Securitron ASSA ABLOY Magnalock DEM680E Series Manual

1 of 12

DEM680E Series Delayed Egress

Magnalock®with EcoMag™Technology

Installation & Operating Instructions

Product Components

A Magnalock & Mounting Bracket

B Strike Housing

C Strike Plate Assembly

D Wall Mounted Key Switch

E Settings Labels

F Sex Bolt & Tapered Washer

G Template Pins

H NFPA Door Label

Installation Hardware Pack Contents

I #14 X 3" Type A Phillips

Pan Head Screw (4)

J Threadlocker Packet

K WOOD DOORS: #6 X

1/2" Phillips Flat Head

Type A Steel Screw (6)

L METAL DOORS: 6-32 X

3/8" Phillips Flat Head

Type F Steel Screw (6)

M #12 X 1-1/2" Type A Phillips

Pan Head Screw (4)

N Rivet Nut Install Tool

O 1/4-20 X 1" Phillips Pan

Head Screw (2)

P 1/4-20 Rivet Nut (2)

Q 3/16" Hex Key

Diagram 1 Product Components

A

C

D

E

FG

H

I

J

K

L

MN

OP

Q

B

Specifications

Dimensions

• Height: 2.50" [64 mm]

• Depth: 2.56" [65 mm]

• Length: 11.50" [292 mm]

Certifications

• UL 10C Fire Rated, 1 Hour

• CAN/ULC-S104 Fire Door Conformant

• UL 294

• UL Tested Ratings: Endurance:

100,000 cycles

• ANSI/BHMA A156.23, Grade

2; E18501 Compliant

• California State Fire Marshal Listed

• NFPA 101

Electrical

• Magnalock Minimum Current Draw

(±10%)

95 mA at 12 VDC

65 mA at 24 VDC

• Magnalock Maximum Current Draw

(±10%)

575 mA at 12 VDC

315 mA at 24 VDC

Static Holding Force

• 1,200 lbs [544kg]

Operating Temperature

• 32˚ to 120˚F [0˚ to 49˚C]

• Indoor use only

NOTE: Hardware is provided for various installations.

There will be leftover parts depending on the type of installation.

IMPORTANT: UL 294 compliance requires that the locking device be powered by a UL

294 (ALVY) or UL 603 (APHV) listed power supply and shall be installed in accordance

with the following UL and National Standards: NFPA 70 – National Electrical Code.

IMPORTANT This Magnalock requires calibration upon installation.

3 of 122 of 12

Performing a

pre-installation survey

1 Before installing the Magnalock, determine and

assess the mounting location for the following:

• Physical strength of the frame — should

be strong enough to meet or exceed the

holding force of the Magnalock.

• Frame and vicinity — should offer protection

for the wiring to prevent vandalism, and provide

adequate protection from rain exposure.

• Door inspection — inspect for any obstacles

that may interfere when mounting the strike

plate and ensure that there is minimum door

movement when the door is latched.

• Proper mounting —The Magnalock comes

with factory default mounting hardware

for use with an out-swing door.

Preparing the Magnalock

1 Ensure that there is at least 2-1/4" between

the closed door and the edge of the header.

If not, a header bracket (sold separately)

may be required (see Diagram 2).

Removing the cover

and mounting bracket

1 Using a Phillips screwdriver, REMOVE the two

(2) screws that secure the cover, as shown in

Diagram 3a, and the (3) screws that secure

the mounting bracket to the top of the

lock chassis as shown in Diagram 3b.

2 SET the cover and screws aside to re-attach later.

3 SLIDE the bracket to disengage from

the top of the lock chassis.

Installing the Magnalock

on a METAL DOOR frame

NOTE: Drilling a pilot hole first or using a step

bit will ensure a snug fit for the blind nuts.

1 DRILL two (2) 3/8" diameter holes in the

frame at the bracket mounting hole marks

(see Diagram 7). DO NOT oversize.

NOTE 1: Blind nuts provide a highly secure and tamper-

resistant system for mounting and are provided for this unit.

NOTE 2: A blind nut installation tool (Securitron BPT-

2, Blind Nut Placement Tool, or similar) can be used

instead of using a box end wrench and hex wrench.

2 INSTALL a blind nut into each 3/8" diameter hole

using the provided tool (see Diagram 8).

• Hold the collapsing nut with a 1/2"

open or box end wrench.

• Maintain pressure against the mounting

surface while tightening the cap screw using a

3/16" hex wrench to collapse the blind nut.

3 DRILL 1/2" diameter wire access holes as needed, on

one or both sides of the bracket (see Diagram 9).

4 REMOVE the protective tape from the frame.

5 Temporarily INSTALL the mounting bracket with

template pins against the closed door using

a Phillips screwdriver and two (2) 1/4-20 x 1"

Phillips pan-head screws (see Diagram 10).

Installing the Magnalock

on a WOOD DOOR frame

1 DRILL two (2) 3/16" diameter mounting

holes by 1-1/4" deep at the bracket-

mounting hole marks (see Diagram 7).

2 DRILL 1/2" diameter wire access holes as needed, on

one or both sides of the bracket (see Diagram 9).

3 REMOVE the protective tape from the frame.

4 Temporarily INSTALL the mounting bracket with

the template pins against the closed door using a

Phillips screwdriver and two (2) #12 x 1-1/2" Type

A, Phillips pan-head screws (see Diagram 10).

Marking the frame

1 PINCH and insert the template pins

flush into the dovetail slots of the

mounting bracket (see Diagram 4).

2 APPLY MASKING TAPE to the door and

frame surfaces to protect from any possible

damage during marking and drilling.

3 PLACE the mounting bracket against the frame stop

on the secure side of the door and on the side of the

door that does not have hinges. Ensure that there

is a minimum a clearance of 1" from the frame.

4 CLOSE the door and adjust the bracket so that

the template pins rest against the door.

5 MARK the frame through the two (2) oblong

(slotted) bracket mounting holes (see Diagram 5).

6 MARK the frame for a wire feed-through hole

at the end closest to where the wire run will be

accessed and ensure the hole marking is centered

at least 5/16” from the end and aligned with the

rear edge of the bracket (see Diagram 6).

7 REMOVE the mounting bracket from the frame.

Diagram 2 Assessing the installation site Diagram 6 Marking the wire feed-through hole

Diagram 7 Drilling the

bracket mounting holes

Diagram 9 Drilling the

wire access holes

Diagram 8 Installing the blind nuts

Diagram 10 Installing the bracket

Diagram 3a Removing the cover

Diagram 4 Inserting

the template pins

Diagram 5 Marking the frame

1-1/8"

Bracket

Mounting

Surface

Anchor Screws

1-11/16" from

door to center

of bracket slots

1/4-20

Blind Nut

AA

2-1/4" from door to trailing

edge of bracket

Diagram 3b Removing

the mounting bracket

1" Min.

5/16"

3/16"

5 of 124 of 12

Diagram 11 Marking the

strike housing mounting hole

locations from the inside

Diagram 13 Securing the plate assembly to the door

Diagram 14 Strike assembly

installed – section view

Diagram 16 Mounting the

Magnalock to the bracket

Diagram 18 Tightening

the mounting screws

Diagram 20 Assembling

the key switch plate

Diagram 22 Installing

the mounting device

Diagram 15 Strike assembly

installed – inside door

Diagram 17 Marking the back

edge of the mounting bracket

Diagram 19 Installing the

final mounting screws

Diagram 21 Marking the wall cut-out

Diagram 23 Installing the key switch

Diagram 12 Drilling the sex

bolt hole from the outside

Installing the strike

on the door

1 With the door closed, ALIGN the strike housing

with the template pins as indicated on the

strike housing. Ensure the strike housing is

pushed up snug against the template pins.

2 MARK seven strike housing mounting

hole locations (see Dia gr am 11).

3 REMOVE the strike housing from the door and the

template pins from the lock mounting bracket.

From the INSIDE

4 DRILL a level 3/8" diameter hole for the

sex bolt all the way through the door at

the strike mounting center mark.

5 FOR A HOLLOW METAL DOOR: DRILL six (6) #36

(0.107") holes through the inside skin of the door for

the strike housing mounting screws.

FOR A WOOD DOOR: DRILL six (6) #36 (0.107)" x 1/2"

deep holes for the strike housing mounting screws.

From the OUTSIDE

6 FOR A HOLLOW METAL DOOR: DRILL out the

3/8" diameter sex bolt hole to 1/2" diameter in the

outside skin of the door (see Diagram 12).

FOR A WOOD DOOR: DRILL out the

3/8" diameter sex bolt hole to 1/2"

diameter completely through door.

Secure the strike plate

assembly to the door

7 INSERT the sex bolt into the hole from the

outside of the door (see Diagram 13).

8 ATTACH the strike plate housing using six (6) 6-32 x

3/8" Phillips flat-head screws for METAL –OR– six (6)

#6 x 1/2" Phillips flat-head screws for WOOD door.

9 CRITICAL STEP: PLACE the tapered washer on the

strike assembly screw with the smaller diameter

surface of the washer facing against the back

of the strike plate, as shown in Diagram 14.

10 APPLY thread-lock compound (included)

to the strike assembly screw.

11 INSERT the strike assembly screw through the

strike housing and door and into the sex bolt.

12 CRITICAL STEP: TIGHTEN the screw into the sex

bolt using the 3/16" hex wrench. While tightening,

gently tap the head of the sex bolt using a rubber

mallet until the head sits flush with the door.

NOTE: To provide maximum door movement after

installation, the head of the strike assembly screw should be

approximately 0.025" (about the thickness of a paperclip)

below the surface of the strike as shown in Diagram 15.

NOTE: DEM680E detects door movement through a concealed

‘patent pending’ strike assembly. OVERTIGHTENING the strike

assembly screw will reduce door movement range and may cause

false alarms. DO NOT OVERTIGHTEN the strike assembly screw.

Mounting the

Magnalock and aligning

to the strike plate

1 SLIDE the Magnalock assembly to fully engage

the lock chassis to the mounting bracket. Install

one of the three screws through one of the top

chassis holes and into the mounting bracket to

temporarily secure the Magnalock (see Diagram 16).

2 SLIDE the lock forward or backward so

that the entire face makes contact with

the strike plate on the closed door.

3 MARK the back edge of the mounting bracket

at each end and remove the Magnalock

from the bracket (see Diagram 17).

4 ENSURE that the mounting bracket

aligns with the marks and TIGHTEN the

mounting screws (see Diagram 18).

5 USING THE BRACKET AS A TEMPLATE, DRILL pilot

holes as necessary, then install and tighten the four

(4) final mounting screws (see Diagram 19).

FOR HOLLOW METAL DOORS: DRILL 3/16" holes and

use #12 x 1-1/2" screws.

FOR WOOD DOORS: DRILL 7/32"

holes and use #14 x 3" screws.

6 RETURN the Magnalock to the bracket and secure

the chassis to the bracket with three (3) screws.

Installing the

wall-mounted switch

1 ASSEMBLE the cylinder and switch to the wall-

mounted key switch plate (see Diagram 20).

2 MARK the corners for the mounting device

at the desired locations on the wall and

create a cut-out (see Diagram 21).

3 INSERT the mounting device into the cut-

out and fasten it in place with a Phillips

screwdriver (see Diagram 22).

4 MAKE the wire connections and install the

key switch plate using a flat-tip screwdriver

and two 6-32 screws (see Diagram 23).

Mark all seven (7) holes

Approximate .025"

Only hand tighten

strike assembly

screw

Strike

Assembly

Screw

Tapered Washer

Orientation

Strike

Plate Sex Bolt

Strike

Housing

Metal Door: 6x 6-32 X 3/8" Self

Tapping Phillips Flat Head Screws

Wood Door: OOv #6 X 1/2" Type

A Phillips Flat Head Screws

STRIKE HOUSING

STRIKE PLATE

STRIKE ASSEMBLY SCREW

3/16" HEX KEY

TAPERED

WASHER

DOOR

SEX BOLT

7 of 126 of 12

H2 (BOND) H3 (DPS) JP3 (EXT INIT)

Table 3 Delayed Egress DIP-switch selection and function

Delayed Egress Function Dip-Switches Position Selection Function/Description Factory Default

Nuisance Delay

SW 1 OFF / SW 2 OFF 0 seconds

Time that the door must be pushed before

triggering the irrevocable alarm cycle. Set

the desired nuisance delay in seconds.

0 seconds

SW 1 ON / SW 2 OFF 1 seconds

SW 1 OFF / SW 2 ON 2 seconds

SW 1 ON / SW 2 ON 3 seconds

Exit Delay

SW 3 OFF 15 seconds Set the desired irrevocable

alarm interval in seconds.

WARNING: a 30 second delay must be

approved by local code enforcement.

15 seconds

SW 3 ON 30 seconds

Bypass Time

SW 4 OFF / SW 5 OFF 0 seconds The expected time for a door closure

after manually bypassing (unlocking)

the system to exit or enter.

Set the desired bypass time in seconds.

0 seconds

SW 4 ON / SW 5 OFF 15 seconds

SW 4 OFF / SW 5 ON 30 seconds

SW 4 ON / SW 5 ON 45 seconds

Post Alarm Reminder

SW 6 OFF Disabled When enabled, provides audible

indication after an alarm event. Disabled

SW 6 ON Enabled

Bypass Expiration

Alarm

SW 7 OFF Disabled When enabled, provides audible indication

when the bypass time has been exceeded. Disabled

SW 7 ON Enabled

Manual/Delayed

Relock

SW 8 OFF Disabled When enabled, the system

automatically relocks 30 seconds

after an irrevocable alarm cycle.

Disabled

SW 8 ON Enabled

Unlocked at Startup

SW 9 OFF Disabled When enabled, system starts

in the unlocked state. Disabled

SW 9 ON Enabled

No Irrevocable

Alarm After Bypass

Expiration

SW 10 OFF Disabled When enabled, prevents irrevocable

alarm after bypass expiration. If SW7

is on, bypass expiration alarm repeats.

If SW7 is off, LED strobe flashes.

Disabled

SW 10 ON Enabled

Table 1 Jumper Settings

Jumpers Position Selection Function/Description Factory Default

H2 (BOND)

1-2 Normally

closed (NC)

Normally closed circuit – opens

when BOND registers secure.

Normally closed

2-3 Normally

open (NO)

Normally open circuit – closes

when BOND registers secure.

H3 (DPS)

1-2 Normally

open (NO)

Normally open circuit

– closes when door opens.

Normally open

2-3 Normally

closed (NC)

Normally closed circuit

– opens when door opens.

JP3 (EXT INIT)

1-2 Disabled When enabled, allows unit to

be initiated from an external

source. (J1, Terminal 4)

Disabled

2-3 Enabled

Table 2 Magnalock DIP-switch selection and function

Magnalock function DIP-switches Position Selection Function/Description Factory Default

LED enable SW 1 ON LED

enabled

When enabled, LEDs

display lock status. ON

SW 1 OFF LED

disabled

(Reserved)

SW 2 – SW 9 N/A Not used. OFF

Reset to Factory Defaults SW 10 OFF Reset

disabled When enabled, restores

Magnalock firmware

to factory settings.

OFF

SW 10 ON Reset

enabled

Diagram 29 Jumper Locations

Diagram 30 DIP-switch Locations

Magnalock Functions

Delayed Egress Functions

Pulling the wiring

NOTE: End-user and installer must comply

with fire and building codes.

1 PULL wires/cables through the wire feed-

through hole(s) drilled in the frame.

2 INSTALL the provided wall-

mounted switch if necessary.

Connecting the

final wiring

1 CONNECT the wires using Diagrams 24

through 28 as guides and as applicable.

NOTE: The positive terminal (+) and reference

voltage (VREF) are internally bussed to provide

a reference voltage for external control.

2 LOCATE the jumpers as shown in Diagram 29.

3 SET the jumpers for the desired

function using Table 1.

4 LOCATE the DIP-switches as

indicated in Diagram 30.

5 Select the desired Magnalock functions

using Table 2 and the desired delay-

egress functions using Table 3.

MAGNALOCK ELECTRICAL INSTALLATION

Diagram 24 Location of J1 and J4 terminals

Diagram 25 Terminal pin-out diagram

Diagram 26 Typical system wiring Diagram 27 Typical system wiring

with external initiate device

Diagram 28 Typical system

wiring with external controls

Terminal Block

Header J4

Terminal Block

Header J1

Door Status

Bond Status

Input

Voltage

External

Controls

External

Alarm

H3

Power

Supply

Wall Mounted

Key Switch

DEM680E

Terminal Block

Header J1

Dry Alarm

Contacts

Power

Supply

External

Initiate

Device

(optional)

Wall Mounted

Key Switch

DEM680E

Terminal Block

Header J1

Dry Alarm

Contacts

Power

Supply

DEM680E

Terminal Block

Header J1

“(+) and ”VREF” Terminals are internally bussed to provide

reference (+) voltage external control use.

Dry Alarm

Contacts

9 of 128 of 12

Reinstalling the cover

NOTE: After wiring, settings, and calibration have been

performed, and the system is functioning properly, the

cover may be reinstalled on the Magnalock.

1 PLACE the cover over the rear of the Magnalock

2 INSTALL the two (2) Phillips screws to

secure the cover (see Diagram 35).

3 APPLY the provided NFPA label with the appropriate

(15 or 30 second) delay designation to the door.

Diagram 35 Reinstalling the cover

Initial calibration

NOTE 1: If calibration does not proceed according to the instructions

below, please see the troubleshooting section at the end of the manual.

NOTE 2: Initial calibration can be performed with a 12-V battery for

installations in facilities that do not yet have commercially-available power.

NOTE 3: Access control systems may register DPS and/or

BOND error conditions during the calibration sequence.

TECH TIP: For installation on a door without a door handle, a pull handle can

be made from masking or other tape to pull the door closed for calibration.

The DEM680E performs an automatic calibration

when the unit is initially powered up. This process only

proceeds if the door is closed and the unit has received

acceptable signals from the DPS and bond sensors.

PERFORM a manual calibration immediately

following installation, if necessary.

1 ENSURE that the door is closed.

2 APPLY power to the Magnalock.

3 PRESS AND RELEASE the calibration button (see Diagram 34).

4 VERIFY that the LED changes from red to amber

to green. The unit is now calibrated.

Calibration Button

Diagram 34 Calibration button

Delayed Egress

status LEDs

The two LEDs shown display the

following Delayed Egress states.

RED GREEN STATE

OFF OFF Unlocked

OFF ON Bypass

ON OFF Egress Alarm

ON ON Locked

Documenting the

configuration settings

1 Indicate the settings on the adhesive-backed labels

included with the Magnalock (see Diagram 32).

2 Complete the labels and affix them to the inside

of the Magnalock cover (see Diagram 33).

Diagram 31 LED location

Diagram 32 System settings

Diagram 33 Settings labels

Behavior of Delayed

Egress Magnalocks with

regional settings

California

Upon power up, lock goes into an alarm state

and requires a manual reset. Nuisance delay

is settable to 0, 1, 2 or 3 seconds and the exit

delay is fixed at 15 or 30 seconds. Bypass delay

is settable to 0, 15, 30 or 45 seconds. A manual

reset is required after a delayed egress event.

Chicago

Upon power up, lock goes into an alarm state and

requires a manual reset. Nuisance delay is fixed at

1 second, the exit delay is fixed at 15 seconds, and

the bypass delay is fixed at 0 seconds. A manual

reset is required after a delayed egress event.

11 of 1210 of 12

Test 1 – Verifying

correct startup

The DEM680E should be calibrated with

a non-zero nuisance delay setting.

1 With the door closed, the LED should be GREEN,

indicating that it is active (see Diagram 36).

• If the LED is RED or AMBER, stop and consult

the Troubleshooting Guide to correct.

Test 2 – Verifying

door security

2 With the door closed, PUSH against the face of

the door WITHOUT releasing the primary locking

mechanism (e.g., an exit device or cylindrical/mortise

door lock). The nuisance alarm should not sound if

the door is adjusted properly (see Diagram 37).

• If the nuisance alarm sounds, there is too much door

movement. The primary locking mechanism must be

adjusted to reduce excessive door travel. Excessive

movement will cause the DEM680E to go into alarm

and unlock when the door is pulled from the unsecure

side. Make necessary corrections and repeat Test 2.

Test 3 – Verify nuisance

alarm function

3 UNLOCK the primary locking mechanism (push bar or turn

handle) and attempt to push the door open. The nuisance

alarm should sound (see Diagram 38). Close the door before

the nuisance interval expires to prevent the alarm state.

• If the nuisance alarm does not sound, the strike

assembly screw may have been overtightened.

Overtightening prevents the door from traveling past

the nuisance threshold. Refer to “No Alarm” in the

Troubleshooting Guide and Diagram 14 which shows

proper adjustment of the strike assembly screw.

Test 4 – Verify countdown

alarm & free egress

4 UNLOCK the primary locking mechanism and attempt to

open the door. The nuisance alarm should sound along

with a flashing strobe. Maintain pressure on the door

until the alarm becomes steady; the DEM680E is now in

alarm state. The door should open in 15 or 30 seconds,

depending on the exit and nuisance delay settings. At

the end of the alarm interval, the LED should turn red,

and the door should freely open. (see Diagram 39).

*After testing, close the door and perform a reset. After

reset, the strobe should turn off and the LED should change

from red to green. VERIFICATION IS COMPLETE.

MAGNALOCK OPERATIONAL TESTS Troubleshooting Guide

TROUBLE INDICATOR POSSIBLE CAUSES POSSIBLE SOLUTIONS

Solid RED

• Two bond sensor failures*

• Supply voltage < 8.5 VDC

• Two bond sensor failures*

• Ensure bond sensor connectors are properly seated

• Check power supply voltage

• Ensure bond connectors are properly seated

Solid RED with

Audible Alarm

• Open door

• DPS failure*

• Attempting to calibrate with two bond sensor failures*

• Strike tray installed upside down

• DPS magnet missing from strike tray

• Close door

• Ensure DPS connector is properly seated

• Ensure bond connectors are properly seated

• Ensure that the strike tray is mounted

with alignment tabs facing up

• Check strike tray for damage, replace if needed

Solid AMBER

• Door sag

• Obstructed strike/magnet face

• Supply voltage < 10.8 VDC

• Single bond sensor failure*

• Magnet disconnected or magnet cable wire broken

• Verify that the strike label has been removed

• Recalibrate

• Check for obstructions between strike and magnet

• Clean face of strike and magnet. Recalibrate

• Check power supply voltage

• Ensure bond connectors are properly seated

• Make sure magnet connector is properly

seated or repair magnet cable wire

Flashing RED • Factory reset • Ensure SW10 is in the OFF position

LED off • LED disabled by SW1

• Supply voltage < 5 VDC

• Turn SW1 to the ON position

• Check power supply

Intermittent alarm

• Over-tightened strike screw

• Unscrew strike screw 1/2 turn at a time

until alarm sound is constant when door

is pushed (Recalibrate lock after each

adjustment and repeat Install Verification)

No alarm

* Failure means that the circut cannot detect a signal from the sensor. Check that the sensor connectors are properly

seated and inspect sensor wires for damage. Call Technical Support if replacement is needed.

Diagram 36 Indicator light displays

Diagram 37

Diagram 39

Diagram 38

12 of 12

techsupport.securitron@assaabloy.com

securitron.com | 800 626 7590

10027 S. 51st Street Phoenix, AZ 85044 USA

Printed in the U.S.A.

Patent pending and/or patent www.assaabloydss.com/patents

Copyright © 2022, Hanchett Entry Systems, Inc., an ASSA ABLOY Group company.

All rights reserved. Reproduction in whole or in part without the express written

permission of Hanchett Entry Systems, Inc. is prohibited. 500-23800_1

Warranty

For information on warranty coverage and replacement options, please visit securitron.com/warranty

Installing the NFPA label

NOTE: Each DEM680E comes with an NFPA exit

delay door label as required by fire code.

1 FOLLOW the included application instructions

to apply the lettering to a door.

Restoring factory

default settings

1 DISCONNECT power from the Magnalock.

2 REMOVE the cover using a Phillips screwdriver.

3 SET DIP-switch 10 (SW 10) to “ON” (see Diagram 40).

NOTE: When power is applied with SW 10 in the ON

position, previous calibration settings are erased. The LED

will continue to flash red until SW 10 is switched OFF.

4 APPLY power to the Magnalock and

verify that the LED flashes red.

5 SET SW 10 to OFF. The unit should auto-calibrate.

If the unit fails to calibrate see Troubleshooting

Guide, or contact technical support.

Diagram 40 Setting DIP-switch 10 to ON

Dip Switch 10 – ON

Table of contents

Other Securitron Lock manuals

Popular Lock manuals by other brands

Canaropa

Canaropa 9500M Series installation instructions

Alarm Lock

Alarm Lock Trilogy DL4100 Series Addendum Programming instructions

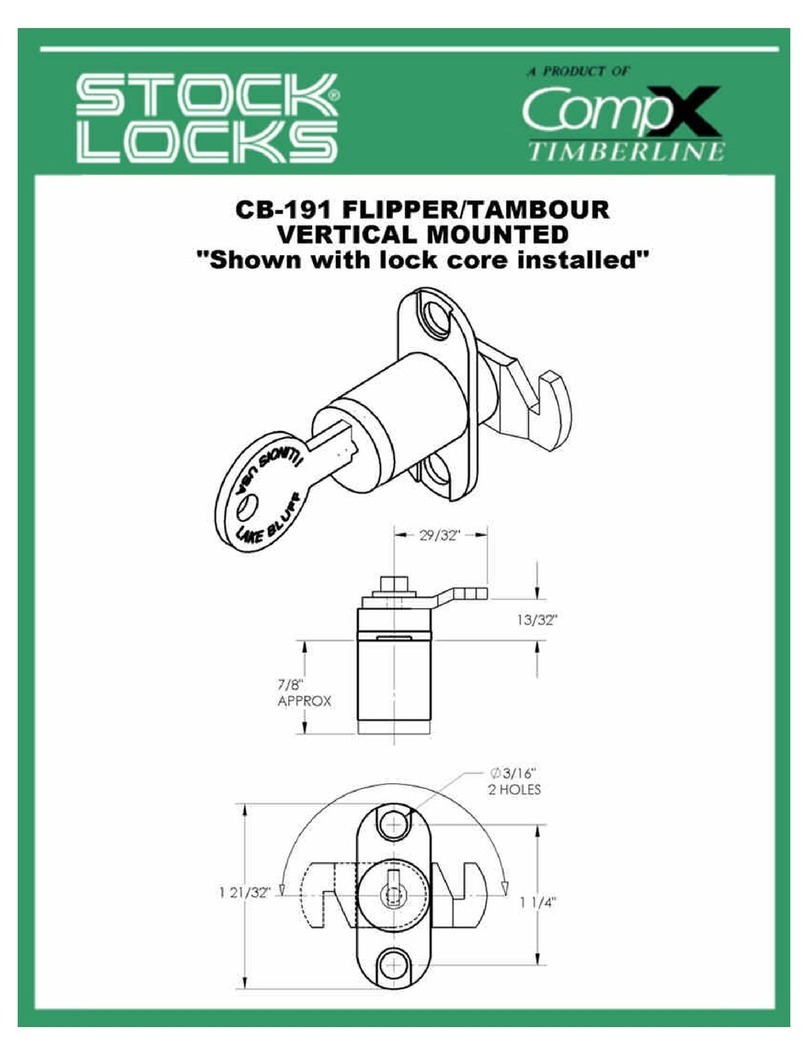

Stock Loks

Stock Loks CB-191 instruction sheet

COMPX

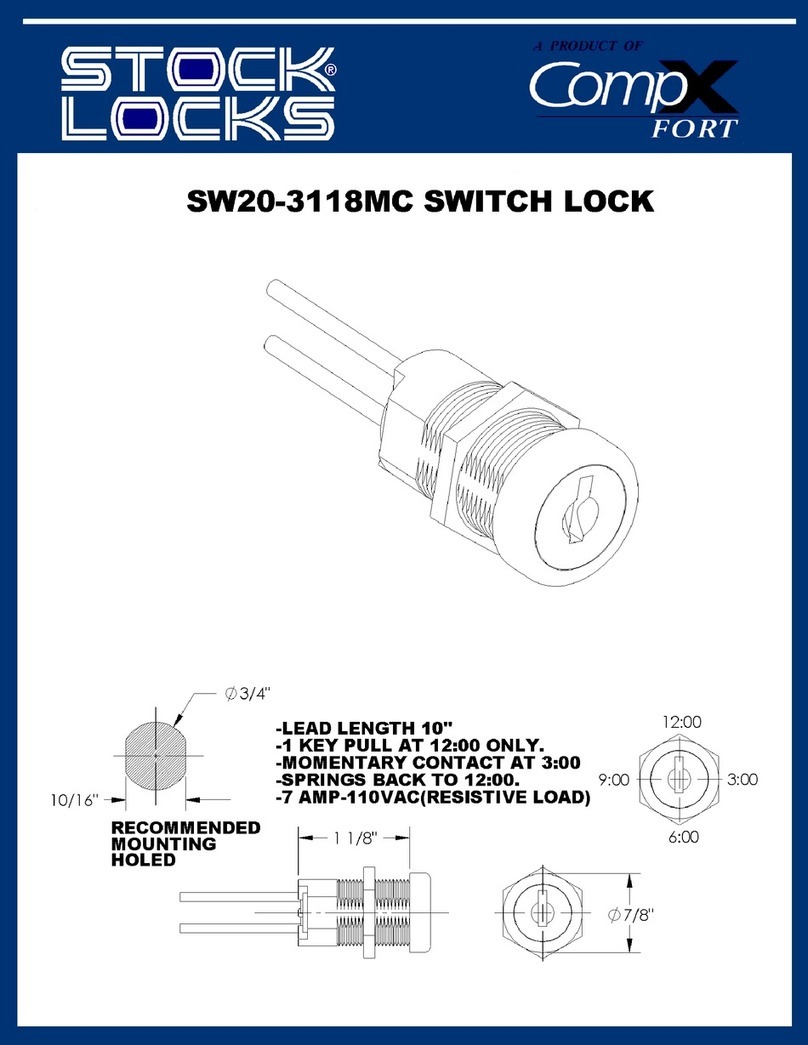

COMPX SW20-3118MC Dimensional drawing

Alarm Lock

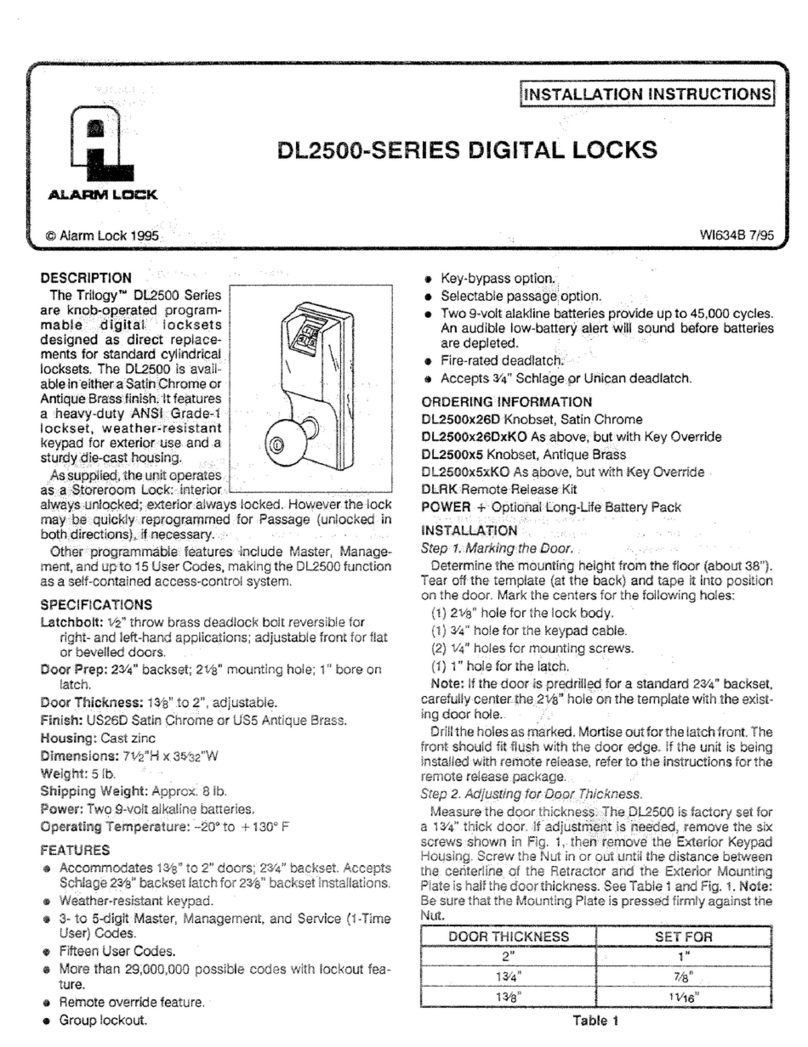

Alarm Lock DL2500-SERIES installation instructions

Ryobi

Ryobi RP4310 Operator's manual

LockMasters

LockMasters LockOne LKM7000 installation instructions

Stock Loks

Stock Loks C8896 instruction sheet

Hammond Manufacturing

Hammond Manufacturing CLHAN-01 Assembly instructions

Schlage

Schlage LINK FE599 user guide

Ingersoll-Rand

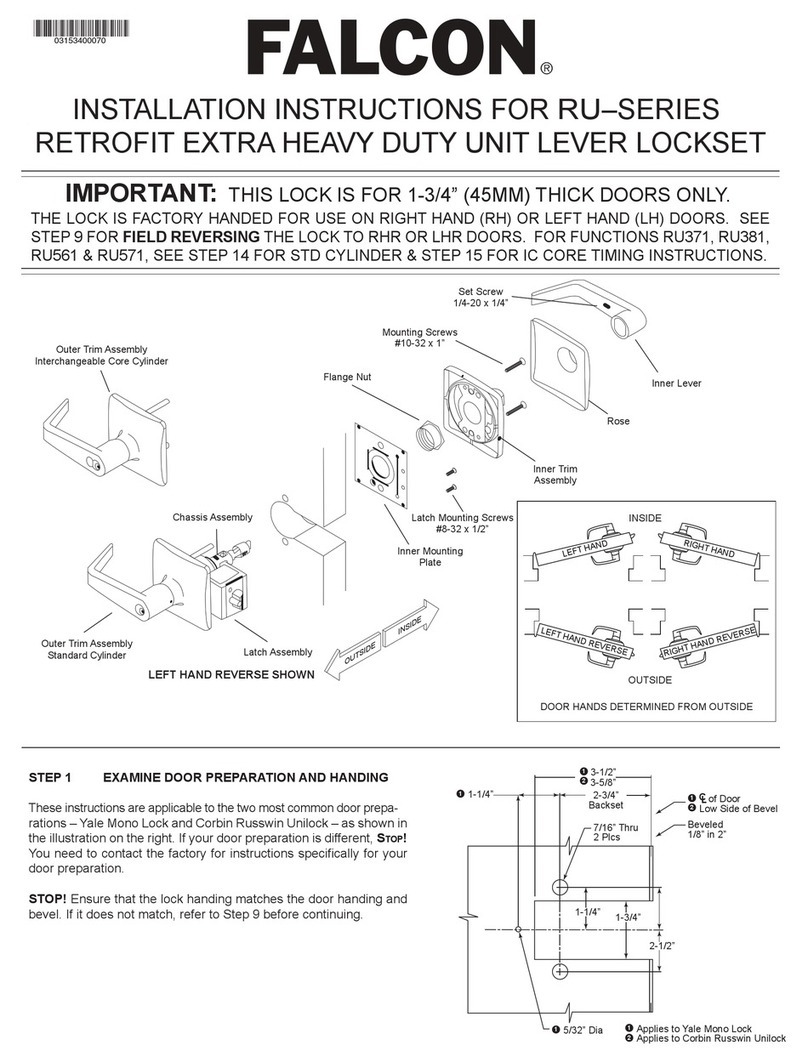

Ingersoll-Rand Falcon RU Series installation instructions

Schlage

Schlage 390G+ installation instructions