4. OPERATION

4.1. Fit the socket to the wrench by snapping it onto the square drive.

NOTE: Use only impact grade sockets.

4.2. Fit the battery pack to the wrench by aligning the tongue on the battery with

the groove in the housing and slide into place. Ensure that the battery pack

is rmly located, a click will be heard when it has locked into position.

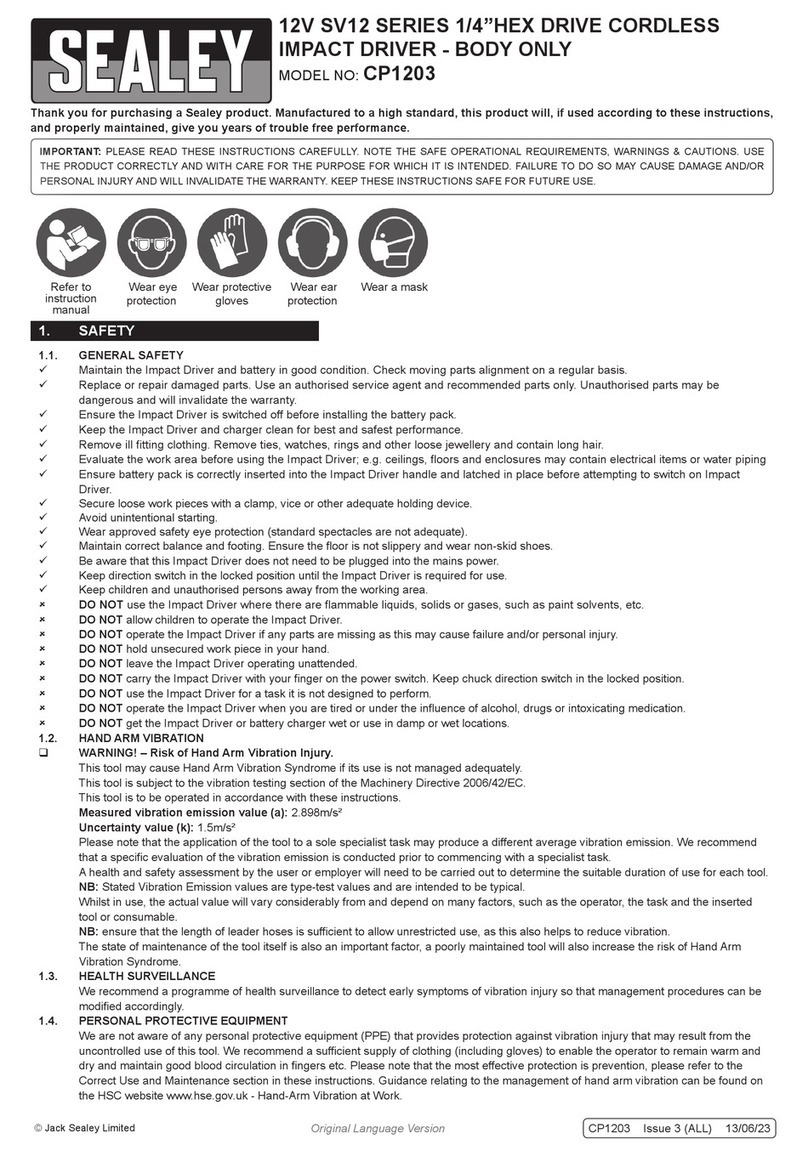

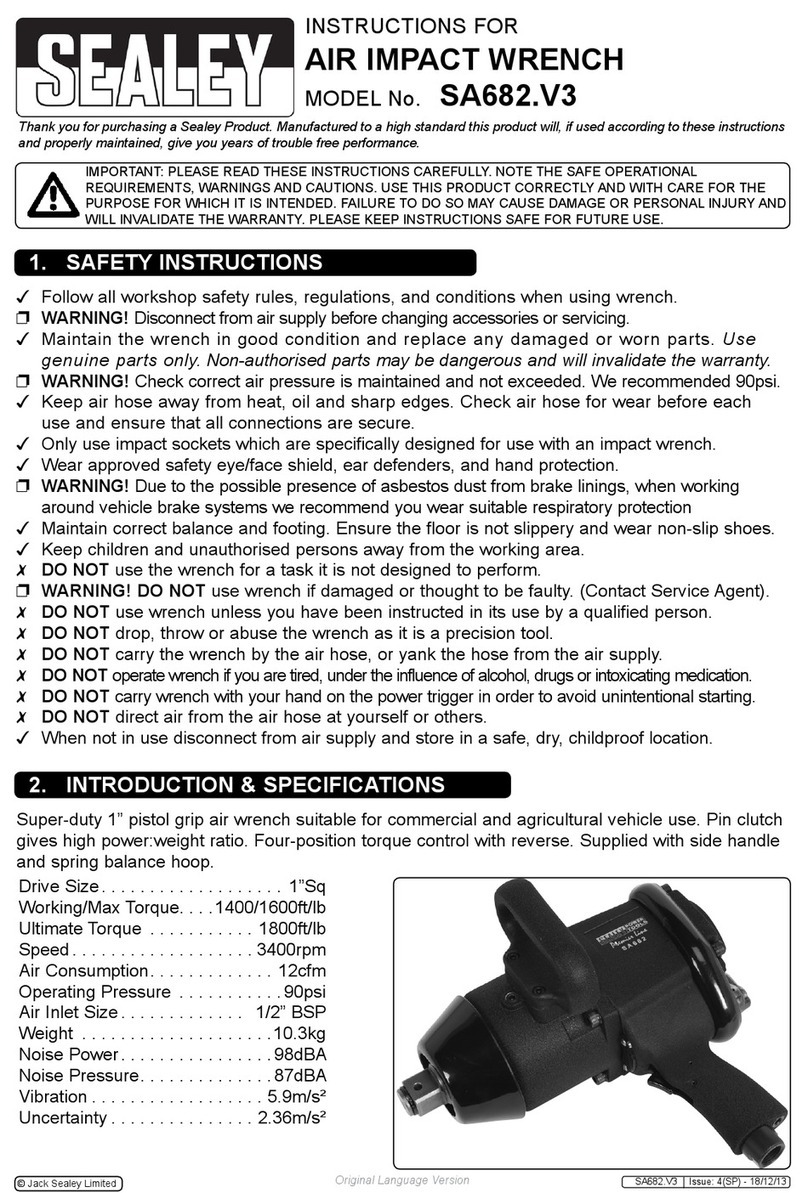

4.3. Select the required direction of rotation. To change direction, turn the

direction control (g.1) to the left or right. DO NOT attempt to change the

direction of rotation whilst trigger is depressed.

4.4. Speed can be controlled by varying the nger pressure on the trigger. Initial

pressure will switch on the work light.

IMPORTANT: When tightening, take care not to over-torque small xings.

NOTE: On critical fixings always check the torque with a torque wrench

according to the product or vehicle manufacturer’s guidelines.

5. MAINTENANCE

WARNING: Always disconnect the battery before carrying out any

inspection, maintenance or cleaning.

5.1. GENERAL INSPECTION

5.1.1. Regularly check that all the xing screws are tight. Repairs should be

carried out by an authorised service centre.

5.2. CLEANING

WARNING: Always wear protective equipment including eye protection and gloves when cleaning this tool.

5.2.1. Keep your tool clean at all times. Dirt and dust will cause internal parts to wear quickly, and shorten the device’s service life.

5.2.2. Clean the body of your machine with a soft brush, or dry cloth.

5.2.3. Never use caustic agents to clean plastic parts. If dry cleaning is not sufcient, a mild detergent on a damp cloth is recommended.

5.2.4. Water must never come into contact with the tool. Ensure the tool is thoroughly dry before using it.

5.2.5. If available, use clean, dry, compressed air to blow through the ventilation holes (where applicable).

5.3. LUBRICATION

5.3.1. Slightly lubricate all moving parts at regular intervals with a suitable spray lubricant.

5.4. STORAGE

5.4.1. Store this tool carefully in a secure, dry place out of the reach of children.

CP20VIWX | Issue 1 12/06/2019

Original Language Version

© Jack Sealey Limited

g.1

WARNING! – Risk of Hand Arm Vibration Injury.

This tool may cause Hand Arm Vibration Syndrome if its use is not managed adequately.

This tool is subject to the vibration testing section of the Machinery Directive 2006/42/EC.

This tool is to be operated in accordance with these instructions.

Measured vibration emission value (a): .........3.051 m/s²

Uncertainty value (k):...........................1.5m/s²

Please note that the application of the tool to a sole specialist task may produce a different average vibration emission. We recommend that

a specific evaluation of the vibration emission is conducted prior to commencing with a specialist task.

A health and safety assessment by the user (or employer) will need to be carried out to determine the suitable duration of use for each tool.

NB: Stated Vibration Emission values are type-test values and are intended to be typical.

Whilst in use, the actual value will vary considerably from and depend on many factors.

Such factors include; the operator, the task and the inserted tool or consumable.

NB: ensure that the length of leader hoses is sufficient to allow unrestricted use, as this also helps to reduce vibration.

The state of maintenance of the tool itself is also an important factor, a poorly maintained tool will also increase the risk of Hand Arm Vibration

Syndrome.

Health surveillance.

We recommend a programme of health surveillance to detect early symptoms of vibration injury so that management procedures

can be modified accordingly.

Personal protective equipment.

We are not aware of any personal protective equipment (PPE) that provides protection against vibration injury that may result from the

uncontrolled use of this tool. We recommend a sufficient supply of clothing (including gloves) to enable the operator to remain warm and dry

and maintain good blood circulation in fingers etc. Please note that the most effective protection is prevention, please refer to the Correct Use

and Maintenance section in these instructions. Guidance relating to the management of hand arm vibration can be found on the HSE website

www.hse.gov.uk - Hand-Arm Vibration at Work.

CP20VIWX | Issue 1 12/06/2019

Original Language Version

© Jack Sealey Limited

Sealey Group, Kempson Way, Suffolk Business Park, Bury St Edmunds, Suffolk. IP32 7AR

01284 757500 01284 703534 sales@sealey.co.uk www.sealey.co.uk

ENVIRONMENT PROTECTION

Recycle unwanted materials instead of disposing of them as waste. All tools, accessories and packaging should be sorted, taken to

a recycling centre and disposed of in a manner which is compatible with the environment. When the product becomes completely

unserviceable and requires disposal, drain any fluids (if applicable) into approved containers and dispose of the product and fluids

according to local regulations.

WEEE REGULATIONS

Dispose of this product at the end of its working life in compliance with the EU Directive on Waste Electrical and Electronic Equipment

(WEEE). When the product is no longer required, it must be disposed of in an environmentally protective way. Contact your local solid

waste authority for recycling information.

Note: It is our policy to continually improve products and as such we reserve the right to alter data, specifications and component parts without prior notice.

Important: No Liability is accepted for incorrect use of this product.

Warranty: Guarantee is 36 months labour and two years parts warranty from purchase date, proof of which is required for any claim.