Seav LRX 2035R User manual

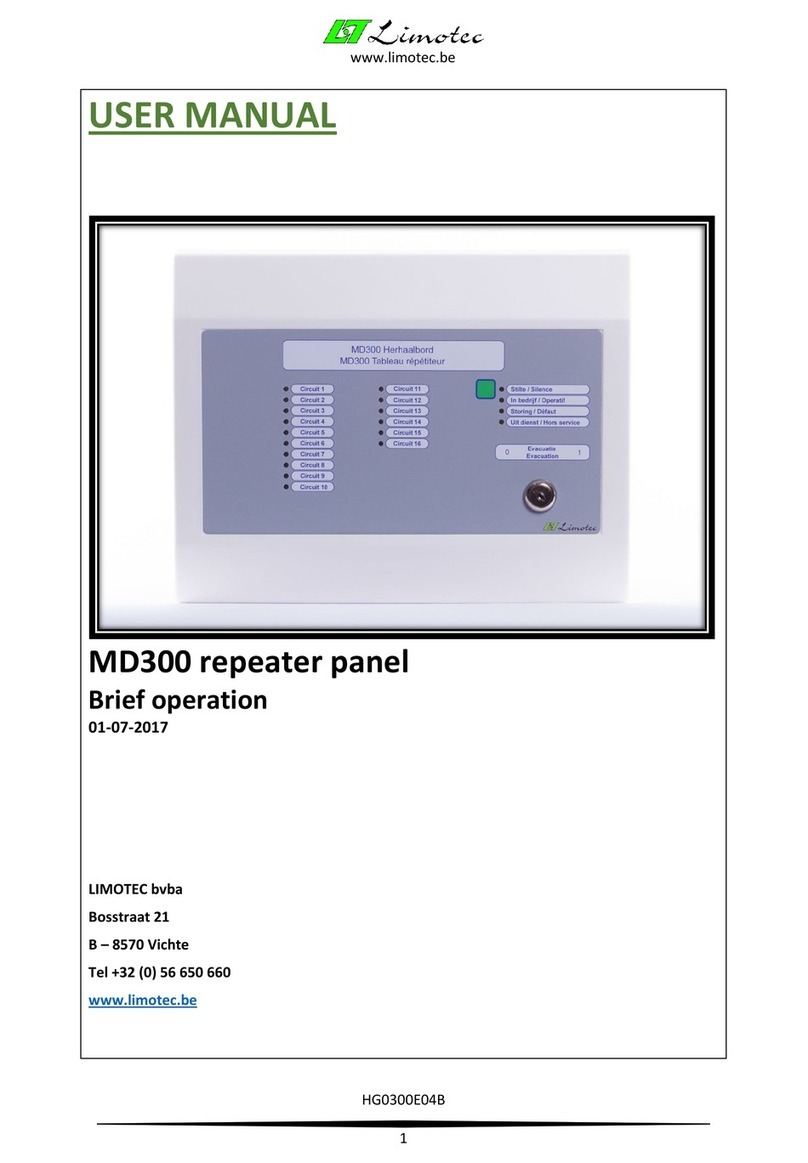

ELECTRONIC PANEL

LRX 2035R

Mono-phase electronic exchange, for the automation of sliding

doors and rolling shutters with an incorporated radio receiver.

- Mod. LG 2035R : Without radio Receiver

- Mod. ( LRQ 2035R ) : 30,875 Mhz

- Mod. ( LR 2035R ) : 306 Mhz

- Mod. ( LR 2035R / 330 ) : 330 Mhz

- Mod. ( LR 2035R / 418 ) : 418 Mhz

- Mod. LRS 2035R : 433,92 Mhz

- Mod. LRS 2035R SET : 433,92 Mhz “narrow band”

( ) This product is designed only for countries in which this use

is allowed

TECHNICAL DATA:

- Power supply: 230 Vac 50Hz 4,5W max.

- Flashing light output: 230 Vac 50Hz

100W Resistive Load max.

50W Inductive Load max.

- Motor output: 230 Vac 50Hz 650 W max.

- Aux. power output: 24 Vac 3 W max.

- Button and safety device input: 24 Vdc

- Working temperature: -10 ÷55 °C

- Radio receiver: refer to type

- Op. transmitters: 12-18 Bit or Rolling Code

- TX max. codes in memory: 60 UP, 60 DOWN or 60 P/P

- Dimension of panel: 110x121x47 mm.

- Container: ABS V-0 ( IP54 ).

TERMINAL BOARD CONNECTION:

CN1 :

1. 230 Vac input (phase)

2. 230 Vac input (Neutral)

3. 230 Vac flash input (Neutral)

4. 230 Vac flash input (Phase)

5. Opening motor output

6. Common motor output

7. Closing motor output

CN2 :

1 : 24 Vac 3 W service feed output.

2 : 24 Vac 3 W service feed output.

3 : Open-close push button input (NA).

4 : Common GND input.

5 : Safety device input (NC).

6 : Aerial earth input.

7 : Aerial hot pole.

I

MPORTANT NOTICE FOR THE INSTALLER

−In order for the receiving part of the radio to function

correctly, in cases where two or more centres are used,

it is advised to install them at a distance of at least 3

metres from each other.

−The centre must not have any type of sectioning

mechanism from the electrical line 230 Vac; it is

therefore the responsibility of the installer to see the

installation of a sectioning device within the plant.

−The fixing of the electricity and connection cables must

be guaranteed by means of the assembly of the cable

press that is supplied in the package.

−The input, which is labelled as normally closed (NC),

must be jumped if not used!!

OPERATING CHARACTERISTICS:

Step by step operation:

By using either the radio control (LED CODE on) or the low

tension button panel (PUL) to operate the gates, commands

will have the following effect:

The first command impulse activates the opening mechanism

until time expiry of the timing motor, the second command

impulse closes the gate, if a command impulse is received

before the time expiry of the timing motor, the direction of

movement of the mechanism will be halted.

A further input implements the re-starting of the motion in the

opposite direction.

Automatic closing:

The control board may be set up automatically to close the

gates.

The set-up procedure is described under the instruction for

setting the delay period.

Safety device:

The control board allows for the connection and control of

Photocells, Tyre sensors (NC).

Command from these devices are ignored during opening

whilst the gate is closing they will reverse the direction of

movement.

If not used the terminals must be jumped.

PROGRAMMING:

SEL button: selects the type of function to be memorised, the

selection is indicated by a flashing Led.

By repeatedly pressing the button it is possible to choose the

desired function. The selection will remain active for 10

seconds indicated by a flashing Led, if no other operations are

executed during this period, the control board will return to its

previous state.

SET button: programmes the information relative the type of

function previously selected with the SEL button.

Led Reference Led off Led on

1) CODE No code Code activated

2) LAMP/CORT. Flashing Courtesy light

3) T. MOT. Unlimited timing Programmed delay

4) T. PAUSA No automatic close With automatic close

1) CODE: (Programming of the radio control)

GB

Functions with one or two remote control commands

It is possible to memorise one or two remote control commands

during the programming stage. One code can be used for a

cyclical function (raising/lowering), whilst two different codes

allows different commands, the first for raising and the second

for lowering.

Programming: The transmission code is programmed in the

following manner: press the SEL button until the LED CODE

flashes, immediately transmit the pre-selected code with the

desired remote control, as soon as the LED CODE begins to

flash rapidly send the second code to be memorised, when the

LED CODE remains lit, the programming is complete. If the

second code is not sent within 10 seconds the control unit will

exit the programming phase and select the function with only

one code of the remote control. When 60 codes have been

stored all 4 LEDs will flash, indicating that no other codes can

be stored.

Programming through Radio command:

This procedure, consents to enable the programming, without

direct intervention of the SEL task on the panel, but executing

the operation at a distance, allows the programming of

transmission codes without the having to use the SEL button

on the central direct.

The ability of programming is executed in the following manner:

send in a continuous manner for max. 10 seconds the codes of

the radio command previously memorised, at the same time

the panel will enter into programming mode as explained

above.

Ability of programming through Radio command:

The panel is furnished by the builder with the radio command

disabled, if you wish to enable the function, proceed in the

following manner: the panel board is powered by an output of

230VAC, keeping the SELL task pressed, at the same time you

will obtain a brief flashing of all the Leeds and the programming

will be complete.

If you wish to disable the function previously enabled, repeat

the operation or follow the RESET procedure.

Cancellation: To cancel all stored codes press the SEL button

and LED CODE will start to flash. Then press the SET button.

The procedure is now complete and LED CODE will stop

flashing.

2) FLASHING / COURTESY LIGHT: (Selection of the flashing

light or the courtesy light)

The central has a 230 Vac output, for connection to a flashing

light or a courtesy light. The central is supplied by the

manufacturer with the flashing function predisposed.

If you wish to set up the courtesy light function, proceed as

follows:

Go to the SEL button, when the LED LAMP / CORT light

flashes then press SET, at the same time the

LED/LAMP/CORT light will light up permanently. Repeat the

operation if you wish to put the previous configuration back into

operation.

Flashing function: The 230 Vac output will be activated each

time that the automation is moving, for the duration of the motor

time. In cases where the time of pause is memorised, the

flashing light will also be active during the pause.

Functioning of the Courtesy light: The 230 Vac output will be

activated for the entire duration of 3 minutes, each time that an

ascent command is given.

3) T. MOT: (Programming the motor operating time max. 4

minutes)

The control unit is factory supplied with a working time motor

predefined equal to 30 sec.

If a reprogramming of the motor operating time is needed, it

must be effected through the closed frame in the following

manner: set the SEL button on the T. MOT flashing led, then

continuously press the SET button, the rolling shutter will start

the opening; when you have reached the required height,

release the SET button key and at the same time the motor

time storage will be completed and the T. MOT. Led will remain

lit and fixed. If you want an infinite motor time, using the SEL

task when the Led T.MOT is flashing press for less than 1

second the SET button, at the same time the Led will shut off

and the operation will be completed. It is advisable to memorise

a time that is a few seconds longer after the frame has reached

the end.

4) T. PAUSE:

(Maximum programmed automatic wing closing 4

minutes)

The manufacturer furnishes the board with an automatic

closure (pause time equal to 15 sec.). If a reprogramming of

the automatic closing time is needed, it must be effected in

closed frame in the following manner: press the SEL button

until the T. PAUSE led flashes, then press and hold down the

SET button for a period equal to the desired pause interval

between closing and opening operations, at the expiry of the

desired time leave the SET button, at the same time the

memorisation of automatic closing time will be determined and

the Led T. PAUSE will be lit.

If decided not to have the automatic closing, take position on

the flash of the Led T. PAUSE after press the SET task for less

than a second, at the same time the Led will shut off and the

operation will be concluded.

RESET :

If it necessary to reset the program board to its default values,

that is with no memorised data, press both SEL and SET

buttons continuously, all the RED LEDs will flash at once

DIAGNOSTIC :

In correspondence to all input commands in low tension, the

centre uses Led signals for every input command to allow rapid

status control. Logic of function: a lit Led means input closed,

an unlit light means input open.

:

Electronic exchange:

LG 2035R - LRS 2035R - LRS 2035R SET

comply with the requirements of Directives R&TTE

99/5/EC, EMC 2004/108/EC, LVD 2006/95/EC.

Rev. 1.6 del 15-05-12

This manual suits for next models

7

Other Seav Control Panel manuals