5. OPERATION

WARNING! Before operating the bandsaw read the entire

manual to familiarise yourself with all aspects of the

machine. Pay particular attention to the Safety

instructions in Section 1.

NOTE: Before operating the machine certain checks and

adjustments will need to be carried out as detailed in

Section.4 ‘Set Up and Adjustments’. It is very important

that these instructions are followed carefully in order that

the machine is set up safely and correctly.

WARNING! The machine is designed for metal cutting

work in engineering workshops, garages, metal fabricators,

etc. The SM355CE must not be used to cut any other

materials (including wood). To do so will invalidate your

insurance cover and your warranty and may cause damage

and/or personal injury.

WARNING! Never operate the saw unless all blade guards are

installed and working properly.

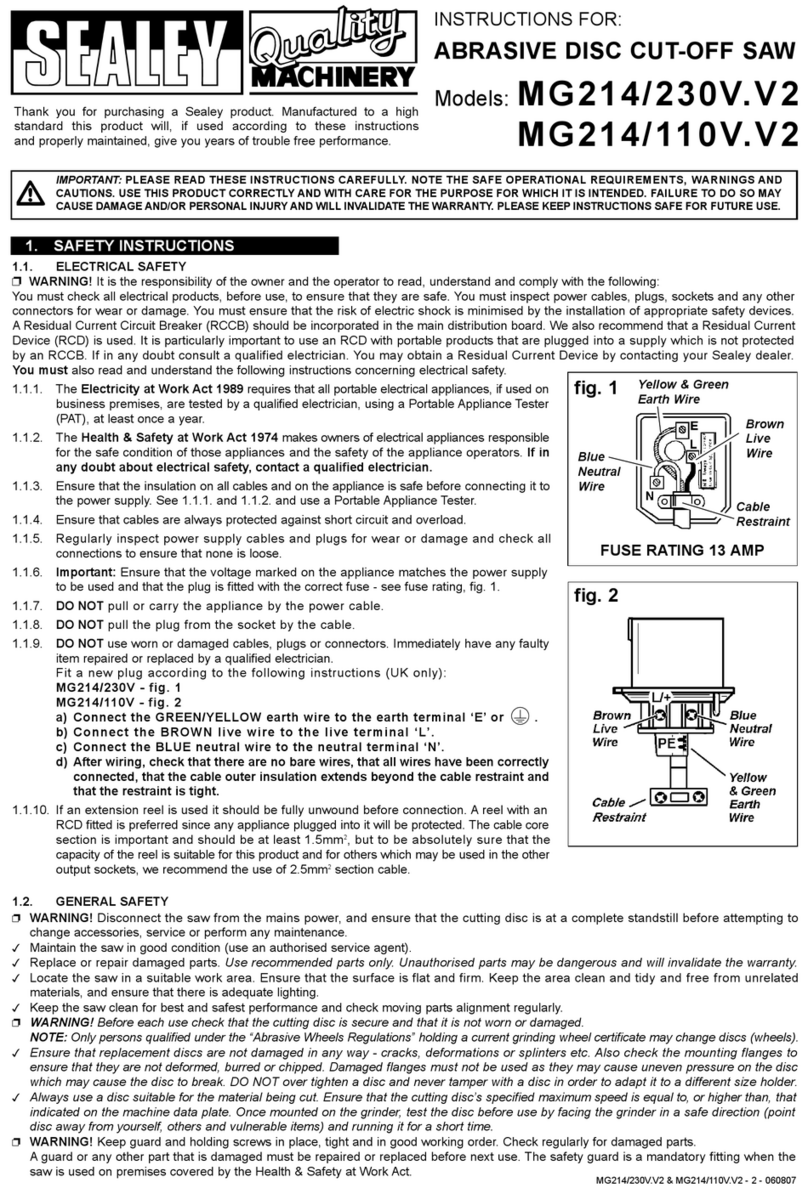

Fig.15

hitting the red emergency OFF button. Refer to the

‘Troubleshooting’ section for common problems).

5.1.12 The coolant pump starts automatically when the machine is

turned on and feeds coolant directly to the blade guides. The

flow can be regulated using the coolant feed tap as described

in section 4.1.

5.1.13 When the cut is completed the machine will switch off

automatically. Turn the mains power switch off and disconnect

the saw from the power supply, raise the blade and remove

the workpiece. Wear gloves as the workpiece will be hot and

have sharp edges.

5.1.14 Hand grip start. The handgrip is used in conjunction with the

hydraulic damper to provide an extra degree of control,

especially when the blade first comes into contact with the

workpiece. Furthermore the hand grip switch has to be held

down to keep the blade running so the machine can be

stopped quickly by releasing the switch if problems occur such

as the blade jamming.

5.1.15 In order to start the machine with the hand grip switch (See 5

in Fig.4) the selection switch on the control panel (See 3 in

Fig.15) must be turned to the hand grip symbol.

5.1.16 Set the blade rotating by holding down the handgrip switch.

Having previously set the rate of descent allow the blade to

move slowly down towards the workpiece by turning the

hydraulic tap to be in line with the cylinder. Allow the blade to

rest lightly onto the workpiece whilst making the initial cut.

Keep the switch held down whilst the cut progresses. (If the

blade should jam or other problems occur release the hand

grip switch immediately).

5.1.17 The coolant pump starts automatically when the machine is

turned on and feeds coolant directly to the blade guides. The

flow can be regulated using the coolant feed tap as described

in section 4.1.

5.1.18 When the cut is completed the machine will switch off

automatically. Turn the mains power switch off and disconnect

the saw from the power supply, raise the blade and remove

the workpiece.

WARNING! Never raise blade when machine is running.

WARNING! Wear gloves when handling sawn metal parts

as the cutting process will have made them hot to touch

and the cut edges will be sharp.

WARNING! Do not rotate the bow when the machine is

running.

5.1.1 Ensure that the saw is disconnected from the power supply.

5.1.2 Adjust the stop bracket to the desired length on the stop rod

as described in Section 4.4

5.1.3 Adjust the vice to the desired angle or set up at 90° to the

blade as required and as described in Sections 4.4 and 4.5

5.1.4 Open vice, insert the workpiece and clamp it securely.

5.1.5 Adjust the blade guide so that it is close to the workpiece as

described in Section 4.8

5.1.6 Adjust the rate of descent of the arm as described in Section

4.2 so that it is creeping slowly down towards the workpiece.

Shut off the hydraulic cylinder when the blade gets close to

the workpiece. DO NOT start cutting on a sharp edge. File it

off first. DO NOT turn on machine until workpiece is secured

and blade has been lowered to just above workpiece.

5.1.7 Before starting the machine ensure that the bed cannot

rotate by moving the lever on the front face of the machine

bed to the locked position i.e. fully over to the right.

(See 20 in fig.4)

5.1.8 Turn on the mains power by turning the switch clockwise.

See (1) in Fig.15 above. The power lamp (2) will light.

5.1.9 Using switch (3) select whether the machine will turn on with

the Start Button (4) on the control panel or the handgrip

switch. See (6) in Fig.4.

5.1.10 Control panel start. Start the saw by pressing the start

button on the control panel.

5.1.11 Having previously set the rate of descent allow the blade to

descend slowly onto the workpiece by turning the hydraulic

tap to be in line with the cylinder. (If the blade should jam or

other problems occur immediately switch off the power by

6. MAINTENANCE

WARNING! Disconnect the bandsaw from the power source

before servicing, changing accessories, or performing any

other maintenance.

6.1.1 Check the gearbox oil level on a monthly basis. This should

be done with the bow raised to its highest position. Observe

the oil level in the sight glass on the side of the gearbox. If

required, top up the oil by removing the filler bolt from the

upper part of the gearbox just below the motor. Change the oil

every 6 months. The drain plug is at the bottom of the

gearbox. Drain the gearbox with the bow in its highest position.

6.1.2 Keep all surfaces clean and free from rust, slag, chips and

coolant build-up.

6.1.3 Do not use compressed air to clean bandsaw. Compressed air

may force chips into the guide bearings and other critical areas

of the saw.

6.1.4 Use a small paint brush or parts cleaning brush to remove

metal particles.

6.1.5 Wipe saw down with a clean dry cloth and oil all unpainted

surfaces with light machine oil.

6.1.6 Keep blade guides clean and free from metal chips.

6.1.7 Check guide bearings frequently to make sure they are

properly adjusted and running freely.

6.1.8 BLADE CLEANING BRUSH. It is important that the blade

cleaning brush be properly adjusted and kept in good working

order. The brush is mounted behind the fixed blade guide.

(See 'H' in Fig.12) Blade life will be shortened severely if the

brush is allowed to go out of adjustment, becomes worn or

damaged. Replace the brush if it becomes worn or damaged.

6.1.9 Clean out the coolant tank at least twice a year.

WARNING! DO NOT attempt to to adjust the blade brush

with the machine running. Adjust only when the machine

is disconnected from the power source.

Original Language Version SM355CE Issue: 3 - 24/03/10