LEAD PAINT WARNING!

Paint once contained lead as a traditional ingredient. The dust from the removal of such paint is toxic if inhaled or ingested and must,

therefore, be avoided. The following action must be taken before using the sander on a surface that you suspect may have contained

lead in the paint.

1. User must determine potential hazard relating to age of paint to be removed. (Modern paints do not contain lead).

2. DANGER! Keep all persons and pets away from the work area. The following are particularly vulnerable to the effects of lead paint dust:

Expectant women, babies and children.

3. We recommend personal protection by using the following safety items:

a) Paint Spray Respirator

b) PE Coated Hooded Coverall

c) Latex Gloves

4. Take adequate measures to contain the paint dust, flakes, and scrapings.

5. Continue to wear safety equipment as in 3 above, and thoroughly clean all areas when task is complete. Ensure that paint waste

is disposed of, in sealed bags or containers, according to local authority regulations.

2. INTRODUCTION

Ergonomic and compact lightweight sander. Brushless

motor with constant speed control even whilst under

load. Seven stage variable speed control. Digital

display. Supplied with dust free Ø150mm backing pad,

four sanding discs and dust extraction hose.

3. SPECIFICATION

Model No: .........................DAS150PS

Electrical Plug Type:....................3-Pin BS

Motor Power: ...........................350W

No Load Speed: ................4000-10000rpm

Orbit Size: . . . . . . . . . . . . . . . . . . . . . . . . . . . . Ø5mm

Pad Size: .......................... Ø150mm

Thread Size: .........................5/16”UNF

Vibration: ............................3.22m/s²

Uncertainty: ...........................1.5m/s²

Noise Power: ........................90.3dB(A)

Noise Pressure: ......................79.7dB(A)

Replacement Parts: ................ PTC/150VA DA Backing Pad for Hook-and-Loop Discs Ø145mm 5/16”UNF

4. OPERATION

WARNING: Ensure the tool is disconnected from the power supply before attaching or changing any accessories, or making any adjustments.

WARNING: Always wear eye protection, adequate respiratory and hearing protection, as well as suitable gloves, when working

with this tool.

4.1. FITTING A SANDING DISC

4.1.1. Always use good quality sanding discs to maximise the quality of the nished task.

It is advisable to do a trial run on a scrap piece of material to determine the optimum grades of sandpaper for a particular job.

If there are still marks on your work after sanding, try either going back to a coarser grade and sanding the marks out before

recommencing with the original choice of grit, or try using a new piece of sandpaper to eliminate the unwanted marks before going

on to a ner grit and nishing the job.

NOTE: DO NOT continue to use worn, torn or heavily clogged sanding discs. Ensure foreign objects, such as nails and screws,

are removed from the workpiece before starting to sand.

WARNING: DO NOT use a sanding disc on wood that has previously been used on metal. This may cause scouring on the wooden

surface.

4.1.2. Remove any dust or debris from the hook & loop sanding base before tting a sanding disc.

4.1.3. Match the holes in a suitable disc with the holes in the base and simply press the disc to the base to attach it.

4.1.4. To remove the disc, peel it away from the base.

NOTE: To maximise the life of the hook & loop sanding base, peel the sanding disc off slowly rather than rapidly removing it to avoid

damage to the hook and loop system.

WARNING: Take care to regularly clean out the build-up of dust on the base underneath the sanding disc and not to let the disc

wear completely down before replacing it. Failure to observe these two precautionary measures can lead to damage to the hooks

and loops on the base, and the sanding disc will not attach properly.

WARNING: Never use the sander unless the entire base is covered by the sanding disc.

4.2. DUST EXTRACTION

WARNING: Always connect the sander to a suitable vacuum cleaner or workshop dust extraction system if the sanding dust

contains harmful substances, such as particles from old paint, varnish, surface coatings etc. Always dispose of harmful dust according

to local laws and regulations.

WARNING: Take special care to guard against harmful and toxic dusts when sanding lead-based painted surfaces, woods and

metals, particularly if you are unsure about the exact substances involved. All persons entering the work area must wear a mask

specially designed for protection against the toxic dust and fumes involved. Children and pregnant women MUST NOT enter the

work area. DO NOT eat, drink or smoke in the work area.

NOTE: The dust extraction port is designed to t a 40mm diameter hose.

WARNING: Always connect the sander to a suitable workshop dust extraction system when sanding metal.

WARNING: Always clean the tool THOROUGHLY when switching from sanding wood to sanding metal, and vice versa.

WARNING: DO NOT touch the moving sanding disc.

NOTE: Always use clamps to secure your workpiece to the workbench wherever possible.

WARNING: Never allow the sandpaper to completely wear down before replacing it. Failure to observe these precautionary

measures can lead to damage to the hook and loop surfaces, resulting in sanding discs failing to attach properly.

DAS150PS | Issue 1 22/08/2019

Original Language Version

© Jack Sealey Limited

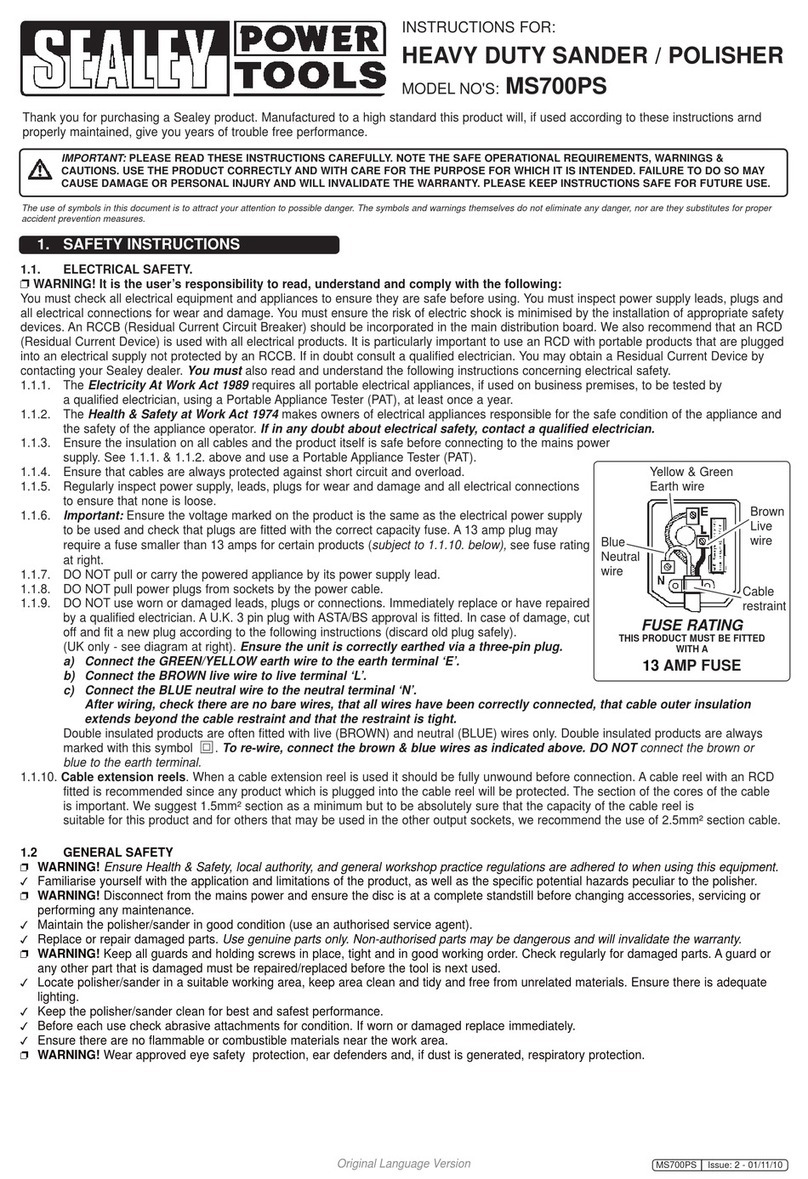

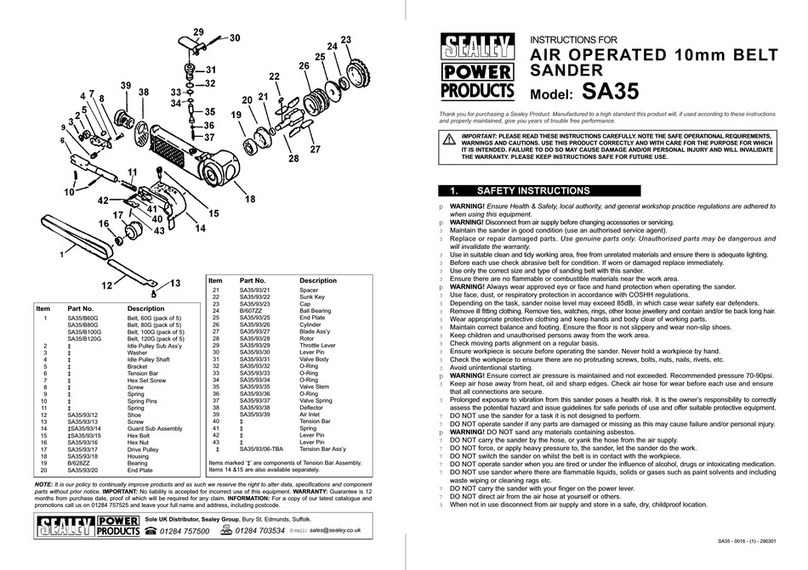

g.1

Sanding Pad

Lever

On/Off Switchrpm+

rpm-