0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

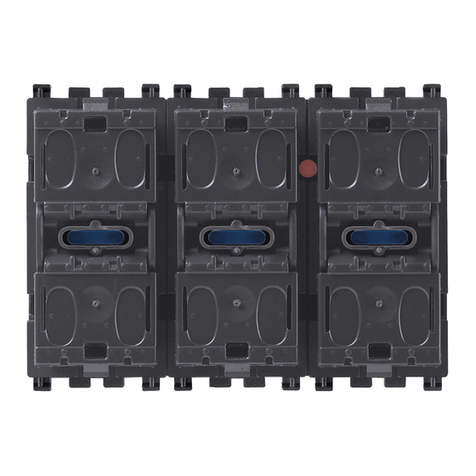

Setting Examples

The four numbered rotary switches marked "1000", "100",

"10", and "1" control the ratio of meter pulses to pump

strokes. Before setting the switches, disconnect power

to the unit by removing the connector from the pump or

unplugging the power adapter.

Problem Probable Cause

TROUBLESHOOTING

Try...

SETTING

Metering pump not stroking Meter dials not turning Check visually, then check for

adequate flow

Meter pickup not working Remove from meter, check with a

magnet

Pump connector not plugged in all the way Check or tighten threaded locking

ring (LMI)

Pump doesn’t supply power to the PD10 Check pump manual, add power

supply

PD10 set to large number or all zeroes Check rotary switches, esp. for

leading zeroes

Pump strokes continually Pump not set for external pacing Check pump manual and selector

switch

Pump doesn’t stroke often enough PD10 set for wrong number Review setting on this page, check

or too often rotary switches

Multiple contacts from meter Set PD10 to 1 contact/pump stroke

(0001) and see if the pump strokes

once for each magnet revolution

Meter ordered with wrong pulse rate Check meter model/serial tag

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

0

1

2

3

4

5

6

7

8

9

8

(Set Leading Switches To Zero)

To set any four-digit number, rotate the dials to the appropri-

ate numbers. For example, to set 1521, set the four switches

to "1", "5", "2", and "1". Any unused switches should be

set to zero. For example, to set 8, position the dials to "0",

"0", "0", "8". See samples below.

LT-10607-C

9/13/06

SeaMetrics Incorporated • 19026 72nd Avenue South • Kent, Washington 98032 • USA

(P) 253.872.0284 • (F) 253.872.0285 • 1.800.975.8153 • www.seametrics.com

Page 4