Telect LCX Series User manual

Bulkhead Style Optical Panels

Telect LCX Series Installation Guide

LCX

Bulkhead-style Hinged Fiber Optical Panels

2

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

Contents

CHAPTER 1: LCX FIBER PANELS 5

1.1 General Information 5

1.1.1 LCX Fiber Splice Panels 5

1.1.1.1 LCX 1RU Fiber Splice Tray –24-Splice Capacity 5

6

1.1.1.2 LCX 2RU, 3RU & 4RU Fiber Splice Trays 6

1.1.2 LCX Fiber Panel 8

1.1.3 Angled and Standard Adapter Plates 9

1.2 Special-Function Modules 9

1.2.1 MTP Breakout Modules 9

1.3 Drawings 10

CHAPTER 2: APPLICATIONS 15

2.1 Interconnecting IFC to Network Elements 15

2.2 Interconnecting Network Elements 15

2.3 Cross-connecting Network Elements 16

2.4 Cross-connecting Combinations 16

2.5 Interconnecting & Cross-connecting with Special-Function Modules 17

CHAPTER 3: PANEL INSTALLATION 18

3.1 Installation Considerations 18

3.1.1 Location & Space 18

3.1.2 Tools & Equipment 18

3.1.3 Inspection 18

3.2 Panel Installation Procedure (All Except 1RU) 19

3.3 Panel Installation –1RU 21

3.4 LCX-H Bulkhead Direction Change 22

CHAPTER 4: FIBER INSTALLATION 23

4.1 Fiber Installation Overview 23

4.2 Fiber Installation (All Except 1RU) 24

4.2.1 Splicing 24

4.2.1.1 Installing & Routing IFC Fiber 24

LCX

Bulkhead-style Hinged Fiber Optical Panels

3

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

4.2.1.2 Installing & Routing Network Element Fiber 26

4.2.1.3 Splicing 27

4.2.2 Patching 28

4.3 Fiber Installation –1RU 28

4.3.1 Splicing 28

4.3.1.1 Installing & Routing IFC Fiber 28

4.3.1.2 Installing & Routing Network Element Fiber 29

4.3.1.3 Splicing 30

4.3.2 Patching 31

4.3.3 Patching in the LCX-H 31

CHAPTER 5: SERVICE 32

5.1 Owner Maintenance 32

5.2 Technical Support 32

5.3 In-Warranty Service 32

5.4 Out-of-Warranty Service 32

5.5 Repacking the Shipment 32

5.6 High Insertion Loss and the Importance of Cleaning Connectors & Adapters 33

5.6.1 How to Clean Connectors & Adapters 33

CHAPTER 6: ACCESSORIES 34

6.1 Accessories and Replacement Parts 34

LCX

Bulkhead-style Hinged Fiber Optical Panels

4

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

List of Figures

Figure 1: LCX Fiber Panels...................................................................................................................................................................5

Figure 2: LCX 1RU Fiber Panel. ...........................................................................................................................................................5

Figure 3: 1RU Fiber Splice Tray..........................................................................................................................................................................6

Figure 4: 1RU Splice Tray (Right Corner Tray).................................................................................................................................................6

Figure 5: 1RU Splice Tray –Fiber Routing............................................................................................................................................6

Figure 6: 1RU Cable Clamp Fits 12 to 24 Fiber IFC .............................................................................................................................6

Figure 7: LCX Splice Panel, 2RU –24Termination Capacity................................................................................................................7

Figure 8: LCX Splice Panel, 3RU –48Termination Capacity................................................................................................................7

Figure 9: LCX Splice Panel, 4RU –72 to 96Termination Capacity.......................................................................................................7

Figure 10: Splice Tray (RightCorner View)...........................................................................................................................................7

Figure 11: Splice Tray (Fiber Routing)...................................................................................................................................................7

Figure 12: Optional Cable Clamp Fits All Sizesof IFC..........................................................................................................................7

Figure 13: LCX Patch Panel, 1RU –12 Terminations......................................................................................................................................8

Figure 14: LCX Patch Panel, 2RU –24 Terminations......................................................................................................................................8

Figure 15: LCX Patch Panel, 3RU –48 Terminations......................................................................................................................................8

Figure 16: LCX Patch Panel, 4RU –72, 96 or 144 Terminations....................................................................................................................8

Figure 17: Patch Plates.........................................................................................................................................................................8

Figure 18: AngledAdapter Plate ...........................................................................................................................................................9

Figure 19: WDM & Splitter Modules......................................................................................................................................................9

Figure 20: MTP Breakout Module .........................................................................................................................................................9

Figure 21: 1RU LCX Chassis................................................................................................................................................................10

Figure 22: 2RU LCX Chassis................................................................................................................................................................11

Figure 23: 3RU LCX Chassis................................................................................................................................................................12

Figure 24: 4RU LCX Chassis................................................................................................................................................................13

Figure 25: Pull-Out & Swing-Out Clearances........................................................................................................................................14

Figure 26: Interconnecting/Splicing Facility Cable to Network Elements..............................................................................................15

Figure 27: Interconnecting Network Elements in a LCX Fiber Patch Panel..........................................................................................15

Figure 28: Cross-Connecting Network Elements..................................................................................................................................16

Figure 29: Cross-Connecting IFC toNetwork Elements .......................................................................................................................16

Figure 30: Interconnecting/Cross-Connecting Along with WDM/Splitter Modules ................................................................................17

Figure 31: Removing Knockouts & Installing Plastic Grommets...........................................................................................................19

Figure 32: Installing a Standard Split Arc..............................................................................................................................................19

Figure 33: Installing a Standard Isolation Hook Kit...............................................................................................................................19

Figure 34: Installing an Optional Arc Kit................................................................................................................................................19

Figure 35: Mounting LCX Panel to Rack...............................................................................................................................................20

Figure 36: Installing Adapter Pack & SpecialFunction Modules...........................................................................................................20

Figure 37: Inserting Cabling Rings........................................................................................................................................................20

Figure 38: Cable Restraint Layout (Top View ofChassis Bottom).........................................................................................................21

Figure 39: Mounting 1RU LCX Panelto Rack.......................................................................................................................................21

Figure 40: Mounting 1RU LCX Combo Panelsto Rack ........................................................................................................................21

Figure 41: Installing Patch Plates & Special Function Modules in a 1RU.............................................................................................21

Figure 42: LCX-H Direction Change (Open Bulkhead andRemove Screws) .......................................................................................22

Figure 43: LCX-H Direction Change (Remove Screws on theFixed Swing).........................................................................................22

Figure 44: LCX-H Direction Change (RemoveAssembly and Rotate)..................................................................................................22

Figure 45: LCX-H Direction Change (Remove Hanger andInstall Opposite) .......................................................................................22

Figure 46: LCX-H Direction Change (Reinstall Screws andClose Bulkhead).......................................................................................22

Figure 47: IFC Clamp............................................................................................................................................................................24

Figure 48: IFC Breakout Length (2RU through 4RU)............................................................................................................................24

Figure 49: Installing IFC for Splicing.....................................................................................................................................................25

Figure 50: Cable Placement and Securing ...........................................................................................................................................26

Figure 51: Splice Tray (RightCorner View)...........................................................................................................................................27

Figure 52: Splice Tray(Fiber Routing) ..................................................................................................................................................27

Figure 53: Installing Interconnects or Cross-Connects in an LCX FiberPatch Panel...........................................................................28

Figure 54: IFC Breakout Length (1RU).................................................................................................................................................29

Figure 55: IFC Breakout Length (1RU).................................................................................................................................................29

Figure 56: Cable Routing ......................................................................................................................................................................29

Figure 57: 1RU Splice Tray (Right Corner Tray)...............................................................................................................................................30

Figure 58: 1RU Splice (Fiber Routing)..................................................................................................................................................30

Figure 59: Patching the LCX-H.............................................................................................................................................................31

Figure 60: Patching the LCX-H.............................................................................................................................................................31

Figure 61: Cleaning the Adapter ...........................................................................................................................................................33

LCX

Bulkhead-style Hinged Fiber Optical Panels

5

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

Chapter 1: LCX Fiber Panels

1.1General Information

Telect manufactures LCX fiber splice panels and LCX fiber patch panels of various densities to suit

network fiber splice, patching and routing requirements.

•2RU through 4RU models vary in density from 24 to 144 fiber terminations. All have spring-

hinged removable front and rear doors (Fig. 1). Knockout holes at the top and bottom of the panel

allow for routing from splice panels to patch panels (and between patch panels) vertically within

the rack. Hole pattern and positions are compatible with panels offered by other manufacturers,

allowing expansion and replacement of those systems using the LCX panels.

•Interconnection and cross-connection cabling from above or below enter at the two front corners

of each LCX panel via isolation hooks and/or radius control arcs (sold separately) installed on-site

to suit the application and entry/exit direction. Eight split arcs and 24 snap-in cable rings are

standard with each panel. Telect also offers optional kits (KIT-CMHOOK, KIT-CMRHOOK, KIT-

CMARK) to satisfy cable management practices requiring multiple arcs or guide posts to separate

and isolate groups of fiber cables.

1RU models have densities up to 24 fiber terminations. Instead of front or rear doors, 1RU panels have a

removable sliding drawer that can be extended at the front or rear of the chassis to maximize access to

fiber connections. Pivoting arcs at corner entries and exits provide cable management. Entry and exit

positions are compatible with entries and exits of other Telect LCX panels and those of other

manufacturers.

1.1.1 LCX Fiber Splice Panels

Telect offers four sizes of LCX fiber splice panels (1RU-4RU) to accommodate up to 144 splices. Each

removable splice tray (LCX-S-HSF) holds up to 24 splices along with about five feet (1½ meters of fiber

cable storage:

•For a 1RU splice tray, all fiber (subunit, cable and strands) is stored on the tray

•For a 2RU, 3RU and 4RU splice tray, all subunit and interconnection cable storage is below the

trays

Trays easily slip free of the panels to allow splicing. Storage spools or arcs, along with splice holders, are

mounted directly on the tray, eliminating the need for special splice cassettes.

1.1.1.1 LCX 1RU Fiber Splice Tray –24-Splice Capacity

LCX 1RU fiber splice trays use sets of pivoting arcs for routing and storing both fiber subunits and

interconnection cable.

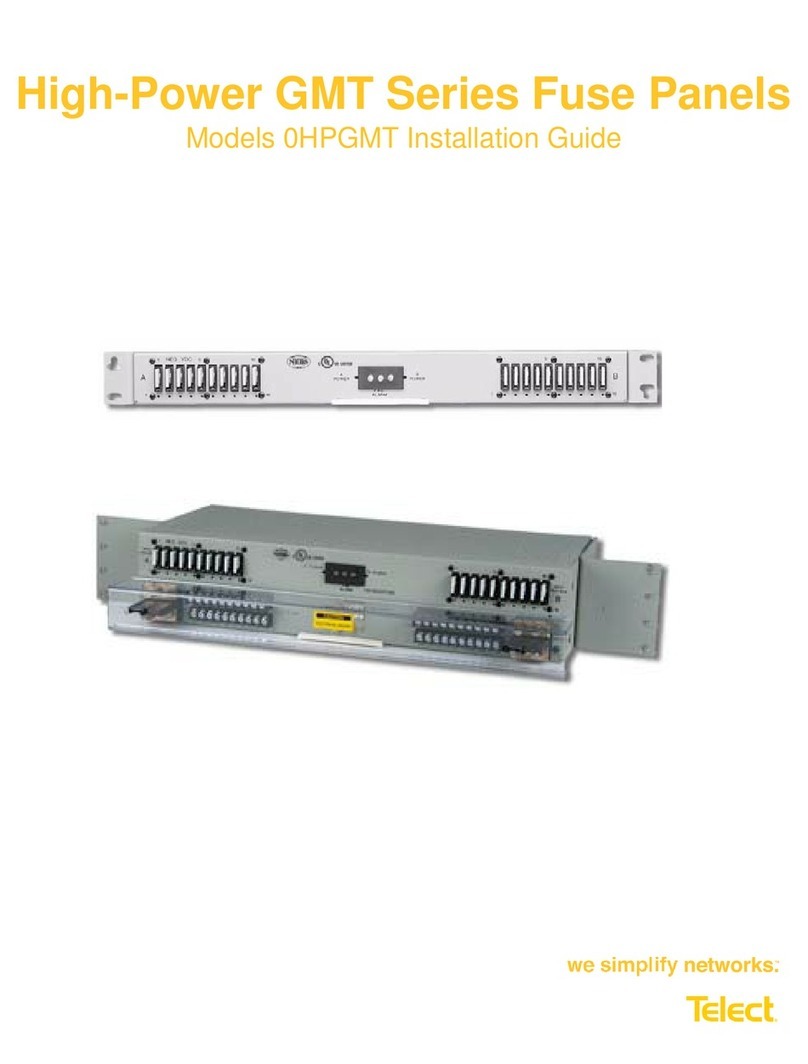

Figure 1: LCX fiber panels

(Common physical features of 2RU-4RU panels)

Brackets (2) for Either

19-in. or 23-in. Rack

Double-Hung Drawer Pulls Out

from Front or Rear

Pivoting Arcs (8) Maintain

Bend Radius

Twist Latch

Figure 2: LCX 1RU fiber panel

LCX

Bulkhead-style Hinged Fiber Optical Panels

6

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

Arcs (14)

Each of Two Splice Holders

Holds 12 Splices

Splice Cover

IFC stranded cable from the splice vault is secured at either rear corner of the LCX splice panel by an

optical cable clamp. A single clamp comes with two rubber bushings to fit either a 12- or 24-fiber IFC

riser/plenum cable.

The following illustration shows a clamp holding an IFC cable installed on the rear rack flange near the

entry/exit of an LCX 1RU splice panel. The interconnection cables enter the tray at one of the other

corners of the splice tray.

1.1.1.2 LCX 2RU, 3RU & 4RU Fiber Splice Trays

A 144-splice 4RU LCX panel (LCX-S141) that houses six splice trays is available but not pictured.

•24-splice 2RU LCX panel, 1 splice tray

•48-splice 3RU LCX panel, 2 splice trays

•72-splice 4RU LCX panel, 3 splice trays

•96-splice 4RU LCX panel, 4 splice trays

2RU, 3RU and 4RU fiber splice trays use storage spools to route and store stranded fiber.

The following figures show termination capacities of LCX 2RU, 3RU and 4RU fiber splice panels.

Figure 3: 1RU fiber splice tray

Figure 4: 1RU splice tray

(Right corner tray)

Tie-Down for Cable Ties*

Tie-Down for Cable Ties*

From

IFC

To Network

Elements * Use either lacing or cable ties to secure cable subunit, flexible tubing, and/or sheathing.

Figure 5: 1RU splice tray, fiber routing

Cable Clamp

24-Fiber IFC

Network Cable

Leave sufficient

slack to allow drawer

to open.

Figure 6 –1RU cable clamp fits 12- to 24-fiber IFC

LCX

Bulkhead-style Hinged Fiber Optical Panels

7

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

IFC stranded cable from the splice vault is secured at either rear corner of the LCX splice panel by an

optional cable clamp. A single clamp, KIT-CLMP, fits all sizes of IFC riser and plenum cable. (Fig. 12

shows a clamp holding a 96-strand IFC cable installed at the left rear corner of an LCX splice panel.)

Cable rings in the rear portion of the panel lead the IFC tubes to one of the front corners of the splice

trays. The interconnection cables enter the tray at the other front corner of the 2RU, 3RU and 4RU splice

tray.

Figure 7: 2RU LCX splice panel, 24-termination capacity

Figure 8: 3RU LCX splice panel, 48-termination capacity

Figure 9: 4RU LCX splice panel, 72- to 96-termination capacity

Ea c h of tw o s p lice holde rs

ho ld s 112 splice s .

T ie -D o w n L o c at io ns

fo r I nc o m in g /O u tg oi ng C a bl e*

Spoo ls (2)

Sp li c e Co v e r

*Use either lacing or cable ties to secure cable

subunit, flexible tubing, and/or sheathing

Figure 10: Splice tray (right corner view)

Tie-Down Locations for Cable Ties

To Network Elements * Strands are always routed clockwise on the left spool and counter-clockwise on the right spool.

Pigtail from NE is wound around

From IFC

the other spool.*around one of the spools...

Stranded fiber from IFC is wound

Figure 11: Splice tray (fiber routing)

Cable Clamp

96-Fiber IFC

Figure 12: Optional cable clamp fits all IFC sizes

LCX

Bulkhead-style Hinged Fiber Optical Panels

8

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

1.1.2 LCX Fiber Panel

LCX fiber patch panels come in six termination capacities and can be loaded with various patch plates

(Figs. 13-16).

In addition to patch panels with or without installed patch plates, Telect offers a special factory-configured

4RU patch panel with 144 discrete SC adapters.

All panels can accommodate SC/UPC, SC/APC, FC/UPC, FC/APC, LC/UPC or ST/UPC patch plates.

Patch plates snap into the chassis’ bulkhead:

•SC/UPC, SC/APC, FC/UPC, FC/APC, ST/UPC, LC/APC and MPO are available in patch plates

with six or eight adapters

•LC/SC is available in patch plates with 12 adapters

•LC/UPC and LC/APC are available in patch plates with 24 adapters

•MTP/MPO feed through patch plates are available with six and eight adapters

All adapters are available in multimode versions and include dust covers. Like the chassis, most patch

plates are available in white or black (Fig. 17).

Figure 13: 1RU LCX patch panel,

24 SC terminations, 24 LC terminations

Figure 14: 2RU LCX patch panel, 24 terminations

Figure 15: 3RU LCX patch panel, 48 terminations

Figure 16: 4RU LCX patch panel, 72, 96 or 144 terminations

Six-adapter patch plate

(SC, FC, ST)

Eight-adapter patch

plate (SC, FC, ST)

12-adapter patch plate

(LC only)

Eight-adapter patch

plate

(MPO)

12-adapter patch plate

(SC duplex)

24-adapter patch plate

(LC quad)

Figure 17: Patch plates

LCX

Bulkhead-style Hinged Fiber Optical Panels

9

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

1.1.3 Angled and Standard Adapter Plates

Angled Patch

Plates

6-port

8-port

12-port

16-port

24-port

SC/UPC

055-0000-6A10

055-0000-6A80

055-0000-6A210

SC/APC

055-0000-6A70

055-0000-6A90

055-0000-6A270

LC/UPC

055-0000-5A10

055-0000-5A11

055-0000-5A210

LC/APC

055-0000-5A90

055-0000-5A91

055-0000-5A290

FC/UPC

055-0000-2A10

055-0000-2A80

FC/APC

055-0000-2A70

055-0000-2A90

ST/UPC

055-0000-3A10

055-0000-3A80

MTP/MPO

055-0000-MTA06

055-0000-MTA08

SC MM

055-0000-6A20

055-0000-6A82

055-0000-6A22

LC MM

055-0000-5A12

055-0000-5A13

055-0000-2A412

Blank adapter plate: 055-0000-9000; Add -BLK for black adapter plates

All standard and angled adapter plates are LGX® compatible and fit in:

•Telect LCX and LCX-H, Corning LDC®, TE/ADC LSX®

•Leviton Lightspace®, OFS LGX®

•AFL WME, XFM® and LS series patch panels

•Any other LGX-compatible panel

1.2 Special-Function Modules

Empty LCX fiber patch panels can be configured on-site with adapter packs and special function

modules. Telect offers a full line of standard-size Wavelength Division Multiplexing (WDM) modules and

splitter modules that can be used in place of adapter packs.

1.2.1 MTP Breakout Modules

Telect offers both MTP and MPO cassettes that are LGX compatible.

Standard Adapter Plates

Part Number

Patch plate, 6-port, FC/UPC

055-0000-2010

Patch plate, 6-port, FC/APC

055-0000-2070

Patch plate, 8-port, FC/UPC

055-0000-2080

Patch plate, 8-port, FC/APC

055-0000-2090

Patch plate, 6-port, ST/UPC

055-0000-3010

Patch plate, 6-port, ST MM

055-0000-3020

Patch plate, 8-port, ST/UPC

055-0000-3080

Patch plate, 12-port, LC/UPC

055-0000-5010

Patch plate, 12-port, LC MM

055-0000-5012

Patch plate, 12-port, LC/APC

055-0000-5090

Patch plate, 6-port, SC/UPC

055-0000-6010

Patch plate, 6-port, SC MM

055-0000-6020

Patch plate, 6-port, SC/APC

055-0000-6070

Patch plate, 8-port, SC/UPC

055-0000-6080

Patch plate, 8-port, SC MM

055-0000-6082

Patch plate, 8-port, SC/APC

055-0000-6090

Patch plate, blank

055-0000-9000

Figure 18: Angled adapter plate

Figure 20: MTP breakout module

Figure 19: WDM & splitter modules

LCX

Bulkhead-style Hinged Fiber Optical Panels

10

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

1.3 Drawings

1.00 [25.4]

1.25 [31.7]

15.06 [382.4]

23.04 [585.3]

22.35 [567.8]

19.04 [483.7]

18.36 [466.3]

0.12 [2.9]

1.73 [44.0]

1.64 [41.6]

3.55 [90.2]

1.50 [38.1]

0.30 [7.6]

0.06 [1.4]

11.00 [279.4]

REAR VIEW

(ROTATED)

NOTE: Dimensions are in in. (mm).

TOP VIEW

FRONT VIEW

Figure 21: 1RU LCX chassis

LCX

Bulkhead-style Hinged Fiber Optical Panels

11

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

0.19 [4.7]

REAR VIEW

(ROTATED)

NOTE: Dimensions are in in. (mm).

10.74 [272.9]

7.38 [187.4]

0.12 [3.1]

0.24 [6.2]

Ø1.50 [Ø38.1]

Ø0.26 [Ø6.5]

0.99 [25.3] 0.24 [6.2] 0.12 [2.9]

TOP VIEW

FRONT VIEW

0.18 [4.7]

0.19 [4.8]

0.19 [4.7]

1.76 [44.6] 2.01 [51.0]

17.03 [432.5]

23.00 [584.2]

22.31 [566.7]

19.00 [482.6]

18.28 [464.3]

3.21 [81.6]

1.50 [38.1]

0.10 [2.5]

3.26 [82.8]

3.45 [87.6]

Figure 22: 2RU LCX chassis

LCX

Bulkhead-style Hinged Fiber Optical Panels

12

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

4.92 [124.8]

0.09 [2.4]

0.19 [4.7]

REAR VIEW

(ROTATED)

NOTE: Dimensions are in in. (mm).

10.75 [273.0]

3.21 [81.6]

1.50 [38.1] 7.38 [187.5]

0.12 [2.9]

0.24 [6.2]

Ø1.50 [Ø38.1]

Ø0.26 [Ø6.5]

0.99 [25.2] 0.24 [6.2] 0.12 [2.9]

19.00 [482.6]

23.00 [584.2]

22.31 [566.7]

18.28 [464.3]

2.01 [51.0]

1.76 [44.6]

TOP VIEW

FRONT VIEW

17.03 [432.5]

0.18 [4.7]

0.19 [4.8]

0.19 [4.7]

Figure 23: 3RU LCX chassis

LCX

Bulkhead-style Hinged Fiber Optical Panels

13

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

Ø1.50 [Ø38.1]

Ø0.26 [Ø6.5]

0.09 [2.4] 0.19 [4.7]

6.72 [170.6]

0.17 [4.3]

1.29 [32.9]

REAR VIEW

(ROTATED)

NOTE: Dimensions are in in. (mm).

10.72 [272.4]

3.21 [81.6]

7.36 [186.9]

0.12 [2.9]

0.24 [6.2]

0.24 [6.2] 0.12 [2.9]

3.00 [76.1]

1.76 [44.6]

TOP VIEW

FRONT VIEW

17.03 [432.5] 0.19 [4.8]

0.19 [4.7]

23.00 [584.3]

22.31 [566.8]

19.01 [482.8]

18.32 [465.3]

Figure 24: 4RU LCX chassis

LCX

Bulkhead-style Hinged Fiber Optical Panels

14

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

R6.85 [R174.0]

R6.85 [R174.0]

R5.05 [R128.3]

R5.05 [R128.3]

R3.39 [R86.2]

R3.39 [R86.1]

4.73 [120.2] 5.69 [144.6]

1RU (Top View)

2RU (Right-Side View)

3RU (Right-Side View)

4RU (Right-Side View)

FRONT REAR

Figure 25: Pullout & swing-out clearances

LCX

Bulkhead-style Hinged Fiber Optical Panels

15

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

Chapter 2: Applications

2.1 Interconnecting IFC to Network Elements

Figure 26 shows a simple interconnection scheme where OSP is spliced at a vault to IFC plenum or riser

cable, which is then spliced at a LCX fiber splice panel to the network elements.

Note: Stranded or ribbon fiber should always enter or leave LCX panels in tied-down tubes, sheathed

cable or flex tubing.

2.2 Interconnecting Network Elements

In Figure 27, fiber from one set of network elements is interconnected to a second set.

To Network Elements

LCX Fiber Splice Panel

Splice Vault

IFC

OSP

Subunit Tube

900µm

2 - 3 mm

Sheathed

Cable

Figure 26: Interconnecting/splicing facility cable to network elements

To/From NE1s

From/To NE2s

Multifiber Sheathed

Cable

LCX Fiber Patch Panel

Use rings to help guide

and organize strands,

ribbon, tubing, and

cable into smooth, neat

groups.

Cables and tubes must be secured to tie

downs using supplied or other restraint

on entering and leaving panel

Tie Down for Restraint

Velco-Style Retrains

are Supplied

2 mm, 3 mm , or

Figure 27: Interconnecting network elements in an LCX fiber patch panel

LCX

Bulkhead-style Hinged Fiber Optical Panels

16

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

2.3 Cross-connecting Network Elements

In a variation of 2.2 Interconnecting Network Elements, NE1s and NE2s are connected to the rear of two

LCX fiber patch panels with the fronts reserved for patch cords to cross-connect the two.

Figure 28 shows a stylized version of this application.

2.4 Cross-connecting Combinations

LCX fiber patch and splice panels can be used in

combination to cross-connect IFC to network

elements.

Figure 29 shows a 48-fiber LCX combination panel

(a 48-fiber LCX splice panel bolted to a 48-fiber LCX

patch panel). After the incoming IFC is spliced, the

fiber strands are passed through the 1.5-inch (38.1

mm) diameter hole in the top of the splice shelf to

the patch shelf.

Flexible edge protectors are used to protect the

unsheathed fiber strand passing through holes to an

upper panel.

NOTE: If you create your own combination LCX

patch and splice panel on-site, remember to remove

knockout plugs at the top and bottom of LCX panels

before installing panels in racks. Knockouts can be

removed and flexible edge protectors can be

installed around the edge of holes after panels are

racked; however, it is easier before panels are

racked.

Avoid removing the knockouts on the top of the top-

most and bottom of the bottom-most LCX

panels. The knockout plugs also provide fire

abatement.

The hardware for connecting the patch splice together is not included when purchased separately.

LCX Fiber Patch Panel

Network

Element 1

I

O

Patch Cords

FrontRear Front Rear

NE2 PigtailsNE1 Pigtails

Figure 28: Cross-connecting network elements

48-F ib er IFC

T o N E s

Sheathed Cable

or Patch Cords

Flexible edge protectors

installed around access

hole edges of 3RU and

4RU combo

Use flex tubing or other

sheathing wherever possible

to protect unsheathed fiber

strands and ribbon.

Subunit

Holes allow panels to be

bolted together and handled

as a unit* Tie Downs. Use Velcro-style strips,

(supplied) or other restraint

wherever cable or tubing enters

or exits panels or trays. Never

restrain unprotected fiber (individual

strands or ribbon); always place strands

or ribbon in protective tubing before restraining.

Leave fire-abatement knockouts in

place at the top of the top-most LCX

panel and at the bottom of the

lower-most panel.

*Combination LCX panels (patch panel on top; splice panel on bottom) are bolted together at the factor y. Combination 3RU and 4RU panels are bolted

top to bottom as shown here. Combination 1RU panels are bolted together by a special rack bracket.

Dimples with bolt holes

Figure 29 –Cross-connecting IFC to network elements

LCX

Bulkhead-style Hinged Fiber Optical Panels

17

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

2.5 Interconnecting & Cross-connecting with Special-Function Modules

Wavelength Division Multiplexing (WDM) and splitter modules can be used in LCX panels.

Figure 30 shows one way a 48-fiber IFC is spliced and then interconnected via splitters/WDMs to network

elements.

Three 3RU LCX configurable panels with dual, 1-to-3 splitters (or dual WDMs) are required for splitting/

de-multiplexing the 48 incoming fiber signals.

Dedicated LCX patch panels can be used to interconnect/cross-connect the split/de-multiplexed signals

with the network elements. In such case:

•Splitting 48 signals three ways requires a 4RU LCX patch panel with 144 adapters

•De-multiplexing 48 signals into two wavelengths requires a 4RU LCX patch panel with 96

adapters

Three, 3RU LCX Configurable Patch Panels

with eight, 1-to-3 dual splitters can be used

to terminate spliced strands from a

single 48-fiber LCX Fiber Splice Panel.

A single, factory-configured 4RU Fiber

Patch Panel can be used for centralized

patching of outputs from the splitters.

One of Three, 3RU LCX Configurable Patch Panels

144-Fiber, 4RU LCX Patch Panel

48-Fiber, 3RU LCX Fiber Splice Panel

48-Fiber IFC

To 144 NEs

Figure 30: Interconnecting/cross-connecting with WDM/splitter modules

LCX

Bulkhead-style Hinged Fiber Optical Panels

18

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

Chapter 3: Panel Installation

3.1 Installation Considerations

WARNING! To avoid eye damage or blindness, never look directly into fibers or connectors.

ADVERTENCIA! Para evitar leslones oculares o ceguera, nunca mire directamente a las fi bras o

conectores.

ATTENTION! Pour éviter toute lésion occulaire ou cécité, ne regardez jamais directement dans les

fibres ou dans les connecteurs.

ALERT! This product must be installed and maintained by qualified technicians.

ALERT! These instructions presume you have verified that the Telect equipment being installed is

compatible with the rest of the system, including power, ground, circuit protection, signal

characteristics, equipment from other vendors and local codes or ordinances.

3.1.1 Location & Space

LCX fiber panels adapt to standard 19-inch, 23-inch or ETSI racks with WECO, EIA or ETSI spacing and

nominal 3¼-in. extensions beyond the front rack flange.

Plan the input/output, upward/downward (cable feed) layout of each panel and its position in the rack

before beginning LCX panel installation. If you plan to pass fiber strands, cable and/or tubing through the

knocked-out holes in the tops and bottoms of the panels, the panels should be mounted in contiguous

vertical rack spaces.

3.1.2 Tools & Equipment

No special tools required.

3.1.3 Inspection

Please read and understand all instructions before starting installation. If you have questions, contact

When you receive the equipment, carefully unpack it and compare it to the packaging list. Please report

any defective or missing parts to Telect.

Telect is not liable for transit damaged. If the product is damaged, please report it to the carrier and

contact Telect.

LCX

Bulkhead-style Hinged Fiber Optical Panels

19

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

3.2 Panel Installation Procedure (All Except 1RU)

Prepare, mount and insert modules and cable management rings

in all panels in a rack before cabling any panels in the rack.

1. If applicable, if you plan to pass fiber strands, cables and/or

tubing through the 1½-in. (38.1 mm) diameter holes in the

tops and bottoms of panels, see the notes below and then

knock out the applicable fire-abatement plugs covering these

holes (Fig. 31). Install flexible edge protectors, 110048-F01 (or

a standard grommet for 1½ in. holes) in place of plugs.

NOTE:

•Avoid removing fire-abatement plugs on the top of the top-

most and bottom of the bottom-most panel

•Plugs can be knocked out when panels are in place on the

rack; however, plug removal is easiest before racking

panels.

2. Install standard entry/exit split arcs and/or either optional

isolation hook kits, KIT-CMHOOK or optional entry/exit arc

kits, KIT-CMARC, at the front and/or rear corners of the panel.

•Installing standard split arcs: Slip the arc over the top

and/or bottom edges of the chassis at the entry/exit

corners. Refer to Figure 32.

NOTE: Two of the provided arcs are longer than the rest.

These should go on the bottom rear of the LCX chassis.

•Installing an isolation hook kit (purchased separately):

Follow these steps and refer to Figure 33.

i. Remove the split arc at the top and bottom of the

applicable corner entry/exit

ii. Use the two Phillips head machine screws

(screws with cross recessed heads) to secure the

hook mounting plate and flat backing plate to

either side of the panel sidewall

•Installing an optional arc kit: Follow these steps and refer

to Figure 34.

NOTE: Arcs are attached to the angle-shaped mounting

bracket using a thread-forming screw and an anti-rotation

boss. The bracket contains two sets of screws and boss

holes so that each arc can be mounted with the arrow-

shaped keeper flange pointing either up or down.

i. Remove the split arc at the top of the applicable

corner entry/exit. Leave the split arc at the bottom

in place, as shown in the illustration on the right.

Flexible Plastic Edge Protector

Figure 31: Removing knockouts & installing

plastic grommets

Standard Split Arcs

Figure 32: Installing a standard split arc

Figure 33: Installing a standard isolation

hook kit

Backing Plate

Leave Bottom Split

Arc in Place

Arcs

Angle Bracket

Figure 34: Installing an optional arc kit

LCX

Bulkhead-style Hinged Fiber Optical Panels

20

© Telect, Inc. All rights reserved. 06.08.17

1.509.926.6000 ─ telect.com

ii. Use the three thread-forming Phillips head

screws (screws with cross-recessed

heads) to attach the arcs to the angle

bracket. Normally, the arrow-shaped

keeper flange of the top two arcs point

down and the bottom one points up. For

flange clearance, the middle and bottom

arcs must use a different set of screw and

boss holes.

iii. Use the two Phillips head machine screws

along with the flatbacking plate to secure

this arc assembly to the panel.

3. Mount each panel to the rack using four 12- to 24-

thread-forming mounting screws supplied, two per side

(Fig. 35).

4. Torque to 35 in.-lb. (4.29 N•m.). For one of the

mounting screws, if desired, include a ground lug and

star washer. (Use one ground lug with #14 AWG

stranded wire per chassis.)

5. Install adapter packs and/or special function modules in configurable LCX fiber patch panels. Figure

36 shows a six-adapter pack being installed in a 4RU LCX fiber configurable patch panel.

6. Push in quick-connect plungers at both ends of faceplate to lock pack or module in bulkhead.

7. Place a plastic cabling ring at each of the four corners of the chassis (Fig. 37-38). Rings can be

added and moved around later during cabling. The rings not only serve as corrals for fiber cable but

also as guideposts. Cables can be inserted in the split rings or routed around the rings.

NOTE: Each shelf of an LCX fiber patch/splice combination panel must be grounded separately.

Figure 35: Mounting LCX panel to rack

Plunger at Top & Bottom

of Patch Plates

Figure 36: Installing adapter pack & special function modules

Plastic Cabling Rings

Figure 37: Inserting cabling rings

Other manuals for LCX Series

1

Table of contents

Other Telect Control Panel manuals

Popular Control Panel manuals by other brands

Setra Systems

Setra Systems SRPM Installation and operating manual

Mitsubishi Electric

Mitsubishi Electric GOT SIMPLE GS2110-WTBD user manual

Bosch

Bosch FPD-7024 operating instructions

AUTOTERM

AUTOTERM PU-5 operating manual

BFT

BFT Rigel 6 QRG Quick reference guide

enware

enware Custodian CN2DF-FF Installation and maintenance instructions

SALUPO

SALUPO SOFT START PLUS 1 Instruction and installation manual

GST

GST 852RPX Installation and operation manual

Honeywell

Honeywell ENVIRAZONE PANEL W8835 Product data

Toro

Toro SENTINEL SATELLITE Quick reference guide

Eaton

Eaton Greengate ControlKeeper CK4A-SSRC installation instructions

Casals

Casals CTRL-DPH User manual and instructions