10

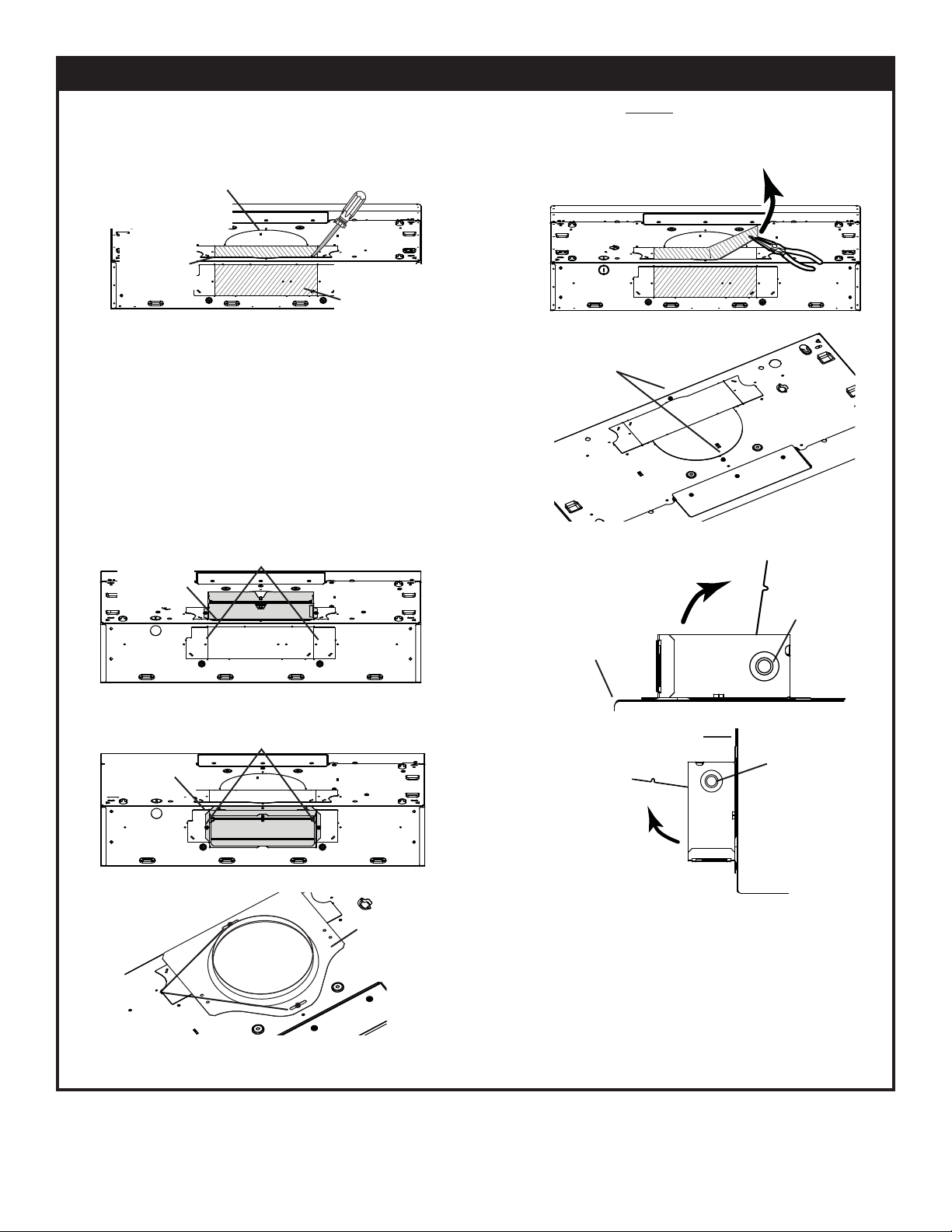

PREPARE THE HOOD LOCATION

NOTE: Before starting installation, read all the steps of

these instructions.

Use the illustration beside to identify your kitchen cabinet

type.

EZ1 One-person installation system

This manual covers 2 kinds of installation: the standard

(without EZ1 brackets) and the EZ1 one-person installation

system (using included template and brackets). For the

standard installation, go to page 14.

FRAMED CABINET FRAMELESS CABINET

CABINET FRONT

C

L

AB

Apoyar este borde contra la pared de atrásPlace this edge against back wall

= 3¼” x 10”

= 3¼” x 14”

RECTANGULAR DUCTING7” ROUND DUCTING OR

Use this template formarking; do not attempt to cut out the ducting hole through it.

NOTE:These cutouts are clearance holes; they do not need tobe the exact size of ducting.

= 3¼ po x 10po

= 3¼ po x 14 po

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO OU

= 3¼ pulg.x 10 pulg.

= 3¼ pulg.x 14 pulg.

CONDUCTO RECTANGULARCONDUCTO REDONDO

DE 7 PULG.O

Appuyer ce bord au mur arrière

Utiliser ce gabarit pour marquer vosrepères; ne pas tenter de découper

le trou pour le conduit à traversle gabarit.

NOTE :Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

êtredu format exact des conduits.

Use esta plantilla para crearmarcados; no trate de cortar el

agujero del conductoa través de la plantilla.

NOTA:Tobe translated in Spanish.

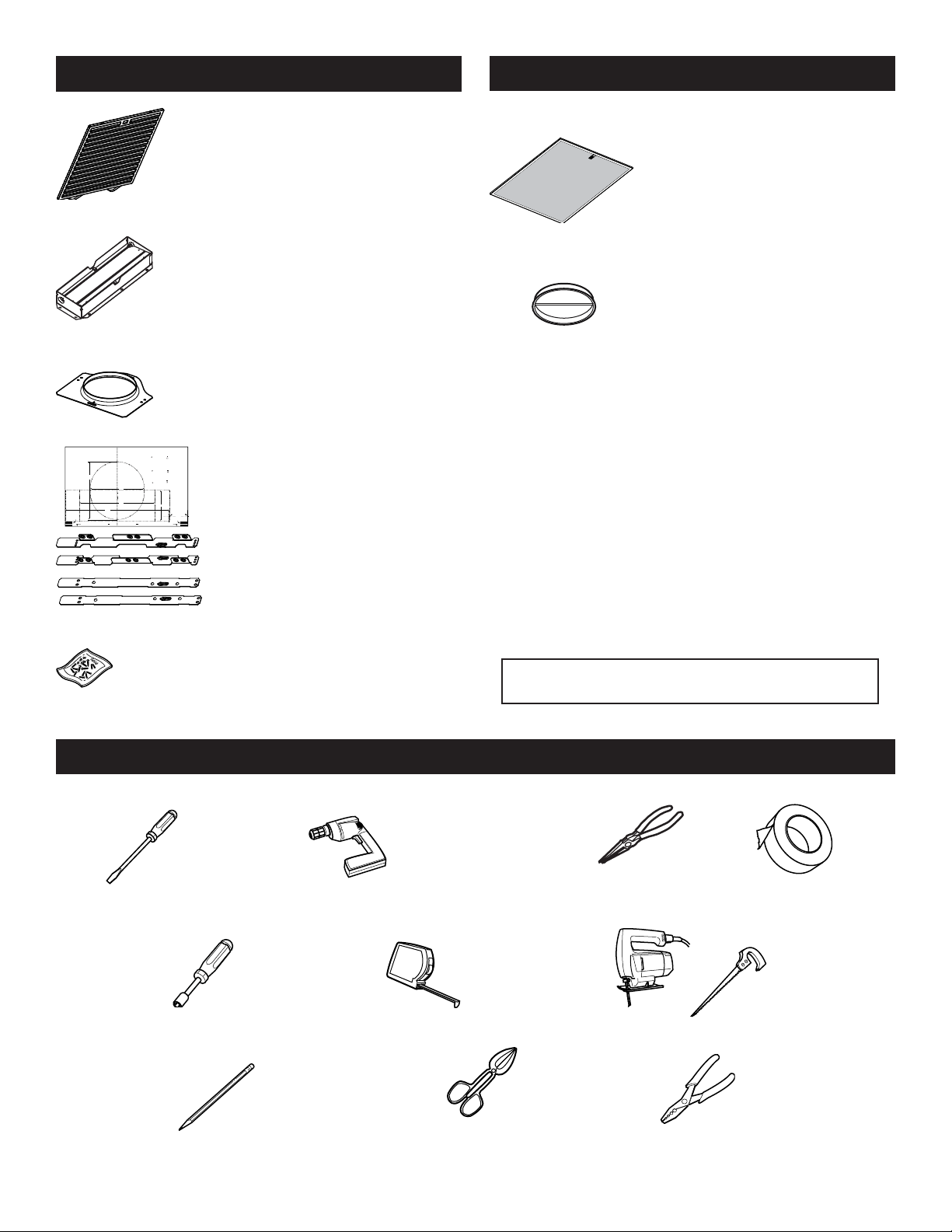

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BE TRANSLATED IN SPANISH

Electrical access hole center

A= single blowerhood

B= double blowerhood

Centre du troupour fil

d’alimentation électrique

A= hotteventilateur simple

B= hotteventilateur double

Tobe translated in Spanish

Electrical access hole center

A= single blowerhood

B= double blowerhood

4¼”

10½”

14½”

8”

7½”

CC

CBend template along graduated

scale when installing to framed

cabinet.

Pour une installation sous une

armoire à fonden retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabariten

conséquence.

Tobe translated in Spanish.

P

C

CABINET FRONT

C

L

AB

= 3¼” x 10”

= 3¼” x 14”

RECTANGULAR DUCTING7” ROUND DUCTING OR

Use this template formarking; do not attempt to cut out the ducting hole through it.

NOTE:These cutouts are clearance holes; they do not need tobe the exact size of ducting.

= 3¼ po x 10po

= 3¼ po x 14 po

CONDUIT RECTANGULAIRECONDUIT ROND DE 7 PO OU

= 3¼ pulg.x 10 pulg.

= 3¼ pulg.x 14 pulg.

CONDUCTO RECTANGULARCONDUCTO REDONDO

DE 7 PULG.O

Utiliser ce gabarit pour marquer vosrepères; ne pas tenter de découper

le trou pour le conduit à traversle gabarit.

NOTE :Les découpes incluent le jeu nécessaire à l’installation; elles ne doivent pas

êtredu format exact des conduits.

Use esta plantilla para crearmarcados; no trate de cortar el

agujero del conductoa través de la plantilla.

NOTA:Tobe translated in Spanish.

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BE TRANSLATED IN SPANISH

Electrical access hole center

A= single blowerhood

B= double blowerhood

Centre du troupour fil

d’alimentation électrique

A= hotteventilateur simple

B= hotteventilateur double

Tobe translated in Spanish

Electrical access hole center

A= single blowerhood

B= double blowerhood

4¼”

10½”

14½”

8”

7½”

CC

CBend template along graduated

scale when installing to framed

cabinet.

Pour une installation sous une

armoire à fonden retrait, utiliser les

lignes pour mesurer l’épaisseur du

décalage causé par le mur de

l’armoire et plier le gabariten

conséquence.

Tobe translated in Spanish.

ELECTRICAL

ACCESS HOLE

LOCATION (B)

(IN CABINET BOTTOM)

CENTER LINE

FOLD TEMPLATE ALONG GRADUATED

SCALE WHEN INSTALLING TO FRAMED

CABINET.

B

VERTICAL

EXHAUST DUCTING

EZ1 installation is designed for use with kitchen cabinets that have the same width designation as the range hood width.

If the cabinet is greater than 1/2” wider than the range hood width, please use the standard installation method.

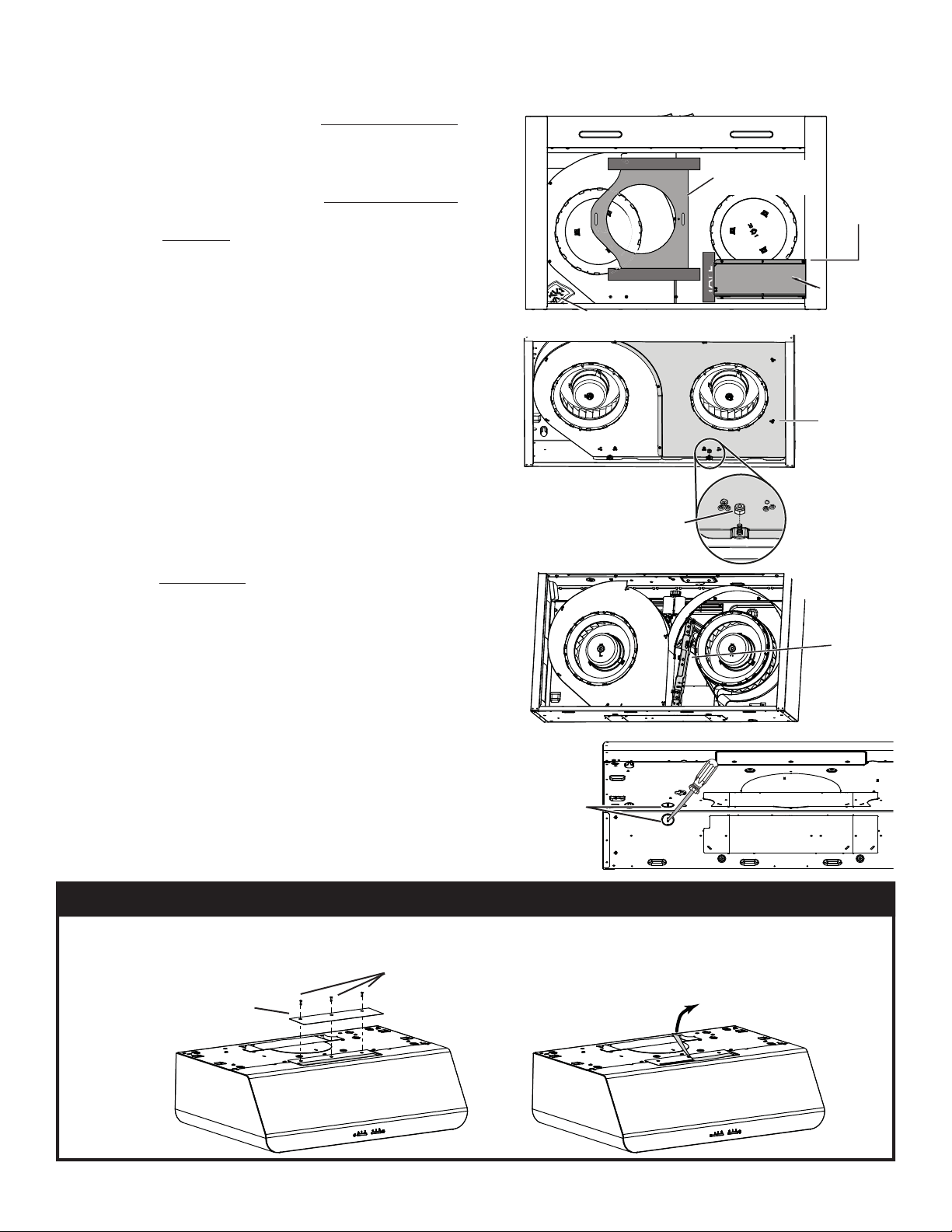

1. Use the proper template for vertical OR horizontal

disharge (included) for placement of ductwork and

electrical cutout in cabinet or wall. For a non-ducted

installation, DO NOT cut a duct access hole, only cut the

hole for electrical wiring. If replacing a hood and plan to

use the existing duct and electrical, steps 2 to 5 may not

be necessary. If so, skip to step 6.

2. Measure and mark the hood center line on cabinet bottom.

3. Align the center line on template with the hood center

line marked on the bottom of the cabinet, placing the

edge (where indicated) of the template against back

wall. When using with framed cabinet for vertical exhaust

installation, fold over rear edge of template equal to the

depth of the cabinet frame at the wall (use graduations

on template, Clocations on template). Tape the template

in place.

NOTE: When facing the installation, Aand B(on

template) must be at right.

ELECTRICAL

ACCESS HOLE

LOCATION (B)

(IN WALL)

CENTER LINE

C

L

AB

Place this edge against

cabinet bottom.

Appuyer ce bord contre le bas

de l’armoire.

Apoyar este borde contra

la base del armario.

= 3¼ pulg.x 10 pulg.

= 3¼ pulg.x 14 pulg.

CONDUCTO RECTANGULAR

= 3¼”x 10”

= 3¼”x 14”

RECTANGULAR DUCTING

= 3¼ po x 10po

= 3¼ po x 14po

CONDUIT RECTANGULAIRE

MARK WHERE INDICATED

FOR THE APPROPRIATE SIZE DUCT OPENING

MARQUER LES REPÈRES AUX ENDROITS INDIQUÉS SELON

LE FORMAT DE CONDUIT UTILISÉ

TITLE TO BE TRANSLATED IN SPANISH

Use this templatefor marking; do not attempt to cut out the ducting hole through it.

NOTE:These cutouts are clearance holes; theydo not need to be the exact size of ducting.

Utiliser ce gabarit pour marquervos repères; ne pas tenter de découper

le trou pour le conduit à traversle gabarit.

NOTE: Les découpes incluent le jeu nécessaire à l’installation;elles ne doivent pas

être du formatexact des conduits.

Use esta plantilla para crearmarcados; no trate de cortar el

agujerodel conducto a través de la plantilla.

NOTA:Tobe translated in Spanish.

Electrical access hole center

A= single blowerhood

B= double blowerhood

Centredu trou pour fil

d’alimentation électrique

A= hotteventilateur simple

B= hotteventilateur double

Tobe translated in Spanish

Electrical access hole center

A= single blowerhood

B= double blowerhood B

ess hole center

wer hood

wer hood

HORIZONTAL

EXHAUST DUCTING

4. Drill a 1/8” dia. pilot hole for house wiring, at Blocation

on template.

5. Use a sharp pencil or 1/8” drill bit to mark the locations

for the appropriate duct access holes (16 locations for 7”

round duct, or 4 corner locations for rectangular duct).

Remove the template.

6. Draw the border for the exhaust ducting by linking its

marks (16 for round duct and 4 for rectangular duct), then

cut the opening in the cabinet bottom (vertical exhaust)

or in the wall (horizontal exhaust). Drill the house wiring

hole by using a 1½” hole saw centered with the pilot hole

previously made in 4.