SEEDMASTER TOOLBAR User manual

SEEDMASTER –2023

TOOLBAR –ULTRAPRO II –NOVA TANK

OPERATOR’S

MANUAL

SEEDMASTER 2023

2

CONTENTS

CONTENTS................................................................................................................................................2

INTRODUCTION ........................................................................................................................................5

SAFETY......................................................................................................................................................6

TIRE TORQUE AND PSI SPECS ..............................................................................................................8

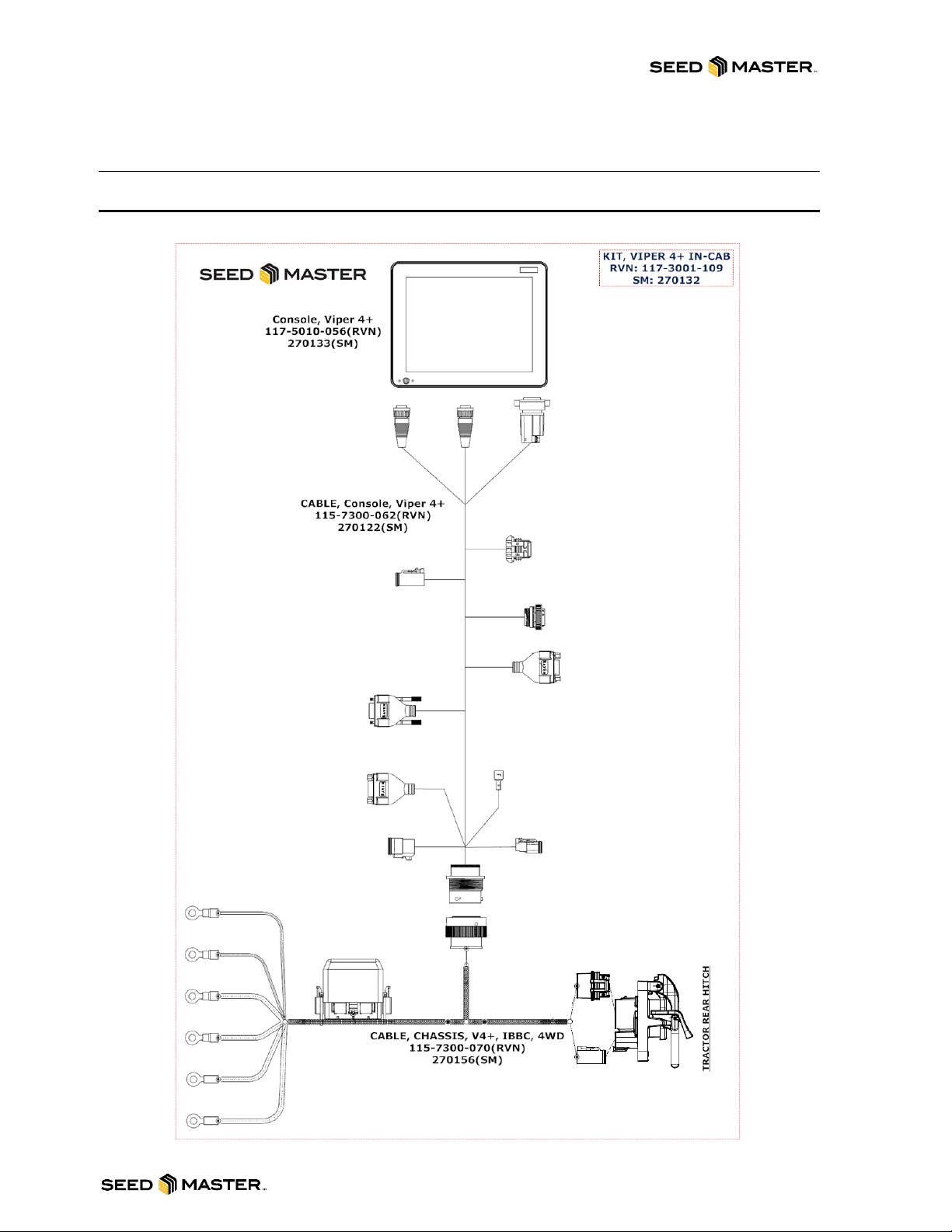

IN-CAB ELECTRICAL HOOKUP................................................................................................................9

RAVEN VIPER 4+ IN-CAB HOOKUP ....................................................................................................9

SEEDMASTER TOOLBOX AND MANUALS ...........................................................................................10

TRACTOR HYDRAULIC HOOKUPS .......................................................................................................11

SEEDMASTER MACHINE HYDRAULIC HOSES................................................................................11

HYDRAULIC CONNECTION REFERENCE CARDS...........................................................................12

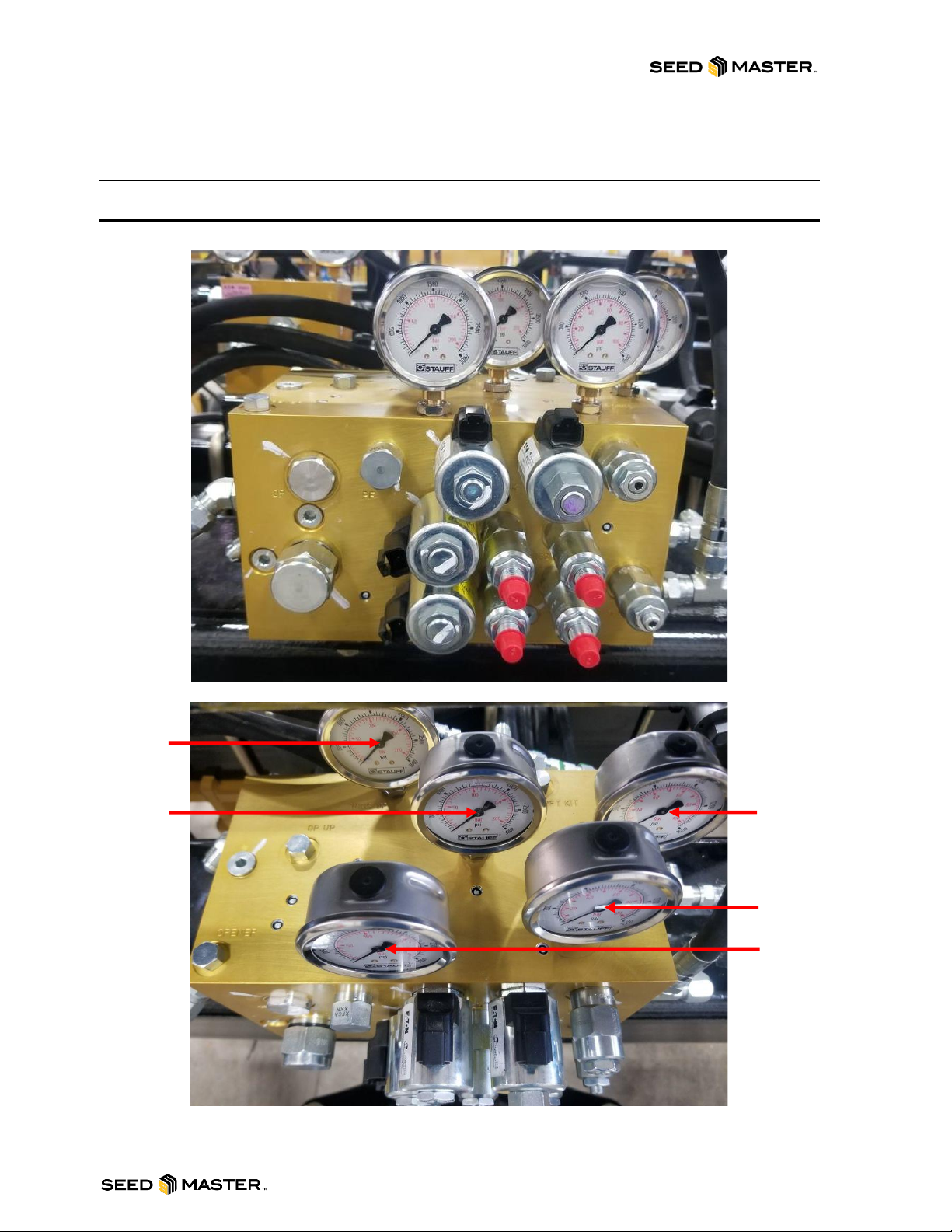

MAIN HYDRAULIC BLOCK DETAILS......................................................................................................13

HYDRAULIC BLOCK GAUGES ...........................................................................................................13

MAIN BLOCK GAUGES.......................................................................................................................14

MAIN BLOCK VALVES, SOLENOIDS, AND PWMS ...........................................................................14

PRESSURE SETTING PROCEDURES...............................................................................................15

LIFT KIT................................................................................................................................................16

SMART OPENERS HYDRAULIC BLOCK DETAILS AND OPERATION ................................................17

SMART OPENERS HYDRAULIC BLOCK ...........................................................................................17

SMART OPENER OPERATION...........................................................................................................17

OPENER DETAILS...................................................................................................................................18

MANUAL SWITCH BOX INSTALLATION AND OPERATION.................................................................19

INSTALLATION....................................................................................................................................19

SWITCH BOX OPERATION.................................................................................................................20

FIELD OPERATION .............................................................................................................................21

ISOBUS TOOLBAR FUNCTIONS............................................................................................................22

HOME SCREEN LAYOUT ...................................................................................................................22

ISO TOOLBAR QUICK START PROCEDURE....................................................................................23

UNFOLDING, FOLDING, AND WING LOCKS.....................................................................................24

MASTER SWITCH CONFIGURATION................................................................................................26

PACKING PRESSURE SET UP AND OPERATION............................................................................26

PACKING PRESSURE OPERATION ON HOME PAGE.....................................................................28

LIFT KIT PRESSURE SET UP AND OPERATION..............................................................................29

SYSTEM INFORMATION HOME PAGE SET UP................................................................................30

SYSTEM ALARMS...............................................................................................................................32

SYSTEM DIAGNOSTICS PAGE..........................................................................................................33

ACTIVE ALARM PAGE ........................................................................................................................33

ULTRAPRO II ONFRAME TANKS (UPII).................................................................................................34

ULTRAPRO II ZONE COMMAND METER BOX (UPII).......................................................................34

SEEDMASTER 2023

3

UPII CALIBRATION PROCEDURE PRE-SETUP................................................................................35

UPII FAN PRESSURE GUIDELINES...................................................................................................37

ZONE COMMAND AIR COMPRESSOR..............................................................................................38

ZONE COMMAND AIR SYSTEM.........................................................................................................39

NOVA TANK.............................................................................................................................................40

NOVA ZONE COMMAND / METER BOX............................................................................................41

TUNABLE TOWER...............................................................................................................................42

ROMAFA DISTRIBUTION MANIFOLD................................................................................................43

NOVA PRODUCT SELECTION...........................................................................................................44

NOVA PRESSURE AND TOP-UP AIR ................................................................................................46

NOVA FAN PRESSURE GUIDELINES................................................................................................47

INDIVIDUAL METER INSPECTION.....................................................................................................48

WORK LIGHTS.....................................................................................................................................49

LID OPERATION..................................................................................................................................50

NOVA CONVEYOR OVERVIEW .........................................................................................................51

NOVA CONVEYOR CONTROLS.........................................................................................................51

KAR-TECH WIRELESS REMOTE.......................................................................................................52

SYNCHRONIZING THE REMOTE TO THE RECEIVER.....................................................................52

CONVEYOR OPERATION...................................................................................................................53

SEEDMASTER APP.................................................................................................................................54

ISOBUS RCM FUNCTIONS.....................................................................................................................57

HOME SCREEN LAYOUT ...................................................................................................................57

ISO RCM QUICK START PROCEDURE.............................................................................................59

RCM MAIN (HOME) PAGE ..................................................................................................................60

CATCH TEST CALIBRATION PROCEDURE......................................................................................63

APPLIED PRODUCT CALIBRATION PROCEDURE ..........................................................................67

RCM SETUP PAGE..............................................................................................................................70

CONTROL VALVE SETUP PAGE .......................................................................................................72

SCALE CALIBRATION.........................................................................................................................73

RCM TOTALS PAGE............................................................................................................................75

RCM DIAGNOSTICS PAGE.................................................................................................................77

GENERAL TROUBLESHOOTING .......................................................................................................80

GRANULAR PRODUCT CONTROL SETUP (DEALER OR SEEDMASTER ASSISTED ONLY).......81

SINGLE LIQUID PRODUCT CONTROL SETUP (DEALER OR SEEDMASTER ASSISTED ONLY).84

EXISTING RCM LIQUID PRODUCT CONTROL SETUP (DEALER OR SEEDMASTER ASSISTED

ONLY)...................................................................................................................................................86

REMOTE TANK MONITOR......................................................................................................................89

SELECT ACTIVE RCM.........................................................................................................................89

VIEWING RCM SERIAL NUMBER ......................................................................................................89

SEEDMASTER 2023

4

TOGGLING BETWEEN RCMS (UPII, NOVA, LIQUID) .......................................................................89

READ AND ZERO TANK WEIGHT VIA TANK/BIN INFO....................................................................90

READ AND ZERO TANK WEIGHT VIA SCALE ..................................................................................91

REMOTE CATCH TEST CALIBRATION PROCEDURE .....................................................................92

REMOTE TANK MONITOR TROUBLESHOOTING ............................................................................96

VIPER 4+..................................................................................................................................................97

POWER BUTTON AND STATUS ........................................................................................................97

VIPER 4+ BUILT-IN SELF TEST..........................................................................................................97

DEVICE SHUT DOWN.........................................................................................................................97

VIPER 4+ MAIN SCREEN NAVIGATION ............................................................................................98

JOB PROFILE PANEL..........................................................................................................................99

ADMINISTRATOR OR USER PANEL................................................................................................100

MACHINE CONFIGURATION PANEL...............................................................................................101

PRODUCT CONFIGURATION PANEL..............................................................................................101

CREATING JOB PROFILES ..............................................................................................................102

CREATING PRODUCT PROFILES ...................................................................................................103

AUTO ZONE COMMAND LOOK AHEAD TIME SETUP ...................................................................104

VIPER 4+ JOB QUICK START PROCEDURE ..................................................................................105

VIPER 4+ RUN SCREENS.................................................................................................................106

MANAGING SCREEN LAYOUTS......................................................................................................107

CREATING A FLIP MAP AND BOUNDARY FOR FIELD..................................................................108

CREATING AN INSIDE FLIP MAP.....................................................................................................110

SEEDING THE VIRTUAL PASS ........................................................................................................110

LOADING A PREVIOUSLY CREATED FLIP MAP ............................................................................111

VIPER 4+ FILE MAINTENANCE........................................................................................................112

3RD PARTY GPS.................................................................................................................................113

SETTING THE TRACTOR MEASUREMENTS..................................................................................114

IMPORTING PRESCRIPTION MAPS................................................................................................115

LOADING RX MAPS WITH A JOB.....................................................................................................116

UPDATING ECUS VIA VIPER 4+ ......................................................................................................118

WIFI OR TETHERED REMOTE SUPPORT ......................................................................................119

SYSTEM ELECTRICAL DRAWINGS.....................................................................................................120

IN-CAB VIPER 4+...............................................................................................................................120

ISO TXB ONLY...................................................................................................................................121

REMOTE TANK MONITOR................................................................................................................121

NOTES ...................................................................................................................................................122

SEEDMASTER 2023

5

INTRODUCTION

Thank you for purchasing a new SeedMaster unit. This manual will assist you in becoming a safe and

efficient operator. The crops you grow because of the proper use of the unit will be your reward for

spending some time studying this manual.

If problems arise, SeedMaster Manufacturing’s dealership network can provide clarification and

correction. It is important that all SeedMaster units maintain a solid reputation.

SeedMaster Manufacturing would like to take this opportunity to thank you, our valued customer, and

our valued dealer, for showing your confidence in purchasing and representing a quality SeedMaster

product.

SEEDMASTER 2023

6

SAFETY

Please be SAFE! Carefully read and understand all safety alerts and warnings in this manual and all

safety decals on the SeedMaster drill and tank. Ensure that anyone who is going to use the SeedMaster

drill and tank reads and understands the Operator’s Manual. We recommend that only mature and well-

trained or experienced persons operate this product. We advise that periodic visual checks continue as

a mandatory part of the implement operating procedure. Conduct regular maintenance checks on

fasteners, hydraulic connections, etc. Always follow safety precautions. Serious INJURY or DEATH can

result from improper operating practices.

Safety notices are one of the primary ways to call attention to potential hazards.

This Safety Alert Symbol identifies important safety messages in this manual. When you

see this symbol, carefully read the message that follows. Be alert to the possibility of personal injury

or death.

Read and understand the Operator’s Manual and all safety signs before operation or

maintenance.

Do not allow riders on any part of the equipment.

Install and properly secure all shields and guards before operating the seeder.

Keep hands, feet, clothing, and hair away from moving and/or rotating parts.

Beware of all power lines and other overhead obstructions. Know the transport height and width

of your SeedMaster drill and tanks. Ensure that minimum safe working distances are always

maintained from any obstruction.

Before servicing, adjusting, repairing, refilling, or unplugging: stop the engine, remove the engine

key, set the park brake, disengage the hydraulics, and wait for all moving parts to stop.

Ensure your seeder is properly marked as required by the local highway and transport authorities.

Make sure the “Slow Moving Vehicle” sign, lights, and all reflectors are in place, clean, and visible

to overtaking or oncoming traffic.

Store a fully stocked first-aid kit in a visible, accessible place for use in case of an accident.

Keep a fire extinguisher in an accessible location.

Be sure that the area is clear of people before starting or moving your machine.

Do not work around or under the raised wings unless the wings are securely chained in the

transport position.

In the event that wheel and tire assemblies must be raised off the ground for maintenance, block

the implement up securely.

Use extreme caution when working around or with high-pressure hydraulic systems. Depressurize

the system when connecting or disconnecting the hose couplers.

Wear heavy gloves and eye protection when searching for suspected hydraulic leaks. If an injury

occurs, seek immediate medical attention as infection and toxic reaction could develop. Use a

piece of cardboard or wood (instead of hands) when searching for such leaks.

Never wear baggy or frayed clothing or hanging jewelry when working around or on any of the

drive system components.

When performing a product catch for meter calibration, keep hands and clothes well clear of

rotating components. Be aware that when the hydraulics are activated, rotation may start

unexpectedly at any time.

We recommend that all maintenance and adjustments on the seeder be made when the

implement wings are lowered.

SEEDMASTER 2023

7

Store and transfer gasoline, solvents, cleaners, or any flammable liquids only in safety standard

(i.e. CSA) approved containers.

Clean and inspect all components in the hydraulic system on a regular basis.

Replace all worn, cut, abraded, flattened, damaged, or crimped hoses and metal lines. Do not

repair hydraulic components with tape, clamps, or cements. The system operates under extremely

high pressure; such repairs will fail and create hazardous and unsafe conditions.

Before applying pressure to the hydraulic system, make sure all connections are tight. Ensure

lines, hoses, and couplings are not damaged.

Ensure that the seeder is properly and safely connected to the tractor.

Transport per local regulations for width and height.

Follow all road safety regulations for your state or province.

Store the seeder on a firm, level surface.

Store with wings down.

Have a qualified tire dealer or service person perform tire maintenance. Failure to follow proper

procedures when mounting a tire on a wheel or rim can cause an explosion that may result in

serious injury or death.

Always keep safety decals and signs clean and legible. Replace safety decals and signs that are

missing or have become illegible.

Ensure proper use of wing lock-up chains in transport.

Always use hitch safety chain.

Do not transport at high speeds on loose gravel behind a truck or a tractor.

Do not transport with product in tanks.

Ensure proper hook-up of safety lights.

Maneuver machine to ensure castors are moving freely before going onto roads.

Do not transport at speeds higher than that recommended on tires (25 mph or 40 kph).

Check all transport wheel nuts after 100 miles and periodically thereafter. (See PAGE 8).

Use proper tire inflation pressures (SEE TIRE TORQUE AND PSI SPECS, PAGE 8).

SEEDMASTER 2023

8

TIRE TORQUE AND PSI SPECS

TIRE SIZE

TORQUE REQUIREMENTS (FT. LBS.)

MAXIMUM PRESSURE RATING (PSI)

12.5L15 (10 PLY)

200

44

12.5L15 (Hwy)

200

90

380/55-16.5

200

72

750/65R26

450

35

800/65R32

450

35

1050/50R32

450

35

Dual 710/70R38

750

23

SEEDMASTER 6012 ULTRAPRO II 360 WITH NOVA 520

SEEDMASTER 2023

9

IN-CAB ELECTRICAL HOOKUP

RAVEN VIPER 4+ IN-CAB HOOKUP

SLINGSHOT POWER

GPS IN

SWITCHED POWER OUTPUT

ISOBUS DIAGNOSTICS PORT

RAVEN CANBUS

ISOBUS TERMINATOR

NOT USED

NOT USED

NOT USED

BATTERY CONNECTIONS

SEEDMASTER 2023

10

SEEDMASTER TOOLBOX AND MANUALS

SeedMaster offers a factory option toolbox to hold any spare parts, tools, or accessories to keep your

seeding operation moving. It is located on the “A-Frame” support beam in the middle of the hitch. The

toolbox has a seal to help reduce the amount of dust and foreign material from contaminating or soiling

the contents. Beside the toolbox is a container that contains your machine-specific manuals. This

container is dust and water tight to ensure that your manuals stay intact in any weather or field

conditions.

For machines with tow-between distribution, or a front-mounted tank, the toolbox will be located at the

top of the “A-frame” beside the main-frame castor.

NOTE: Do not stand or walk on the toolbox!

SEEDMASTER 2023

11

TRACTOR HYDRAULIC HOOKUPS

SEEDMASTER MACHINE HYDRAULIC HOSES

HOSE MARKING CONVENTION: Each hose pair has been assigned a unique colour. The hose with 1

colour band is pressure, and the hose with 2 colour bands is return.

OPENER RAISE/LOWER HOSES: Red Tagged Lines –The two ½” Direct Opener Lift & Lower

hydraulic lines with red colour bands are the opener lift and lower lines. These lines are connected to

one tractor remote. The hose with 1 red band is opener down pressure. The hose with 2 red bands is

pressurized to raise the openers. The openers are held up in transport with a Pilot Operated Check

Valve. This maintains the pressure on the opener up pressure circuit for long transport and to facilitate

unhooking under lift pressure. Leave the pressure engaged to operate the Smart Openers.NOTE: See

page 17 for operation instructions.

SYSTEM PRESSURE HOSES: Green Tagged Lines - The two 1/2” hydraulic lines with the green colour

bands are used to activate the block and raise and lower the wings. These lines are connected to one

tractor remote. In the field, operating position for this remote is locked-on to provide continuous pressure

to the block via the line with 1 green band. Pressure should be adjusted and set between 2600-3000 psi

by using the tractor remote flow control.

SEED AND FERT FAN HOSES ONFRAME: There may be one or two ¾” fan pairs. If you are running

an UltraPro II 350 or 360 machine, the single fan hoses will be tagged with 1x orange (pressure) and 2x

orange (return). If you are running an UltraPro II 540 machine, the seed fan hoses will be tagged with 1x

orange (pressure) and 2x orange (return) and the fertilizer fan will be tagged with 1x purple (pressure)

and 2x purple (return).

SEED AND FERT FAN HOSES NOVA: If you are running a NOVA Cart the seed fan hoses will be

tagged with 1x yellow (pressure) and 2x yellow (return) and the fertilizer fan will be tagged with 1x blue

(pressure) and 2x blue (return).

Ensure that you connect the right pair of hoses together on your tractor.

CASE DRAIN HOSE: Drills and tanks are set up with ONE 1/2" case drain/return line (zero back

pressure). This line has a ½” NPT full open return coupler without any restriction or back pressure.

Ensure this return line is routed to your tractor properly without any possibility of back pressure.

Improper connection or undersized return lines on the tractor may cause inaccuracies in operation and

the possibility for severe damage to the drill’s hydraulic system. SeedMaster Manufacturing

recommends using the factory connections provided with the drill and tank.

SEEDMASTER 2023

12

HYDRAULIC CONNECTION REFERENCE CARDS

SeedMaster machines come in several different configurations. Please refer to your configuration below.

Ensure that you are hooking the pressure and return hoses to the appropriate remotes on your tractor:

Pressure to Retract, Return to Extend.

OnFrame UPII 350/360/540 Only Hydraulic

hookup

OnFrame UPII 350/360 and Nova Hydraulic

hookup

SEEDMASTER 2023

13

MAIN HYDRAULIC BLOCK DETAILS

HYDRAULIC BLOCK GAUGES

RAVEN

WING DOWN

TANK

SYSTEM

PRESSURE

WING UP

SEEDMASTER 2023

14

MAIN BLOCK GAUGES

WING UP: The WING UP gauge reads the amount of pressure applied and required for lifting and

should read 0 psi until folding up. A positive reading during field operation is an indication of back

pressure on the system.

RAVEN: The RAVEN gauge reads the amount of pressure being supplied to the hydraulic metering

motors.

TANK: The TANK gauge reads the amount of pressure being returned to tank.

WING DOWN: The WING DOWN gauge reads the amount psi being applied to the wings while they are

down and in field operation.

SYS: The SYS gauge reads the amount of system pressure being applied to the system. System

Pressure is the main pressure supply for the WING UP/DN, LIFT KIT, RAVEN (METERING) circuits.

2600-3000 psi indicates tractor working pressure to block. Pressure fluctuation can indicate back

pressure or lack of flow to the circuit. Adjust tractor flow as necessary to hold within range.

MAIN BLOCK VALVES, SOLENOIDS, AND PWMS

LEFT WING LOCK: This on/off solenoid turns the oil flow on/off to the left wing cylinders.

RIGHT WING LOCK: This on/off solenoid turns the oil flow on/off to the right wing cylinders.

OUTER WING LOCK: This on/off solenoid turns the oil flow on/off to the outer wing cylinders.

FAST WING: This on/off solenoid turns the oil flow on/off to the inner wing cylinders.

HIGH PRESSURE WING RELIEF (THERMAL): High tank pressure cut off cartridge is preset set at

3500 psi

TANK LINE RELIEF: The tank line relief cartridge is preset at 450 psi. If the cartridge exceeds 450 psi it

will relieve to the atmosphere.

WING-DOWN PRESSURE: 180 psi (NOTE: REQUIRED PRESSURE SETTING MAY VARY FROM

FACTORY PRESET TO SPECIFIC TRACTOR AND DRILL COMBINATIONS).

HIGH

PRESSURE

WING RELIEF

(THERMAL)

OUTER WING

LOCK

LEFT WING

LOCK

RIGHT WING

LOCK

FAST WING

WING DOWN

PRESSURE

TANK LINE

RELIEF

FAST WING

PRESSURE

LIFT KIT

RAVEN (METER)

SUPPLY

PRESSURE

SAFETY SHIFT

VALVE

SEEDMASTER 2023

15

Wing-Down pressure may need to be increased if the wings start to float and not contour correctly while

in the seeding position or if a positive Wing-Up pressure is detected.

Wing-Down pressure may need to be decreased if the wings become too rigid while in the

seeding position.

RAVEN (METER) SUPPLY PRESSURE: 2000 psi

LIFT KIT: 200 psi

FAST WING PRESSURE: 1500 psi

SAFETY SHIFT VALVE: The safety shift valve will shut the hydraulic flow off to the block if back

pressure reaches 240 psi on tank line to prevent system damage.

PRESSURE SETTING PROCEDURES

Setting Wing-Down Procedure (WING-DOWN PRESSURE)

The Wing-Down pressure is the amount of hydraulic pressure being applied to the inner and outer wing

circuits; the oil supply is supplied from the system pressure. The Wing-Down Pressure is required so the

wings will contour while travelling through the field. SeedMaster requires Net Wing-Down Pressure. To

determine your net value, subtract your wing-up pressure from your current wing-down pressure (ie. 380

PSI wing-down –200 PSI wing-up = 180 PSI net wing-down).

-To adjust the WING-DOWN PRESSURE, loosen the jam nut on the cartridge in port WD on the

main block. Turn the cartridge in to increase the pressure, and out to decrease the pressure.

When the desired pressure is set, re-tighten the jam nut.

Setting Wing Unfold Procedure (FAST WING PRESSURE)

The wing unfold pressure is the amount of hydraulic pressure being applied to the inner and outer wing

circuits while the tool bar is unfolding. This is also known as the Fast Wing Pressure. If the wings are not

unfolding the pressure will need to be increased. The oil supply is supplied from the system pressure.

-To adjust the FAST WING PRESSURE, loosen the jam nut on the cartridge in port FW PRESS

on the main block. Turn the cartridge in to increase the pressure and out to decrease the

pressure. When the desired pressure is set, re-tighten the jam nut.

Active Wing Brace Check

The Active Wing Brace supports the wing

sections of the frame. While in the field, a

hydraulic cylinder pulls the rear of the wing

section forward counteracting draft while

seeding. The hydraulic pressure comes

from the opener cylinder hydraulic circuit.

The higher the pressure is set to the active

wing brace circuit, the more it will pull the

rear wing square. When the packing

pressure is increased, so is the amount of

pull on the brace to a set maximum.

-Adjusting the wing brace: Start

by unfolding the SM drill and

activating the system pressure.

Next, pressure the openers down with the opener pressure switch and adjust the shank down

hydraulic pressure to 1000psi, activating the active wing braces. After the system has been

completely pressurized, inspect each wing brace cylinder indicator. They should be fully

retracted against the plate limiter. If not, please adjust the length of the active wing brace using

the threaded link. The braces should be periodically checked to ensure proper adjustment. This

will ensure your frame integrity remains true and helps increase the longevity of your machine.

Meter Drive Pressure Setting Procedure (RAVEN METER SUPPLY PRESSURE)

The Meter Drive Pressure is the amount of hydraulic pressure allowed to the hydraulic metering drives.

The torque to the metering drives increases as the pressure increases. Do not exceed 2200 psi. The oil

supply for RAVEN METER SUPPLY PRESSURE is supplied from the system pressure.

-To adjust the RAVEN METER SUPPLY PRESSURE, loosen the jam nut on the cartridge in port

RAVEN on the main block. Turn the cartridge in to increase the pressure and out to decrease

the pressure. When the desired pressure is set, re-tighten the jam nut.

SEEDMASTER 2023

16

LIFT KIT

LIFT KIT: The Lift Kit is designed to decrease the weight on the main frame front caster wheels during

field operation. It is hydraulically operated utilizing supply oil from the main hydraulic block’s system

pressure. The Lift Kit increases floatation by redistributing weight from the front caster wheels of the drill

forward to the tractor hitch and backwards to the rear of the drill. The reduced weight and draft on the

drill then adds weight and traction to the rear of the tractor. It also reduces stress on the hitch and frame

of the drill when seeding in wet conditions.

Setting Lift Kit Procedure (Auto-PWM)

-See page 30 for in cab pressure readout, pressure adjustment, and operating modes for this

feature.

SEEDMASTER 2023

17

SMART OPENERS HYDRAULIC BLOCK DETAILS

AND OPERATION

SMART OPENERS HYDRAULIC BLOCK

The Smart Openers block contains the main functions of your SeedMaster openers: raising, lowering,

and down-pressure. These functions are controlled by a Master ON/OFF solenoid and coil to raise and

lower, and a PWM valve for down-pressure. The Smart Openers block is located on the first rank behind

the main block. For it to operate, you will leave the connected tractor hydraulic remote engaged during

field operation. Recommended maximum flow for this remote is 75%.

SMART OPENER OPERATION

LOWER, LIFTING, THEN LOWERING THE OPENERS

LOWER:

1. LOCK ON REMOTE TO SUPPLY OPENERS WITH HYDRAULIC PRESSURE.

2. CYCLE MASTER FOOT SWITCH FROM OFF TO ON AND LEAVE THE MASTER SWITCH

“ON”. OPENERS WILL LOWER AND BUILD PRESSURE TO YOUR PRESET VALUE.

LIFT:

3. AFTER THE TOOLBAR IS COMPLETEY OVERLAPPED INTO AN APPLIED AREA, SHUT

THE MASTER FOOT SWITCH OFF. OPENERS WILL LIFT.

4. COMPLETE THE TURN.

LOWER:

5. CYCLE MASTER FOOT SWITCH FROM OFF TO ON AND LEAVE THE MASTER SWITCH

“ON” OPENERS WILL LOWER AND BUILD PRESSURE TO YOUR PRESET VALUE.

SEEDMASTER 2023

18

OPENER DETAILS

The opener is preset for seed and fertilizer depth. The seed depth is factory set at 3/4” below the

packed surface and the fertilizer depth is factory set approximately 3/4” below and 1 ½” to the side of

the seed.

In varying field conditions,

soil types, and moisture

conditions, it may be

required to adjust the

openers from the pre-set

depths. We recommend

seeding cereals, oil seeds,

and all other products at the

determined seed and

fertilizer depths desired by

the owner/operator. The

notches on the hub plate

correspond to 1/4” changes

in depth, with the inverted

notch being the factory pre-

set depth of 3/4”.

To change depth using the SeedMaster Quick

Depth Adjusting Tool, simply loosen the nut on

the slotted portion of the hub plate and rotate

packer tire upwards to increase depth, or

downwards to decrease depth.

Semi-pneumatic packer tires are a standard

feature on all SeedMaster drills. There is no

internal air pressure that needs to be checked.

The resulting dent the packer wheel leaves

behind is dependent on soil type and hardness.

The variation in dent depth does not affect the

crop since the seed depth is always monitored

from the packed surface.

*Avoid the temptation to harrow after seeding, as harrowing will reduce the uniformity of crop

emergence and reduce yield potential. The dent left by the packer wheel and the loose soil tossed to the

side as the openers move through the soil may appear rough at first glance, but you will find the residue

and soil settles over time leaving just the ripple of the packer wheel. This dent provides several

agronomic benefits.

Warning: Avoid turning your drill very short. The opener is designed to seed primarily in

straight lines. A sharp turn will cause the openers to be dragged sideways, resulting in an

improper seeding job and undue stress on the openers. Never turn so short that the inside

openers move straight sideways or backwards.

Always store the drill for extended periods of time in the unfolded wing position. This is to avoid

water getting into the packer tire and wing wheel bearings. This is very important for winter

storage.

SEEDMASTER 2023

19

MANUAL SWITCH BOX INSTALLATION AND

OPERATION

INSTALLATION

The SeedMaster Manual Switch Box consists of 7 switches, a 20-amp fuse, and a wiring harness.

1. Place the electrical box

in the cab at a

convenient location.

2. Mount the box at the

chosen location by

opening the box and

fastening the back panel

at a desired location in

the tractor cab.

3. Use a 14-gauge wire to

provide ground to the

white wire. This can be

from the battery, or from

your tractor’s switched

power.

4. Use a 14-gauge wire to

provide 12-volts to the

red wire. This can be from the battery, or from your tractor’s switched power.

5. Run the harness through the cab to the hitch. Connect the plugs at the hitch to the mating plugs

on the drill.

BLUE AUXILIARY WIRE

If you are using our switch box in combination with a third-party metering system, you may be able to

link the two using the blue auxiliary wire (provided both are operating at 12 volts). This allows the

operator to activate only one switch for a headland turn. There are two different ways the blue wire can

be used:

1. Use the blue wire to apply 12-volt signal to activate a relay for 3rd party metering devices. Power

is supplied to the blue wire when the opener pressure on/off switch is activated from the

SeedMaster control box.

2. If you are using another manufacturer’s 12-volt product metering system, you can use the blue

wire to signal the SeedMaster Manual Switch Box “opener pressure on/off switch”. This is done

by back-feeding 12-volt power to the blue wire. If this is your choice, always leave the switch in

the off position.

NOTE: The blue auxiliary wire is not a ground. It may or may not be used depending on seeding

system installation.

This manual suits for next models

2

Table of contents

Other SEEDMASTER Farm Equipment manuals

Popular Farm Equipment manuals by other brands

ATI Corporation

ATI Corporation Level Best Grader Blade Operator's & parts manual

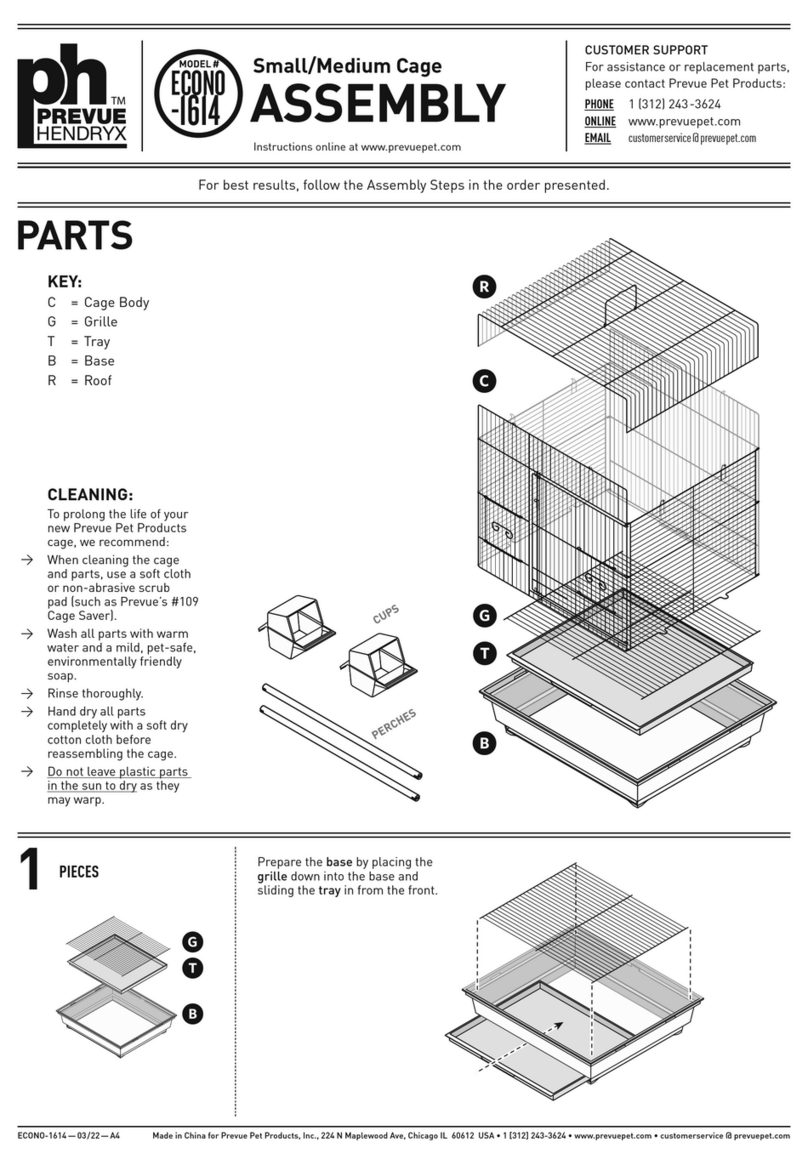

Prevue Hendryx

Prevue Hendryx ECONO-1614 Assembly

PEQUEA

PEQUEA TT6101 Operator's manual

Thurston

Thurston BLU-JET AT2000 Assembly and operators manual

GSi

GSi 40 Series Construction manual

MacDon

MacDon D1X Series Assembly instructions

Hardi

Hardi MERCURY 2000 Instruction book

Galebreaker

Galebreaker Bayscreen Installation and operating instructions

EJWOX

EJWOX 43 Gallon Tumbling Composter manual

Kubota

Kubota RA2584 Operator's manual

KUHL

KUHL FC 303 GL Pre-delivery instructions

LOFTNESS

LOFTNESS Battle Ax 207460 Owner's manual and parts book