3. 2. Connecting the gas cylinder

3. 2. 1. When using Argon or Argon mixtures, you

will need to use the bull nose adaptor. If

you intend to use CO2 gas the regulator will

fit directly onto the cylinder. Fit the bull nose

adaptor to the cylinder with a spanner.

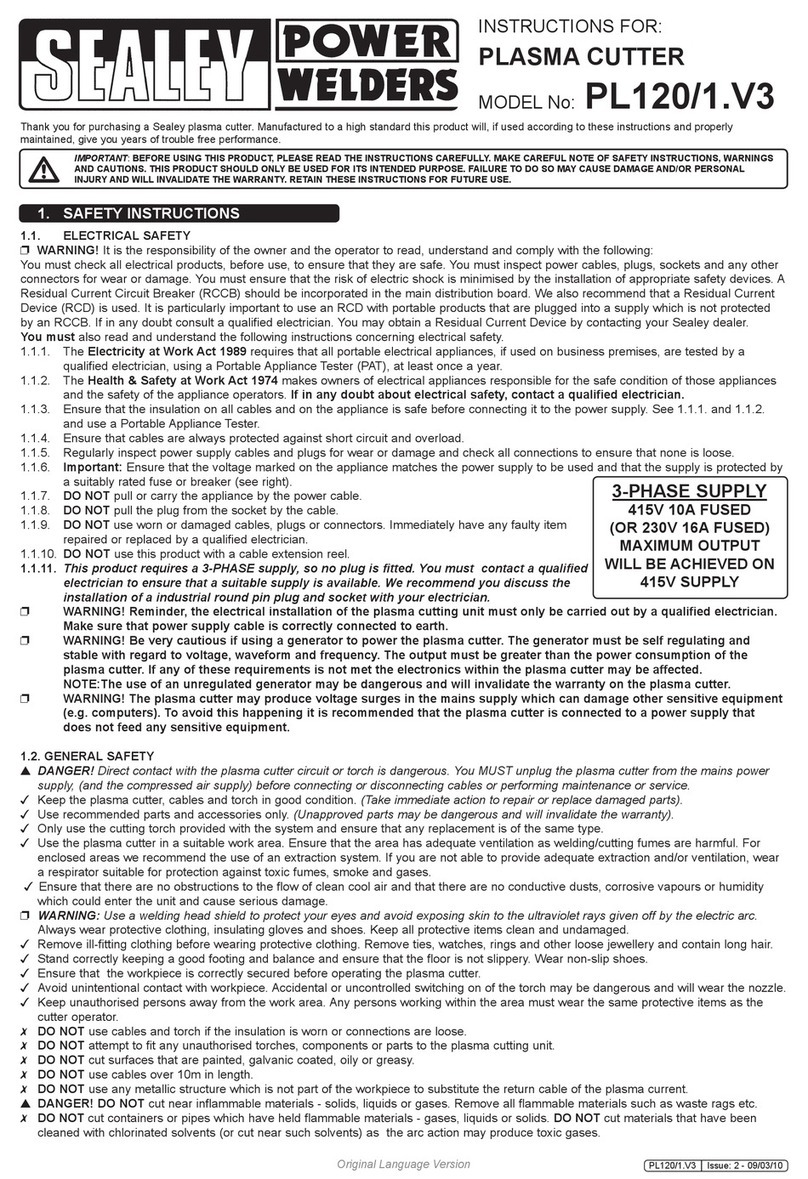

3. 2. 2. Fit the gas regulator on the bull nose

adaptor and connect it to the machine gas

hose (fig.2).

3. 2. 3. Set the regulator flow rate to 5-8 litres/min

depending on the material to be welded,

and whether there are draughts which are

strong enough to disturb the gas flow.

3. 3. Fitting a reel of wire - Ensure the welder

is unplugged from mains power.

( Refer to fig.4 )Your machine comes with a

mini spool of wire, but will accept up to 5kg spools without modification.

Firstly remove the nut, spring, metal washer and outer plastic retainer from

the threaded reel shaft.

3. 3. 1. Push the reel of wire over the threaded spindle and onto the flange of the

inner circular plastic retainer. Replace the nut, spring, metal washer and outer

plastic retainer. Tighten the nut whilst turning the reel until a slight braking

pressure is felt. Do not over tighten. Ensure the spool rotates clockwise, with

the wire drawing off the reel from the top as shown in fig 5.

3. 3. 2. Reduce the wire feed tension by turning the wire feed knob ( fig.6-A ) 2 or 3

turns anticlockwise. ( Do not unscrew the knob completely.) Pull the knob

towards you and allow it to disengage from the counter roller bracket and

hinge downwards to the position shown in fig.5. Push the counter roller

bracket upwards and away from the grooved drive roller as shown in fig.5.

3. 3. 3. Ensure that the correct size of drive roller is installed and that the roller is the

right way round to drive the the chosen wire. Refer to section 3.5.

3. 3. 4. Before releasing the wire from the reel ensure that the reel is not

freewheeling ( See section 3.3.1 ) As you release the wire keep a slight

tension on it to prevent coils coming off the reel. Straighten the first 50mm of

the wire and feed it into the flexible hose ( see fig.5A ), over the grooved

drive roller ( see fig.5B ), and into the torch liner collet ( see fig.5C ).

3. 3. 5. Now hinge the counter roller bracket back down onto the wire and secure it by

swinging the tension lever/knob up into the socket in the bracket. Turn the knob

clockwise by 2 or 3 turns to exert medium pressure. ( fig.6-A )

3. 3. 6. Before feeding the wire through to the torch remove the gas cup (fig 3.3.5.a) and

contact tip (b) from end of torch as follows:

a) Take torch in left hand with the torch tip facing to the right.

b) Grasp gas cup firmly in your right hand.

c) Turn gas cup clockwise only (c) and pull cup out to the right.

pWARNING! do not turn gas cup anti-clockwise, as this will damage internal spring.

d) Unscrew the copper contact tip (right hand thread) to remove.

3. 3. 7. Check welder is switched off 0, and that the earth clamp is away from the torch tip.

Connect the welder to the mains power supply and set the voltage switch to one.

3. 3. 8. Set the wire speed knob to position 5 or 6. Keeping the torch cable as straight as

possible and press the torch switch. The wire will feed through the torch.

3. 3. 9. When wire has fed through, switch welder off, unplug from mains.

a) Take torch in left hand and screw contact tip back into place. Cut the wire back to

within 3mm of the tip.

b) Grasp gas cup in right hand, push onto torch head and turn clockwise only.

pWARNING! do not turn gas cup anti-clockwise, as this will damage internal spring.

c) Cut wire so that it is just protruding the cup.

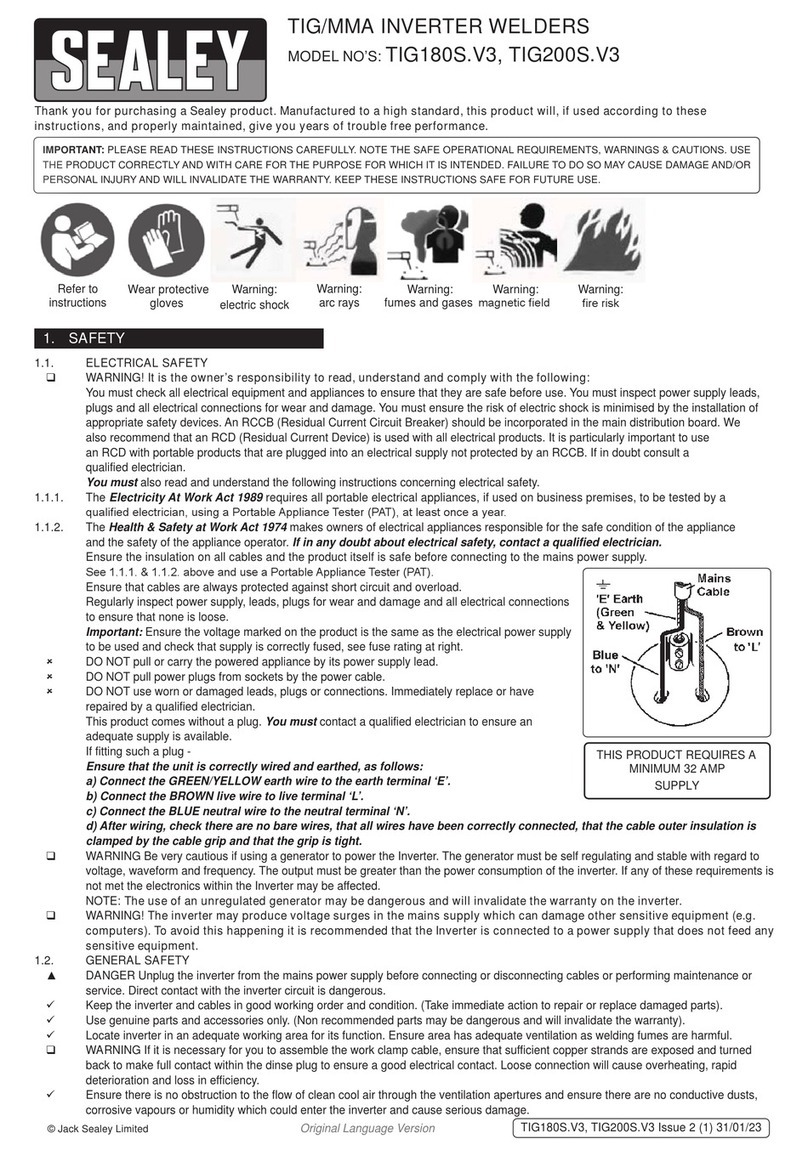

fig 1.

fig 2.

3. ASSEMBLY

To fit the mains power plug see safety instructions (Chapter 1).

SPECIFICATION.

This Manual contains instructions to assist you prepare your Mig Set for welding, together with information on maintenance, and trouble shooting. Read manual

carefully in order to get the best results from your machine. These instructions are not intended to show you how to be an expert welder. It is with continued

practice that you will achieve the desired results. Mig welding requires a steady hand, and time spent practising with scrap metal will be rewarded when you

progress to an actual workpiece.

The SUPERMIG150/5.V2 is a compact power source with integral wire feed which protects the wire from dust and dirt (especially in Body Shops). It is suitable for

welding with either CO2, Argon/CO2 mix or Argon gas. The unit has a forced air cooling system to slow transformer heating in order to increase the duty cycle and

a non live torch to prevent the risk of accidentally striking an arc. Your Mig is designed to operate with two diameters of welding wire, 0.6mm, & 0.8mm. (We

recommend that 0,8mm wire is used for welding stainless steel and aluminium).

MODEL IS EQUIPPED WITH:3Torch, 3Mini reel of 0.6mm wire, 3Argon/CO2 regulator, 3Bull nose adaptor 3Gas hose.

Welding Current . . . . . . . . . . . . . . . . . . .30-150 Amps

Duty Cycle . . . . . . . . . . . . . . . . . . . . . . .100% @ 30A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80% @ 50A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50% @ 70A

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10% @ 150A

2. INTRODUCTION & SPECIFICATION

Power efficiency . . . . . . . . . . . . . . . . . . .4.3 Kva

Wire capacity . . . . . . . . . . . . . . . . . . . . . . . . .5kg

Power input . . . . . . . . . . . . . . . . . . . .230V - 1ph

Power efficiency . . . . . . . . . . . . . . . . . . . .4.3kVA

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . .26kg

fig 4

fig 3.

fig 5.

fig 6.

3. 1. Wheel Assembly

Fit the axle on to the bottom (rear) of the machine with the nuts,

bolts and washers provided. Push the wheels on to the axle and

hold them in place by pushing the wheel retainers supplied onto

the ends of the axles.( See fig.1) Fit front stay by screwing it into

the centrally placed threaded insert on the underside of the

chassis close to the front face of the unit.

SUPERMIG150/5.V2 - (1) - 241002