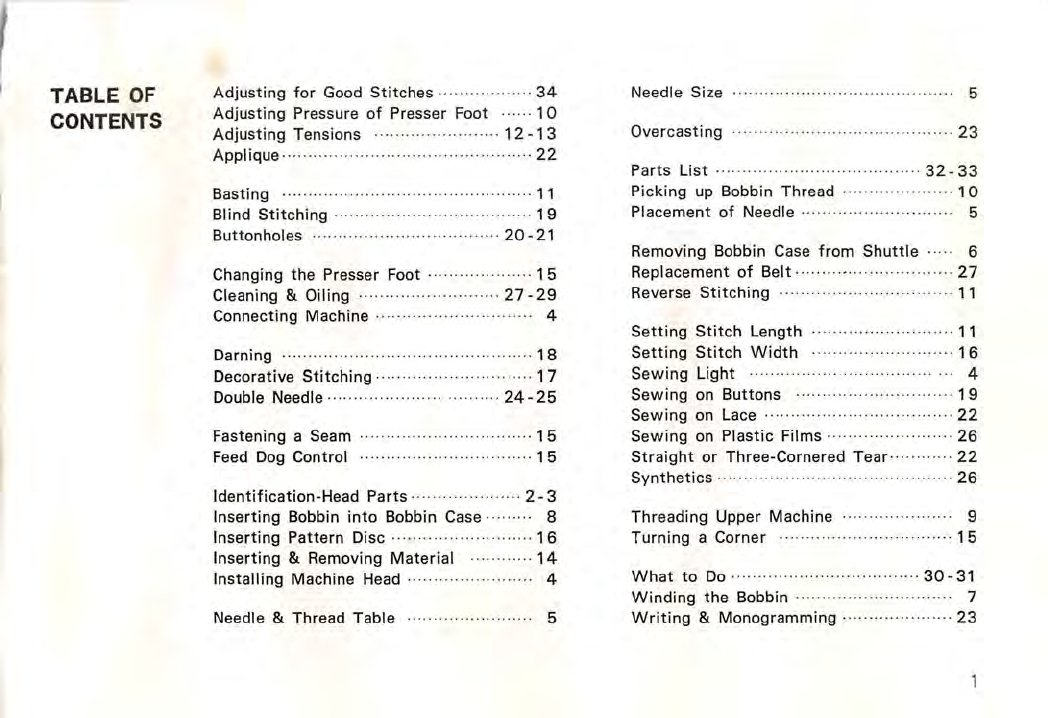

TABLE

OF

CON

TENTS

Adjusting

for

Good

Stitches

····· ··

··

··

34

Ad

ju

stin

g Pressure of Presser Foot ·· 10

Adjus

tin

g Tensions

··

·

··

·· 12 -

13

Applique

··

· ····

··

22

Basting ··

··

.......

11

Blind

St

i

tching

··

Buttonholes ··

··

··· . .

..

... ... .

........

19

..

..........

..

....

..

....

20

-

21

Changing the Presser Foot ....

..

..

· .......... 15

Cleaning & Oiling .........

..

..

..

27

-

29

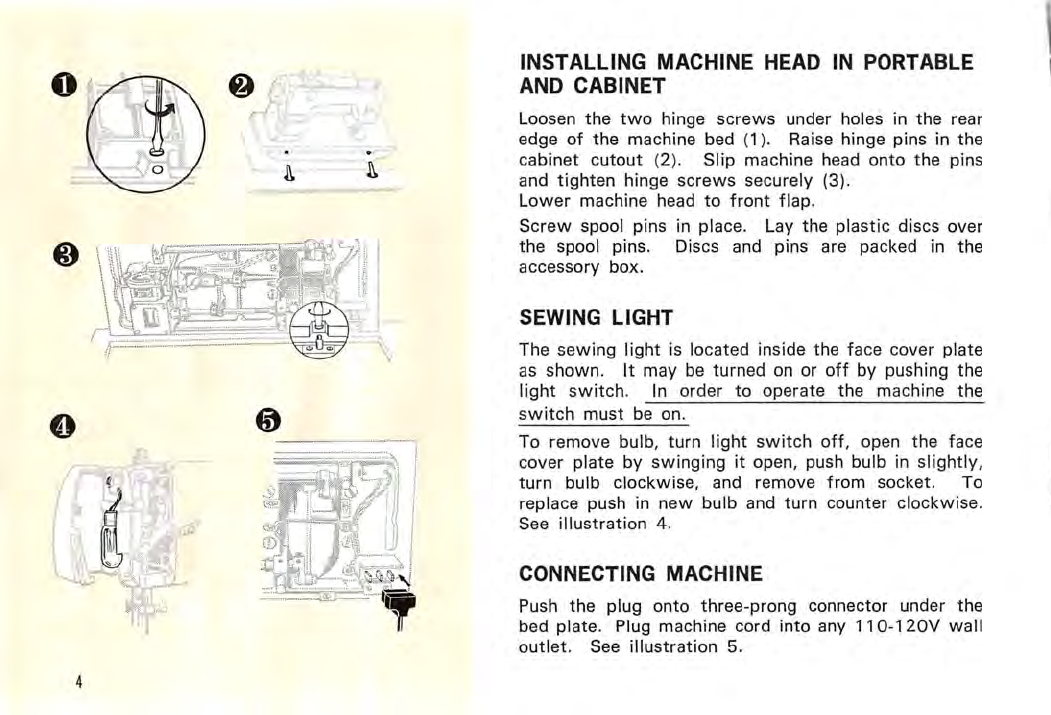

Connecting Machine ·

..

....

...

..

....

..

..

....

..

..

4

Darning

..

..

...

..

..........

..

..

..

..

............ ...

18

Decorative

Stitching

·

.........

17

Double Needle ....· .......

..

..

..

·

..

·

24-25

Fastening a Seam

Feed Dog Control

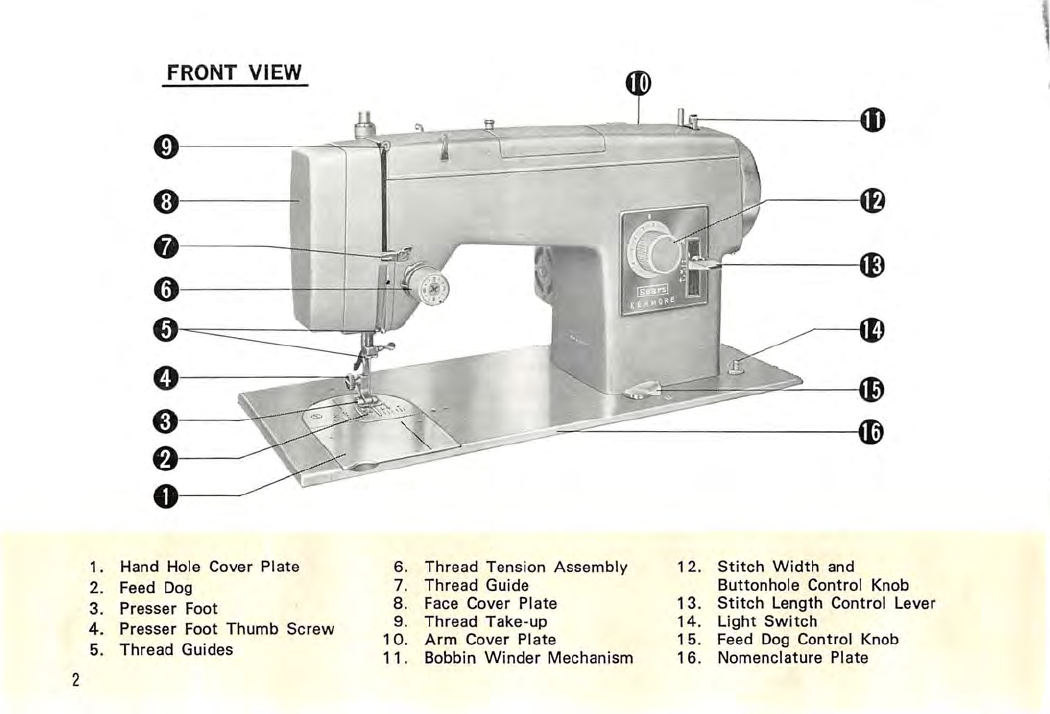

Identif

ication-Head Parts ......

......

15

......

15

..

.... 2 - 3

Inserting

Bobbin

into

Bobbin Case

··

· 8

Inserting Pattern Disc

..

..

· .... 16

Inserting

& Removing

Material

....·

14

Installing

Machine Head · ...........

..

........· 4

Needle & Thread Table ................ 5

Ne

edle Size

..

..

......

..

..

..

..

......

..

....

..

....

..

..

5

Overcasting .......

..

...

..

...... 23

Parts

List

··· · 3

2-3

3

Pi

cking

up Bobbin

Thr

e

ad

...

..

..............

· 10

Placement

of

Needle ....· ...........

..

..

.......· 5

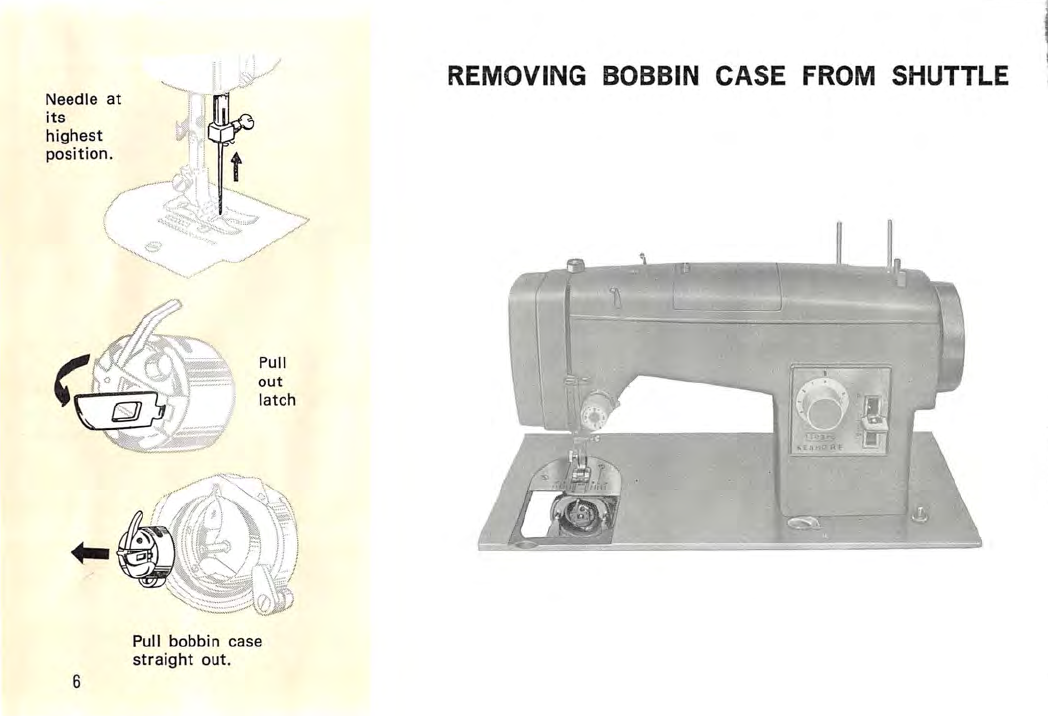

Removing Bobbin

Cas

e

from

Shuttle

..

6

Replacement

of

Belt

............

..

..........

27

Rever

se

Stit

ching

......

......

..........

......

..

·

11

Setting

Stitch

Length ··· 11

Setting

Stitch

Width

..

.

..

....... 16

Sew

ing

Light

..

..

..

.. ..

· 4

Sewing

on Buttons ·

..

·

..

.

..

..

..

..

....·

19

Sewing

on Lace · ......

..

..

·..

..

....·

22

Sewing

on Plastic Films · · ·........... ·

26

Straight

or

Thre

e-Cornered Tear

..

..

·

22

Synth

e

tics

.. ..

........

..

....

·

26

Threading Upper Machine

..

..

..

..

.........

· 9

Turning

a Corner

..

..

..

..

.. 15

What

to

Do

·

.....................

............

30

-

31

Wind

ing the Bobbin

..

..

......· 7

Writing

& Monogramming

....................

23