ALLpaQ Packaging Group Genesis Series User manual

Chapter 1 - ALLpaQ Genesis 500 Operational Instructions

1.1 Moving the Container

Pallet Base may be moved using manual

handling equipment such as Fork lift truck

or manual pallet jack.

The Pallet base allows for a four way entry

however if the handling equipment in use

has forks lifting from the legs; two way entry

should be used from short either side. (see

Fig 1.2).

1.2 Unfold the container for use

When you receive an empty container it will be collapsed or folded with the lid on.

Turn red catches to unlock position. (Fig 2.4)

Simply lift the lid from the base unit and

store safely away from marked walk way

(Fig 2.1).

DO NOT attempt to lift by red catches to avoid damage.

Erect by lifting the top of the sidewalls by pulling towards the

body and clicking into locked position. (Fig 2.2)

Replace lid as necessary (Fig 2.3)

When replacing the lid ensure that you lock red catches into

position to avoid accidental damage.

Manual V1 - (Sept 14th 2012)

Fig1.1

Fig 1.2

Fig 2.1

Fig 2.2

Fig 2.3

Fig 2.4

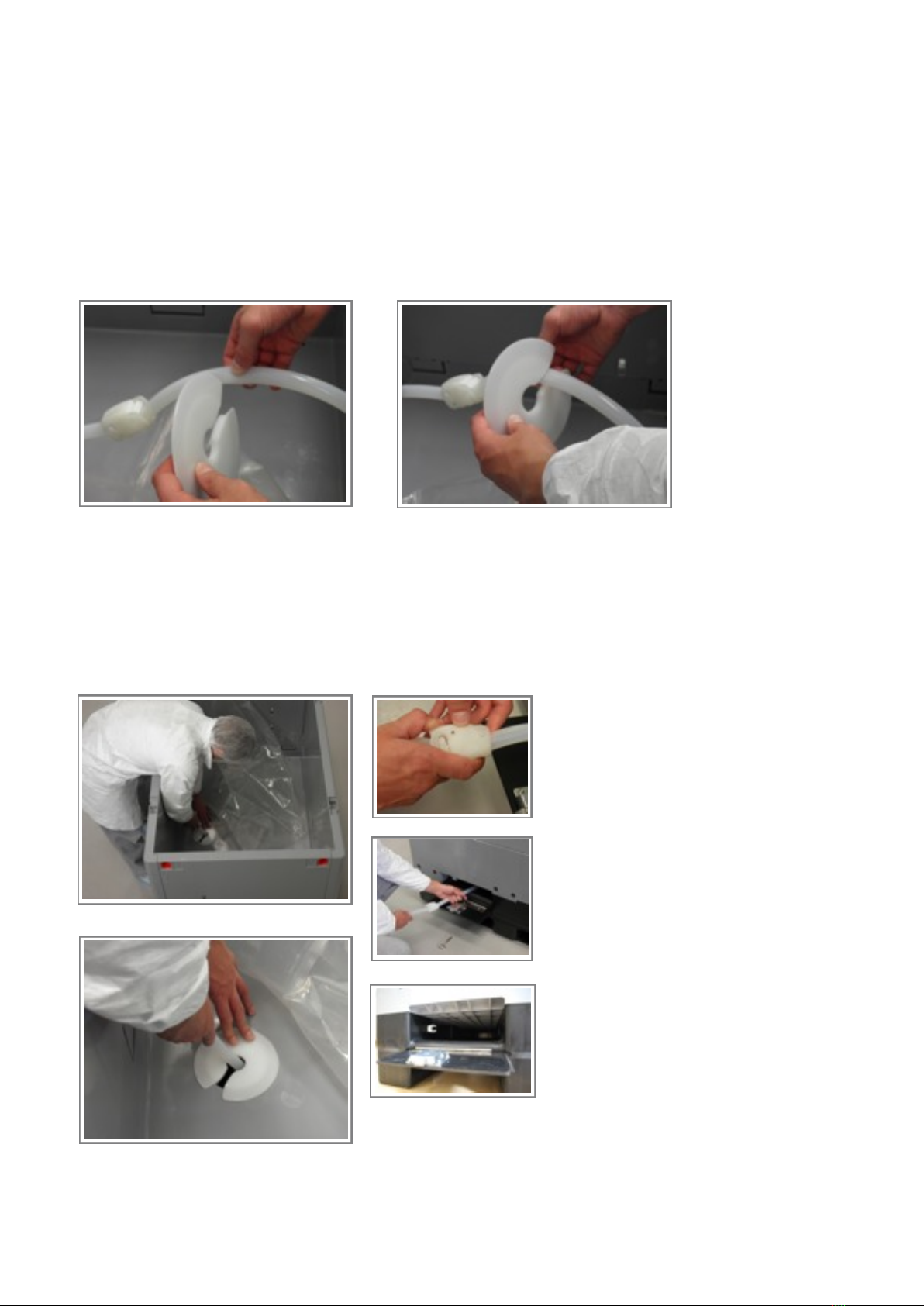

1.3 Fitting port position plates to bag

ALLpaQ recommend that all 3D bags used in conjunction with it bioprocess range of containers

should be fitted with a small plastic support disc when filled. Some bags may be pre fitted with a

similar disc however if this is not the case please contact ALLpaQ immediately before use.

To fit the disc simply squeeze the tubing (Fig 3.1) and slide towards the centre of the disc as

shown (Fig 3.2).

1.4 Fitting the bag

When fitting a bag the operator can access the base of the container over the erected side panels

(Fig 4.1).

The bag can be located from this position.

Please ensure that the clamp on the

outlet tube is closed/open prior to

operation according to manufacturers

instruction. (Fig 4.3)

Feed the outlet tubing through the

drain hole in the base of the

container (Fig 4.1).

It may be helpful to pull the tubing by

accessing the chamber via the front

door on the base of the unit (Fig 4.4).

Once the tubing has been fed

through, the white disc will locate in

the bottom drain hole of the base

unit (Fig 4.2).

The end of the drain tubing should

be fitted to the tube clamp for easy

access (Fig 4.5)

Bag filling can commence, according to manufacturers recommendations.

ALLpaQ recommend foam dunnage for all shipping containers (see 2:4 Fig 4.5)

Manual V1 - (Sept 14th 2012)

Fig 3.1 Fig 3.2

Fig 4.1

Fig 4.3

Fig 4.2

Fig 4.5

Fig 4.4

1.5 Fitting the lid

One Operator

Hold the lid against the front panel (Fig 5.1). Simply lower the lid until it is located across all four

corners of the container (Fig 5.2). Always lock the lid to a fully erected container.

1.6 Moving the container to storage

Pallet base allows for four way entry provided the manual handling equipment used is either a

pallet jack or fork lift truck (See Fig 1.1 and 1.2 above).

Material handling equipment with forks lifting from the legs (Fig 6.2) ensure two way entry is used

when lifting from front or rear of the base.

1.7 Emptying the container

Move the container into position as described in point 1.6

1.8 Removing the lid

Please do not attempt to lift the lid using the red catches this will increase the risk of breakage.

Please refer to instruction 1.2

Manual V1 - (Sept 14th 2012)

Fig 5.1 Fig 5.2

Fig 6.2

Fig 6.1

1.9 Connect Bag Outlet

Open the front base access door using the square key (Fig 9.1).

The outlet tubing can be taken from the clamp (Fig 9.4), the end

of drain tubing pulled from base storage area (Fig 9.3) and

connected according to bag suppliers instructions.

Bag can now be drained.

1.10 Removal of bag

Once the bag is drained apply any clamps to the outlet tubing

(Fig 10.1).

The bag can now be pulled out of

the top of the container.

Once removed the base access

door should be closed (Fig 10.2)

Once removed the bag should be

disposed of in line with company

policy.

1.11. Folding the container

To begin with the lid is removed

and the container is empty.

Start with either of the short

sided panels; slide red catches to

the centre of the panel (Fig 11.2).

Manual V1 - (Sept 14th 2012)

Fig 9.1

Fig 10.1

Fig 10.2

Fig 9.2 Fig 9.3

Fig 11.1

Fig 11.2

Fig 9.4

Once the panel has been released allow the panel to be lowered into the box using both hands.

Repeat the procedure with the opposite short panel.

Starting with either of the

remaining long sided panels,

lower the panel folding towards

the centre (Fig 11.3).

Repeat the process for the last

side panel ( Fig 11.4)

The lid should then be fitted to the folded container.

Note that the red locking catches may be in the locked

position before operation. (Fig 11.5).

1.12 Moving the container to storage area.

Please refer to instruction point 1.6 (refer to Fig 6.1 and 6.2).

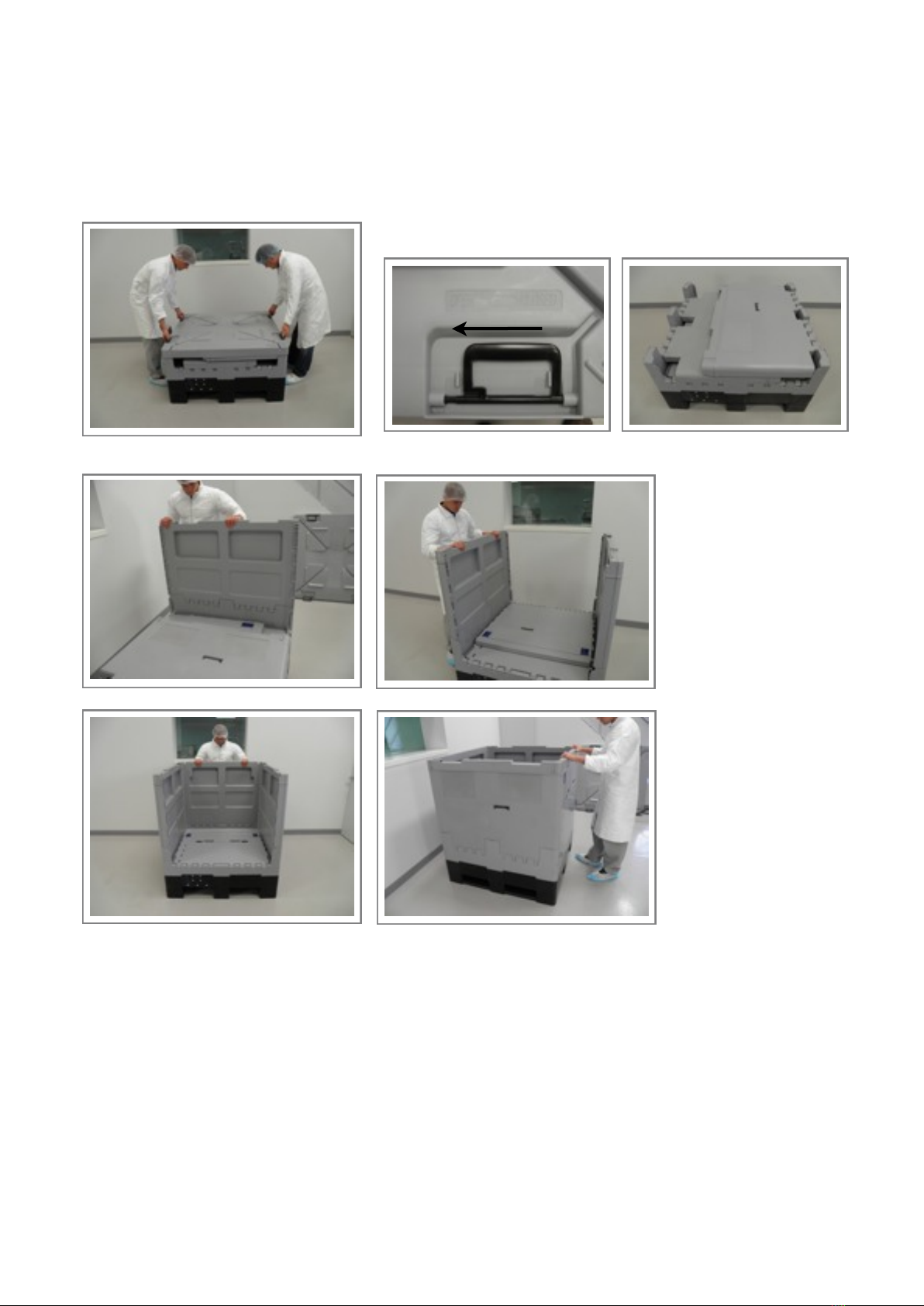

Chapter 2 - ALLpaQ Genesis 1000 operational Instructions

2.1 Moving the Container

As with the ALLpaQ Genesis 500L container the pallet base allows for 4 way entry (Fig 1.2) when

using a pallet jack or fork lift truck. Material handling equipment using forks which lift from the legs

must use the 2 way entry front and rear (Fig 1.1).

Manual V1 - (Sept 14th 2012)

Fig 11.3

Fig 11.4

Fig 11.5

Fig 1.1 Fig 1.2

2.2 Unfolding the container for use

When lifting the lid of a 1000 Litre container it is recommended that two people be involved in the

operation.

Hold and lift the

black handles at the

four corners of the

lid and move

towards the centre,

to the open position

(Fig 2.2).

Using both hands

pull the side panel

towards you to erect

the first sidewall (Fig

2.4).

Repeat this action

for the opposite

panel (Fig 2.5)

Complete the same

action with the rear

panel making sure

the wall clicks into

position (Fig 2.6)

Lock the front and final sidewall into position (Fig 2.7).

Replace the lid in a reversal of the description see instruction 2.5 below (Fig 5.1).

2.3 Fitting port position plate to bag

ALLpaQ recommend that all 3D bags used in conjunction with it bioprocess range of containers

should be fitted with a small plastic support disc when filled. Some bags may be pre fitted with a

similar disc however if this is not the case please contact ALLpaQ immediately before use.

For full instructions refer to instruction 1.3

Manual V1 - (Sept 14th 2012)

Fig 2.1

Fig 2.2 Fig 2.3

Fig 2.4 Fig 2.5

Fig 2.6 Fig 2.7

2.4 Fitting the bag

Before fitting the bag make sure you can gain access to the base by opening the drop door

situated at the front of a standard unit (Fig 4.1). Note units may be supplied with two drop doors.

Place the fingers in the slots provided and lift upwards (Fig

4.2), pull towards your body to unhinge the door; allow the

door to rest against the front wall of the container (Fig 4.3).

For full instruction on fitting the bag (see1.4 above).

Once the bag has been fitted correctly and filling is complete

in accordance with bag suppliers instructions a foam

shipping pad is placed over the bag for additional protection

during transportation and storage (Fig 4.5).

ALLpaQ recommend that foam dunnage (Fig 4.5) always be

used during shipment in its range of containers. If foam

dunnage has not been supplied contact ALLpaQ

immediately.

The foam dunnage is simply placed on top of the filled bag

before fitting and securing the lid for storage and

transportation.

Each pad is designed to bag specification to accommodate

the inlet tubing.

2.5 Fitting the lid

Each operator lifts the lid until square over the container.

Lock catches should be open (see Fig 2.2 above).

Push lid down over all four corners then slide the lid handles

to the locked position.

Manual V1 - (Sept 14th 2012)

Fig 4.1

Fig 4.2 Fig 4.3

Fig 4.4

Fig 4.5

Fig 5.1

2.6 Moving the container to storage area

Pallet base allows for four way entry provided the manual handling equipment used is either a

pallet jack or fork lift truck (See Fig 1.1 and 1.2 above). Material handling equipment with forks

lifting from the legs (1.6, Fig 6.2) ensure two way entry is used when lifting from front or rear of the

base.

2.7 Emptying the container

Move container into position in line with previous instructions (see 1.6).

2.8 Removing the lid

When removing the lid please refer to instruction 1.2.

2.9 Connect bag outlet

Connecting bag please refer to previous instructions (see 1.9)

2.10 Removal of the bag

Removing the bag please refer to previous instructions (see 1.10)

2.11 Folding the container

Remove the lid and ensure

the container is empty.

Locate fingers onto the blue

door catches and depress

towards the centre of the box

(Fig 11.1)

Allow the panel to fold

inwards and rest on the

base of the container

(Fig11.2).

Repeat this process for

the opposite rear panel.

On the side panel insert fingers lift panel and fold inwards (Fig 11.3)

Repeat process for opposite panel (Fig 11.4).

Replace lid using ensuring black handles are in open position first (Fig 1.5).

2.12 Moving the container to storage

Pallet base allows for four way entry and two entry dependent upon manual handling equipment.

For detailed information please refer to instruction at (See 1.6)

Manual V1 - (Sept 14th 2012)

Fig 11.1

Fig 11.2

Fig 11.3

Fig 11.4

Fig 11.5Fig 11.4

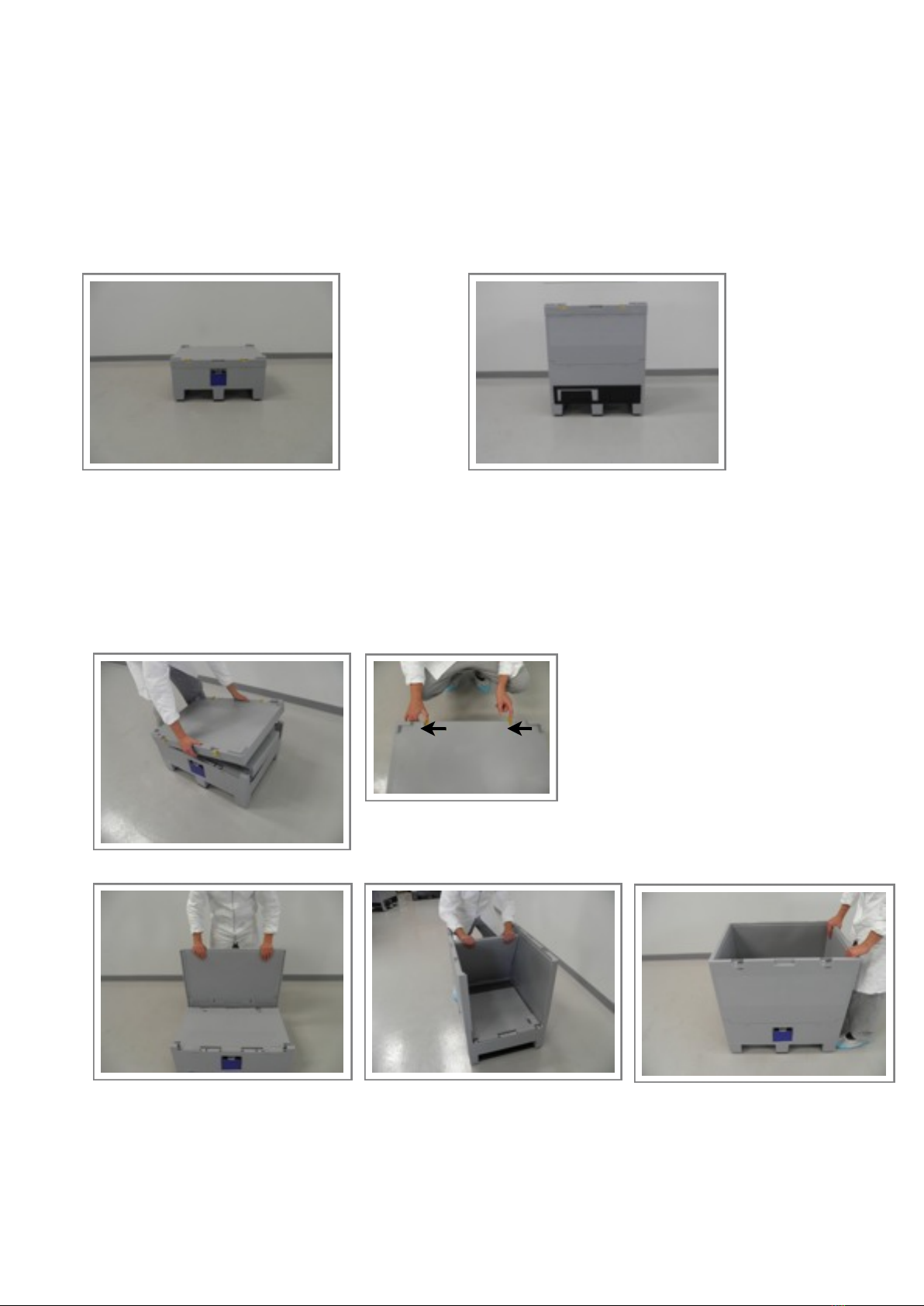

Chapter 3 - All ALLpaQ Genesis 50 - 250 E & C Versions

3.1 Moving the Container

Pallet base may be moved using manual handling equipment such as Fork lift truck or manual

pallet jack.

Both units are based upon the same foot print and both pallet bases allow a two way entry on the

long side (see Fig 1.1 & 1.2).

3.2 Unfolding the container for use

This instruction is applicable to all versions.

Open the yellow catches to

release the lid from the base (Fig

2.2).

Simply lift the lid from the base

unit and store safely away from

marked walk way (Fig 2.1).

DO NOT attempt to lift by yellow catches to avoid damage.

Erect by lifting the top of the long sidewall by pulling towards the body

(Fig 2.3).

Repeat procedure for the opposing long sidewall before erecting the short sidewalls in sequence

and locking into position (Fig 2.4 and 2.5)

Manual V1 - (Sept 14th 2012)

Fig 1.1

ALLpaQ Genesis 200E

ALLpaQ Genesis 250 C

Fig 1.2

Fig 2.2

Fig 2.1

Fig 2.3 Fig 2.4 Fig 2.5

ALLpaQ Genesis 200E Only

Once the container is unfolded remove the padded detachable floor panel and place safely near

the unit avoiding any marked walkways.

This will reveal a steel frame in the collapsed position (Fig 2.6).

Lift frame and unfold legs to each corner of the container and ensure white legs are at the rear of

the container Fig (2.7)

Replace detachable padded floor panel (Fig 2.8) and container is ready for use.

3.3 Fitting the port position plate to the bag

The procedure for fitting the port position follows the same procedure for the 500L & 1000L

versions of the ALLpaQ Genesis range.

ALLpaQ recommend that all 3D bags used in conjunction with it bioprocess range of containers

should be fitted with a small plastic support disc when filled. Some bags may be pre fitted with a

similar disc however if this is not the case please contact ALLpaQ immediately before use.

For full instructions see 1.3

3.4 Fitting the bag

Instruction applies for the ALLpaQ Genesis 200E (Fig 4.1)

and ALLpaQ Genesis 250 (Fig 4.2).

To access the container operator can reach over the side

panels to position the bag.

Any tubes and clamps should be

closed/open in according to

manufacturers recommendations.

Feed the drain tubing through the hole in the base of the

container.

It may be helpful to pull the tubing through the front of the

base via the access door (Fig 4.2 inset).

Manual V1 - (Sept 14th 2012)

Front

Fig 2.6

Fig 2.7 Fig 2.8

Fig 4.2

Fig 4.1

Once the tubing has been fed through, the white disc will locate in the bottom drain hole of the

base unit (Fig 4.2).

Bag filling can commence in according to manufacturers recommendations. ALLpaQ recommend

foam dunnage for all shipping containers (see 2:4 Fig 4.5)

3.5 Fitting the lid

Hold the lid against the panel (Fig 5.1). Simply lower the lid until it is located across all four

corners of the container (Fig 5.3). Always lock the lid to a fully erected container.

Ensure the yellow catches are in the

open position before attempting to fit the

lid to the container. (Fig 5.2)

Once the lid is on the container return the

yellow catches to the locked position. (Fig

5.3)

3.6 Moving the container to storage area

Please refer to instruction 3.1

3.7 Emptying the container

Move container into position in line with previous instructions (see 3.1).

3.8 Removing the lid

When removing the lid please refer to instruction 3.2

3.9 Connect bag outlet

ALLpaQ 250. Open the front base access door by sliding door to the centre of the unit. (Fig 9.1)

ALLpaQ 200E by opening the hinged door. (Fig 9.1 inset)

Bag outlet tubing can be pulled and connected according to

bag suppliers recommendations. (Fig 9.2 and 9.2 inset)

Manual V1 - (Sept 14th 2012)

Fig 5.3

Fig 5.2

Fig 5.1

Fig 9.1

Any sampling should be conducted according to bag suppliers

recommendations.

Bag can be drained.

3.10 Removal of bag

Once the bag is drained

apply any clamps to the

outlet tubing (Fig 10.1).

The bag can now be pulled

out of the top of the

container.

Once removed the base access door should be closed (Fig 10.2)

Once removed the bag should be disposed of in line with company policy.

3.11 Folding Container

First fold steel frame then rest in the base and replace the

padded floor by reversing the procedure at 3.2 (Fig 2.7)

Hold either of the two short sided panels and firmly push towards the centre of the unit. (Fig 11.1)

Allow the panel to rest on the base inside the unit and repeat the action for the opposite short side

panel. (Fig 11.2)

The remaining long side panels may be folded in sequence and the lid fitted to the folded container

Ensure the yellow catches are in open position to fit the lid, then locked inwards on completion.

3.12 Moving the container to storage

Pallet base allows for four way entry and two entry dependent upon manual handling equipment.

For detailed information please refer to instruction at (See 3.1).

Manual V1 - (Sept 14th 2012)

Fig 9.2

Fig 10.1 Fig 10.2

Fig 11.1

Fig 11.2

Fig 11.3

Fig 11.4

This manual suits for next models

5

Table of contents