2.3 Installation of KATKA into cabinet

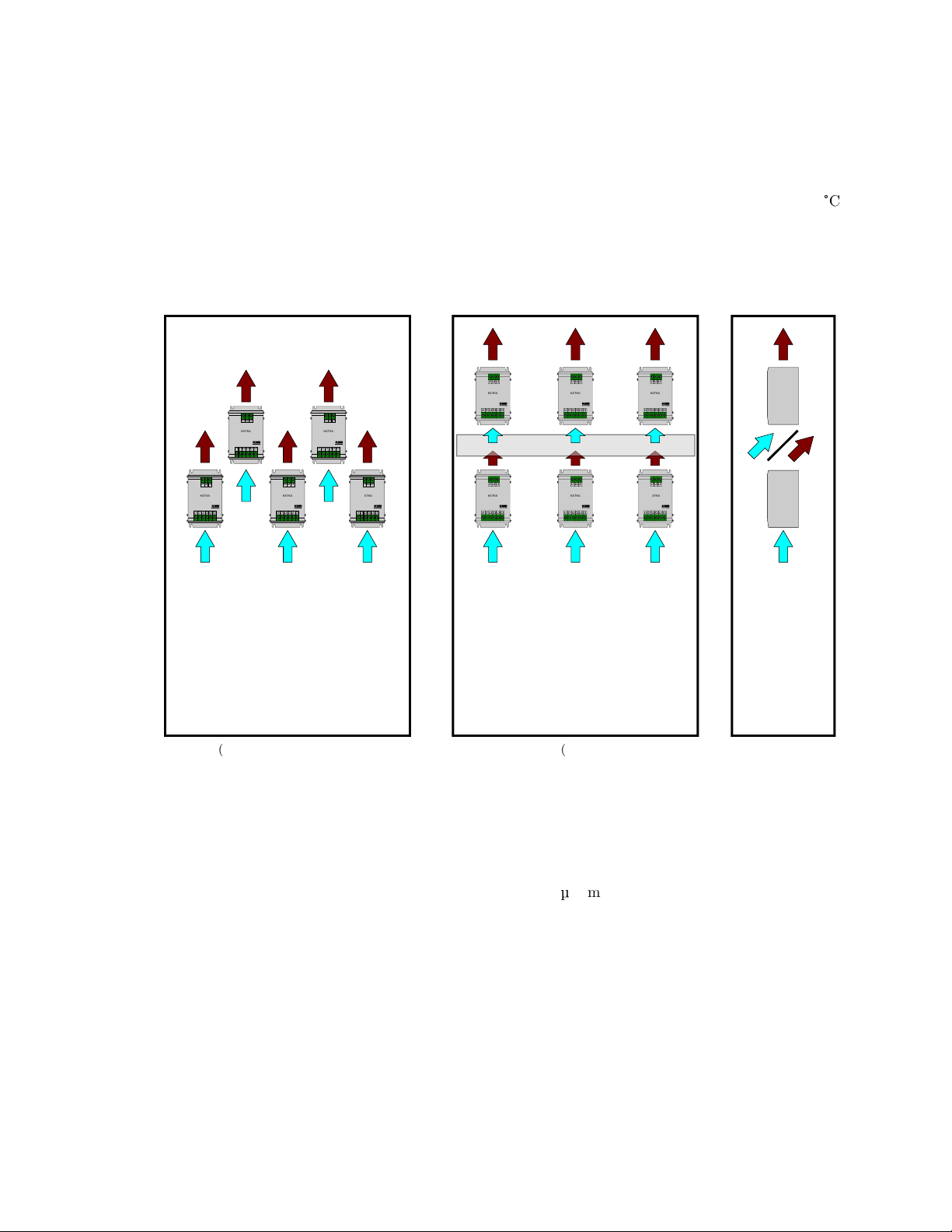

During normal operation, modules produce great amount of heat. Therefore it’s necessary to provide sufficient

air flow in the cabinet (holes in bottom and top of the cabinet) and sometimes also use of active cooling (use

of fan) might be necessary. Modules have to be installed vertically to allow air to flow through heatsink from

bottom to top. Ambient temperature (air provided for cooling of the module) should be kept bellow 45

°

C.

When installing multiple rows of modules in one cabinet each row should be staggered or heat deflectors

should be used. Air coming out of the module is very hot and might have negative effect to module directly

above. Modules should be installed to higher levels so hot air can escape cabinet as soon as possible.

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

(a) Staggered placing

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

KATKA

L1 C1 L2 C2 L3 C3

L1 L2 L3

(b) Use of heat deflectors

Figure 3: Installation example

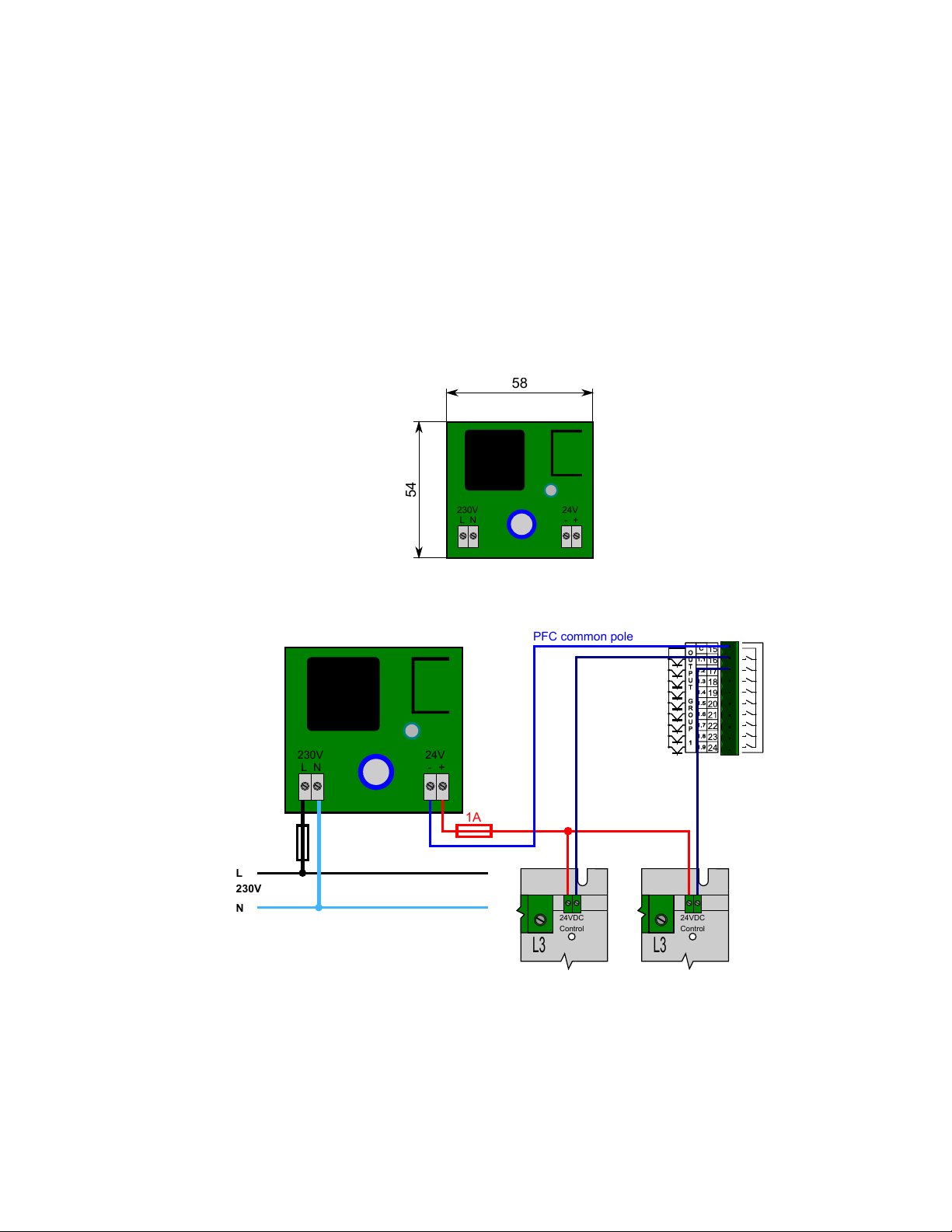

2.4 Connection of Load

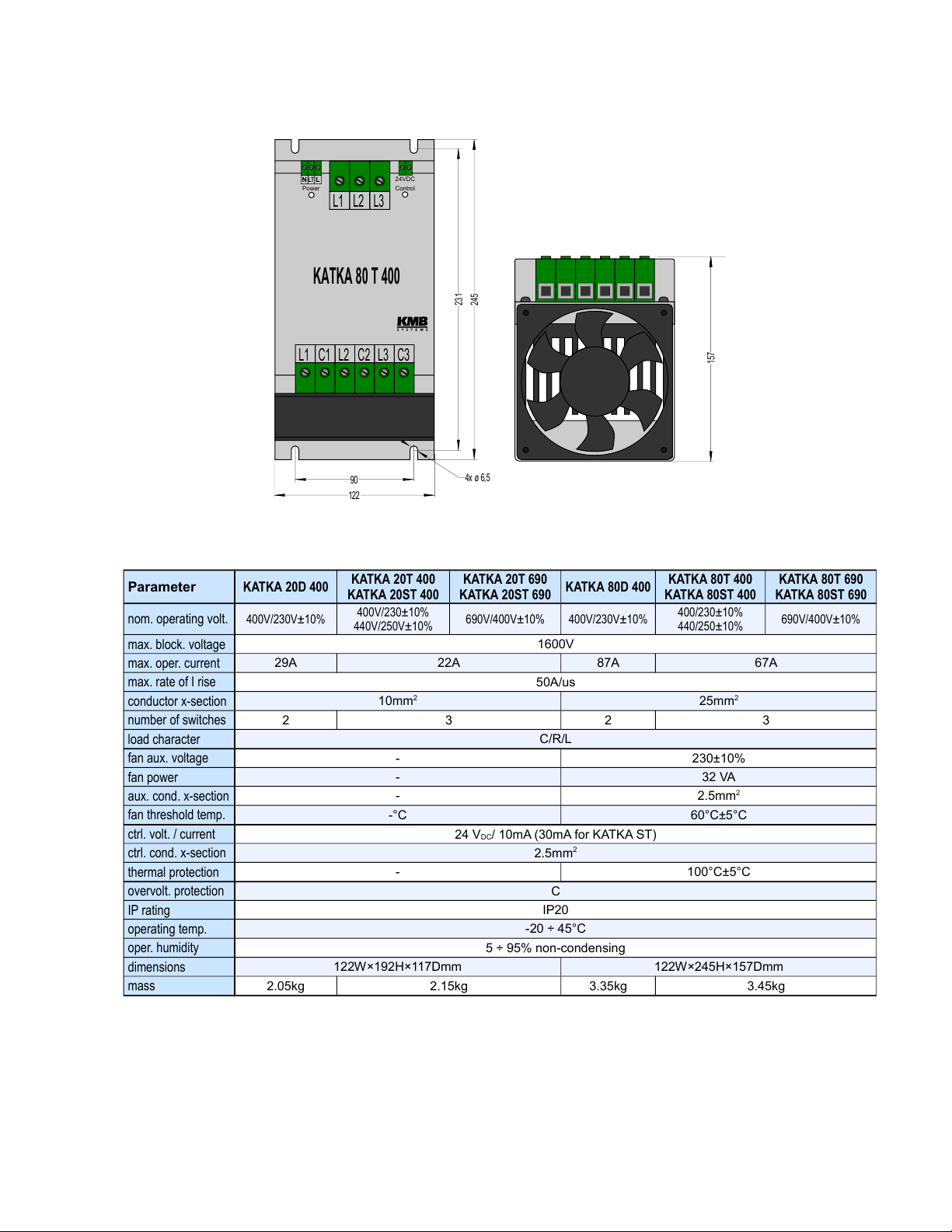

When using power factor correction capacitors, implementation of detuned power factor correction is

highly recommended, otherwise an inductance of at least 12

µ

H must be wired in series with the switch to

prevent thyristor damage by reducing speed of current rise. A detuning reactor also expands life of power factor

correction capacitors and improves control accuracy. The modules incorporate class C over-voltage protection

varistors. It is further recommended that a class B, 50 kA, lightning current protection device should be installed

in the power lead.

5