or in handling other services during the warranty period is maintained for the sole

purpose of servicing the product. TCGRx does not disclose personal information to third parties without

your consent except when services are outsourced or when we are legally obliged to disclose your

information.

Note: This unit and the system are not intended to replace a pharmacist. The medications that the unit package

must be inspected by a pharmacist before they are given to a patient.

ATP Operator Instructions

|Introduction

6

Mandatory Safety Precautions

The following instructions must be observed to prevent injury to persons and damage to property.

The following signal words are used to indicate the level of injury or damage that could result from

incorrect use of the product.

The following symbols are used to indicate instructions that must be observed.

The following symbol shows the Label on the unit.

The HEATER will remain hot.

To avoid injury, DO NOT touch the HEATER.

ATP Operator Instructions

|Introduction

7

Do not damage the power cord or the

power plug (through abuse or by

modifying it, using it close to a heater,

or by bending, twisting or pulling it

hard, placing heavy objects on it or

bundling it up, etc.)

Do not use the unit outdoors.

Using a damaged power cord could

result in electric shock, short-circuiting

or fire. Consult our sales representative

or agent for cord or plug replacements.

Current leakage or electric shock may

result if exposed to rain water .

Remove dust or debris from the power

plug at regular intervals.

Install the unit on a sturdy, level floor

and take adequate precaution to

prevent the unit from turning over.

Any dust that adheres to the plug could

attract moisture and cause insulation

failure. Disconnect the power plug and

wipe it with a dry cloth.

If the floor is not strong enough or the

installation is not adequate, this may

result in injury from the unit turning

over.

Fully insert the power plug. Installation work should be performed

by authorized personnel.

Incomplete insertion creates a risk of

electric shock or fire from generated

heat. Do not use a damaged plug or

loose AC outlet.

Improper installation by the user may

result in water leakage, electric shock or

fire.

Do not connect or disconnect the

power plug with wet hands.

Never install the unit in a humid

location or a location where it is likely

to be splashed by water.

Touching electric equipment with wet

hands could result in electric shock.

Deterioration of the insulation may

result which could cause current leakage

or electric shock.

The product must be connected to an

outlet with a 15 A rating that is not

shared with other equipment.

Disconnect the power plug if there is

something wrong with the unit.

When the same AC outlet is also used

for other equipment, more heat will be

generated and there is a risk of fire. Use

Continued abnormal operation may

cause electric shock or fire

ATP Operator Instructions

|Introduction

8

only a single cord extensions that has a

15 A rating.

Any medication created by this unit

must be examined by a pharmacist.

Turn off the power switch and

disconnect the power plug of the unit

prior to any repair or maintenance.

This unit cannot replace a pharmacist.

All packaged medications must be

checked by a pharmacist.

Failure to do so may result in electric

shock or injury.

Never disassemble, repair, or modify

the unit yourself.

Always ground the unit to prevent

electric shock.

The unit contains high-voltage

components that can cause electric

shock. All inspection and repair work

inside the unit must be limited to service

personnel or other authorized

personnel.

A unit that is not properly grounded

could cause electric shock. If the power

supply outlet is not grounded,

authorized personnel will have to

properly ground the unit.

Never splash water directly onto the

unit.

Do not touch the cutter blade or

perforation blade during cleaning.

Water could enter the unit causing

short-circuiting and electric shock.

Touching the blades may result in injury

.

Never ground the unit through a gas

pipe, water pipe, telephone line or

lightning rod.

Turn off the unit off before replacing

the blade.

Such a ground connection could result in

electric shock .

Doing so when the unit is operating

could result in injury.

Do not insert metal objects such as pins

or wires into any vent or gap on the

unit.

Replace the blade as described in the

instruction manual.

Such objects could cause electric shock

or injury by accidental contact with

moving parts.

Touching the blade will result in injury.

Do not place objects in front of the air

exhaust vents.

Do not touch the cutter blade.

Since the internal fan rotates at high

speed, inserting an object could result in

injury.

Touching the blade will result in injury .

ATP Operator Instructions

|Introduction

9

Do not insert foreign materials into the

medication exit.

Only use the specified medication for

each canister.

Doing so when the unit is operating

could result in injury.

Refilling tablets other than those

specified could lead to a medical

accident.

Do not touch the seal mechanism

heater.

Do not lean on the cabinet.

Touching it could result in burn injuries. It could turn over and cause injury.

Do not touch the heater after the

power has been recently turned off.

Clean the motor base and the pill

detecting sensor

The heater block can become very hot.

Do not touch it before it cools down.

Failure to do so may result in medical

accidents caused by underdosing,

overdosing or contamination.

Pull out only one TC drawer in a row

during filling.

Make sure that the polyvinyl bags used

for packaging are kept out of reach of

children.

The cabinet could tip over and injure

somebody if several storage drawers are

pulled out at the same time.

A child could pull a polyvinyl bag over

their head, the bag could form an

airtight seal around their nose and

mouth, which could result in suffocation.

Do not touch electric equipment or

operate switches with wet hands.

Secure the unit using the supplied

anchor bolts.

Touching electric equipment with wet

hands could result in electric shock.

This may result in injury from the unit

turning over

Install to a location that can be pulled

out the power plug.

This may remove the power plug from

the power supply outlet during the

abnormal operation .

ATP Operator Instructions

|Introduction

10

This unit must not be used as a long-

term storage of medications.

Wear a mask when cleaning the unit to

prevent breathing in medication dust.

Changes in medication due to end of storage

life, temperature or humidity could lead to a

medical accident.

Failure to do so may lead to health

problems.

Do not lean on a TC drawer. Dust from medications must be removed

from the unit at regular intervals.

It could turn over and cause injury. Leaving dust from medications could cause

medical accidents from cross contamination

.

Do not stand on the unit or place objects on

top of it.

Do not touch inside or around the UTC tray

when it is being opened closed.

The unit could turn over, be damaged

or fall and cause injury.

Touching the tray could result in injury .

Grip the power plug when disconnecting the

power cord.

Do not touch inside the TC drawer when it

is being closed.

Pulling the cord may cause electric

shock or fire.

Touching the drawer could result in injury.

Clean the packaging unit when the heater

has cooled down.

The heater in the packaging unit becomes

very hot. Turn off the power switch and

wait for the heater to cool properly before

starting cleaning. Cleaning while the heater

is still on will lead to injury.

When the unit will not be used for an

extended period of time, disconnect the

power cord from the power supply

Do not use medication canisters for storing

medications.

Deterioration of insulation could cause

electric shock or fire .

Changes in medication due to end of

storage life, temperature or humidity

could lead to a medical accident .

ATP Operator Instructions

|Introduction

11

Turn the power switch off before starting to

clean the UTC tray.

Do not touch the components near the

UTC tray when cleaning the area below it.

Otherwise the electrical components of

the UTC tray could short circuit or cause

electric shock.

You could hurt your self if you press it very

hard.

When you close the primary shutter base,

do not touch the area behind the push latch.

Relocation work of the unit should be

performed by authorized personnel.

You could get your fingers caught between

the push latch and the bracket on the

receiving side and hurt yourself.

Improper relocation by user may result in

injury from the unit turning over.

ATP Operator Instructions

|Introduction

12

Chapter 2 | INTRODUCTION

Introducing the ATP-E320

The ATP-E320 combines packaging and unit or multi-dose dispensing with comprehensive software

System that allows you to control and track patient medication orders.

This system delivers all of your patients' medications sealed in unit-dose or multi-dose packages labeled

with name, barcodes, medication information, and dosage time printed clearly on each package.

The ATP-E320 System is comprised of the following items:

•The ATP-E320 pill dispensing and packaging hardware, which includes calibrated drug

canisters / cassettes, a universal drag tray, and unit-dose and multi-dose packaging system

multi-label formatting and barcode printing.

•A computer which contains the software system that communicates with the ATP-E320

hardware to fill and track patient medication orders.

•A LAN cable that connects the ATP-E320 hardware to the computer.

ATP Operator Instructions

|Selecting an Installation Site

13

Chapter 3 | SELECTING AN INSTALLATION SITE

Overview

This unit is a precision instrument. To operate this unit properly and to obtain maximum performance,

install it in a location that meets the following conditions. The unit stores a certain amount of medications

in the tablet canisters while dispensing the required amount. Temperature and humidity conditions must

be closely monitored since medications are temporarily stored.

•Install the unit indoors.

•Select a location not exposed to direct sunlight and that is free from dust.

•Install it on a sturdy, level floor.

•Select a location with low humidity. But, avoid a location that is too dry.

•Do not install it near a wash basin or kitchen sink.

•Install it in a location without stoves, gas ranges and other heat-generating equipment.

•Do not install it near equipment that generates strong magnetic fields.

•Select a location away from TV or radio sets. Otherwise, the unit may distort the picture and sound of these

appliances.

•Leave a space of at least 10 cm from the rear side of the unit to ensure that the internal fan is not blocked.

•Ambient temperature:15 to 28 ℃

•Ambient humidity: 20.to 70 %R.H.

•At an altitude up to 6,562 feet (2000 m)

•Using a mains supply voltage that does not exceed 115VAC ± 10%, 60Hz. <6 amperes, with transient over

voltages II in accordance with IEC-60664-1

•Consistent with Pollution Degree 2 in accordance with IEC-60664-1

•Use a grounded AC wall outlet to prevent electric shock. Have authorized personnel install a grounded AC

wall outlet in a location that is not provided with one.

ATP Operator Instructions

|Selecting an Installation Site

14

Securing the Unit

Install the unit in a location that meets the requirements; adjust it so that it is level with the floor before

securing it to the floor.

Make sure that the unit is horizontal to the floor both back-to-front and right and left direction. If it is not level,

use the four level adjusting screws (leveling bolts) to adjust it.

ATP Operator Instructions

|Installation

15

Chapter 4 | INSTALLATION

Securing the Unit to the Floor

This unit is supplied with four anchor bolts and four fixtures. Use these fixtures to secure the unit to the

floor.

1. Use anchor bolts and secure the unit to the floor (Figure 3-1)

a. Use a drill to open holes in the floor that are 50 mm deep and 10 mm in diameter.

b. Embed the anchor bolt so that the rod is 2 or 3 threads above the nut.

c. Use a hammer to insert the rod.

d. When the rod reaches the head of the bolt, the anchor expands to secure the bolt.

Figure 3-1

ATP Operator Instructions

|Installation

16

2. Secure the unit to the floor using anchor bolts (Figure 3-2)

a. Place the bolts in the four floor brackets to secure the unit to the floor.

b. Use the nuts to tighten the anchor bolts.

Figure 3-2

Note: Remove the cable tie from the power cord. The covering of the power cord could corrode if the cord stays

bundled up for too long

ATP Operator Instructions

|Part Names and Functions

17

Chapter 5 | PART NAMES AND FUNCTIONS

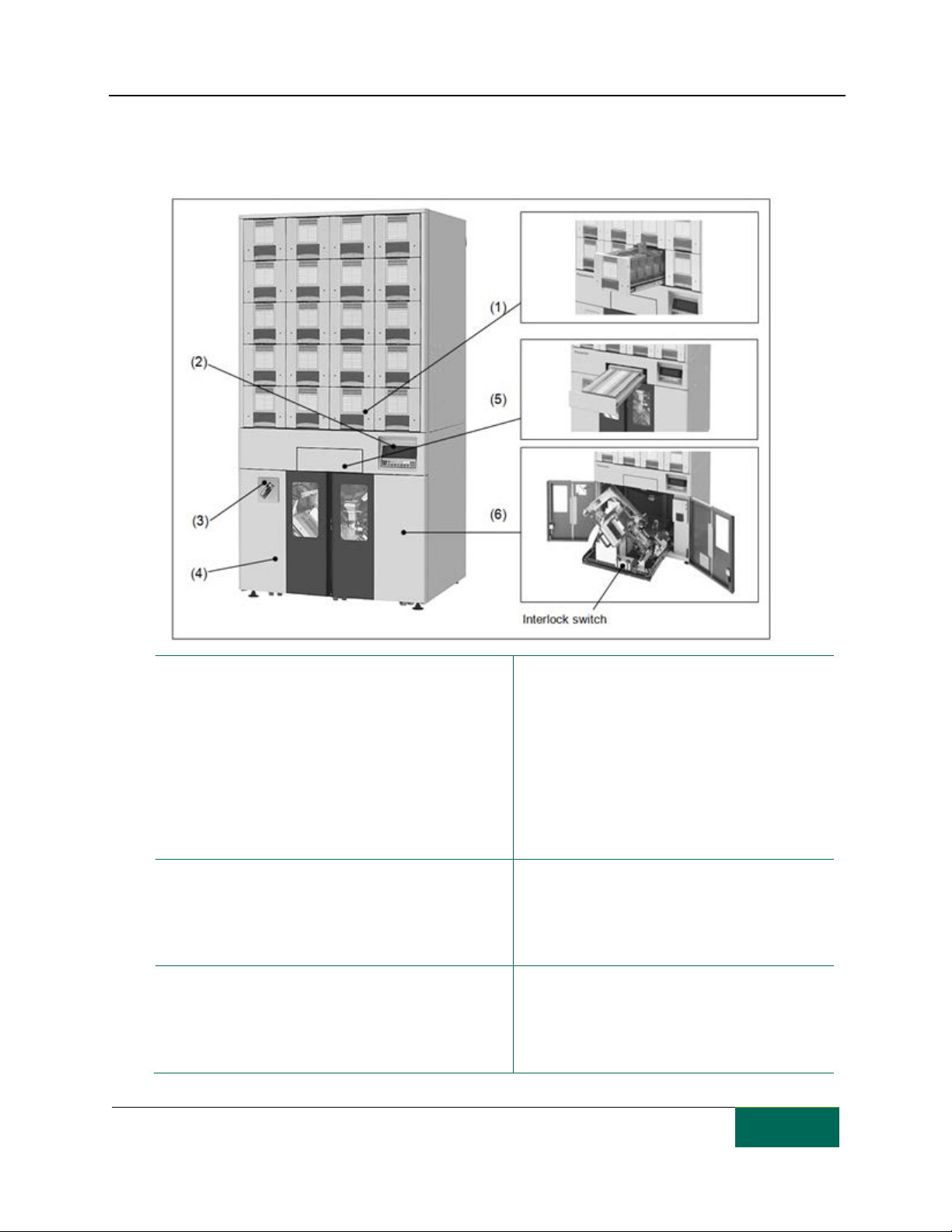

ATP

1. TC (tablet canister) drawer: A drawer for storing

tablet canisters (these are referred to as TC drawers).

The ATP-E320 can hold up to 20 (5 rows of 4) TC

drawers. Each drawer can hold up to 16 tablet

canisters (canisters).

The TC drawer is normally locked to maintain

security. To pull out a drawer for refilling or for other

reasons, press the open switch to open one drawer.

4. Front door: This door leads to the packaging

mechanism. The front door protects the

packaging mechanism (motor, heater and other

equipment). Opening this door activates the

interlock switch that stops unit operation.

2. Control panel: Shows the packaged medications

and state of packaging. The control panel comes with

the START button used when alarms occur and a

number of control keys.

5. UTC tray: Used for storing half tablets and

other medications that cannot be stored in a

tablet canister. The tray has a 2-tier

configuration and each tier has 64 cells.

3. Medication exit: Packaged medications exit the

ATP here. Packaged medications are transported by

the internal conveyor belt to this exit.

6. Packaging mechanism: Contains the

conveyor for transporting medications, drug

dispensing shutter, seals, cutter and other

equipment for packaging medications.

ATP Operator Instructions

|Part Names and Functions

18

Control Panel

1. LCD display: Displays currently dispensing

medications. At the bottom of the screen there is

an area for displaying alarm status.

LCD display is normally brightly lit by a backlight,

which goes off after a preset time period. Press a

function key to turn on the backlight.

6. Feed: Creates one empty package. Use this to

perform a packaging test after paper replacement.

2. Start: When the unit stops due to an alarm,

process the alarm and press this button to restart

dispensing. Clears the alarm display field.

7. Mode: Press to set or change operating modes.

3. Stop: Press this button during dispensing will

turn off the unit and "System stopped" will

appear in the alarm display field.

8. Press these buttons to switch

screens on the LCD.

4. Cancel: When an alarm is displayed during

dispensing, hold down this button for 2 seconds

or more to cancel dispensing.

9. Remaining Paper Indicator: Shows 4 levels of

remaining paper. 3 LEDs go off one after the other to

indicate paper consumption. They provide a rough

guide to when paper needs to be replaced.

5. Cut: Press this button after completing a

packaging test following a package paper change

to cut the paper and transport it to the

medication exit.

10. Use the UTC tray to preset

medications. Place a medication in the UTC tray and

close the tray. Holding down this button for 1 sec or

longer will display “UTC SET " and dispensing will

continue without stopping when the “Refilling UTC"

alarm appears. In “UTC SET,”it is not possible to visually

confirm the medications in the UTC during dispensing

so extra caution is needed.

11. Press to open the UTC tray.

ATP Operator Instructions

|Part Names and Functions

19

Tablet Canister (Canister)

1. Sample medication and desiccant: Space for

inserting sample medication and desiccant.

Open the lid, remove the bottom cover, place

the sample medication in the space that is

visible from the front and place the desiccant in

the space behind the medication name card.

The sample shows a visual for canister refills.

The desiccant reduces the effect of humidity on

medication.

4. Separator: A part that allows the canister to

release medications one by one. The separator

uses a brush. The separator will become soiled

and deformed with long-term use. It is

recommended that you clean it regularly.

2. Medication name card: A card that indicates

the name and size of the medication. This card is

attached when the unit is shipped.

5. Positioning groove: This groove positions the

tablet canister when it is placed in the unit. It

ensures that the canister is correctly positioned.

3. Lid: The lid is hinged. Open this lid when

refilling medication. Be sure to close the lid.

Be sure to properly close the lid of the tablet

canister. If left open the lid may break when it

comes into contact with the unit.

6. Pins preventing incorrect placement Placing

a tablet canister in the wrong location could

lead to incorrect dispensing. Pins correspond to

holes in the motor base and prevent incorrect

canister placement.

NOTE: The separator in the tablet canister is a consumable. Consult TCGRx in the unlikely event of a malfunction.

ATP Operator Instructions

|Part Names and Functions

20

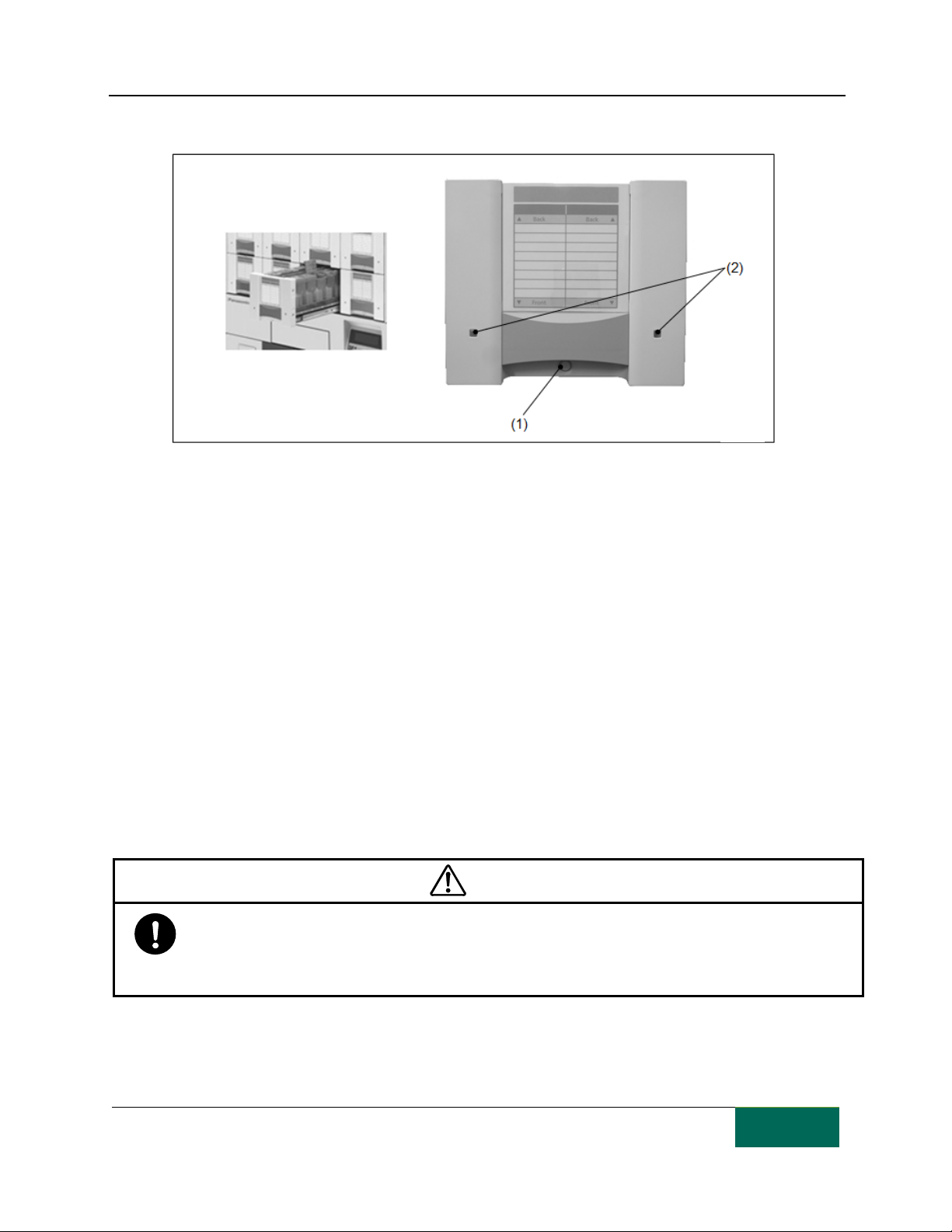

TC Drawer

A TC drawer is a drawer for storing TK-60S tablet canisters.

Each drawer holds 8 canisters on the left and 8 canisters on the right side for a total of 16 tablet canisters.

(1) Open switch

A lock release switch that allows you to open a TC drawer.

Press this switch to release the lock before pulling out a drawer.

(2) LED lamp

An LED on the front panel lights when there are no medications in the tablet canister or when a

malfunction is detected.

There is one LED on the right and left sides of the unit that indicate on which side the malfunction

occurred.

WARNING

Pull out only one TC drawer in a row during filling or other operation.

The cabinet could turn over and injure somebody if several storage drawers are pulled out at the same

time.

This manual suits for next models

2

Table of contents