Sealed Air Diversey Care TASKI swingo 2100 micro User manual

Edition: V1.00/2015

Technical Manual

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 1-1

Copyright © 2015, Diversey Care

technical manual swingo 2100µicro_V1.00TOC.fm

Index

1Forward 1

1.1 Target 1

1.2 Technical Training 1

1.3 Technical Manual 1

1.4 Summary 2

2Elementary 1

2.1 Health & Safety 1

2.2 ESD 1

3 General 1

3.1 General information 1

3.1.1 Part reference 1

3.1.2 Consumable supplies 1

3.1.3 Direction description 1

3.1.4 Power source 1

3.2 Required material 2

3.2.1 Tools 2

3.2.2 Material 2

4Technicaldata 1

4.1 Machine range 1

4.2 Technical information 2

4.2.1 Machine profile 2

4.2.2 Technical data 2

4.2.3 Machine speed 3

4.2.4 Dimensions and weights 3

4.2.5 Battery 4

4.2.5.1 Battery compartment 4

4.2.5.2 Battery specifications 5

4.2.6 Charger 6

4.2.7 Brush system 6

4.2.8 Suction power 7

4.2.9 Additional 7

4.3 Accessories & Additional parts 8

4.3.1 Accessories 8

4.3.2 Additional parts 8

5 Mechanical 1

5.1 Upper part, tank 1

5.1.1 Removing of vacuum motor 1

5.1.2 Mounting of vacuum motor 3

5.1.3 Removing of tank cover 4

5.1.4 Mounting of tank cover 5

5.2 Tank 6

5.2.1 Removing of recovery water tank 6

5.2.2 Mounting of recovery water tank 8

5.2.3 Removing of fresh water tank 9

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 1-2

Copyright © 2015, Diversey Care

technical manual swingo 2100µicro_V1.00TOC.fm

5.2.4 Mounting of fresh water tank 11

5.3 Driver seat 13

5.3.1 Removing of driver seat 13

5.3.2 Mounting of driver seat 14

5.3.3 Removing of driver seat cover 15

5.3.4 Mounting of driver seat cover 16

5.4 Steering unit 17

5.4.1 Removing of steering roller chain 17

5.4.2 Mounting of steering roller chain 18

5.4.3 Removing of front wheel 19

5.4.4 Mounting of front wheel 20

5.5 Pedals 21

5.5.1 Removing of pedal spring 21

5.5.2 Mounting of pedal spring 22

5.6 Tool lowering unit 23

5.6.1 Removing of tool lowering unit 23

5.6.2 Mounting of tool lowering unit 25

5.6.3 Removing of linear drive for offset 28

5.6.4 Mounting of linear drive for offset 30

5.6.5 Removing of metal rope compl 31

5.6.6 Mounting of metal rope compl 32

5.6.7 Removing of metal rope 33

5.6.8 Mounting of metal rope 34

5.6.9 Removing of pressure spring 35

5.6.10 Mounting of pressure spring 36

5.6.11 Removing of linear drive 37

5.6.12 Mounting of linear drive 39

5.7 Drive unit 40

5.7.1 Removing of drive wheel 40

5.7.2 Mounting of drive wheel 41

5.7.3 Removing of encoder 42

5.7.4 Mounting of encoder 44

5.7.5 Removing of brake 46

5.7.6 Mounting of brake 47

5.7.7 Removing of drive unit 48

5.7.8 Mounting of drive unit 50

5.8 Squeegee 51

5.8.1 Removing of wire spring 51

5.8.2 Mounting of wire spring 52

5.8.3 Removing of pressure spring 53

5.8.4 Mounting of pressure spring 54

5.8.5 Removing of front blade 55

5.8.6 Mounting of front blade 56

5.8.7 Removing of back blade 57

5.8.8 Mounting of back blade 58

5.9 Lower part 59

5.9.1 Removing of pump 59

5.9.2 Mounting of pump 60

5.9.3 Removing of housing compl 61

5.9.4 Mounting of housing compl 62

5.9.5 Removing of magnetic valve 63

5.9.6 Mounting of magnetic valve 64

5.9.7 Removing of front cover 65

5.9.8 Mounting of front cover 67

5.10 Brush drive 69

5.10.1 Removing of brush drive 69

5.10.2 Mounting of brush drive 71

5.10.3 Removing of brush belt 73

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 1-3

Copyright © 2015, Diversey Care

technical manual swingo 2100µicro_V1.00TOC.fm

5.10.4 Mounting of brush belt 75

5.10.5 Removing of flat belt pulley 77

5.10.6 Mounting of flat belt pulley 78

5.10.7 Removing of brush motor 80

5.10.8 Mounting of brush motor 82

6 Electrical 1

6.1 System architecture 1

6.1.1 General 1

6.1.2 Start up/Self holding 2

6.1.3 Emergency loop 3

6.2 Dashboard 4

6.2.1 Removing of dashboard 4

6.2.2 Mounting of dashboard 5

6.2.3 Connections 6

6.3 Electronics 11

6.3.1 Removing of electronics 11

6.3.2 Mounting of electronics 12

6.3.3 Connections 13

6.4 Charger 20

6.4.1 Removing of charger 20

6.4.2 Mounting of charger 21

6.4.3 Connections 22

6.5 Hall sensor 24

6.5.1 Description 24

6.5.2 Removing of hall sensor steering angle 25

6.5.3 Mounting of hall sensor steering angle 26

6.5.4 Removing of hall sensor throttle 28

6.5.5 Mounting of hall sensor throttle 29

6.6 Main relay 30

6.6.1 Removing of main relay 30

6.6.2 Mounting of main relay 31

6.7 Drive relay 32

6.7.1 Removing of drive relay 32

6.7.2 Mounting of drive relay 33

6.8 Schematics 34

6.8.1 Battery connection 34

6.8.2 Electrical schematics 35

7 Additional information 1

7.1 Available GTS Newsletter/Instructions 1

8Revision 1

9Appendix 1

10 Notes 1

11. December 2015 Edition: V1.00/2015

Copyright © 2015, Diversey Care

Technical Manual

1 Forward

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 1-1

Copyright © 2015, Diversey Care

01.1 TASKI - foreword_V1.10.fm

1 Foreword

1.1 Target

To serve our customers faster and more efficient it is important to achieve a general

standard of technical know how with our partners in the market.

Therefore we developed a Technical Training concept which is based on e-spares. The

concept consists of a Technical Manual and a Technical Training.

These two tools will be produced for each newly launched machine with a certain com-

plexity. The Technical Manual will be available as PDF file and can be downloaded from

e-spares. The Technical Training documentation will be distributed after having attend-

ed the technical training.

1.2 Technical Training

The Technical Training is addressed as reference book for the technical training sessions

and will be distributed to the floor care responsible and/or to the technical training re-

sponsible after attending a training session provided by GTS (max. 2 persons per coun-

try).

The intension is, that after this session, a technical trainer is able to perform technical

training for their local technical staff and in this way to transfer the knowledge to all ser-

vice technicians.

The Technical Training is not intended as manual for the service technicians and will be

distributed only to the training responsible of each country.

1.3 Technical Manual

The Technical Manual is addressed to the service technicians and should be translated

and distributed after a technical training.

It contains a summary of procedures, hints and suggestions etc. which are helpful and

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 1-2

Copyright © 2015, Diversey Care

01.1 TASKI - foreword_V1.10.fm

essential for the daily business. The Technical Manual can be downloaded from TASKI

spares/documents.

1.4 Summary

We are convinced that the Technical Manual concept together with the Technical Training

are powerful tools, which will help our service organisations to achieve a higher level of

quality in repairs and customer satisfaction.

If you have any comments or questions do not hesitate to contact your country respon-

sible.

Sincerely yours

GTS Team

11. December 2015 Edition: V1.00/2015

Copyright © 2015, Diversey Care

Technical Manual

2 Elementary

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 2-1

Copyright © 2015, Diversey Care

02.1 TASKI - elementary_V1.00.fm

2Elementary

2.1 Health & Safety

Scrubber dryers may be powered by mains electricity or batteries. There are risks asso-

ciated with both, which call for proper precautions, such as the provision of good venti-

lation and the elimination of risk of ignition.

All work, carried out on such machines, should only be performed by trained personnel

in accordance with local regulations.

Before working on such a machine, isolate it from any electrical power source.

Always wear the required personal protective equipment (including gloves and goggles)

that must be worn when potentially exposed to any hazardous material and when carry-

ing out hazardous tasks.

Note that parts may be contaminated with chemical product. If possible flush hoses out

with fresh water prior to carrying out any maintenance. For information on chemical

products that are used in this machine, please carefully read the product label and Ma-

terial Safety Data Sheet (MSDS).

Empty water tanks prior to carrying out any maintenance. Ensure contaminated water is

emptied into an approved drain. Avoid pollution.

2.2 ESD

Static electricity is electricity at rest or the accumulation of electric charge, as opposed

to an electric current which is the movement of electricity. The flow or movement of peo-

ple and/or materials in and through the environment causes separation of electrons and

therefore static electricity. A familiar example of static electricity is when a person walks

across a carpeted floor. Static electricity/electrostatic charge is generated simply by the

contact and separation of the soles of that individual's shoes from the carpeted floor.

Electrostatic Discharge (ESD) occurs when the electrostatic charge is transferred from a

material that carries the charge to an electrostatic sensitive device. In the example above,

this electrostatic discharge is the „shock“ felt after walking across the carpeted floor and

then touching a door knob. It is this electrostatic discharge, which comes in varying de-

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 2-2

Copyright © 2015, Diversey Care

02.1 TASKI - elementary_V1.00.fm

grees, that can be most damaging to electronical devices.

Static electricity, is a natural phenomenon and consequently electrostatic discharge is

the primary cause of countless problems affecting industry, business and personal life.

These problems can be as simple as the shock resulting from walking across a carpet; as

costly as the destruction of sensitive electronic components.

Almost any material can generate static electricity. The ability to store or unload the

charge depends on the type of material.

Static discharge can damage devices, this can result in immediate product failure or in a

latent failure. Latent failures can go undetected for a period of time, the results are prod-

uct failure in the field.

Electrostatic fields are associated with charged objects.

The degree of severity of ESD events depends on the type of discharge which occurs. The

three most common ESD charge transfers are:

• from an external object to the device.

• from a device to another object.

• resulting from electrostatic fields.

Please do not store electronics without ESD bags at any time.

11. December 2015 Edition: V1.00/2015

Copyright © 2015, Diversey Care

Technical Manual

3 General

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 3-1

Copyright © 2015, Diversey Care

03.1 TASKI - general_V1.10.fm

3 General

3.1 General information

3.1.1 Part reference

Explicitly mentioned parts are defined by references/parts number

corresponding to the spare parts list.

3.1.2 Consumable supplies

If you have to remove cable ties then position the new ones at the

original place.

If you have to remove self locking nuts, you should replace them by

new ones.

3.1.3 Direction description

On the „RH“ always means on the right hand side of the machine in

working direction (when you are standing behind the machine).

On the „LH“ always means on the left hand side of the machine in

working direction (when you are standing behind the machine).

3.1.4 Power source

Depending on the work it might be required to remove the power

source (mains/batteries) from the machine.

The in here mentioned sequences (mechanical and electrical) are

based on the assumption that the power source (mains/batteries)

were removed from the machine before.

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 3-2

Copyright © 2015, Diversey Care

03.1 TASKI - general_V1.10.fm

3.2 Required material

3.2.1 Tools

• A standard range of tools is required e.g.

• Fork spanners.

• Allen keys.

•Torxkeys.

3.2.2 Material

• No special tools are required.

The above listings are only a recommendation for the technical

training.

11. December 2015 Edition: V1.00/2015

Copyright © 2015, Diversey Care

Technical Manual

4 Technical data

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 4-1

Copyright © 2015, Diversey Care

04.1 swingo 2100µicro - technical data_V1.00.fm

4Technicaldata

4.1 Machine range

SKU Description Version Series

7523409 TASKI swingo 2100µicro 01

7523418 TASKI swingo 2100µicro seafreigth 01

7523419 TASKI swingo 2100µicro BMS SEV 01

7523420 TASKI swingo 2100µicro BMS EURO 01

7523421 TASKI swingo 2100µicro BMS EURO seafreight 01

7523422 TASKI swingo 2100µicro BMS UK 01

7523423 TASKI swingo 2100µicro BMS UK seafreight 01

7523424 TASKI swingo 2100µicro BMS CN seafreight 01

7523425 TASKI swingo 2100µicro BMS IN seafreight 01

7523491 TASKI swingo 2100µicro BMS BR seafreight 01

7523492 TASKI swingo 2100µicro BMS NA seafreight 01

Table 1: Machine range

Remarks

SKU‘s for all TASKI swingo 2100µicro types are the „naked machine“. The brush has to

be ordered separately.

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 4-2

Copyright © 2015, Diversey Care

04.1 swingo 2100µicro - technical data_V1.00.fm

4.2 Technical information

4.2.1 Machine profile

4.2.2 Technical data

Pos. Unit Value

Theoretical performance (at 5.5 km/h) (m²/h) 3025

Working width (mm) 55

Squeegee width (mm) 63

Solution tank (l) 70

Recovery tank (l) 73

Table 2: Machine profile

Pos. Unit Value

Noise level (dB(A)) <70

Vibration (m/s2) 0.43

Approvals CB

Nominal consumption (W) 1200

Power drive motor (W) 450

Power suction motor (when cleaning) (W) 491

Voltage (V) 24

Battery capacity max. (maintenance free) (Ah)/C5 180

Battery autonomy max.

(180 Ah maintenance free battery)

(h) <4

Internal charger only in BMS

Protection class Class lll

IP class IPX3

Table 3: Technical data

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 4-3

Copyright © 2015, Diversey Care

04.1 swingo 2100µicro - technical data_V1.00.fm

4.2.3 Machine speed

4.2.4 Dimensions and weights

Pos. Unit Value

Transportation speed (km/h) 5.5

Cleaning speed (km/h) 5.5

Reverse speed (km/h) 2.5

Ramp max. cleaning (%) 2.0

Ramp max. transport (%) 10

Table 4: Machine speed

Pos. Unit Value

Dimensions L/W/H (mm) 1350/630/1280

Door pass through with (without) squeegee (mm) 630 (630)

Battery compartment L/W/H (mm) 390 x 500 x 280 (270)

Net weight without batteries; empty tank (kg) 201

Weight, ready to use (kg) 470

Max. floor pressure front (N/mm2) 0.83

Max. floor pressure rear (N/mm2) 0.88

Wheel diameter traction (mm) 250

Wheel diameter castor (mm) 200

Table 5: Dimensions and weights

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 4-4

Copyright © 2015, Diversey Care

04.1 swingo 2100µicro - technical data_V1.00.fm

Picture 1: Dimensions

4.2.5 Battery

4.2.5.1 Battery compartment

Pos. Unit Value

Battery compartment L/W/H (mm) 390 x 500 x 280 (270)

Table 6: Battery compartment

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 4-5

Copyright © 2015, Diversey Care

04.1 swingo 2100µicro - technical data_V1.00.fm

Picture 2: Battery compartment

4.2.5.2 Battery specifications

Please use batteries from Exide/Sonnenschein, as this is our preferred

partner.

BMS machines can be set to the necessary charging curve. Please

adjust to the type of batteries you use.

For the correct connection of the batteries, pay attention to the

voltage of each battery and the correct connection. Therefore refer to

TASKI spares.

Supplier Type

Voltage

Ah/C5

Length [mm]

Width [mm]

Height [mm]

Weight [kg]

Excide Sonnenschein GF106180V 6 180 244 190 275 31

Table 7: Dry (GEL) batteries

GTS Technical Manual

11. December 2015 Edition: V1.00/2015 4-6

Copyright © 2015, Diversey Care

04.1 swingo 2100µicro - technical data_V1.00.fm

4.2.6 Charger

4.2.7 Brush system

Pos. Unit Value Value

Primary (V) 220-240 100-240

Primary (Hz) 50-60 50-60

Secondary (V) 24 24

Secondary (A) 25 25

Protection class (BMS model) II I

Approval CE CB/UL/TICK/

KTL

Cable length/BMS cable (m) 5 5

Table 8: Charger

Pos. Unit Value

Brush system (mm) 2 x 280

Brush motor (W) 500

Brush speed (rpm) 190

Brush pressure max. (N/cm2) 0.30

Table 9: Brush system

Other manuals for Diversey Care TASKI swingo 2100 micro

1

Table of contents

Other Sealed Air Scrubber manuals

Popular Scrubber manuals by other brands

Tornado

Tornado VORTEX 18 MULTIWASH Operation and maintenance manual

Ghibli & Wirbel

Ghibli & Wirbel ROUND 45 E 55 TOUCH Use and maintenance

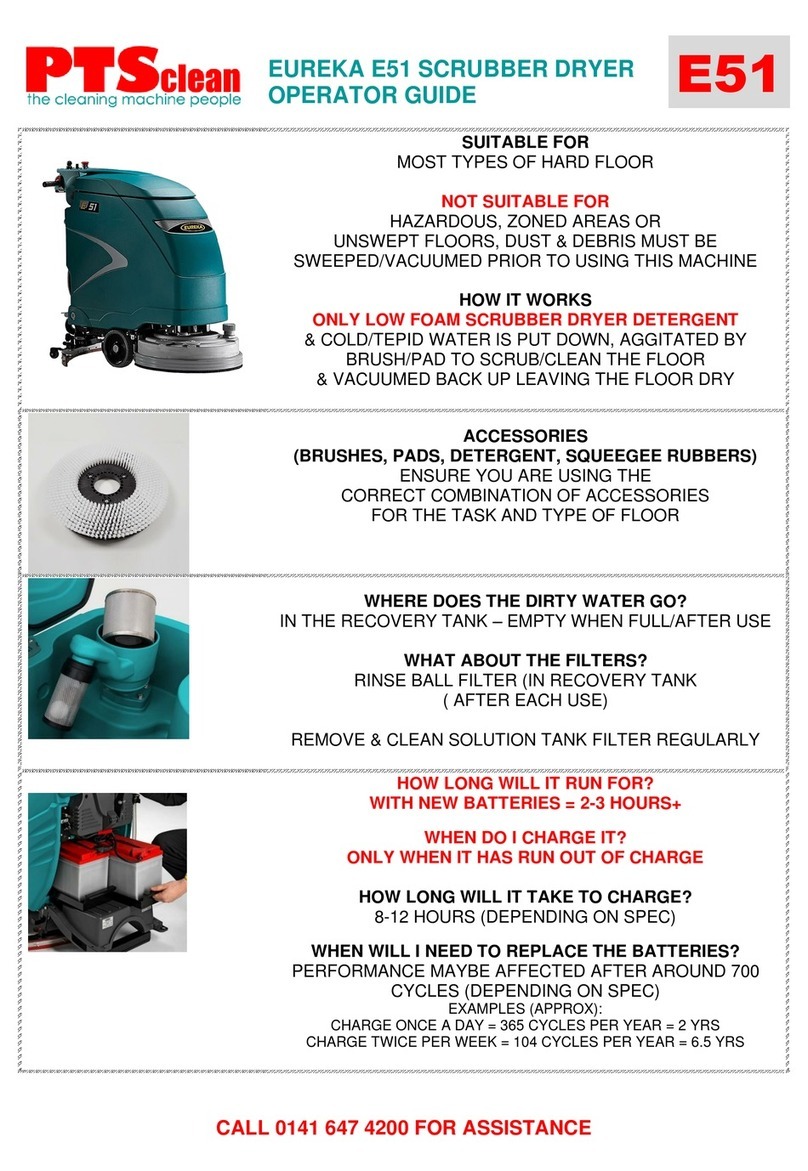

Pts

Pts EUREKA E51 Operator's guide

Tennant

Tennant 800 Operator's manual

Truvox International

Truvox International Cimex Cyclone CR38 user manual

Nilfisk-Advance

Nilfisk-Advance 9087331020 Instructions for use