Sealed Air Fill-Air Rocket User manual

Rev. C © Sealed Air Corporation (US) 2014

1

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

!

READY

#1 BL6T

!

READY

#1 BL6T

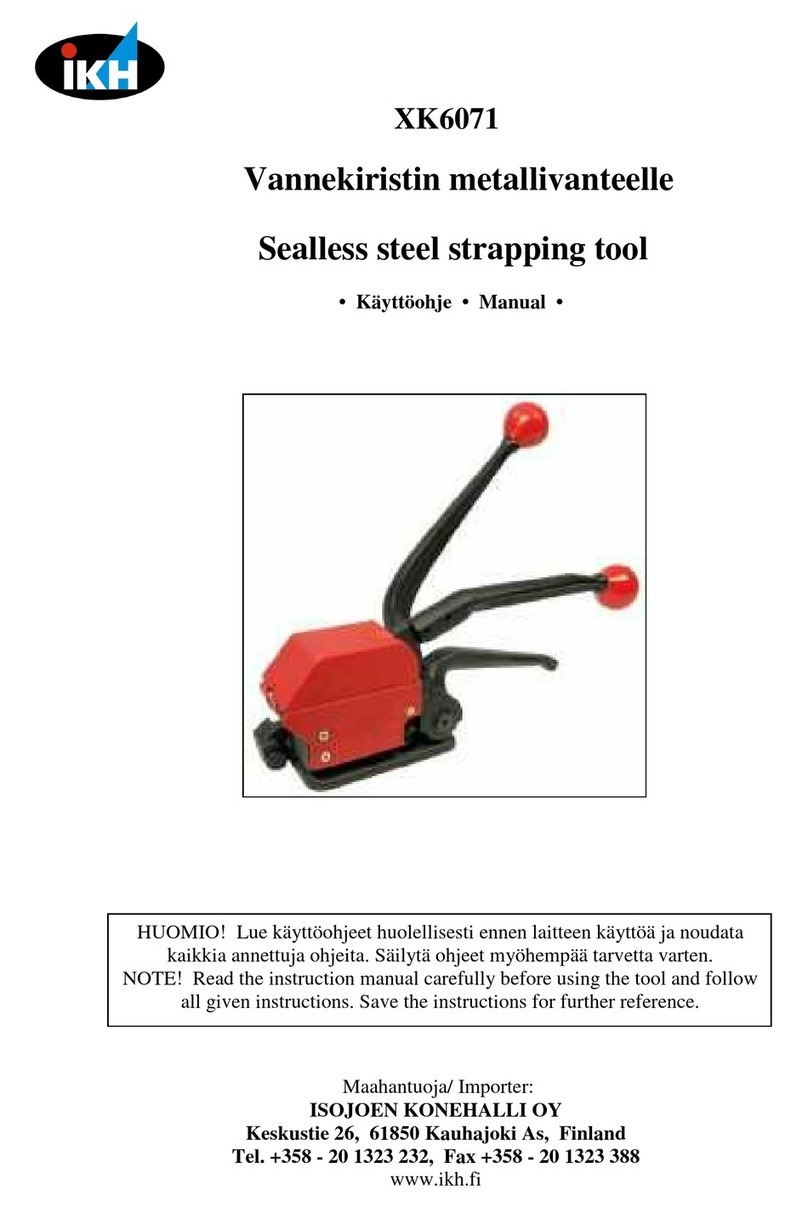

Standard Tabletop

Version

Optional Stand with

Integrated Bin

Fill-Air

Rocket™

Inflatable Packaging System

User’s Guide

Original Instructions

Rev. C

© Sealed Air Corporation (US) 2014 2

Rev. C © Sealed Air Corporation (US) 2014

3

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

Model: _____________________________________________________________

SerialNo: _____________________________________________________________

Accessories: _____________________________________________________________

_____________________________________________________________

Please attach the business card

of your SealedAir® Representative here

Fill-AirRocket™InatablePackagingSystem

For Toll Free Service Information Call 1-800-243-1102 (U.S.)

Rev. C

© Sealed Air Corporation (US) 2014 4

1.0 AboutThisGuide .............................................................................................................................. 8

2.0 Safety

2.1 Important Safety Precautions ....................................................................................................... 11

2.2 Compliance .................................................................................................................................. 16

3.0 Overview

3.1 System Description ...................................................................................................................... 18

3.2 Sequence of Operation ................................................................................................................. 18

3.3 Electrical Power Requirements .................................................................................................... 20

3.4 Material ........................................................................................................................................ 21

3.5 System Components ................................................................................................................... 22

4.0 Set-up

4.1 System Set-up .............................................................................................................................. 28

4.2 Applications ................................................................................................................................. 31

5.0 Operation

5.1 Loading the Material Roll ............................................................................................................ 34

5.2 System Controls ........................................................................................................................... 36

5.3 Control Panel ............................................................................................................................... 38

5.4 Producing Air-Filled Bags ........................................................................................................... 40

5.5 Producing Air-Filled Bags in Auto Replenish Mode ................................................................... 42

5.6 Producing Air-Filled Bags in Batch Mode ................................................................................... 44

Table of Contents

Table of Contents

Rev. C © Sealed Air Corporation (US) 2014

5

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

Table of Contents

Table of Contents (cont.)

6.0 MaintenanceandRepair

6.1 Preventative Maintenance .............................................................................................................47

6.2 Replacing the Edge Seal ..............................................................................................................48

7.0 Troubleshooting

7.1 There is no power to the system and the control panel Power LED is OFF .................................50

7.2 Displayed Fault Messages .............................................................................................................51

7.3 Problems with Making Inated Bags ............................................................................................53

7.3.1 The material will not advance when the start button is pressed -

the control panel Power LED is ON. ..................................................................................53

7.3.2 The material advances and edge seals are present but the bags do not ll with air ...........54

7.3.3 The material advances, the bags ll with air, but do not seal or seal fully .........................55

7.3.4 The inated bags leak air ...................................................................................................57

7.3.5 The inated bags have an inconsistent air-ll amount .......................................................59

7.3.6 The system does not stop producing bags when the bin is full - creating a pile-up

or a material jam .................................................................................................................60

8.0 CustomerService

8.1 Who to Contact in the United States .............................................................................................61

8.2 Using Technical Support in the United States ..............................................................................62

8.3 Who to Contact in Europe .............................................................................................................63

8.4 Spare Parts ....................................................................................................................................64

8.5 Film - US.......................................................................................................................................64

8.6 Film - EU ......................................................................................................................................65

Notesx ............................................................................................................................................66

Rev. C

© Sealed Air Corporation (US) 2014 6

List of Tables and Illustrations

Table of Contents

2.0 Safety

Fig. 2-1 Safety Devices - Section View ...........................................................................................14

3.0 Overview

Fig. 3-1 Sequence of Operation .......................................................................................................19

Tab. 3-2 Electrical Power Requirements ..........................................................................................20

Fig. 3-3 Component Locations - 1 ...................................................................................................23

Fig. 3-4 Component Locations - 2 ...................................................................................................25

Fig. 3-5 Component Locations - 3 ...................................................................................................27

4.0 SystemSet-up

Fig. 4-1 System Set-up - Table Top Version ....................................................................................29

Fig. 4-2 System Set-up - Stand Version ...........................................................................................30

Fig. 4-3 Typical Application - Remote Ination ..............................................................................31

Fig. 4-4 Typical Application - On-Line Ination with Optional Stand with Integrated Bin ............32

5.0 Operation

Fig. 5-1 Loading the Material Roll - Steps 1 and 2 .........................................................................34

Fig. 5-2 Loading the Material Roll - Step 3 .....................................................................................35

Fig. 5-3 System Controls .................................................................................................................37

Fig. 5-4 Control Panel ......................................................................................................................39

Fig. 5-5 Producing Air-Filled Bags ..................................................................................................41

Rev. C © Sealed Air Corporation (US) 2014

7

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

List of Tables and Illustrations

Table of Contents

5.0 Operation(cont.)

Fig. 5-6 Producing Air-Filled Bags into a Bin in Auto Replenish Mode .........................................43

Fig. 5-7 Producing Air-Filled Bags in Batch Mode .........................................................................45

6.0 MaintenanceandRepair

Tab. 6-1 Preventative Maintenance Schedule ...................................................................................47

Fig. 6-2 Replacing the Edge Seal ....................................................................................................49

Rev. C

© Sealed Air Corporation (US) 2014 8

The Fill-Air Rocket™ Inatable Packaging System User’s Guide is written and illustrated to easily

familiarize the operator with system component locations, system operation, and basic troubleshooting

procedures.

This guide covers the Fill-Air Rocket™Inatable Packaging System.

U.S. and other patents pending.

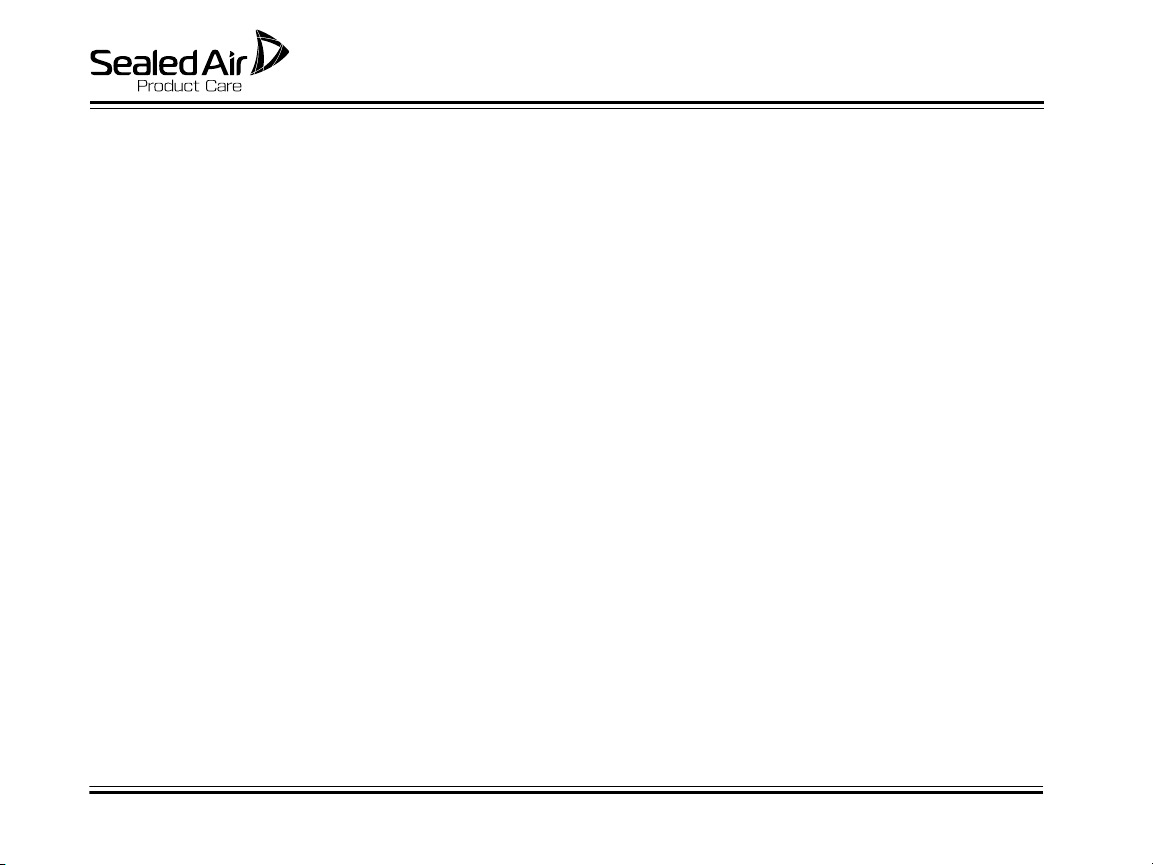

Informationsymbolsusedthroughoutthisguide:

This “bolt of lightning” symbol indicates that there is non-insulated material within your unit that may cause an

electrical shock.

This “hot” symbol calls attention to the need to be aware of components that may be hot.

This “goggles” symbol calls attention to the need to wear protective eye wear while performing maintenance procedures.

This “exclamation point” symbol calls attention to equipment features that you should be familiar with by reading the

enclosed literature. This will help prevent operating and maintenance problems.

This “triangle”symbol calls attention to special notes that will enhance operating and maintenance and repair

procedures.

This “float”symbol indicates that the bag must not be used as a otation device.

This “toy”symbol indicates that the bag must not be used as a toy.

This “pillow”symbol indicates that the bag must not be used as a pillow.

1.0 About This Guide

1.0 About This Guide

Rev. C © Sealed Air Corporation (US) 2014

9

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

1.0 About This Guide (cont.)

1.0 About This Guide

NOTICE

© Copyright 2014 by SealedAirCorporation(US). All rights reserved.

This document is copyrighted. The material contained herein is protected under the US Copyright Act of 1976. This document, in whole or in part, may not be copied,

photocopied, reproduced, translated or reduced to any electronic or machine-readable form without the prior written permission of SealedAirCorporation(US).

Denitionsusedthroughoutthisguide:

•

An Operator is dened as those individuals who have been trained by a Sealed Air® representative and

are

authorized to: operate the system and to perform basic maintenance as outlined in this guide.

Warning!Only qualied service personnel who have been trained by a Sealed Air® representative

are allowed to perform maintenance and repair procedures.

• Qualied Service Personnel is dened as those individuals who have been trained by a Sealed Air®

representative and are authorized to: operate the system and to perform most maintenance and repair

procedures.

• A Sealed Air® representative is dened as those individuals who are authorized to install and

decommission the system, operate the system, train Operators, train Qualied Service Personnel, and

to perform all maintenance and repair procedures.

Rev. C

© Sealed Air Corporation (US) 2014 10

(intentionally blank)

Rev. C © Sealed Air Corporation (US) 2014

11

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

2.0 Safety

2.0 Safety

2.1 Important Safety Precautions

1. Readandthoroughlyunderstandthisguide.

2. BeforeoperatingtheFill-AirRocket™System,besureofthefollowing:

• The operator has received full training by an authorized Sealed Air® Representative.

• The operator has read and understood all safety instruction labels attached to the system.

• The system is plugged into a properly rated, grounded outlet - see 3.3 Electrical Power

Requirements.

Warning! Failure to properly ground the system could create an electrical shock hazard.

Warning! Do not remove the guards or access covers. The guards and access covers should

be removed only by an authorized Sealed Air® Representative or qualied service personnel

that have been trained by a Sealed Air® representative.

Warning!RiskofEntrapment - Keep ngers, loose hair, clothing and jewelry away from

the edge seal roller when material is feeding, inating, and sealing.

Warning!HotSurface- Be aware of the edge seal roller function and location.

Rev. C

© Sealed Air Corporation (US) 2014 12

3. TheFill-AirRocket™Systempackagingisintendedtobeusedonlyaspackagingmaterial.

Warning! Do not use the bags as a otation device.

Warning! Do not use the bags as a toy.

Warning! Do not use the bags as a pillow.

4. Beforeperformingmaintenanceandrepairprocedures,besureofthefollowing:

• Turn the main power switch to the OFF position, unplug the power cord, and follow proper

Lockout/Tagout procedures when instructed.

Warning! Do not attempt to repair or modify the Fill-Air Rocket™ system other than the

procedures contained in the 4.0 Set-up, 5.0 Operation, or 6.0 Maintenance and Repair sections

of this guide. All repairs must be done by a Sealed Air® Representative or qualied service

personnel that have been trained by a Sealed Air® representative.

Warning! Use protective eye wear as indicated when performing maintenance and repair

procedures.

Warning! Do not open the covers except where instructed in the 5.0 Operation or the

6.0 Maintenance and Repair sections of this guide.

5. Lockout/Tagout(LOTO):

• All maintenance and repair procedures should be performed in the approved manner using

Lockout/Tagout recommendations.

2.0 Safety

2.1 Important Safety Precautions (cont.)

Rev. C © Sealed Air Corporation (US) 2014

13

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

2.1 Important Safety Precautions (cont.)

2.0 Safety

6. Inspectatregularintervalstoensurethat:

• Component cables are not cut, broken, or damaged.

• All controls and indicators function properly.

Warning! If operation of the system differs from the descriptions in this guide, turn the

system OFF and disconnect and lock-out the main power until the unit can be inspected by a

Sealed Air® representative.

7. AirborneNoiseEmission:

• This machine does not exceed 75 dB(A) during normal operation. Please check to make sure

you comply with your local health and safety requirements.

8. Environmentalconditions:

• Storage temperature: machine and material rolls 32º-110ºF / 0º-43ºC

• Operating temperature: machine and material rolls 60º-110ºF / 16º-43ºC

Note:Material rolls, if extremely cold or hot, must be brought to operating temperature to

properly seal. Materials stored at temperatures outside the specied storage temperature range

can be damaged and rendered unusable.

9. ResidualRisk:

Safety guarding is incorporated into the Fill-Air

Rocket™

system, however minimal access is present

at the edge seal assembly. Care and avoidance need to be taken to prevent possible contact with

or entrapment by the hot roller.

(see the following pages for 10. Safety Devices)

Rev. C

© Sealed Air Corporation (US) 2014 14

2.0 Safety

2.1 Important Safety Precautions (cont.)

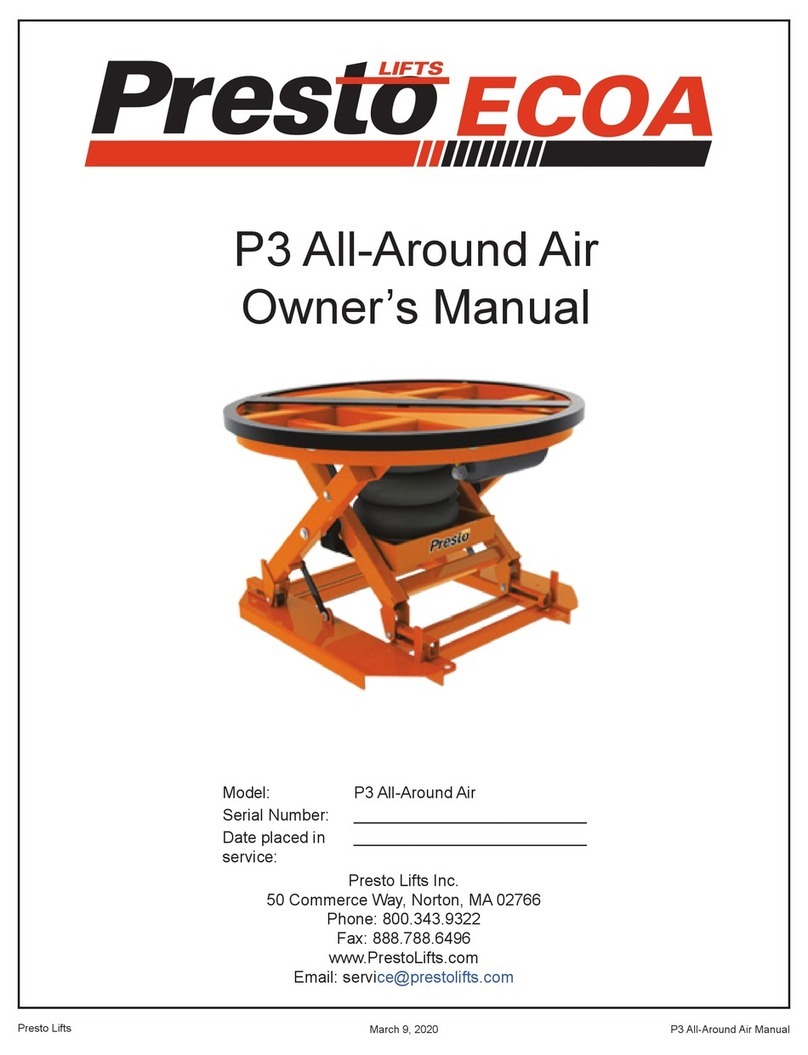

Safety Devices - Section View

Figure 2-1

!

Warning! Hot Roller

and Risk of Entrapment

Material Roll

ON/OFF

Switch

E-Stop

Button

Edge Seal

Assembly

Rev. C © Sealed Air Corporation (US) 2014

15

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

2.0 Safety

2.1 Important Safety Precautions (cont.)

10. SafetyDevices-seeFigure 2-1:

Warning! Do not remove or tamper with the following built-in safety devices.

• EmergencyStopButton(E-Stop)- This red button, when pushed, disables all system

functions. It is located above the control panel.

Warning!HotRoller - When material is inating and sealing, the edge seal roller is hot.

Be aware of the edge seal function and location.

Warning!RiskofEntrapment - Keep ngers, loose hair, clothing and jewelry away from

the edge seal roller when material is feeding, inating, and sealing.

Rev. C

© Sealed Air Corporation (US) 2014 16

2.0 Safety

2.2 Compliance

The Fill-Air Rocket™ System is eligible to bear the CSA mark shown with adjacent indicators ‘C’ and ‘US’,

the PSE mark, and the CE mark.

The Fill-Air Rocket™ system has been designed and constructed to fulll all the relevant provisions of the

2006/42/EC Machinery Directive, 2006/95/EC Low Voltage Directive, the 2004/108/EC

Electromagnetic Compatibility (EMC) Directive, and the 2011/65/EU RoHS Directive.

EN 60204-1: Safety of Machinery – Electrical equipment of machines

EN 13849: Safety Controls

EN 12100: 2010: Safety of Machinery – Principles for risk assessment

EN ISO 13857: Safety of Machinery – Safety distance to prevent danger zones being reached by upper

limbs

EN 349: Safety of Machinery – Minimum gaps to avoid crushing of parts of the human body

EN 953-1: Safety of Machinery – General requirements for the design and the construction of xed and

removable guards

Rev. C © Sealed Air Corporation (US) 2014

17

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

2.0 Safety

2.2 Compliance (cont.)

EN 61000-6-4: Generic Emissions, Industrial Environment

EN 55011: Radio interference characteristics of ISM equipment

EN 55014: Radio interference characteristics of Household equipment

EN 61000-6-2: Generic Immunity, Industrial Environment

EN 61000-4-2: ESD

EN 61000-4-3: Radiated immunity

EN 61000-4-4: EFT

EN 61000-4-5: Surge

EN 61000-4-6: Conducted immunity

EN 61000-4-11: Voltage dips and interruptions

EN 50581: RoHS

UL 963: Sealing, Wrapping, and Marking Equipment

CSA C22.2 no 68 Motor operated appliance

Verify

Rev. C

© Sealed Air Corporation (US) 2014 18

3.1 System Description

The Fill-Air Rocket™ Inatable Packaging System creates on-demand air-lled packaging from a

compact/uninated pre-formed roll of bags. The

inated bag chain is perforated between

bags and

can easily be separated by the operator as needed.

There are three (3) modes of producing air-lled bags:

• Manual Mode

Press the Start Key to begin producing bags and the Stop Key to end production - see 5.4

Producing Air-Filled Bags.

• Auto Replenish Mode

When a bin sensor or optional accessory is employed, the supply of inated bags can be

continually/ automatically replenished - see 5.5 Producing Air-Filled Bags in Auto Replenish

Mode.

• Batch Mode

Dispense a programmed length of bags - see 5.6 Producing Air-Filled Bags in Batch Mode.

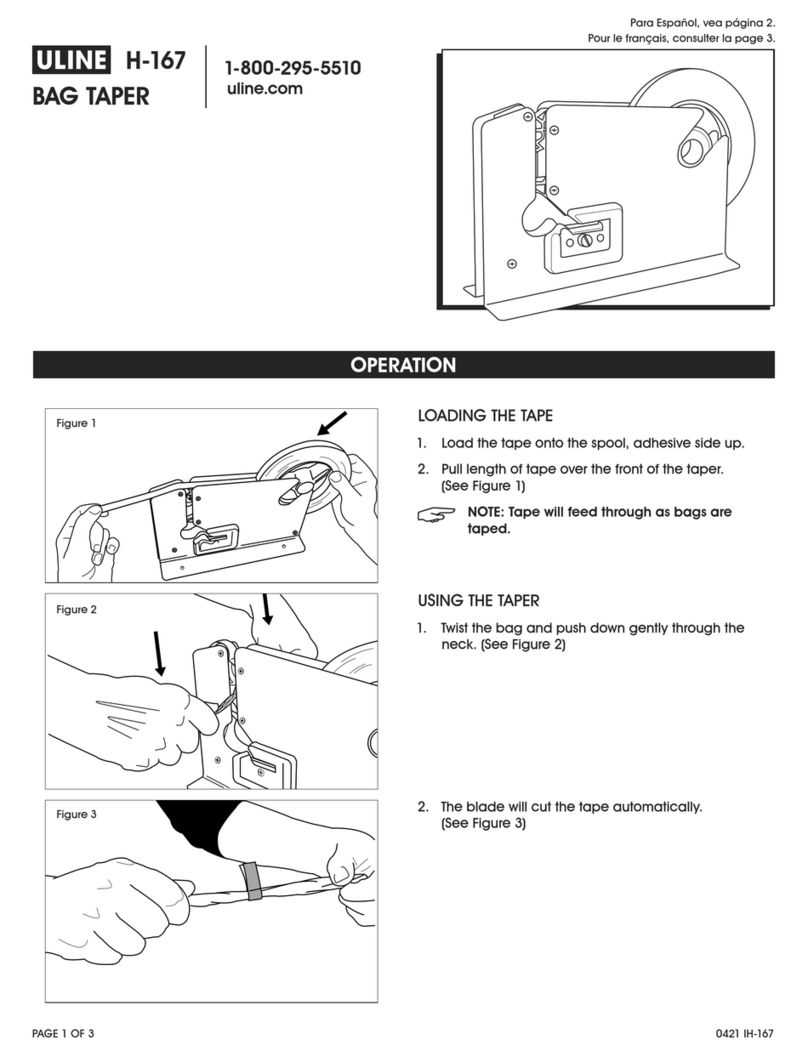

3.2 Sequence of Operation

1. The operator presses the start key and the drive motor is activated, drawing the material from

the material roll and over the xed material bar.

2. The material is drawn over the ination nozzle where the two webs are separated and lled with air.

3. The material is drawn through the edge seal where a heat seal traps the air inside the bag.

4. The air-lled bags exit the system.

3.0 Overview

3.0 Overview

Rev. C © Sealed Air Corporation (US) 2014

19

Fill-Air Rocket ™ Inatable Packaging System User’s Guide

3.0 Overview

Sequence of Operation

Figure 3-1

3.2 Sequence of Operation (cont.)

Material

Roll

Material Bar

2

1

Inflation Nozzle

3

Edge Seal

Start Key

4

Rev. C

© Sealed Air Corporation (US) 2014 20

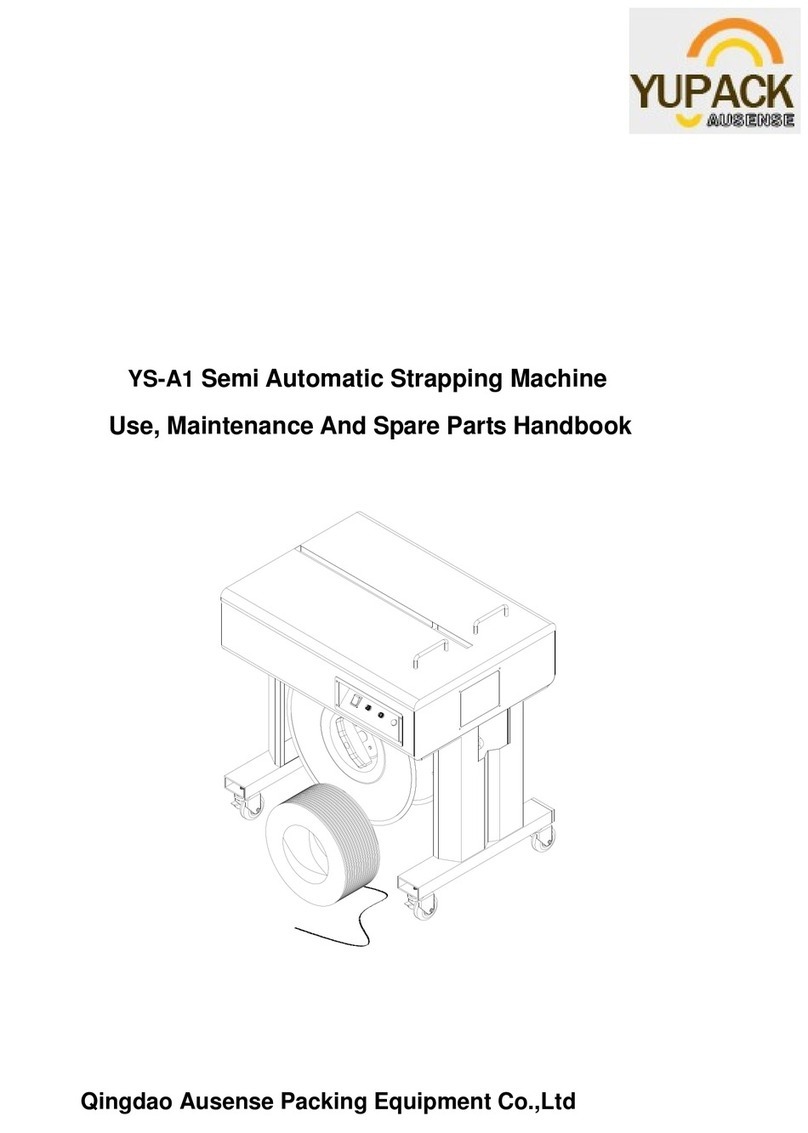

Warning! Failure to properly ground the system could create an electrical shock hazard.

Warning!Use of an extension cord will increase the levels of static, resulting in operational

problems as well as operator discomfort due to static discharge.

Electrical Power Requirements

Table 3-2

3.3 Electrical Power Requirements

3.0 Overview

Fill-Air Rocket ™ Receptacle A/C Voltage Phase Current

Inflatable Packaging System Type

115 VAC Version NEMA 5-15R 100 - 120 VAC Single Phase 15 Amp Service

50/60 Hz Grounded (2.2 avg.)

230 VAC Version CEE 7/7 220 - 240 VAC Single Phase 13 Amp Service

50/60 Hz Grounded (1.1 amps avg.)

Table of contents

Other Sealed Air Packaging Equipment manuals

Popular Packaging Equipment manuals by other brands

Minipack-Torre

Minipack-Torre eco modular instruction manual

Floeter

Floeter AirWave 2 operating instructions

ErgoPack

ErgoPack Air 713-580 Original operating instructions

hawo

hawo hd 680 DE-V instruction manual

optimax

optimax TMS300 operating instructions

Minipack-Torre

Minipack-Torre FM77A Digit instruction manual