Secced SC-402-6 User manual

Thanks for choosing SECCED’s Traveler Crane

For your reference

SN

Date of purchase

Name and address of the distributor

1

Safety Guideline

1. The assembly instructions must be read and understood before set-up or

operation. The crane may only be assembled in accordance with the

manufacturer’s instruction manual. The manufacturer’s technical specifications

and limits must be adhered to all times and in no way exceeded.

2. The Traveler Crane may only be set-up or operated by trained and experienced

personnel. To avoid misuse by untrained personnel, the crane should be

dismantled when not in use or under supervision.

3. The crane may not be assembled or operated under influence of alcohol, drugs or

any other intoxicating substances.

4. The manufacturer accepts no liability for damages or injuries for incidents or

accidents occurring due to negligence by the crane operator, misuse of the crane

or disregarding the instruction manual.

5. The camera crane shall be used on the even terrain. If it is used on an uneven

terrain, it is not allowed to use the dolly, and the solution is to adjust the tripod to

maintain level.

6. After setup of the crane, the pan & tilt remote head shall be positioned under the

central pivot section when it is left unattended in assembled state, and if the pan &

tilt remote head is higher than the central pivot section, there should be someone

to look after the crane system.

7. Make sure that there is no wire with electric power which has higher voltage than

safety level within movement range of the whole crane system.

8. Be sure to avoid abruptly swiveling or stopping the crane, otherwise it may cause

falling of crane.

9. It is not allowed to use the crane under the environment with wind speed faster

than 5.5~7.9meter/per second.

10. When the camera crane is used in a rainy day, the pan & tilt remote head and

controlling bar shall be protected against rain.

11. Avoid anybody standing under the crane.

12. No loose objects may be stored or placed on the crane.

13. Before the counterweights are removed from counterweight rod, ensure the remote

head is resting on the ground or alternatively supported by an appropriate stable

underlay. Gradually remove the counterweights before the remote head, camera or

other parts are removed.

14. Make sure the location where the crane is installed can support the overall weight

of the crane (including the counterweight), and the special attention shall be given

when it is set up on roof and aerial construction.

15. When the control system is working, it is not allowed to turn the gear of the remote

head. If it needs to be adjusted, power supply should be switched off.

16. In the interest of safe crane operation, abrupt or sudden movement of the crane

should be avoided.

17. Only original accessories manufactured by Secced may be used with the crane.

2

Content

Setup .....................................................................................................4

1. Dolly .................................................................................................4

2. Tripod ...............................................................................................4

3. Central Pivot Section ........................................................................5

4. Arm ...................................................................................................5

5. Camera and remote head ................................................................6

6. Balance steel cable ..........................................................................8

7. Tension steel cable ...........................................................................8

8. Controlling bar ..................................................................................9

9. Counterweight ................................................................................10

10. Power supply box .........................................................................10

Wire Connection ............................................................................10

Operation ...........................................................................................12

1. Control of remote head ..................................................................12

2. Control of camera ...........................................................................12

Specifications and Technical Data .........................................14

Packing List ......................................................................................15

Appendix ............................................................................................16

3

Setup

1. Dolly

The dolly of the crane system is the foldable dolly in ‘Y’ pattern. Unfold the leg by depressing the leg

locking pin (Figure 1), and pull out the folding leg. Revolve 120 degree till the leg locking pin lock

the legs in the open position. Repeat the above steps for the spreading another folding leg.

All operation instructions are same with our SC-3920 dolly, please see our operators guide for

further information on operating this dolly.

Leg locking pin

Figure 1

2. Tripod

When installing the tripod on the dolly, insert all three tripod feet into slots on the dolly (Figure 2).

4

Fi

g

ure 2

Figure 3

Tripod Foot

Knob of locking sleeve

Knob of protective sleeve

Figure 4

By observing the leveling bubble (Figure 5), one can know if the tripod is horizontally leveled. If

tripod is not horizontally leveled, please adjust the height of tripod to reach level.

To adjust height of tripod, please loosen the knob of locking sleeve (Figure 3) and the inner tube

can be lengthened. After making sure the feet are prolonged to the proper length, tighten the

locking bolt. Loosen the knob of protective sleeve (Figure 3), put the protective sleeve upward to

the highest position and then tighten the knob. The purpose of protective sleeve is to prevent the

outer tube sliding down.

Locking sleeve of tripod

Protective sleeve of tripod

Figure 5

Figure 6

Leveling bubble

3. Central pivot section

Central pivot section should be installed on the tripod and allow the crane arm to swivel horizontally.

As shown in Figure 7, please put the central pivot section on tripod and tighten it with locking knob

(Figure 8).

Attention: To avoid any possible accident may occur, please lock the crane with tilt & pan locking

levers if the crane left unattended.

A

C

B

Figure 8

A. Tilt locking lever

B. Pan locking lever

C. Locking knob of central pivot section

Figure 7

4. Arm

The arm is formed by 5 tubes. The tubes are numbered from the end of counterweight rod. The

installation of the arm shall start from the section 2 tube which has been already mounted on the

central pivot section since the product was completed. The section 5 tube is the one which has the

mounting plate at one end (Figure 10).

5

Other arms are connected with each other by the way shown from Figure 9-1 to Figure 9-2, and use

inner-hexagon spanner to tighten nut and tighten the knob under the tube as well.

Figure 9-2

Figure 9-1

6

Figure 9-3

Figure 9-3

Attention: The right mount counterweight should be mounted after installation of all arm is

completed to avoid any falling down of crane arm.

5. Camera and remote head

To install the remote head, simply plug the remote head onto the mounting frame, and turn locking

lever to tighten it. (Figure 10)

Remote head Mounting frame

Leveling bubble Locking lever

Figure 10

Balance should be adjusted after the camera is installed. If camera uses battery to supply power,

the battery should be installed before adjusting balance. First of all, release the gear of tilt motor;

put the DV camera on the camera plate, use the screw to fix it. Then adjust the positions of the plate

backward or forward according to which way the camera turns, adjust balancing frame upward or

downward according to which way the camera turns, and repeatedly adjust the positions of plate

and balancing frame to ensure the camera doesn’t move anymore when turning to any position.

B

F

A

D

C

G E

Figure 11-2

Figure 11-1

A. Locking lever for tilt motor E. Locking lever for camera plate

B. Tilt gear F. Camera adaptor

C. Screws G. Tilt motor

D. Camera plate

Figure 11-3

Secced SC-3950 Camera adaptor

Figure 12

Iris motor

Iris gear

Focus motor

Focus gear

Motor frame

As shown in figure 12, install the focus and iris control (lens control motor) on the lens.

7

There are two focus gears available, one is for Canon lens, and another is for Fujinon lens. Select

the gear matching with the lens used and install it on the motor frame. Turn clockwise the

focus-adjusting wheel on the lens to the end, and turn anticlockwise the motor gear to the end.

Engage the two gears and tighten the knob of motor fastening. The IRIS motor can be installed by

the same method.

Due to influence of cables on the camera, it may not move when it reaches any positions. Under

such a situation, influence of such a force should be minimized.

6. Balance steel cable

8

Figure 13-1

Front

Figure 13-2

Locking nut 1

Locking nut 2

Locking nut 3

Cable pressing plate Cable guide

Back

Turnbuckle

Figure 13-3

Figure 14

The balancing steel cable is installed upon the arm to make sure the pan & tilt remote head

maintain level. Connect one end at which there is a turnbuckle with mounting frame, and reach the

state which is demonstrated in Figure 13. Another end is placed on the central pivot section, First of

all, use inner-hexagon spanner to loose all three nut (Figure 12-3) and roll the balancing cable over

the cable guide like the way in Figure 12-1 and get it fixed with cable pressing plate (Figure 12-1)

and tighten the three nuts (Figure 12-3).

After installation of the balancing steel cable, please check if the remote head is vertical to the

ground by observing the leveling bubble (Figure 10). Adjust the turnbuckle and remote head after to

make sure the remote head is level.

7. Tension steel cable

The tension steel cable is used for giving a tension force to the pan & tilt remote head and the

camera, keeping the crane straight, increasing the rigidity of the crane arm, and preventing camera

shaking while swiveling the crane.

The top tension steel cable are hooked with both section 1 and section 5 tubes (Figure 14 and 15).

The supporting rods have to be inserted into the hole and put the cable on the top of rod. And use

the turnbuckle to tighten the cable.

A C

D

B

Figure 17

Figure 15

E

A. Tension cable

B. Hook

C. Tension cable supporting rod

D. Balancing cable

E. Turnbuckle

Figure 16

8. Controlling bar

As shown in Figure 17, to install the controlling bar on the counterweight rod and tighten the locking

knob.

Figure 18

Counterweight discs

Locking lever of controlling bar

Counterweight rod

Controlling bar

9

9. Counterweight

Install the counterweight (optional) on counterweight rod as shown in Figure 17, and adjust the

weight to enable the crane to keep balance.

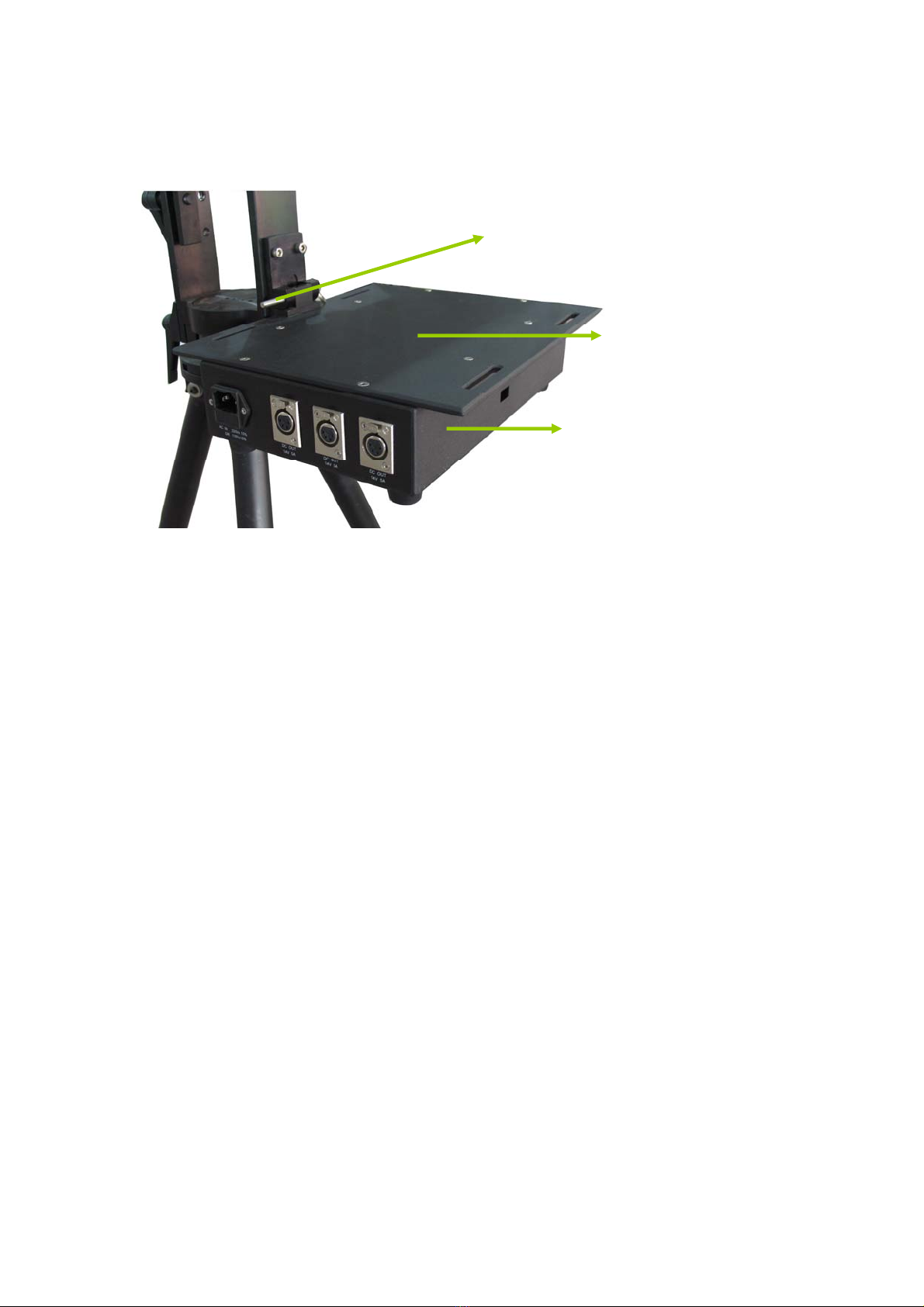

10. Power supply box

Fixing pin

Supporting plate for monitor

Power supply box

Figure 19

.

The power supply box is for supplying the power to the camera, remote head, controlling bar and

monitor. There is two way to get power input, one is the AC 220V or 110V input and another one is

the A–mounting interface under power supply box. To install power supply box, simply plug in the

pin to fix it.

Attention: Operators can change the A-mount interface into V-mount interface by simply taking

down A-mount interface, put on a V-mount plate and tighten the nuts.

Wire Connection

1. Remote head controlling bar, as in Figure 19, insert crane cable, power cable and controlling

bar cable (connecting with camera controlling bar) into the corresponding sockets. (The

sockets for power supply cable and crane cable are on the left-hand side of remote head

controlling bar. The socket for controlling bar cable is on the back of remote head controlling

bar.)

2. Camera controlling bar, insert the controlling bar cable into socket (Figure 20) on back of the

camera controlling bar (Figure 19), which is connected with remote head controlling bar.

3. Remote head, insert the plugs of crane cable into the tilt and pan motors respectively. The plug

with long cable is for tilt motor, and the plug with short cable is for pan motor.

4. Connect the remote head controlling bar with lens control box by using crane cable. Smaller

plug of crane cable is connected with lens control box. Connect the lens control box with

camera lens, by using lens control cable. Three plugs are for ‘ZOOM’, ‘FOCUS’, and ‘IRIS’

respectively, as shown in Figure 22.

5. Monitor: insert video cable into AV output socket of camera, and another end (with yellow sign)

is connected with monitor.

10

6. Using the bounding strap to fix the crane cable with crane arm to avoid any disturbance caused

by cable while in operation.

Controlling bar cable

Integrated controlling bar

Socket

Power supply cable

Figure 20

Figure 21

Remote head controlling bar

Crane cable

Lens control box

For ‘FOCUS’ control

For ‘IRIS’ control

Lens control cable

For ‘ZOOM’ control

Figure 22

11

12

For remote head controlling bar

Crane Cable

Connected For pan motor

For tilt motor

For ‘ZOOM’ control

Connected

Lens control box

Figure 23

Lens control cable

For ‘FOCUS’ and ‘IRIS’ control

Operation

The panels of two controlling bars are shown as follows.

1. Control of remote head

There is a joystick on the remote head controlling bar to control panning and tilting of remote head,

meanwhile there are also some knobs and switches on this controlling bar. ‘SPEED’ controls the

speed of rotation of remote head, ‘CENTER’ can control the remote head rotate automatically as

the speed which is set up with ‘SPEED’ control knob, and ‘DAMP’ is for adjusting the damping of the

remote head. When the damp is small, the pan & tilt head can quickly starts and stops. When the

damp is large, the start and stop of the pan & tilt head have the obvious delay.

2. Control of camera

In Figure 24, the lever labeled with “T” and “W” is used for controlling the zoom of lens, the

“DIRECT” switch is used to change the control direction. “RATE” switch is used to control speed.

The knob under the camera controlling bar is used for adjusting focus (Figure 25). The “DIRECT”

switch is used for changing direction of ‘FOCUS’. The knob above the lens control bar is used for

adjusting Iris. CON/FUJI switch is for switching the control between Canon lens and Fujinon lens.

VCR is to start recording.

Figure 24

Camera controlling barRemote head controlling bar

Figure 25

‘FOCUS’ controlling knob

Back of camera controlling bar

13

14

Specifications and Technical Data

Length 6m

1.64m (including dolly)

Height of central axis 1.45m (excluding dolly)

60°(including dolly)

Elevation angle 50°(excluding dolly)

Rotation radius of pan & tilt head 4.34m

Highest point of pan & tilt head 5.6m

Payload of pan & tilt head 10kg

Horizontal: Unlimited

Rotation angle of pan & tilt head Vertical: ±1800

Horizontal: 10 rounds/min.

Fastest speed of pan & tilt head Vertical: 10 rounds/min.

Line: AC100~240V

Power input AC adaptor: DC 12V 5A

Case 1: 600×450×220

Size of packing case (L x W x H mm) Case 2: 1330×390×390

Case 1: 14.5kg

Case 2: 52kg

Gross weight (Kg)

Total weight: 66.5Kg

15

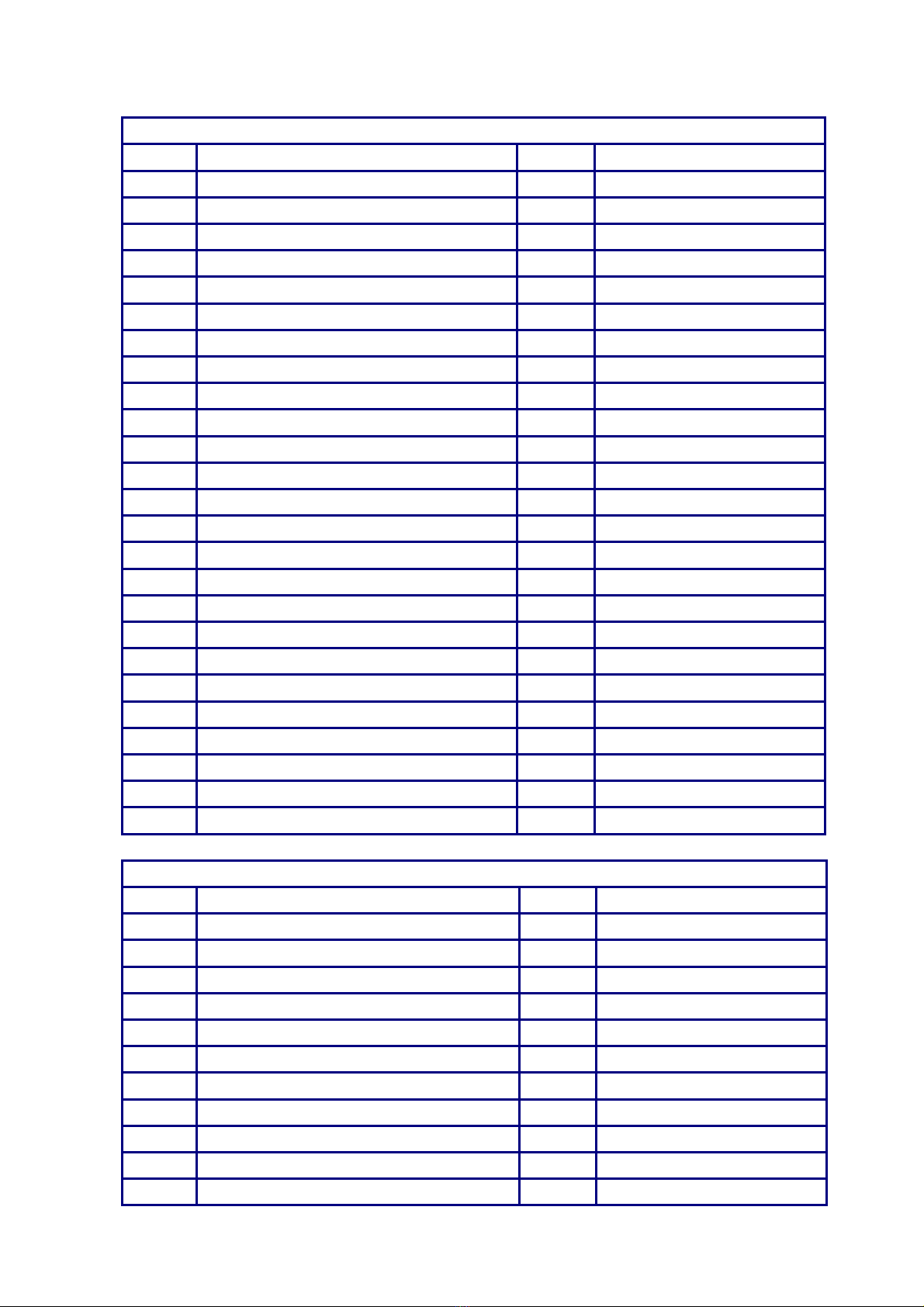

Packing List

No.1 Case

Number Name Quantity Remark

1 Remote head 1 With pan and tilt motors

2 Remote head controlling bar 1

3 Camera controlling bar 1

4 Crane Cable 1

5 Power cable for controlling bar 1

6 Controlling bar cable 1

7 Video cable 1

8 Power cable for camera 1

9 Power cable for power supply box 1

10 Power cable for monitor 1

11 Bounding strap for monitor 2

12 Lens control cable 1

13 Power supply cable 1

14 Canon/Fujinon lens conversion cable 1

15 Iris & Focus motor 2

16 Mounting frame for Iris & Focus motor 1

17 Iris & Focus gears for Fujinon lens 2

18 Bounding straps 5

19 1/4” for Camera adaptor 1

20 3/8” for Camera adaptor 1

21 Screw for tripod 1

22 Screw for tube 1

23 8-10mm spanner 1

24 12-14 mm spanner 1

25 Inner-hexagon spanner 1

No.2 Case

Number Name Quantity Remark

1 Section 1 tube 1 With bounding strap

2 Section 2 tube 1 With central pivot section

3 Section 3 tube 1

4 Section 4 tube 1

5 Section 5 tube 1 With mounting plate

6 Tripod 1

7 Dolly 1

8 Tension steel cable 2

9 Balance steel cable 1

10 Supporting rod 2 With two knobs

11 Counterweight rod 1

Appendix

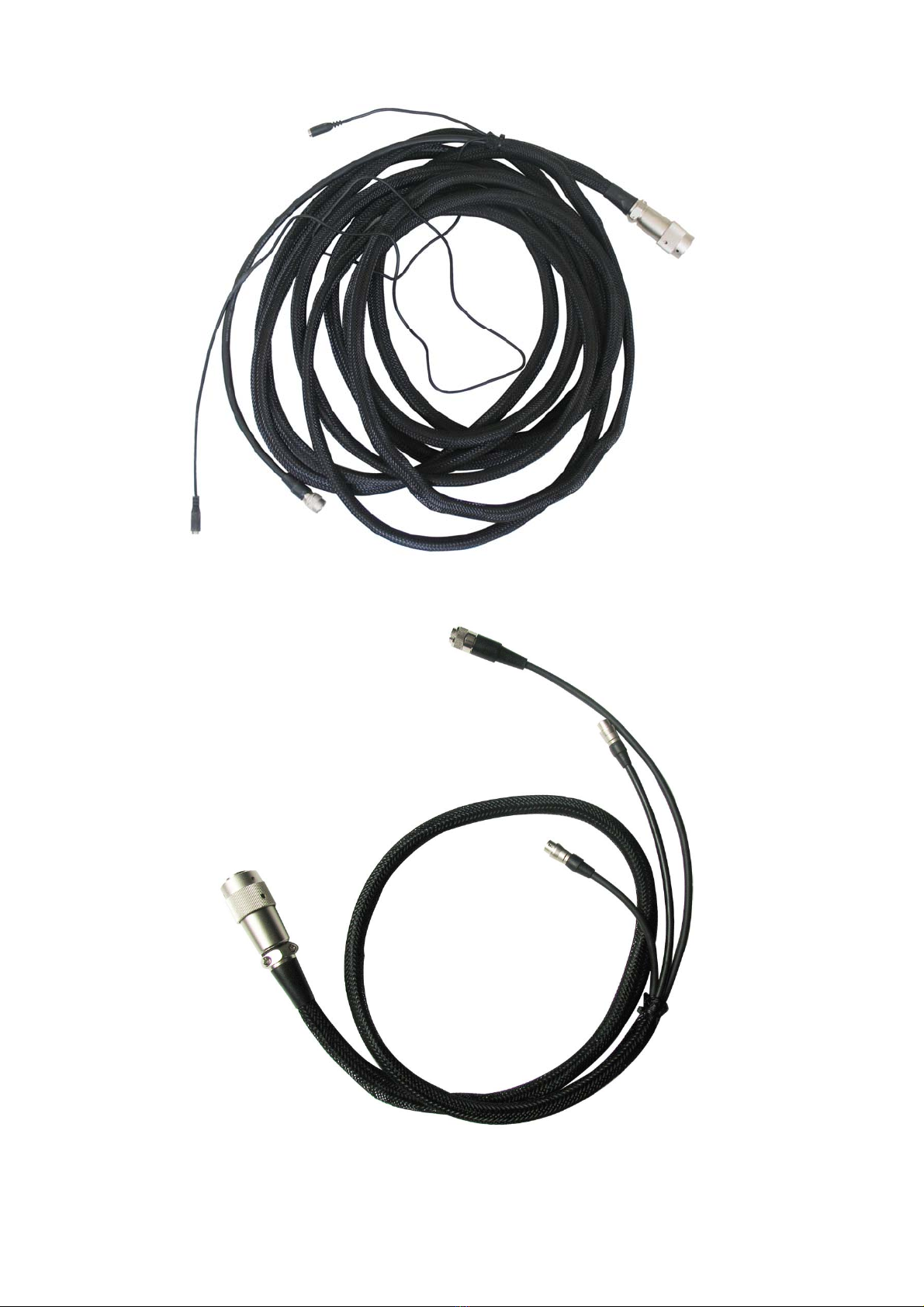

Crane Cable

Lens control cable

16

Controlling bar cable

Video Cable

17

Table of contents