AIR IMPACT WRENCH 3/4” SQ. DRIVE

COMPACT TWIN HAMMER

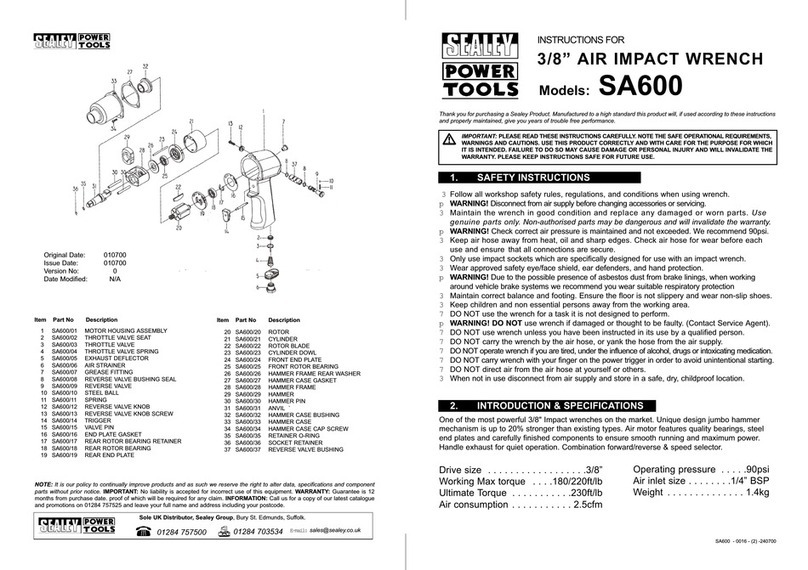

MODEL NO: SA6004.V2

Thank you for purchasing a Sealey product. Manufactured to a high standard, this product will, if used according to these instructions,

and properly maintained, give you years of trouble free performance.

IMPORTANT: PLEASE READ THESE INSTRUCTIONS CAREFULLY. NOTE THE SAFE OPERATIONAL REQUIREMENTS, WARNINGS & CAUTIONS. USE

THE PRODUCT CORRECTLY AND WITH CARE FOR THE PURPOSE FOR WHICH IT IS INTENDED. FAILURE TO DO SO MAY CAUSE DAMAGE AND/OR

PERSONAL INJURY AND WILL INVALIDATE THE WARRANTY. KEEP THESE INSTRUCTIONS SAFE FOR FUTURE USE.

1. SAFETYi

WARNING! DO NOT use wrench if damaged or thought to be faulty. Contact Sealey stockist.

WARNING! Disconnect from the air supply before changing accessories or servicing.

WARNING! Due to the possible presence of asbestos dust from brake linings, when working around vehicle brake systems we

recommend you wear suitable respiratory protection.

WARNING! Check correct air pressure is maintained and not exceeded. We recommend 90psi.

8DO NOT use the wrench for a task it is not designed to perform.

8DO NOT use worn, or damaged sockets.

8DO NOT use the wrench unless you have been instructed in its use by a qualified person.

8DO NOT use the wrench for a task it is not designed to perform.

8DO NOT carry the wrench by the air hose.

8DO NOT operate the wrench if you are tired or under the influence of alcohol, drugs or intoxicating medication.

8DO NOT carry the wrench with your hand on the power trigger in order to avoid unintentional starting.

8DO NOT direct air from the air hose at yourself or others.

9Maintain the wrench in good condition and replace any damaged or worn parts. Use genuine parts only. Unauthorised parts

may be dangerous and will invalidate the warranty.

9Keep air hose away from heat, oil and sharp edges. Check air hose for wear before each use and ensure that all connections are

secure.

9 Onlyuseimpactsocketswhicharespecicallydesignedforusewithanimpactwrench.

9Wear approved safety eye/face shield, ear defenders, dust mask and hand protection.

9Follow all workshop safety rules, regulations, and conditions when using the wrench.

9Maintain correct balance and footing. Ensure the floor is not slippery and wear non-slip shoes.

9Operate with both hands when practical to do so.

9When wearing gloves always be sure that the gloves will not prevent the throttle mechanism from being released.

9Keep children and non essential persons away from the working area.

9When not in use disconnect from air supply and store in a safe, dry, childproof location.

WARNING! The warnings, cautions and instructions in this manual cannot cover all possible conditions and situations that

may occur. It must be understood by the operator that common sense and caution are factors which cannot be built into

this product, but must be applied by the operator.

2. i INTRODUCTION

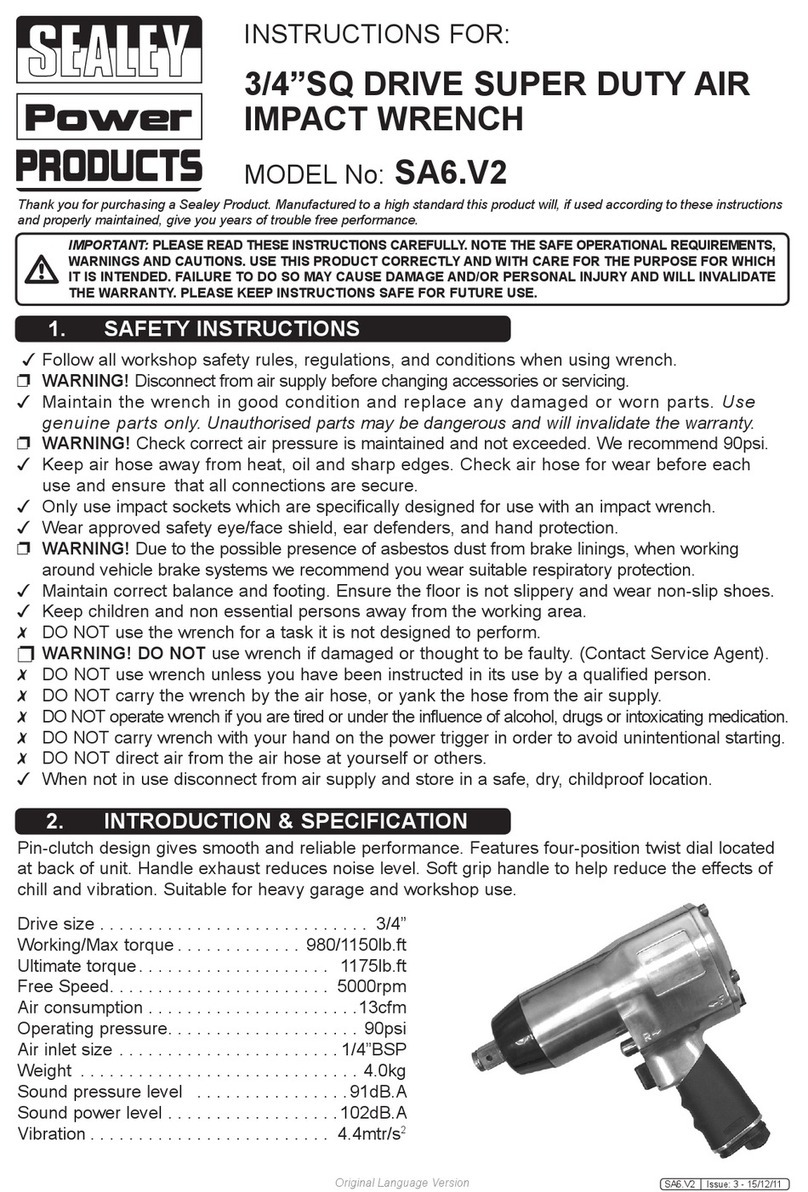

Compact and lightweight compared to traditional 3/4” impact wrenches, yet still produces a high torque output. Composite casing with

two extruding edge strips to help protect housing. Specially designed motor gives high torque, whilst working on low air consumption.

One-handoperationwiththree-speedselectorswitchandforward/reversecontrolatyourngertips.Handlefeaturesadownward

facing exhaust to lower noise level and soft grips to help reduce vibration and chill. Suitable for professional garages.

3. i SPECIFICATION

Model No: ............................................................. SA6004_V2

Drive: .............................................................................. 3/4”Sq

Maximum Torque: .........................................800lb.ft (1085Nm)

Breakaway Torque......................................1400lb.ft (1900Nm)

Free Speed:................................................................ 7300rpm

Air Consumption:............................................................5.4cfm

Operating Pressure: ......................................................... 90psi

Air Inlet Size: .............................................................. 1/4“ BSP

Noise Power: ................................................................ 114dBA

Noise Pressure:............................................................ 103dBA

Vibration ....................................................................7.333m/s2

Uncertainty................................................................. 2.9m/s2

Original Language Version

© Jack Sealey Limited

Refer to

instruction

manual

Wear protective

gloves

Wear eye

protection

Wear face

mask

Wear ear

protection

Wear protective

clothing

SA6004.V2 Issue 1 12/07/19

All manuals and user guides at all-guides.com